Академический Документы

Профессиональный Документы

Культура Документы

IMS WetScrubberEVS-150 Rev2.0 20180402

Загружено:

David FergusonАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

IMS WetScrubberEVS-150 Rev2.0 20180402

Загружено:

David FergusonАвторское право:

Доступные форматы

EMERGENCY CHLORINE SCRUBBER SYSTEM - EVS Series

The EVS-150 emergency chlorine scrubber is a multi-stage wet scrubber system designed to treat chlorine vapors from a bank of

150lb (70kg) chlorine cylinders, at leak rates of 28 lbs/min or more, exceeding the requirement of the Uniform Fire Code. The EVS-

150 system is designed to maintain negative pressure in the chlorination and chlorine storage rooms, while limiting the atmospheric

release of chlorine to less than 1 ppm.

The factory-assembled EVS-150 system is very compact, with low profile suitable for either indoor or outdoor installation. It is de-

signed by Roop Jain, the founder of RJ Environmental, and a renowned leader and innovator in chlorine scrubber technology for the

last 25 years.

GUARANTEED PERFORMANCE

The EVS-150 scrubber is capable of reducing the inlet chlorine gas concentration to less than 1 ppm at the

outlet.

A pre-treatment stage handles extremely high concentrations while subsequent high-efficiency stages remove

the remainder of the toxic vapors.

During catastrophic releases, the EVS-150 achieves more than 99.999% chlorine vapor removal efficiency.

MAJOR SYSTEM

COMPONENTS

FRP Scrubber Vessel

Integral FRP Caustic Storage Tank

FRP Exhaust Fan

Caustic Recirculation Pump

FRP Control Panel

FRP Exhaust Stack

EVS-150 - Process & Instrumentation Diagram

© 2018 INTEGRITY MUNICIPAL SYSTEMS. ALL RIGHTS RESERVED.

HOW IT WORKS

The emergency chlorine vapor scrubbing system is a three-stage chemical absorption system consisting of a horizontal crossflow

spray system followed by two horizontal crossflow packed bed sections. An induced draft fan pulls vapors through the scrubber,

where intimate contact with a recirculating caustic solution results in the complete absorption and removal of chlorine or sulfur

dioxide vapors. A high efficiency mist eliminator is located in the gas stream, prior to exhaust, to remove any residual caustic solution.

A chlorine detector or manual remote start switch activates the system in two steps. The caustic pump is activated first to permit

proper wetting of packing in the scrubber stages before starting the exhaust fan, with a 0 to 5 second adjustable time delay. The time

delay is typically set for 3 to 5 seconds. This feature allows the scrubber to be ready prior to passing any chlorine laden gases through it.

The exhaust fan is placed downstream of the scrubber. This feature allows the complete system to be under negative pressure until

the gases are completely scrubbed. The absorber is placed on top of a caustic storage tank, which is an integral part of the system.

SYSTEM FEATURES SYSTEM BENEFITS

Factory-assembled, System is assembled, piped, wired and tested at factory

Packaged System Enables better quality control at the factory

Easier transportation, handling and installation

Installation time of less than 8 hours

Minimum Installation Installation requires only provision of concrete pad,

Cost and Time inlet ductwork, utility connections and fill of caustic soda

Superior Design and Excess liquid to absorb heat of absorption for maximum chlorine release

High Performance Low pressure recirculation of scrubber liquid enhances safety

Three-stage chemical process ensures efficiency greater than 99.999%

Random packing provides large surface area for gas-liquid contact

Low Cost of Operation & Low profile with top and side access for easy maintenance

Easy Maintenance Vertical seal-less pump

Low horsepower for pump and fan motors

Automatic and Manual System can run in manual mode for maintenance purposes and in fully

Operation automatic mode for standby emergency operation

Standby recirculation pump

Optional Features for Standby induced exhaust fan

Maximum Safety Sump insulation / sump heater

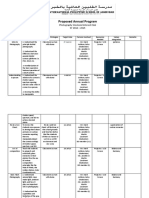

EVS-150 DESIGN INFORMATION

Design Caustic Dimensions Shipping Operating

Airflow Pump Motor Fan Motor

Capacity Volume LxWxH Weight Weight

System Rate cfm HP HP

lbs Gallons ft lbs lbs

(m3/h) (kW) (kW)

