Академический Документы

Профессиональный Документы

Культура Документы

Joints in Concrete Slabs PDF

Загружено:

Suhas NatuОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Joints in Concrete Slabs PDF

Загружено:

Suhas NatuАвторское право:

Доступные форматы

joints in Concrete Slabs Page 1

Cadman Products Tools & Resources Cadman Store About Us Job Opportunities Contact Us

Joints in Concrete Slabs Printable Version

Search...

Go >

Forms & Applications

Technical Reference What Are Joints?

› Admixtures for Concrete

› Air Content Loss in Pump Although concrete expands and contracts with changes in moisture and temperature the general overall

› Concrete Blisters tendency is to shrink and, therefore, crack. Irregular cracks are unsightly and difficult to maintain. Joints are

› Concrete Maintenance simply pre-planned cracks.

› Corrosion of Steel In Concrete

› Cracking Basement Wall

› Cracking Concrete Surfaces Some forms of joints are:

› Cracking Plastic Shrinkage

› Crazing Concrete Surfaces a. Control (contraction) joint –

› Curing In-Place Concrete

These joints are constructed to

› Curling of Concrete Slabs

create planes of weakness so

› Discoloration

› Discrepancies in Yield that cracks will occur at the

› Dusting Concrete Surfaces desired location.

› Finishing Concrete Flatwork

› Flexural Strength of Concrete b. Isolation (expansion) joints –

› Flowable Fill Materials They separate or isolate slabs

› Grout from other parts of the structure

› Hot Weather Concreting such as walls, footings, or

› Info., Brochures, and Color Charts columns, and driveways and

› Joints in Concrete Slabs patios from sidewalks, garage

› Low Concrete Strength slabs, stairs, light poles and

› Radon Resistant Buildings other obstructions. They permit

› Scaling Concrete Surfaces

movement of the slab and help

› Strength of In-Place Concrete

minimize cracking caused when

such movements are restrained.

Truck Dimensions

c. Construction joints – These are

joints that are placed at the end

Concrete Calculators

of a day’s work. In slabs they

may be designed to permit

movement and/or to transfer

load. Often in reinforced

concrete a conscious effort is

made to clean the joint and bond

the next day’s work.

Why Are Joints Constructed?

Concert cracks cannot be prevented entirely, but they can be controlled and minimized by properly

designed joints, because:

a. Concrete is weak in tension and, therefore, if its natural tendency to shrink is restrained, tensile

stressed develop and cracks are likely to occur.

b. At early ages, before the concrete dries out, most cracking is caused by temperature changes or by

the slight contraction that takes place as the concrete sets and hardens. Later as the concrete

dries it will shrink further and either additional cracks may form or preexisting cracks may become

wider.

c. Joints provide relief for the tensile stresses and are less objectionable than random cracks.

How to Construct Joints

Joints must be carefully designed and properly constructed if uncontrolled cracking of concrete flatwork is

to be avoided. The following recommended practices should be observed:

a. The maximum joint spacing in feet should not exceed 2.5 times the thickness in inches. For

example in an 8 in. slab the joints should be no further apart than 20 feet.

b. All panels should be square or nearly so. The length should not exceed 1.5 times the width. L-

shaped panels should be avoided.

c. The joint groove should have a depth of ¼ the thickness of the slab, but not less than one inch.

Tooled joints must be run early in the finishing process and rerun later to assure groove bond has

not occurred.

d. Control joints can be tooled during finishing or sawed with a carborundum blade at an early age.

Sawed joints may not be practical if the concrete is made with hard aggregate such as quartz

gravel or trap rock. Sawing is easier if coarse aggregates contain materials such as limestone or

sandstone. If the joint edges ravel during sawing it must be delayed, but if sawing is delayed too

long it may become difficult. With abrasive saw blades’ sawing is often done at an age of one day

http://www.cadman.com/section.asp?pageid=3167 21/04/2012 11:39:08

joints in Concrete Slabs Page 2

long it may become difficult. With abrasive saw blades’ sawing is often done at an age of one day

or even earlier.

e. Premolded joint filler, building paper or polyethylene should be used to isolate slabs from building

walls or footings. At least two inches of sand over the top of a footing will also prevent bond to the

footing.

