Академический Документы

Профессиональный Документы

Культура Документы

GBH Enterprises, LTD.: SMR Pre-Reformer Design Case Study #0618416GB/H

Загружено:

Anonymous qPt2MHzXTОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GBH Enterprises, LTD.: SMR Pre-Reformer Design Case Study #0618416GB/H

Загружено:

Anonymous qPt2MHzXTАвторское право:

Доступные форматы

GBH Enterprises, Ltd.

SMR PRE-REFORMER DESIGN

Case Study #0618416GB/H

Process Information Disclaimer

Information contained in this publication or as otherwise supplied to Users is

believed to be accurate and correct at time of going to press, and is given in

good faith, but it is for the User to satisfy itself of the suitability of the Product for

its own particular purpose. GBHE gives no warranty as to the fitness of the

Product for any particular purpose and any implied warranty or condition

(statutory or otherwise) is excluded except to the extent that exclusion is

prevented by law. GBHE accepts no liability for loss, damage or personnel injury

caused or resulting from reliance on this information. Freedom under Patent,

Copyright and Designs cannot be assumed.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

SMR Pre-Reformer Design: Case study

Objective: Evaluation of a proposed SMR Pre-Reformer design.

Background

Pre-Reformers

React hydrocarbon feed with steam to give a methane rich product

suitable for further downstream reforming.

Pre-reforming works as an adiabatic steam reforming step over a Ni based

catalyst.

The basis for the reforming may be considered

as the reaction between a hydrocarbon and steam

• steam / methane reaction

• water / gas shift reaction

Typical Pre-Reformer Installation:

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

SMR Pre-Reformer Design: Case Study #0618416GB/H

Contents

1. SMR Pre-Reformer Design

2. Inlet Baffle Design

3. Outlet Collector

4. Hold Down Grating

5. Floating Hold Down Screen

6. Catalyst Drop Out Nozzle

7. Thermowell Detail

8. Technical Performance requirements

9. SMR Pre-Reformer Isolation

Technical Review and Commentary on Proposed Design

APPENDIX

A. Operating / Mechanical Data

B. Materials Specifications

C. Fabrication and Inspection Requirements

D. Weights

E. Nozzle Data

F. Instrument Connections

G. Manholes

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

SMR Pre-Reformer

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Inlet Baffle

INLET BAFFLE NOTE:

1. Number, size and placement of support vanes by EPC contractor

minimum 4 vanes required.

2. Final design and details by EPC contractor.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Outlet Collector

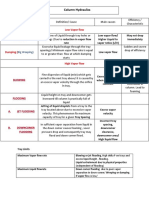

Table of Dimensions

Nozzle Specifications:

A, o C: 198

B, mm: 25

2

Open Area, m : 0.56

ΔP, bar: 2.86

C, mm: 25

D, o C: 250

Notes:

1. Uniformly perforate elliptical head with (“A”) “B” Dia. Holes pitch may be

square or triangular.

2. Collector must withstand tabulated DP plus bed weight.

3. Open area tabulated is effective (i.e., hole area x wire screen open area)

4. Final design and details by EPC Contractor. Supplied by vessel vendor.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Hold Down Grating

Notes:

1. Vessel vendor to install (2) sets of continuous rings at indicated elevations

shown on sheet 6 to accommodate catalyst bed heights depending on

which catalyst supplier is used. The continuous rings above hold down

grating from overturning while allowing up and down movement. Rings to

be welded to the shell.

2. Minimum open area is 70%.

3. Final design and details by EPC contractor.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Floating Hold down Screen

Note:

1. Wire Screen to be 6 x 6 x 1.19 mm Diameter wire.

2. Vessel vendor shall supply sufficient 1.0 mm diameter wire for field use to

lace screen sections together along the overlaps.

3. Match mark sections for field installation. Screen sections and ring

segments must pass through vessel manhole.

