Академический Документы

Профессиональный Документы

Культура Документы

Classification of Steam Turbines

Загружено:

Shon Rick AnisАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Classification of Steam Turbines

Загружено:

Shon Rick AnisАвторское право:

Доступные форматы

Classifications of Steam Turbine

WHAT IS A STEAM TURBINE?

A Steam Turbine is a mechanical device that extracts thermal energy from pressurized

steam and transforms it into mechanical work. It is powered by steam. As hot, gaseous steam

flows past the turbine' spinning blades, steam expands and cools, giving off most of the energy it

contains. This steam spins the blades continuously. The blades thus convert most of the steam's

potential energy into kinetic energy. The turbine is then used to run a generator,

producing electricity.

THE CLASSIFICATIONS OF STEAM TURBINE

1. PRINCIPLE OF OPERATION

A. IMPULSE

The drop in pressure takes place only in the nozzles and not in the moving plates.

This means that the pressure in the outlet sides of the blade is equal to the inlet side.

Fig. 1.A Impulse Turbine

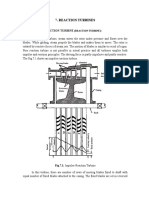

B. REACTION

A reaction turbine is a type of turbine that develops torque by reacting to the

pressure or weight of a fluid. The operation of reaction turbines is described by Newton's

third law of motion.

ANIS, Shon Rick N.

ME-5C March 25, 2019

Classifications of Steam Turbine

Fig 1.B Reaction Turbine

2. DIRECTION OF FLOW

A. Axial

The steam flows along the axis of the shaft. It is the most suitable turbine for

large-turbo generators and that is why it is used in all modern steam power plants.

Fig 2.A Axial Flow Turbine

B. Radial

The steam flows in radial direction. It incorporates two shafts, end-to-end, each

driving a separate generator. The two sets of blading countering each other, in this way a

relative speed is achieved in every blade row is made to work.

ANIS, Shon Rick N.

ME-5C March 25, 2019

Classifications of Steam Turbine

Fig 2.B Radial Flow Turbine

C. Tangential

The steam flows in the tangential direction. This turbine is very robust but not

particularly efficient machine, sometimes used for driving power station auxiliaries. In

this turbine, nozzle directs steam tangentially into buckets milled in the periphery of a

single wheel, and on exit the steam turns through a reversing chamber, reentering bucket

further round the periphery. This process is repeated several times, the steam flowing a

helical path. Several nozzles with reversing chambers may be used around the wheel

periphery.

Fig 2.C Tangential Flow Turbine

ANIS, Shon Rick N.

ME-5C March 25, 2019

Classifications of Steam Turbine

3. MEANS OF HEAT SUPPLY

A. Single Pressure

In this type of turbine, there is single source of steam supply.

B. Mixed Pressure

It uses two sources of steam, at different pressures. The dual pressure turbine is

found in nuclear power stations where it uses both sources continuously.

C. Reheated

its passage through the turbine steam may be taken out to be reheated in a

reheater incorporated in the boiler and returned at higher temperature to be expanded.

This is done to avoid erosion and corrosion problems in the bladings and to improve the

power output and efficiency. The reheating may be single or double or triple.

4. MEANS OF HEAT REJECTION

A. Pass Out / Extraction

A considerable proportion of the steam is extracted from some suitable point in

the turbine where the pressure is sufficient for use in process heating; the remainder

continuing through the turbine. The latter is controlled by separate valve-gear to meet the

difference between the pass-out steam and electrical load requirements. This type of

turbine is suitable where there is dual demand of steam-one for power and the other for

industrial heating, for example sugar industries. Double pass-out turbines are sometimes

used.

Fig 4.A Pass Out / Extraction Turbine

ANIS, Shon Rick N.

ME-5C March 25, 2019

Classifications of Steam Turbine

B. Regenerative

This turbine incorporates a number of extraction branches; through which small

proportions of the steam are continuously extracted for the purpose of heating the boiler

feed water in a feed heater in order to increase the thermal efficiency of the plant. Now

days, all steam power plants are equipped with reheating and regenerative arrangement.