f. To isolate columns from slabs, form circular or square openings which will not be filled until after the

floor has hardened. Slab control joints should intersect at the openings for columns. If square

openings are used around columns the square should be turned at 45 degrees to have the control

joints intersect at the diagonals of the square.

g. If the slab contains wire mesh cut out alternate wires across control joints. Note that wire mesh will

not prevent cracking. Mesh tends to keep the cracks and joints tightly closed.

h. Construction joints key the two edges of the slab together either to provide transfer of loads or to

help prevent curling or warping of the two adjacent edges. Galvanized metal keys are preferred for

interior slabs, however, a beveled 1 by 2 inch strip, nailed to bulkheads or form boards, can be

used in slabs that are at least 5 inches thick to form a key which will resist vertical loads and

movements. Metal dowels can also be used in slabs that will carry heavy loads. Dowels must be

carefully lined up and parallel or they may induce restraint and cause random cracking at the end of

the dowel.

i. Joints in industrial floors subject to heavy traffic require special attention to avoid spalling of joint

edges. Such joints should be filled with a material capable of supporting joint edges. Manufacturer’s

recommendations and performance records should be checked before use.

Follow These Rules for Proper Jointing

1. Plan exact location of all joints before construction

2. Provide isolation joints between slabs and columns, walls and footing, and at junctions of

driveways with walks, curbs or other obstructions.

3. Provide control joints and joint filling materials as outlined in specifications.

References

1. ACI 302.1, “Guide for Concrete Floor and Slab Construction,” ACI Manual of Concrete Practice.

2. “Slabs on Grade,” ACI Concrete Craftsman Series, American Concrete Institute, Detroit, Mi.

3. “Cracks in Concrete: Causes, Prevention, Repair,” a collection of articles from Concrete

Construction Magazine, June, 1973.

Home | Cadman Products | Tools & Resources | Cadman Store | About Us | Job Opportunities | Contact Us | Site Map

Content Management System (CMS) by Snaptech Marketing

Copyright © 1996-2012 Cadman, Inc. All rights reserved.

Questions? Comments? Please email us or send us your feedback.

http://www.cadman.com/section.asp?pageid=3167 21/04/2012 11:39:08

Вам также может понравиться

- SB Series BreakersДокумент12 страницSB Series BreakersManuel Pedro InácioОценок пока нет

- Technical Information: Rubblizing of Concrete Pavements: A Discussion of Its UseДокумент12 страницTechnical Information: Rubblizing of Concrete Pavements: A Discussion of Its UseErasmo AlexanderОценок пока нет

- SB AtlasДокумент12 страницSB AtlasAlberto de la cruzОценок пока нет

- Major Causes of Cracks Classification of Cracks: UNIT II: Cracks in BuildingsДокумент6 страницMajor Causes of Cracks Classification of Cracks: UNIT II: Cracks in BuildingsPriyankaОценок пока нет

- CIP 6 Joints in Concrete Slabs On The Ground - En.esДокумент2 страницыCIP 6 Joints in Concrete Slabs On The Ground - En.esKame SenninОценок пока нет

- Placing and Compacting ConcreteДокумент8 страницPlacing and Compacting ConcreteNorazly Awang0% (1)

- Circumferential CrackingДокумент6 страницCircumferential CrackingMagdykamelwilliamОценок пока нет

- Speakmon Thickness Handout 12 2020Документ15 страницSpeakmon Thickness Handout 12 2020Fernão DiasОценок пока нет

- WBS Name Activity Name PredecessorДокумент55 страницWBS Name Activity Name Predecessorjules_gwapoОценок пока нет

- Methods of Concrete CompactionДокумент1 страницаMethods of Concrete CompactionPrabhakar SvОценок пока нет

- Concreting SopДокумент9 страницConcreting SopvivekОценок пока нет

- Building Materials Construction Planning PDFДокумент252 страницыBuilding Materials Construction Planning PDFTharun TejaОценок пока нет