4. Final design and details by EPC Contractor.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Catalyst Dropout Nozzle

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Thermowell Design Details

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

SMR Pre-Reformer Isolation

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Technical Review and Commentary on Proposed Design

Bed Temperature Measurement:

Bed temperature measurement is provided via a single thermo-well. There is no

indication of the number of measurement points this will contain. For a vessel of

this diameter a single thermo-well does not provide adequate coverage through

the vessel.

Pre-reforming catalysts should not be allowed to come into contact with liquid

water. The proposed temperature control arrangement (both upstream and

downstream of the reactor) provides a potential source of water to enter the

system. In any future statement with respect to pre-reformer performance it will

be assumed that water injected upstream of the pre-reformer feed pre-heater will

be fully vaporized before coming into contact with the catalyst bed.

Should this be found to not be the case in ultimate operation of the plant this will

invalidate any performance guarantees that may be offered at the time of catalyst

purchase.

Note: Without additional information we are unable to comment on the

suitability or otherwise of the proposed temperature control arrangement.

Inlet Gas distributor:

GBHE has no experience on this type of design and cannot comment on its

performance. The inlet pipe does not meet the GBHE’s ‘straight length’

requirement and hence even more importance is placed on the good

performance of the distributor itself. Good distribution is essential to ensure even

flow through the bed.

Hold Down Grid:

It is proposed to place a hold down grid on top of the bed together with a wire

mesh. Use of a wire mesh can lead to the potential risk of a partial blockage

resulting in mal-distribution in flow. The use of wire mesh screens in the reactor

is unacceptable.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Outlet Collector:

The outlet collector is, shown as covered by a wire cloth. As mentioned above

the use of wire mesh is unacceptable in the reactor.

Isolation system:

The sketch shown indicates that on an emergency shutdown the pre-reformer is

automatically bypassed and the reactor isolated. Apparently it is intended that the

bypass be used to maintain production during catalyst change out, or perhaps it

is a feature in the proposed start-up or shut down sequence?

Without more knowledge of the overall operating philosophy to be used GBHE is

unable to provide any detailed comment on adequacy of the proposed

arrangement.

Flaw List:

The list provided makes reference to the possible presence of BTX in the feed

but does not state how much.

Pre-Reforming catalyst can tolerate aromatic compounds and will successfully

operate in the presence of such components. The levels present may impact on

life of the catalyst and this can only be evaluated at the time of the catalyst

enquiry when performance/guarantee levels are being considered.

Inert Ballast:

Three types of inert materials are recommended. GBHE experience suggests

that only material of the following specification is acceptable;

Al2O3 99.0 wt% (min)

SiO2 0.2 wt% (max)

TiO2 0.5 wt % (max)

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

APPENDIX

A. Operating Data

Working temperature 515 0C

Working Pressure 27.5 bar ga

Design temperature, upper / lower 535 / 4 0C

Design pressure 33 bar ga

Vapor 79.08 kg/s

Molecular Weight 17.8

Density at working temperature 7.81 kg/m3

Mechanical Data

Diameter of Shell ID 3500 mm

Length between Tangent Lines 2500 mm

Height of skirt to bottom tangent line 7300 mm

Type of Heads Hemispherical

Wall Thickness

Shell 110 mm

Top Head 56 mm

Bottom Head 56 mm

Corrosion allowance 3 mm

Insulation thickness 200 mm (Hot)

Catalyst Volume 25.5 m3

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

B. Materials Specifications

Shell EN 10028-2 10CrMo9-10 Downcomers

Cladding/lining of Shell N/A Baffles

Heads EN 10028-2 10CrMo9-10 Internal Pipe

Fittings

Cladding/lining of Heads N/A Stud Bolts External

Reinforcing rings N/A Nuts External

Skirt (Top 2000mm) EN 10028-2 10CrMo9-10 Bolts Internal

Skirt Balance ASTM A516 – Gr.70 Nuts Internal

Jacket N/A Gaskets Internal

Shell flanges N/A Gaskets Internal

Nozzels prEN 10216-2 10cRmO9-10 “

(DN 350 and smaller)