(kg) (Liters) (m) (kg) (kg)

300 250 275 7.0 x 3.0 x 4.8 1,000 4,000 3.0 1.0

EVS-150-2

(135) (425) (1040) (2.1 x 0.9 x 1.5) (450) (1800) (2.2) (0.75)

600 250 550 7.0 x 3.0 x 6.5 1,500 7,500 3.0 1.0

EVS-150-4

(270) (425) (2082) (2.1 x 0.9 x 2.0) (700) (3400) (2.2) (0.75)

900 250 660 7.0 x 3.0 x 7.5 2,000 9,200 3.0 1.0

EVS-150-6

(400) (425) (2500) (2.1 x 0.9 x 2.3) (900) (4200) (2.2) (0.75)

13135 DANIELSON STREET, SUITE 204 POWAY, CA 92064

04/02/2018 Rev. 2.0 PHONE: (858) 486-1620 FAX: (858) 486-1659 www.integrityms.net

Вам также может понравиться

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingОт EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingРейтинг: 5 из 5 звезд5/5 (3)

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshОт EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshОценок пока нет

- QSZ13G6Документ3 страницыQSZ13G6Jonny Ubaldo Zambrano MeraОценок пока нет

- Ce Series Filters & Moisture Separator: Compressed Air & Power SolutionsДокумент4 страницыCe Series Filters & Moisture Separator: Compressed Air & Power SolutionsTim MitchellОценок пока нет

- Orca HL - SeriesДокумент2 страницыOrca HL - SerieserwinОценок пока нет

- QSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Документ3 страницыQSZ13-G7: EU Stage IIIA / U.S. EPA Tier 3Franyusmid Gomez Bolivar100% (1)

- Power Plant FundamentalsДокумент23 страницыPower Plant FundamentalsJeffcaster ComelОценок пока нет

- ERG Venturi ScrubbersДокумент2 страницыERG Venturi ScrubberscsreyeroОценок пока нет

- SEP Catalog SWK2000 EmailДокумент4 страницыSEP Catalog SWK2000 Emailகோவி கோபால் ஆர்ட்ஸ்Оценок пока нет

- Central Cooling SystemДокумент8 страницCentral Cooling SystemYonilОценок пока нет

- ACO Aeropur Plus 3 - 100Документ8 страницACO Aeropur Plus 3 - 100duga11Оценок пока нет

- 2020-12-04 FP-Series - BrochureДокумент2 страницы2020-12-04 FP-Series - BrochureAnil DeendayalОценок пока нет

- Sullair 900electricДокумент2 страницыSullair 900electricchavezramirez.carlosdanielОценок пока нет

- QSZ13-G5: EU Stage IIДокумент3 страницыQSZ13-G5: EU Stage IIluis blancoОценок пока нет

- Primatic LH SeriesДокумент2 страницыPrimatic LH Seriessatya.unitamaОценок пока нет

- Brochure PAS VAR Dewatering Pumps English v06Документ20 страницBrochure PAS VAR Dewatering Pumps English v06Maximo MartinezОценок пока нет

- Prowadest ®/1: KLC EvaporatorДокумент2 страницыProwadest ®/1: KLC EvaporatorAhmed SpahicОценок пока нет

- QSZ13G7Документ3 страницыQSZ13G7Kevin GuoОценок пока нет

- Desozone Odor ControlДокумент5 страницDesozone Odor Controlsolo7651Оценок пока нет

- COMPANY PRESENTATION Dec 2016Документ30 страницCOMPANY PRESENTATION Dec 2016mbohramurtazaОценок пока нет

- Flue Gas System: Producing Inert Gas On BoardДокумент4 страницыFlue Gas System: Producing Inert Gas On Board3 GamerОценок пока нет

- Scarab Merlin Uni-Drive Technical SpecificationsДокумент4 страницыScarab Merlin Uni-Drive Technical SpecificationsScarab SweepersОценок пока нет