- Evaluation of Concrete Prior To Rehabilitation: John S. Lund, PE, FACI Principal, Investigative EngineeringДокумент33 страницыEvaluation of Concrete Prior To Rehabilitation: John S. Lund, PE, FACI Principal, Investigative EngineeringAnis ShatnawiОценок пока нет

- Indeco Catalogue 17 12 G H GB 05 01Документ11 страницIndeco Catalogue 17 12 G H GB 05 01Luka BornaОценок пока нет

- Lesson 03Документ25 страницLesson 03Lia CambangayОценок пока нет

- Cast in Place ConcreteДокумент19 страницCast in Place ConcretejhansiОценок пока нет

- Hydraulic Breakers: HP SeriesДокумент11 страницHydraulic Breakers: HP SeriesjoshОценок пока нет

- Placing Finish Conc 1Документ57 страницPlacing Finish Conc 1Mang AwitОценок пока нет

- Hilti - PostInstalled Vs CastIn RebarДокумент82 страницыHilti - PostInstalled Vs CastIn RebarSantosoОценок пока нет

- Jeas 101Документ15 страницJeas 101Mr. A. A. PandeОценок пока нет

- CE 6105 - Lecture-9 Time Dependent DeformationДокумент31 страницаCE 6105 - Lecture-9 Time Dependent DeformationMahbub AlamОценок пока нет

- CIP 6 - Controlling Concrete Cracks with JointsДокумент2 страницыCIP 6 - Controlling Concrete Cracks with JointsBalaji_Rajaman_2280Оценок пока нет

- Civil Equaltion PDFДокумент2 страницыCivil Equaltion PDFBalaji_Rajaman_2280Оценок пока нет

- Placing and Finishing ConcreteДокумент62 страницыPlacing and Finishing ConcreteMohamad A. HawaliОценок пока нет

- Cracking in Composite-Corrugated Metal Decking Floor SlabsДокумент3 страницыCracking in Composite-Corrugated Metal Decking Floor SlabsBolanle OlaawoОценок пока нет

- Adamson University explores rigid pavementsДокумент16 страницAdamson University explores rigid pavementsJohnrick LasquetyОценок пока нет

- Repair of Concrete Pavement - RestorationДокумент2 страницыRepair of Concrete Pavement - RestorationRana MahatoОценок пока нет

- Housing Report Concrete Shear Wall Highrise BuildingsДокумент16 страницHousing Report Concrete Shear Wall Highrise BuildingsionutfalcescuОценок пока нет

- Nepal Repair and Retrofitting Manual for Earthquake Damaged RCC StructuresДокумент53 страницыNepal Repair and Retrofitting Manual for Earthquake Damaged RCC StructureserjuniorsanjipОценок пока нет

- Project Planning and Reporting Assignment BSQ3523Документ62 страницыProject Planning and Reporting Assignment BSQ3523ArdiniОценок пока нет

- Construction Joint: Sheating Stud Braces WalesДокумент2 страницыConstruction Joint: Sheating Stud Braces WalesLovely BautistaОценок пока нет

- Work Breakdown Structure (WBS)Документ6 страницWork Breakdown Structure (WBS)Zamri MohamedОценок пока нет

- Code ComparisonДокумент4 страницыCode ComparisonSnehaОценок пока нет

- RCC - BC Unit-IvДокумент37 страницRCC - BC Unit-Ivsai keerthiОценок пока нет

- Retaining Strucutres Enstp2023 Pack01Документ24 страницыRetaining Strucutres Enstp2023 Pack01modiotoukemvirginieОценок пока нет

- Highway Group 2Документ17 страницHighway Group 2Johnrick LasquetyОценок пока нет

- ch10Документ13 страницch10Jira YesusОценок пока нет

- Inspecting Concrete Buildings for Structural DeteriorationДокумент37 страницInspecting Concrete Buildings for Structural DeteriorationjoshuaisraeliОценок пока нет

- Formation DamageДокумент64 страницыFormation Damagearturo_partida_1Оценок пока нет

- SUBMITTED BY: 2016-AE-15: Floor Finishing Wall Fininshing Doors & Windows Fixing CeilingДокумент1 страницаSUBMITTED BY: 2016-AE-15: Floor Finishing Wall Fininshing Doors & Windows Fixing CeilingghinwanaeemОценок пока нет