Nozzles prEN 10216-2 10cRmO9-10 “

(DN 400 and larger)

Flanges (ASME) EN 10222-2 11CrMo9-10 Internal Wire

Screen

Flanges (Non-ASME) EN 10222-2 11CrMo9-10 Hold Down Grating

Welding fittings prEN 10216-2 10cRmO9-10 Floating Hold

Down rings

Stiffening rings N/A

Insulation Support Rings As Shell

Cleats for platforms, etc. As Shell

Internal Parts As Shell

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

C. Fabrication and Inspection Requirements

Inspection Authority Client Third Party, including

design review

Stress relieving Yes, per code

Special heat treatment Yes, EPC Contractor

Radiography Per Code

Other Non-destructive Testing Per Code

Chemical Analysis See GBHE

D. Weights

Erection weight (shipping weight) 58,000 kg

Total weight operating 105,000 kg

Total Weight Full of Water 124,000 kg

Max O/T Moment at Base 500 kNm

Max Base Shear 70 kN

E. Nozzle Data

Vapor In DN 750 CL 900 # RFLWN

Vapor Out DN 750 CL 900 # RFLWN

Drain DN 80 CL 900 # RFLWN

Utility Connection DN 50 CL 900 # RFLWN

Catalyst Unloading Connection DN 200 CL 900 # RFLWN

F. Instrument Connections

Diff Press Indicator DN 50 CL 900 # RFWN

Thermowell DN 80 CL 900 # RFWN

PG DN 50 CL 900 # RFWN

G. Manholes 600 I.D. CL 900# RFLWN

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology – Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology – Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Вам также может понравиться

- Shortcut Methodsofdistillation Design PDFДокумент15 страницShortcut Methodsofdistillation Design PDFAle SanzОценок пока нет

- Selection of Reboilers For Distillation ColumnsДокумент25 страницSelection of Reboilers For Distillation Columnswisnu_bayusaktiОценок пока нет

- Selection of Internals For Distillation ColumnsДокумент29 страницSelection of Internals For Distillation ColumnsAliya JamesОценок пока нет

- Process Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentОт EverandProcess Engineering for a Small Planet: How to Reuse, Re-Purpose, and Retrofit Existing Process EquipmentОценок пока нет

- Thermal Cracking and Delayed Coking ProcessesДокумент8 страницThermal Cracking and Delayed Coking ProcessesAnonymous rUs4PjYo5Оценок пока нет

- CEeNews2 04 PDFДокумент6 страницCEeNews2 04 PDFJohn AnthoniОценок пока нет

- Fractionation and Absorption For The Process Man PDFДокумент70 страницFractionation and Absorption For The Process Man PDFWilliam SandersОценок пока нет

- Improve Exchanger Efficiency with Tube EnhancementДокумент3 страницыImprove Exchanger Efficiency with Tube Enhancementaegean227Оценок пока нет

- Ammonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEOДокумент33 страницыAmmonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEOAkil PrabhuОценок пока нет

- Vacuum Preflash TowersДокумент32 страницыVacuum Preflash TowersJayaprakash RattiОценок пока нет

- Refinery Energy Systems TrainingДокумент208 страницRefinery Energy Systems TrainingLuis Enrique Leyva OvalleОценок пока нет

- Stepwise Simulation of Vacuum Transfer2Документ7 страницStepwise Simulation of Vacuum Transfer2Hadis ShojaeiОценок пока нет

- Column Hydraulics NotesДокумент4 страницыColumn Hydraulics NotessatishchemengОценок пока нет

- Simulation Optimization of Propylene-Propane SplitterДокумент4 страницыSimulation Optimization of Propylene-Propane SplitterAnonymous UY9QffОценок пока нет