C. Condensing

The exhaust steam is condensed in a condenser and the condensate is used as feed

water in the boiler. By this way the condensing turbine allows the steam to expand to the

lowest possible pressure before being condensed. All steam power plants use this type of

turbine

Fig 4.C Condensing Type Turbine

D. Non-condensing

When the exhaust steam coming out from the turbine is not condensed but

exhausted in the atmosphere is called non- condensing turbine. The exhaust steam is not

recovered for feed water in the boiler.

ANIS, Shon Rick N.

ME-5C March 25, 2019

Classifications of Steam Turbine

Fig 4.D Non-condensing Type Turbine

E. Back Pressure

This type of turbine rejects the steam after expansion to the lowest suitable

possible pressure at which it is used for heating purpose. Thus back pressure turbine

supplies power as well as heat energy. The back pressure turbine generally used in sugar

industries provides low pressure steam for heating apparatus, where as a topping turbine

exhausts into a turbine designed for lower steam conditions.

Fig 4.E Back Pressure Type Turbine

5. NUMBER OF CYLINDER

A. Single

When all stages of turbine are housed in one casing, then it is called single

cylinder. Such a single cylinder turbine uses one shaft.

B. Multi Cylinder

In large output turbine, the number of the stages needed becomes so high that

additional bearings are required to support the shaft. Under these circumstances, multi-

cylinders are used.

ANIS, Shon Rick N.

ME-5C March 25, 2019

Classifications of Steam Turbine

6. ARRANGEMENT OF CYLINDER BASE ON GENERAL FLOW OF STEAM

A. Single

In a single flow turbine the steam enters at one end, flows once through the

bladings in a direction approximately parallel to this axis, emerges at the other end. High

pressure cylinder uses single flow. This is also common in small turbines.

Fig 6.A Single Flow Turbine

B. Double

In this type of turbines, the steam enters at the centre and divides, the two portions

passing axially away from other through separate sets of blading on the same rotor. The

low pressure cylinder normally uses double flow). This type of unit is completely

balanced against the end thrust and gives large area of flow through two sets of bladings.

This also helps in reducing the blade height as mass flow rate becomes half as compared

to single flow for the same conditions.

Fig 6.B Double Flow Turbine

ANIS, Shon Rick N.

ME-5C March 25, 2019

Classifications of Steam Turbine

C. Reversed

Reversed flow arrangement is sometimes used in h.p, cylinder where higher

temperature steam is used on the larger sets in order to minimize differential expansion.

Fig 6.C Reversed Flow Turbine

7. NUMBER OF SHAFT

A. Tandem Compound

Most multi-cylinder turbines drive a single shaft and single generator Such

turbines are termed as tandem compound turbines.

Fig 7.A Tandem Compound Turbine

B. Crossed Compound

In this type, two shafts are used driving separate generator. The may be one of

turbine house arrangement, limited generator size, or a desire to run shafting at half

speed. The latter choice is sometimes preferred so that for the same centrifugal stress,

longer blades may be used, giving a larger leaving area, a smaller velocity and hence a

small leaving loss.

ANIS, Shon Rick N.

ME-5C March 25, 2019

Classifications of Steam Turbine

Fig 7.B Cross Compound Turbine

8. ROTATIONAL SPEED

A. Constant

Requirements of rotational speed are extremely rigid in turbines which are

directly connected to electric generators as these must be a-c unit except in the smallest

sizes and must therefore run at speeds corresponding to the standard number of cycles per

second and governed by the following equation.

N = 120 × Number of cycles per second = 120 f/p Number of poles

The minimum number of poles, in a generator is two and correspondingly the

maximum possible speed for 60 cycle is 3,600 rpm; for 50 c/s of frequency, the speeds

would be 3,000, 1500 and 750 rpm for 2, 4 and 8 poles machines respectively.

B. Variable

These turbines have geared units and may have practically any speed ratio

between the turbine and the driven machine so that the turbine may be designed for its

own most efficient speed. Such turbines are used to drive ships, compressors, blowers

and variable frequency generators.

ANIS, Shon Rick N.

ME-5C March 25, 2019

Classifications of Steam Turbine

References:

http://www.mechanicaltutorial.com/working-principle-of-steam-turbine-classification-or-types-

of-steam-turbine

https://www.slideshare.net/WaqasAbid7/classification-of-steam-turbines-72248076

https://www.researchgate.net/figure/Schematic-diagram-of-a-single-pressure-combined-cycle-

power-plant-1PG-generator_fig1_318654413

http://www.daviddarling.info/encyclopedia/R/AE_reaction_turbine.html

ANIS, Shon Rick N.