- Design, Construction & Maintenance of Rigid Pavement PDFДокумент3 страницыDesign, Construction & Maintenance of Rigid Pavement PDFDipak PatelОценок пока нет

- Concrete MixturesДокумент1 страницаConcrete MixturesJelaiОценок пока нет

- Case Studies: Solutions For Maintenance, Rehabilitation, StrengtheningДокумент3 страницыCase Studies: Solutions For Maintenance, Rehabilitation, StrengtheningRith JRОценок пока нет

- Day 1 - ACI Amman Series - 2 - Curing ConcreteДокумент11 страницDay 1 - ACI Amman Series - 2 - Curing ConcreteTaha GargoumОценок пока нет

- EQTip 09Документ2 страницыEQTip 09raj_ferrariОценок пока нет

- Unit-4 (RCC)Документ24 страницыUnit-4 (RCC)Usmitha KommuriОценок пока нет

- Construction Joints in Concrete Structures - Structural GuideДокумент15 страницConstruction Joints in Concrete Structures - Structural GuideHEMANTОценок пока нет

- RCD - PPT - Part 1Документ32 страницыRCD - PPT - Part 1Christian Josh DomingoОценок пока нет

- CEMENT CONCRETE TECHNOLOGY FACTORS AFFECTING DURABILITYДокумент1 страницаCEMENT CONCRETE TECHNOLOGY FACTORS AFFECTING DURABILITYNeeraj VashistОценок пока нет

- WBS for Banglo Type A (2 Tiers) Construction ProjectДокумент5 страницWBS for Banglo Type A (2 Tiers) Construction ProjectZamri MohamedОценок пока нет

- AssignmentДокумент60 страницAssignmentArdiniОценок пока нет

- Soft Storey in Buildings and Its Vulnerability Towards EarthquakesДокумент6 страницSoft Storey in Buildings and Its Vulnerability Towards EarthquakesJustin MusopoleОценок пока нет

- Bu Mat OPT7S CBCPreventMaintConcDecksДокумент42 страницыBu Mat OPT7S CBCPreventMaintConcDecksRooja BajracharyaОценок пока нет

- ML12153A412 Fisuras PDFДокумент62 страницыML12153A412 Fisuras PDFJuan Gutier CcОценок пока нет

- Precast Concrete Construction: By: Ahmed Aloudah Civil InspectorДокумент6 страницPrecast Concrete Construction: By: Ahmed Aloudah Civil Inspectorahmed aloudahОценок пока нет

- Introductions: Concrete Crack of Ballastless Track Structure and Its RepairДокумент7 страницIntroductions: Concrete Crack of Ballastless Track Structure and Its RepairSahil SharmaОценок пока нет

- WH 100031Документ19 страницWH 100031Harun ArslanОценок пока нет

- Pre-Paving ConsiderationsДокумент106 страницPre-Paving ConsiderationsLupita RamirezОценок пока нет

- Cover Berore Fresh Concrete: All-In-One Journal 3sttadДокумент16 страницCover Berore Fresh Concrete: All-In-One Journal 3sttadShyam NaniОценок пока нет

- Introduction To OpenglДокумент3 страницыIntroduction To OpenglGayathri DasОценок пока нет

- Backfill Drainage of Retaining WallsДокумент1 страницаBackfill Drainage of Retaining WallsSuhas NatuОценок пока нет

- Unified Approach To Thrust Restraint DesignДокумент6 страницUnified Approach To Thrust Restraint DesigncherryОценок пока нет

- Three Dimensional PrimitivesДокумент10 страницThree Dimensional PrimitivesSuhas NatuОценок пока нет

- Three Dimensional PrimitivesДокумент10 страницThree Dimensional PrimitivesSuhas NatuОценок пока нет

- SSB05 Detailed Design of Trusses 2010-03-22Документ131 страницаSSB05 Detailed Design of Trusses 2010-03-22DN GHОценок пока нет

- Unit1 SLДокумент12 страницUnit1 SLGayathri DasОценок пока нет

- 4.1 Affine Transformations: Transformation Is A Function That Takes A Point (Vector) and Maps It Into AnotherДокумент13 страниц4.1 Affine Transformations: Transformation Is A Function That Takes A Point (Vector) and Maps It Into AnotherSuhas NatuОценок пока нет