- Simulation and Optimization of Distillation Processes For Separating A Close-Boiling Mixture of N-Butanol and IsobutanolДокумент6 страницSimulation and Optimization of Distillation Processes For Separating A Close-Boiling Mixture of N-Butanol and IsobutanolZangОценок пока нет

- A I Che Weir Loading SPR 2009Документ13 страницA I Che Weir Loading SPR 2009mehul10941Оценок пока нет

- Dynamic simulation and control of sour water stripping process for effective pressure managementДокумент11 страницDynamic simulation and control of sour water stripping process for effective pressure managementjavilapiedraОценок пока нет

- 04454H45-14-DB-0001 Rev0Документ9 страниц04454H45-14-DB-0001 Rev0garciahoОценок пока нет

- FCC GCU Stripper RevampДокумент5 страницFCC GCU Stripper RevampRavi NookalaОценок пока нет

- 94c Effect of Tray Spacing On Tray Performance AIChE Paper 94cДокумент28 страниц94c Effect of Tray Spacing On Tray Performance AIChE Paper 94cFranklin Revill100% (1)

- Article - 1001191 Managing Fouling in Refinery PDFДокумент13 страницArticle - 1001191 Managing Fouling in Refinery PDFDavid Diaz PadillaОценок пока нет

- Shift Conversion OperationДокумент26 страницShift Conversion OperationMuhammad JunaidОценок пока нет

- Heat Exchanger Monitoring and TroubleshootingДокумент14 страницHeat Exchanger Monitoring and TroubleshootingJorge Enciso AcuñaОценок пока нет

- 3 3 MR Robert PardemannДокумент47 страниц3 3 MR Robert Pardemannhoremheb1Оценок пока нет

- The Fischer Tropsch Process 1950 - 200 - Mark E DryДокумент15 страницThe Fischer Tropsch Process 1950 - 200 - Mark E DryNalre OcehcapОценок пока нет

- Sieve Tray ExtractorДокумент12 страницSieve Tray ExtractorCris-Anne Juangco III100% (2)

- Divided Wall Column 496Документ6 страницDivided Wall Column 496GeorgeОценок пока нет

- Vapour Compression For Propane-Propylene SplittersДокумент3 страницыVapour Compression For Propane-Propylene SplittersJohnОценок пока нет

- Tower Design & Spec.Документ25 страницTower Design & Spec.MuruganОценок пока нет

- DistillationWebSeminar PDFДокумент30 страницDistillationWebSeminar PDFKetan ParikhОценок пока нет

- Debottleneck Gas Plant Reboiler Circuits Without HardwareДокумент16 страницDebottleneck Gas Plant Reboiler Circuits Without HardwareteddyОценок пока нет

- Piping Design Articles by Robert Kern PDFДокумент53 страницыPiping Design Articles by Robert Kern PDFDiego IQ100% (1)

- Relief ValvesДокумент128 страницRelief Valvesvasudev palaganiОценок пока нет

- PRO II Column Algorithms SelectionДокумент6 страницPRO II Column Algorithms SelectionWade ColemanОценок пока нет

- Control of Simple Distillation TowersДокумент46 страницControl of Simple Distillation TowersDian Ardiansyah100% (1)

- Consider Practical Conditions For Vacuum Unit ModelingДокумент6 страницConsider Practical Conditions For Vacuum Unit ModelingstudyendlessОценок пока нет

- Distillation Column InternalsДокумент16 страницDistillation Column InternalsBon Joey BernestoОценок пока нет

- Packed Column Design GuideДокумент32 страницыPacked Column Design GuideAnaBelenMedranoBarrientosОценок пока нет

- A An ND D Ffo Orr: Increase CapacityДокумент7 страницA An ND D Ffo Orr: Increase CapacityLuis Enrique Leyva OvalleОценок пока нет

- Section 02 - Heat TransferДокумент39 страницSection 02 - Heat TransferaminОценок пока нет