ME-5C March 25, 2019

Вам также может понравиться

- Introduction to the simulation of power plants for EBSILON®Professional Version 15От EverandIntroduction to the simulation of power plants for EBSILON®Professional Version 15Оценок пока нет

- Steam TurbinesДокумент27 страницSteam Turbinesm_mukbel8752100% (1)

- E. Steam Power Plant - Pe - ExamДокумент4 страницыE. Steam Power Plant - Pe - ExamallovidОценок пока нет

- Steam Cycles - Lecture 2ndДокумент21 страницаSteam Cycles - Lecture 2ndSaifAdamz's100% (1)

- Performance Test of A Hydraulic Turbine Mid Term 2Документ8 страницPerformance Test of A Hydraulic Turbine Mid Term 2jethro ganeloОценок пока нет

- Steam TurbineДокумент27 страницSteam TurbinePrakashKr100% (1)

- Vapour Cycles GoodДокумент19 страницVapour Cycles GoodParameswararao Billa100% (1)

- Steam NozzlesДокумент24 страницыSteam NozzlesGokulAgОценок пока нет

- Boiler:: Working Principle of A BoilerДокумент22 страницыBoiler:: Working Principle of A BoilerZeshan AbdullahОценок пока нет

- Unit 4 (Reaction Turbines.) 1Документ12 страницUnit 4 (Reaction Turbines.) 1amarparimiОценок пока нет

- Basic Principle of Bourdon Tube Pressure GaugeДокумент3 страницыBasic Principle of Bourdon Tube Pressure GaugeWaseem AnwarОценок пока нет

- ME 188 - Combined Brayton & Rankine CyclesДокумент44 страницыME 188 - Combined Brayton & Rankine CyclesAzherRoiFerrer100% (1)

- Unit-7 - Steam and Gas TurbineДокумент24 страницыUnit-7 - Steam and Gas TurbineKedir Mohammed100% (1)

- Unit 7 GGДокумент24 страницыUnit 7 GGAbhijeeth Nagaraj100% (2)

- Compiled Lab ReportДокумент25 страницCompiled Lab ReportSaAhRaОценок пока нет

- Gas TurbineДокумент14 страницGas Turbineاحمد الربيعي100% (1)

- Steam TurbineДокумент4 страницыSteam TurbineRowin Mark Sabornido100% (1)

- At AssignmentДокумент3 страницыAt AssignmentYogesh PatilОценок пока нет

- Steam Turbine and Condenser Lab Report FullДокумент2 страницыSteam Turbine and Condenser Lab Report FullJoshua Reynolds0% (3)

- The Brayton Cycle With RegenerationДокумент14 страницThe Brayton Cycle With RegenerationMuh Indrawan100% (1)

- Steam TurbineДокумент77 страницSteam TurbineAmit KhadkaОценок пока нет

- ME Con-1 Mock-1Документ15 страницME Con-1 Mock-1vidya chakitwarОценок пока нет

- CH 08Документ28 страницCH 08hirenpatel_universalОценок пока нет

- Steam Turbine PowerpointДокумент25 страницSteam Turbine PowerpointD.P. MishraОценок пока нет

- Experiment No. 2 ME LAB 2Документ1 страницаExperiment No. 2 ME LAB 2Art Angel GingoОценок пока нет

- Elemen Mesin Rem PDFДокумент46 страницElemen Mesin Rem PDFM Fathin NaufalОценок пока нет

- FLR - Performance of A Tubular CondenserДокумент12 страницFLR - Performance of A Tubular CondenserNazario Emil LintagОценок пока нет

- ME LAB 3 ReportДокумент37 страницME LAB 3 ReportwijawijaОценок пока нет

- MitsubishiДокумент10 страницMitsubishiPrabhat Kisku100% (1)

- Assignment 2Документ28 страницAssignment 2ahsan aliОценок пока нет

- T 9109Документ9 страницT 9109Ayush Singh BeruvarОценок пока нет

- CH-10 Boiler PerformanceДокумент27 страницCH-10 Boiler PerformanceRavi ShankarОценок пока нет