- C200 HPNG - 331043A - LowresДокумент2 страницыC200 HPNG - 331043A - LowresOmar SelamiОценок пока нет

- Aries: Underground DrillsДокумент3 страницыAries: Underground DrillsEmanuel Nicolas Villarruel100% (1)

- Manual OyM - Compresor 900hДокумент2 страницыManual OyM - Compresor 900hCARLOSОценок пока нет

- Fiche Technique QES 390 CDДокумент6 страницFiche Technique QES 390 CDMProd AmmoОценок пока нет

- Wolf 4000 - DatasheetДокумент3 страницыWolf 4000 - DatasheetsuharmantoОценок пока нет

- SCW Scrubber 012013Документ8 страницSCW Scrubber 012013Daniele BacchiОценок пока нет

- QSX15-G8: TA Luft CompliantДокумент3 страницыQSX15-G8: TA Luft CompliantNguyen CuongОценок пока нет

- QSL9-G3 CoolpackДокумент3 страницыQSL9-G3 Coolpackmohsen_cumminsОценок пока нет

- VHP Series Five P9394Gsi S5: With Esm2 and Empact Emission Control SystemДокумент2 страницыVHP Series Five P9394Gsi S5: With Esm2 and Empact Emission Control SystemGabrielito PachacamaОценок пока нет

- Brosur Datasheet Sariling-Perkins-Sae 300 Kva Silent Type PDFДокумент6 страницBrosur Datasheet Sariling-Perkins-Sae 300 Kva Silent Type PDFPusat GensetОценок пока нет

- Cornell BR Mine DewateringДокумент8 страницCornell BR Mine Dewateringtan_dat2003Оценок пока нет

- Recuperador de Vapor Por Condensacion y Tratamiento de GasДокумент3 страницыRecuperador de Vapor Por Condensacion y Tratamiento de GasambientesiaОценок пока нет

- Atlas Copco Wagner Inc.: Technical Specifications and Performance DataДокумент4 страницыAtlas Copco Wagner Inc.: Technical Specifications and Performance DataDee DayОценок пока нет

- Super Duty, Independent Dual System Hydraulic Power Unit / Diesel PoweredДокумент6 страницSuper Duty, Independent Dual System Hydraulic Power Unit / Diesel PoweredTrần Quang ThắngОценок пока нет

- Principle of Operation:: Venturi BlowerДокумент3 страницыPrinciple of Operation:: Venturi BlowerPraveen PaviОценок пока нет

- Product Catalog: Compact Screen, Single Screen & Multi Screen FiltersДокумент26 страницProduct Catalog: Compact Screen, Single Screen & Multi Screen FiltersLuan NguyenОценок пока нет

- Urea Toyo ACES21 - BrochureДокумент8 страницUrea Toyo ACES21 - BrochureSanti SevenfoldОценок пока нет

- Komatsu PC1250-8 Backhoe Loader Specs & FeaturesДокумент24 страницыKomatsu PC1250-8 Backhoe Loader Specs & FeaturesAS ku SwandaniОценок пока нет

- DX700LC PDFДокумент20 страницDX700LC PDFA Ramos GabyОценок пока нет

- 05 EngineДокумент41 страница05 EngineAriel Farinon100% (2)

- QSL9 G7Документ3 страницыQSL9 G7Naushad ShaikhОценок пока нет

- Jet AerationДокумент6 страницJet Aerationbladeliger22Оценок пока нет

- Humidification and Evaporative CoolingДокумент8 страницHumidification and Evaporative CoolingTanveer AzizОценок пока нет

- Cat® Bulk Fuel Filtration SystemsДокумент4 страницыCat® Bulk Fuel Filtration Systemsdoncia100% (1)

- ATLAS COPCO 610 to 810 CFM Air Compressors - LeafletДокумент4 страницыATLAS COPCO 610 to 810 CFM Air Compressors - Leafletlalji halaiОценок пока нет

- PC800 800LC 8R1 LoadingДокумент24 страницыPC800 800LC 8R1 LoadingAkhmad SebehОценок пока нет

- Steam Heat ExchangerДокумент2 страницыSteam Heat ExchangerAbdul Hafeez AkramОценок пока нет