- Aspen Plus Gettingstarted ElectrolytesДокумент63 страницыAspen Plus Gettingstarted ElectrolytessamrickyОценок пока нет

- Kinetics of Toulene Disproportionation Over Unmodified and Modified ZSM-5 ZeolitesДокумент7 страницKinetics of Toulene Disproportionation Over Unmodified and Modified ZSM-5 ZeolitesWaheed MiranОценок пока нет

- Documents - Pub - Front End Selective Hydrogenation Catalysts Enhance 2 1200 DR Wolffront EndДокумент28 страницDocuments - Pub - Front End Selective Hydrogenation Catalysts Enhance 2 1200 DR Wolffront Endnafees ahmadОценок пока нет

- Interview Questions For Chemical EngineeringДокумент6 страницInterview Questions For Chemical EngineeringNikunj PatelОценок пока нет

- Knovel Charts For Water & Steam, SI & English Units, 2006, Norwich, 26pgДокумент26 страницKnovel Charts For Water & Steam, SI & English Units, 2006, Norwich, 26pgVlad ElenaОценок пока нет

- 92015BASF Molecular Sieve Brochure USL 190411 110814Документ8 страниц92015BASF Molecular Sieve Brochure USL 190411 110814FrankОценок пока нет

- General Guidelines For Distillation ColumnДокумент23 страницыGeneral Guidelines For Distillation ColumnCristinaОценок пока нет

- Topsoe Hydrocracking Processes 2011Документ17 страницTopsoe Hydrocracking Processes 2011Cal100% (1)

- IMTPДокумент16 страницIMTPDHAVALESH AMОценок пока нет

- Extractive Distillation Separates Benzene and CyclohexaneДокумент12 страницExtractive Distillation Separates Benzene and CyclohexaneROHAN PATILОценок пока нет

- Random PackingДокумент16 страницRandom PackingIng Antony MatosОценок пока нет

- REBOILER CALCULATION GUIDEДокумент12 страницREBOILER CALCULATION GUIDESabba CabbaОценок пока нет

- Sulzer Structured Packings PDFДокумент28 страницSulzer Structured Packings PDFCordero JulioОценок пока нет

- Cdu - VduДокумент3 страницыCdu - VduRobson2305Оценок пока нет

- PHD Thesis Naveen BhutaniДокумент252 страницыPHD Thesis Naveen BhutaniSagar SrinivasОценок пока нет

- FCC Revamp Solutions Offer ReliabilityДокумент34 страницыFCC Revamp Solutions Offer ReliabilityFederico JanzenОценок пока нет

- Energy and Process Optimization for the Process IndustriesОт EverandEnergy and Process Optimization for the Process IndustriesОценок пока нет

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОт EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationОценок пока нет

- Natural Gas Processing from Midstream to DownstreamОт EverandNatural Gas Processing from Midstream to DownstreamNimir O. ElbashirОценок пока нет

- 7 Hazards of Molten Sulfur Storage and Handling by J Johnson and N HatcherДокумент22 страницы7 Hazards of Molten Sulfur Storage and Handling by J Johnson and N HatcherAnonymous qPt2MHzXT100% (1)

- Review of DesignДокумент35 страницReview of DesignAnonymous qPt2MHzXTОценок пока нет

- Project MonitoringДокумент60 страницProject MonitoringAnonymous qPt2MHzXTОценок пока нет

- Operational Control For Stacker/reclaimers: January 2013Документ7 страницOperational Control For Stacker/reclaimers: January 2013Anonymous qPt2MHzXTОценок пока нет

- Example - Heat ExchangersДокумент2 страницыExample - Heat Exchangersabdessamad CHADDOUОценок пока нет

- Sulphur Solidification and FormingДокумент37 страницSulphur Solidification and FormingAnonymous qPt2MHzXTОценок пока нет

- Bulk Solids HandlingДокумент303 страницыBulk Solids HandlingDr_M_Soliman100% (12)