- 7.UDCPR Sanctioned.... 111 PDFДокумент397 страниц7.UDCPR Sanctioned.... 111 PDFRajesh KetОценок пока нет

- Combined Bend - FormulaДокумент1 страницаCombined Bend - FormulaSuhas NatuОценок пока нет

- Ret Walls MCNДокумент8 страницRet Walls MCNSuhas NatuОценок пока нет

- 7.UDCPR Sanctioned.... 111 PDFДокумент397 страниц7.UDCPR Sanctioned.... 111 PDFRajesh KetОценок пока нет

- Unit1 SLДокумент12 страницUnit1 SLGayathri DasОценок пока нет

- Top 5 Input Devices for Graphics WorkstationsДокумент5 страницTop 5 Input Devices for Graphics WorkstationsGayathri DasОценок пока нет

- 7.UDCPR Sanctioned.... 111 PDFДокумент397 страниц7.UDCPR Sanctioned.... 111 PDFRajesh KetОценок пока нет

- Macau Bus Routes - Bus Guide - MetropolasiaДокумент14 страницMacau Bus Routes - Bus Guide - MetropolasiaSuhas NatuОценок пока нет

- KyotoДокумент15 страницKyotoSuhas NatuОценок пока нет

- Russian Numbers - Russian Language Lesson 2 PDFДокумент1 страницаRussian Numbers - Russian Language Lesson 2 PDFSuhas Natu100% (1)

- Tourist Bus Ticket From Kathmandu, Pokhara, Chitwan, Lumnini in NepalДокумент4 страницыTourist Bus Ticket From Kathmandu, Pokhara, Chitwan, Lumnini in NepalSuhas NatuОценок пока нет

- LokfixДокумент4 страницыLokfixclicknagpalОценок пока нет

- Station KyotoДокумент13 страницStation KyotoSuhas NatuОценок пока нет

- Station Exit: Mitsukoshimae Station (Z9/ G12) : 0.3 KM Shin-Nihombashi Station: (JO20) : 0.40 KMДокумент5 страницStation Exit: Mitsukoshimae Station (Z9/ G12) : 0.3 KM Shin-Nihombashi Station: (JO20) : 0.40 KMSuhas NatuОценок пока нет

- ICA - Visa Free Transit FacilityДокумент2 страницыICA - Visa Free Transit FacilitySuhas NatuОценок пока нет

- Buddhist World - Map of The Land of The BuddhaДокумент1 страницаBuddhist World - Map of The Land of The BuddhaSuhas NatuОценок пока нет

- Changi Transit Programme - Singapore AirlinesДокумент3 страницыChangi Transit Programme - Singapore AirlinesSuhas NatuОценок пока нет

- FREE Shuttle Buses For Tourists in Tokyo - City-CostДокумент2 страницыFREE Shuttle Buses For Tourists in Tokyo - City-CostSuhas NatuОценок пока нет

- Welcome To Iplex Pipelines Australia Pty LimitedДокумент4 страницыWelcome To Iplex Pipelines Australia Pty LimitedSuhas NatuОценок пока нет

- Osaka Transportation - Osaka StationДокумент9 страницOsaka Transportation - Osaka StationSuhas NatuОценок пока нет

- 4-Day Visa Free Transit Facility in Singapore For IndiansДокумент2 страницы4-Day Visa Free Transit Facility in Singapore For IndiansSuhas NatuОценок пока нет

- 2F Shinkansen Central Gate and West GateДокумент2 страницы2F Shinkansen Central Gate and West GateSuhas NatuОценок пока нет

- Overtime AccomplishmentДокумент9 страницOvertime AccomplishmentKate PerezОценок пока нет

- Seismic Analysis and DesignДокумент11 страницSeismic Analysis and DesignYra Mae ViluanОценок пока нет

- Essential (2019)Документ2 страницыEssential (2019)namita nagarОценок пока нет

- Standard construction equipment performanceДокумент34 страницыStandard construction equipment performanceTewodros TadesseОценок пока нет