- Aqua Series Vapor Compression DistillerДокумент1 страницаAqua Series Vapor Compression DistillerMohd Khairul Ahmad AliasОценок пока нет

- HL-ADS compressed air dryer packagesДокумент17 страницHL-ADS compressed air dryer packagesMarcoAlbaОценок пока нет

- GPL 4.13Документ4 страницыGPL 4.13FabricioVОценок пока нет

- Low Noise Solutions For Turbine Bypass To Air-Cooled CondensersДокумент10 страницLow Noise Solutions For Turbine Bypass To Air-Cooled CondensersElavarasan Ramalingam100% (1)

- LS 730 JCX Industrial Filtration SystemsДокумент4 страницыLS 730 JCX Industrial Filtration SystemsSadiОценок пока нет

- Sebf-I: The Art of Powerful Cleaning..Документ3 страницыSebf-I: The Art of Powerful Cleaning..Pn ThanhОценок пока нет

- Excavadora Komatsu PC800Документ24 страницыExcavadora Komatsu PC800fia c.lОценок пока нет

- Procedimientos de Flushing AxiaДокумент7 страницProcedimientos de Flushing AxiaAlejandro GarciaОценок пока нет

- VHP Series Four L5794Gsi: With Esm2 and Empact Emission Control SystemДокумент2 страницыVHP Series Four L5794Gsi: With Esm2 and Empact Emission Control Systemjordan navarroОценок пока нет

- Multistage Centrifugal: Blowers/ExhaustersДокумент12 страницMultistage Centrifugal: Blowers/Exhaustershardik033Оценок пока нет

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationОт EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationРейтинг: 1 из 5 звезд1/5 (1)

- NSF Cert NG840 PDFДокумент9 страницNSF Cert NG840 PDFDavid FergusonОценок пока нет

- Pump Performance Datasheet: Customer ReferenceДокумент1 страницаPump Performance Datasheet: Customer ReferenceDavid FergusonОценок пока нет

- Data Sheet Sigmadur 1800 PDFДокумент5 страницData Sheet Sigmadur 1800 PDFDavid FergusonОценок пока нет

- en-US 7468Документ6 страницen-US 7468Francis ReyesОценок пока нет

- 400 Series Standards PDFДокумент8 страниц400 Series Standards PDFDavid FergusonОценок пока нет

- Painting DFT Rules-SSPC-PA-2Документ16 страницPainting DFT Rules-SSPC-PA-2Michael AlbuquerqueОценок пока нет

- Quality 1/: Prstective & Marine Coaüngs NoДокумент2 страницыQuality 1/: Prstective & Marine Coaüngs NoDavid FergusonОценок пока нет

- Data Sheet Novaguard 615Документ4 страницыData Sheet Novaguard 615David FergusonОценок пока нет

- Energy Effiency en Water and Wastewater Facilities PDFДокумент57 страницEnergy Effiency en Water and Wastewater Facilities PDFDavid FergusonОценок пока нет

- Ductile Iron Pipe Iso en Standards E779dc24Документ24 страницыDuctile Iron Pipe Iso en Standards E779dc24David FergusonОценок пока нет

- Astm A53 A53mДокумент23 страницыAstm A53 A53mRaviprakash Chauhan100% (2)

- Enzyme Industrial UsesДокумент7 страницEnzyme Industrial UsesDavid FergusonОценок пока нет

- Catalogo Submersible Sewage PumpДокумент80 страницCatalogo Submersible Sewage PumpDavid FergusonОценок пока нет

- Welded Steel PenstockДокумент63 страницыWelded Steel PenstockIfnu Setyadi100% (1)

- IPTV Kanalai.m3uДокумент2 страницыIPTV Kanalai.m3uDavid FergusonОценок пока нет

- Water Chemistry Industrial and Power Plant Water TreatmentДокумент153 страницыWater Chemistry Industrial and Power Plant Water Treatmentbackstreetboy17100% (1)

- IPTV Kanalai.m3uДокумент2 страницыIPTV Kanalai.m3uDavid FergusonОценок пока нет