- Sulfur PDFДокумент6 страницSulfur PDFAnonymous qPt2MHzXTОценок пока нет

- SulfurДокумент8 страницSulfursutanuprojectsОценок пока нет

- Sulfur Storage PDFДокумент77 страницSulfur Storage PDFAnonymous qPt2MHzXTОценок пока нет

- Facility LayoutДокумент63 страницыFacility LayoutBharti KumariОценок пока нет

- CHPPDFДокумент33 страницыCHPPDFpanjumuttaiОценок пока нет

- Operational Control For Stacker/reclaimers: January 2013Документ7 страницOperational Control For Stacker/reclaimers: January 2013Anonymous qPt2MHzXTОценок пока нет

- How To Apply 6 Hats ThinkingДокумент19 страницHow To Apply 6 Hats ThinkingAnonymous qPt2MHzXT100% (3)

- Certificate in Chemical Process Operation and ControlДокумент4 страницыCertificate in Chemical Process Operation and ControlAnonymous qPt2MHzXTОценок пока нет

- Modern Techniques For Optimisation of Reformer OperationДокумент19 страницModern Techniques For Optimisation of Reformer OperationAnonymous qPt2MHzXTОценок пока нет

- Solve Process Problems Quickly with Simulation TrainingДокумент6 страницSolve Process Problems Quickly with Simulation TrainingAnonymous qPt2MHzXTОценок пока нет

- 2005 Utkast NorsokДокумент30 страниц2005 Utkast NorsokFarzad RezaeiОценок пока нет

- Spallina3 Et Al Et Al. 2017Документ10 страницSpallina3 Et Al Et Al. 2017Anonymous qPt2MHzXTОценок пока нет

- 5e3e PDFДокумент6 страниц5e3e PDFAnonymous qPt2MHzXTОценок пока нет

- Schade PresentationДокумент30 страницSchade PresentationAnonymous qPt2MHzXTОценок пока нет

- RCAДокумент2 страницыRCAAnonymous qPt2MHzXTОценок пока нет

- 5e3e PDFДокумент6 страниц5e3e PDFAnonymous qPt2MHzXTОценок пока нет

- Topsoe Large Scale Hydrogen ProducДокумент20 страницTopsoe Large Scale Hydrogen ProducAnonymous j9s0eQ0uОценок пока нет

- 5e3e PDFДокумент6 страниц5e3e PDFAnonymous qPt2MHzXTОценок пока нет

- Prmary Reformer Catastrophic FailureДокумент9 страницPrmary Reformer Catastrophic FailureRizwan GujjarОценок пока нет

- 2 75 140713323460 62Документ3 страницы2 75 140713323460 62Anonymous qPt2MHzXTОценок пока нет

- Furnace 27Документ27 страницFurnace 27Anonymous kTLYjoBqОценок пока нет

- Section 224000 Plumbing Fixtures Port of PortlandДокумент9 страницSection 224000 Plumbing Fixtures Port of PortlandAnonymous qPt2MHzXTОценок пока нет

- Ficha Tecnica Viking PDFДокумент11 страницFicha Tecnica Viking PDFRichie ChicolОценок пока нет

- Form-HSE-TMR-006 Compressor, Genzet, Water Jet InspectionДокумент2 страницыForm-HSE-TMR-006 Compressor, Genzet, Water Jet Inspectionkenia infoОценок пока нет

- B.E. Civil Engineering Project ProposalДокумент10 страницB.E. Civil Engineering Project Proposalmahipal287Оценок пока нет

- Accidentally Pulled A Remote Branch Into Different Local Branch - How To Undo The Pull?: GitДокумент4 страницыAccidentally Pulled A Remote Branch Into Different Local Branch - How To Undo The Pull?: GitEdouard Francis Dufour DarbellayОценок пока нет

- The Future of HovercraftДокумент3 страницыThe Future of Hovercrafthovpod6214100% (4)