- Folded PlateДокумент14 страницFolded PlateTanvi Yadav100% (3)

- Katalog Groud Mounting 1Документ5 страницKatalog Groud Mounting 1Марко ЈелићОценок пока нет

- Jawahar Kala Kendra: Aayojan School of Architecture, JaipurДокумент9 страницJawahar Kala Kendra: Aayojan School of Architecture, JaipurPrakriti GoelОценок пока нет

- Rawan M. AlAli - Architect PortfolioДокумент19 страницRawan M. AlAli - Architect PortfolioRawan Mohammed Al-AliОценок пока нет

- Crossing The Street: Literature and Urban SpaceДокумент12 страницCrossing The Street: Literature and Urban SpaceAndreea RasuceanuОценок пока нет

- PPT On FRCДокумент59 страницPPT On FRCVijay MОценок пока нет

- Ce36-Construction Techniques, EquipmentsДокумент27 страницCe36-Construction Techniques, EquipmentshelloitskalaiОценок пока нет

- Sagrika DDДокумент26 страницSagrika DDsagrikakhandkaОценок пока нет

- Robert VenturiДокумент10 страницRobert VenturiRamsrajОценок пока нет

- Price List 2020Документ12 страницPrice List 2020muphils2019Оценок пока нет

- Thumb Rules For Steel&Concrete DesignДокумент11 страницThumb Rules For Steel&Concrete DesigngvgbabuОценок пока нет

- Webforge BrochureДокумент39 страницWebforge Brochurebakkali_bilalОценок пока нет

- 7-Front Elevation Villa 2 and Left Elevation Villa 1Документ1 страница7-Front Elevation Villa 2 and Left Elevation Villa 1Uzair QuraishiОценок пока нет

- Scheerlinckk Depthconfigurations - Proximity, PermeabilityandterritorialboundariesinurbanprojectsДокумент16 страницScheerlinckk Depthconfigurations - Proximity, PermeabilityandterritorialboundariesinurbanprojectsIvan JimenezОценок пока нет

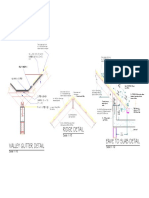

- Eave To Slab Detail Valley Gutter Detail Ridge Detail: Scale 1:10Документ1 страницаEave To Slab Detail Valley Gutter Detail Ridge Detail: Scale 1:10Jordan BrownОценок пока нет

- How Laminated Glass Is MadeДокумент2 страницыHow Laminated Glass Is MadeHan JoeОценок пока нет

- Applying Ancient Indian Architectural Principles TodayДокумент230 страницApplying Ancient Indian Architectural Principles TodayAlejandro Sanchez100% (2)

- GFA Definition Part 1Документ16 страницGFA Definition Part 1letuananhbОценок пока нет

- FLYT (Selected Projects 1999-2015)Документ106 страницFLYT (Selected Projects 1999-2015)Frven Lim Yew TiongОценок пока нет

- The Transect of Urban Settlement: Defining Neighborhood Centers Through a Transect ApproachДокумент17 страницThe Transect of Urban Settlement: Defining Neighborhood Centers Through a Transect ApproachcarlosanchietaОценок пока нет

- BOMBA - Fire Fighting SystemДокумент31 страницаBOMBA - Fire Fighting SystemSadDecemberОценок пока нет

- UBBL 1984 Guide: Design, Submission & Construction StagesДокумент14 страницUBBL 1984 Guide: Design, Submission & Construction Stagesagitent33% (3)

- Classic Lite Rh90: Texture and Grid IntersectionsДокумент2 страницыClassic Lite Rh90: Texture and Grid Intersectionszikrillah1Оценок пока нет

- OBJ Datastream PDFДокумент104 страницыOBJ Datastream PDFБјелић ТеодораОценок пока нет

- Fosroc Nitowrap Carbon Fibre SheetДокумент4 страницыFosroc Nitowrap Carbon Fibre Sheetalexcus1539Оценок пока нет

- PROPOSED MIXED-USE BUILDINGДокумент29 страницPROPOSED MIXED-USE BUILDINGAYSON N. DELA CRUZОценок пока нет