- 05 Steam TurbineДокумент11 страниц05 Steam TurbineJohn Paulo ArchinueОценок пока нет

- Actual Vapor Compression Refrigeration Cycle Part 1Документ12 страницActual Vapor Compression Refrigeration Cycle Part 1jjОценок пока нет

- Lecture10 StreamTurbines ReactionTurbineДокумент7 страницLecture10 StreamTurbines ReactionTurbineIjazzzAliОценок пока нет

- Otto Cycle, Fuels, Combustion PDFДокумент39 страницOtto Cycle, Fuels, Combustion PDFAchmad Rizal FirmansyahОценок пока нет

- Hydraulic Turbine IДокумент27 страницHydraulic Turbine IRam Krishna Singh100% (3)

- Centrifugal Pump AnalysisДокумент69 страницCentrifugal Pump AnalysisFA AyОценок пока нет

- Ideal Reheat Rankine Cycle EfficiencySample CalculationДокумент6 страницIdeal Reheat Rankine Cycle EfficiencySample CalculationManHeng Yit100% (3)

- Chapter 11 Refrigeration CyclesДокумент20 страницChapter 11 Refrigeration Cycleskalite123Оценок пока нет

- Refrigeration Paper in IJSER FormatДокумент14 страницRefrigeration Paper in IJSER Formattitto84886Оценок пока нет

- p1 IntroductionДокумент55 страницp1 IntroductionJala GergesОценок пока нет

- Homework SteamДокумент6 страницHomework SteamCherry May Basinang-RamosОценок пока нет

- Gas Turbine Power PlantДокумент11 страницGas Turbine Power PlantCK Godinez100% (1)

- Applied Thermodynamics in DetailДокумент412 страницApplied Thermodynamics in DetailAditya RaoОценок пока нет

- Fdocuments - in Otto Cycle PresentationДокумент97 страницFdocuments - in Otto Cycle PresentationUTSAV KUMARОценок пока нет

- Chemcad SimulationДокумент69 страницChemcad Simulationmei krismahariyantoОценок пока нет

- Impulse and Reaction Turbines My PresentationДокумент13 страницImpulse and Reaction Turbines My Presentationumarmanan100% (1)

- Steam Table in BarsДокумент9 страницSteam Table in BarsZaib RehmanОценок пока нет

- Determination of Dryness FractionДокумент8 страницDetermination of Dryness FractionSln ReddyОценок пока нет

- Working Principle of Steam Jet Refrigeration SystemДокумент3 страницыWorking Principle of Steam Jet Refrigeration SystemKhaled Abd ElraoufОценок пока нет

- Ic Engines Laboratory ManualДокумент35 страницIc Engines Laboratory ManualYuvaraj Yuvi0% (1)

- Study of Steam TurbineДокумент3 страницыStudy of Steam TurbineJohn FredyОценок пока нет

- Basic Cycle BraytonДокумент15 страницBasic Cycle BraytonMarin Andreea100% (1)

- Turbomachanies & ClassificationДокумент7 страницTurbomachanies & ClassificationVinay ChandwaniОценок пока нет

- Piston PumpДокумент7 страницPiston Pumpmohanadymt100% (1)

- A1 4Документ6 страницA1 4Mohit PassiОценок пока нет

- Gas Turbine Power PlantДокумент48 страницGas Turbine Power PlantArif Ahmed100% (1)

- Power Plant Part2Документ80 страницPower Plant Part2مصطفى العبادي100% (2)

- Chapter-1 Steam Turbine TheoryДокумент17 страницChapter-1 Steam Turbine TheorybhaskarОценок пока нет

- ME Lab QuestionsДокумент51 страницаME Lab QuestionsShon Rick AnisОценок пока нет

- IPreportДокумент5 страницIPreportShon Rick AnisОценок пока нет

- IPreportДокумент5 страницIPreportShon Rick AnisОценок пока нет

- Helical GearsДокумент10 страницHelical GearsShon Rick AnisОценок пока нет

- OSH Standards Amended 1989 LatestДокумент338 страницOSH Standards Amended 1989 Latestverkie100% (1)

- Basic Concepts, Principles, and Definitions Basic Concepts, Principles, and DefinitionsДокумент15 страницBasic Concepts, Principles, and Definitions Basic Concepts, Principles, and DefinitionsShon Rick AnisОценок пока нет