- Appointment Reciept GДокумент3 страницыAppointment Reciept GSanОценок пока нет

- Manual (4906-9127)Документ6 страницManual (4906-9127)LuisCabreraOroscoОценок пока нет

- Track The 5 Most Important Call Center MetricsДокумент3 страницыTrack The 5 Most Important Call Center Metricssalesforce.comОценок пока нет

- Finaldc 2Документ10 страницFinaldc 2Noel BactonОценок пока нет

- Design of Water Cooled Electric Motors Using CFD and Thermography TechniquesДокумент6 страницDesign of Water Cooled Electric Motors Using CFD and Thermography TechniquesNicolas JerezОценок пока нет

- NATO Tactical Nuclear Weapons in EuropeДокумент35 страницNATO Tactical Nuclear Weapons in EuropeMaria Mont' SerratОценок пока нет

- Fix 3Документ12 страницFix 3Eng TrОценок пока нет

- A Study On Customer Satisfaction Towards Online Banking ServicesДокумент12 страницA Study On Customer Satisfaction Towards Online Banking ServicesEditor IJTSRD100% (1)

- Watershed & Four Water ConceptДокумент31 страницаWatershed & Four Water ConceptNarendra SinghОценок пока нет

- Class XII Computer Science: HOTS (High Order Thinking Skill)Документ14 страницClass XII Computer Science: HOTS (High Order Thinking Skill)JanakiОценок пока нет

- Strategic Control ProcessДокумент18 страницStrategic Control ProcessMudassir IslamОценок пока нет

- Physics 05-01 Fluids and DensityДокумент2 страницыPhysics 05-01 Fluids and DensityRocelin E. MolabolaОценок пока нет

- SWOT) Analysis, Marketing Process, Marketing PlanДокумент24 страницыSWOT) Analysis, Marketing Process, Marketing PlanSagar Patil100% (2)

- UNIT - 1 TQM Objetive QuestionsДокумент7 страницUNIT - 1 TQM Objetive QuestionsNitin SinghОценок пока нет

- Fault Database - Flat TVДокумент3 страницыFault Database - Flat TVZu AhmadОценок пока нет

- Model 2000 Flow ComputerДокумент8 страницModel 2000 Flow ComputerAdnan SalihbegovicОценок пока нет

- Elite FY'22 On Campus - SRM Institute of Science and Technology - Business Interview Schedule 29-Sep-21Документ40 страницElite FY'22 On Campus - SRM Institute of Science and Technology - Business Interview Schedule 29-Sep-21aayush raghav (RA1811003020302)Оценок пока нет

- FUTURE SHOCK by ALVIN TOFFLERДокумент5 страницFUTURE SHOCK by ALVIN TOFFLERgeraldine100% (1)

- Al Washali2016Документ17 страницAl Washali2016tomi wirawanОценок пока нет

- Bugcrowd Vulnerability Rating Taxonomy 1.7Документ13 страницBugcrowd Vulnerability Rating Taxonomy 1.7junior108Оценок пока нет

- Tahap Amalan Penggunaan Lestari Dalam Kalangan Guru Di Puchong, SelangorДокумент8 страницTahap Amalan Penggunaan Lestari Dalam Kalangan Guru Di Puchong, SelangorMasliana SahadОценок пока нет

- Sadi Mohammad Naved: Duties/ResponsibilitiesДокумент3 страницыSadi Mohammad Naved: Duties/ResponsibilitiesNick SanchezОценок пока нет

- PGCB ReportДокумент36 страницPGCB ReportNayemul Hasan NayemОценок пока нет

- AIR Intelligence Manual 33 308100 004 RemoteДокумент88 страницAIR Intelligence Manual 33 308100 004 RemoteLeChancheОценок пока нет

- Min. Requirements For Retaining Wall/Sloping BackfillДокумент6 страницMin. Requirements For Retaining Wall/Sloping Backfillfostbarr0% (1)