- Speak Out Test Unit 1Документ4 страницыSpeak Out Test Unit 1boj210457% (7)

- UNSPSC Spanish v14 0801Документ1 953 страницыUNSPSC Spanish v14 0801LYCANTROPOFAGO0% (1)

- AGI CatalogДокумент8 страницAGI Cataloghusein965Оценок пока нет

- (Rock Crusher) : Machine Design 2Документ64 страницы(Rock Crusher) : Machine Design 2almira genabeОценок пока нет

- Automation Technology: Full Line Catalog, Volume 3 - Edition 2019/2020Документ564 страницыAutomation Technology: Full Line Catalog, Volume 3 - Edition 2019/2020Serdar AksoyОценок пока нет

- Ata 33 LightsДокумент141 страницаAta 33 LightsAvtech100% (1)

- July 2017Документ96 страницJuly 2017Pumper MagazineОценок пока нет

- Feed Water SystemДокумент18 страницFeed Water SystempajriramadhanОценок пока нет

- UltraTemp Heat Pump Installation and Users Guide EnglishДокумент38 страницUltraTemp Heat Pump Installation and Users Guide EnglishEstefania MerinoОценок пока нет

- PC500LC 8RДокумент20 страницPC500LC 8RSabahОценок пока нет

- M14 Spring GuidesДокумент4 страницыM14 Spring Guideswatch_sutОценок пока нет

- Industry Alloted Property 111Документ46 страницIndustry Alloted Property 111JeffОценок пока нет

- SBT LNG 07 v1Документ10 страницSBT LNG 07 v1Erwin Paulian SihombingОценок пока нет

- HOW TO BUILD A FAST PINEWOOD DERBY CAR UNDER 40 CHARACTERSДокумент45 страницHOW TO BUILD A FAST PINEWOOD DERBY CAR UNDER 40 CHARACTERSRaajeswaran BaskaranОценок пока нет

- John Deere Fall - 2001Документ20 страницJohn Deere Fall - 2001sethhutchinsonОценок пока нет

- AeroShell Turbine Oil 500 PDFДокумент2 страницыAeroShell Turbine Oil 500 PDFAnonymous oAbjbl4HОценок пока нет

- Spe Exam Jan 2014Документ2 страницыSpe Exam Jan 2014Ahmed FaragallahОценок пока нет

- Overhead FPIДокумент2 страницыOverhead FPIbibhas_samantaОценок пока нет

- Hydropower Engineering IIДокумент141 страницаHydropower Engineering IIashe zinab100% (7)

- MAN-02-00067-RD 24 V Power Station ManualДокумент3 страницыMAN-02-00067-RD 24 V Power Station ManualAnonymous xMpBefLОценок пока нет

- Tamilnadu Dindul Karur Expressway Limited (TNDK)Документ40 страницTamilnadu Dindul Karur Expressway Limited (TNDK)malepulaОценок пока нет

- 2031 Mysore Masterplan ProposalsДокумент97 страниц2031 Mysore Masterplan Proposalspriya rajeev100% (1)

- PHOTOGRAPHY Class Action PlanДокумент7 страницPHOTOGRAPHY Class Action PlanJennifer MartinОценок пока нет

- Pushover Analysis ExplainedДокумент62 страницыPushover Analysis ExplainedRakesh7770100% (2)

- 4206 PtoДокумент3 страницы4206 PtoHaidar Chandu100% (1)

- Electric Machines ManualДокумент631 страницаElectric Machines ManualFarazОценок пока нет

- Profile MJCДокумент18 страницProfile MJCsahaОценок пока нет

- EGR Cooler Clean Volvo D16Документ5 страницEGR Cooler Clean Volvo D16ISRRAELОценок пока нет

- VDI2221Документ8 страницVDI2221hansen_golsvokОценок пока нет

- Wrought Iron Properties ApplicationsДокумент2 страницыWrought Iron Properties ApplicationsRaymond LiewОценок пока нет

- Monitoreo de Ensuciamiento en IntercambiadoresДокумент11 страницMonitoreo de Ensuciamiento en IntercambiadoresHernan CobaОценок пока нет