- Basic Concepts, Principles, and Definitions Basic Concepts, Principles, and DefinitionsДокумент15 страницBasic Concepts, Principles, and Definitions Basic Concepts, Principles, and DefinitionsShon Rick AnisОценок пока нет

- AWG CatalogДокумент444 страницыAWG CatalogFire NowОценок пока нет

- CGBДокумент2 страницыCGBMauricio Oropeza CabreraОценок пока нет

- The A. Hoen & Co Lithograph BuildingДокумент1 страницаThe A. Hoen & Co Lithograph BuildingFOX45Оценок пока нет

- Affiliated Colleges de 2009-10Документ2 страницыAffiliated Colleges de 2009-10hardikjthakkarОценок пока нет

- BrochureДокумент14 страницBrochureMonika MukherjeeОценок пока нет

- Handout t1124f 1511 3869 Onb Bus Das Srs TNДокумент37 страницHandout t1124f 1511 3869 Onb Bus Das Srs TNlequangthongОценок пока нет

- Ds PVC Bottle Grade k57Документ1 страницаDs PVC Bottle Grade k57Thambik DuraiОценок пока нет

- Lesson Guide in Earth Science I. ObjectivesДокумент4 страницыLesson Guide in Earth Science I. ObjectivesallanrnmanalotoОценок пока нет

- Codici Avaria EMS II D16Документ10 страницCodici Avaria EMS II D16Claudio CarrettiОценок пока нет

- 05-2806a01-L-Mds Inet Series Ref ManДокумент173 страницы05-2806a01-L-Mds Inet Series Ref ManPedro Vives MelendezОценок пока нет

- Crude and Refinery CalculationsДокумент4 страницыCrude and Refinery Calculationsbakhtyar21100% (1)

- Dga 1000 PartsДокумент20 страницDga 1000 Partswaltech2005Оценок пока нет

- Emt 1250Документ7 страницEmt 1250TayiefОценок пока нет

- BCMS Information Note 1-2018 Guidance On Timber Frame WallsДокумент5 страницBCMS Information Note 1-2018 Guidance On Timber Frame WallsLiam MinogueОценок пока нет

- Pieux Design Pile Foundation Following Eurocode 7 - R. Franck + Examples PDFДокумент19 страницPieux Design Pile Foundation Following Eurocode 7 - R. Franck + Examples PDFmichalakis483Оценок пока нет

- Vc1100e PDFДокумент102 страницыVc1100e PDFOscar Pérez NotarioОценок пока нет

- LS3 Maintenance Manual PDFДокумент134 страницыLS3 Maintenance Manual PDFIzhar Dhiya Ul HayyanОценок пока нет

- Will Endeavour Spec GAДокумент2 страницыWill Endeavour Spec GAAstrid MonteroОценок пока нет

- Manual Service CominoxДокумент29 страницManual Service CominoxDorin Ilie100% (1)

- Building Commissioning GuideДокумент22 страницыBuilding Commissioning GuidesolarstuffОценок пока нет

- Book of Abstract - DeMII 2017Документ186 страницBook of Abstract - DeMII 2017GogyОценок пока нет

- 2 - Compressibility of SoilsДокумент34 страницы2 - Compressibility of SoilsKatherine Shayne YeeОценок пока нет

- PNGRB T4SДокумент52 страницыPNGRB T4SC D JOSHIОценок пока нет

- Catalogo APOLLO - Valvulas EsferaДокумент38 страницCatalogo APOLLO - Valvulas EsferaAntonio Jimenez DCОценок пока нет

- Raise Borer EpirocДокумент8 страницRaise Borer EpirocDiego Ignacio VelizОценок пока нет

- Power Ibr Piping BomДокумент43 страницыPower Ibr Piping BomManikandan elumalaiОценок пока нет

- Seles PeedДокумент26 страницSeles PeedBoris Andres Diaz AguilarОценок пока нет

- BMCP-Important QuestionsAnd Answers PDFДокумент19 страницBMCP-Important QuestionsAnd Answers PDFVarshini Patel0% (1)

- Wheel Chair (Spec) (R)Документ1 страницаWheel Chair (Spec) (R)Andri StyaОценок пока нет

- Soundproof DoorДокумент4 страницыSoundproof DoormageshxxxОценок пока нет