Академический Документы

Профессиональный Документы

Культура Документы

low-cost-construction-materials-and-techniques-civil-project-report-Students3k.com.docx

Загружено:

Nitin GuptaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

low-cost-construction-materials-and-techniques-civil-project-report-Students3k.com.docx

Загружено:

Nitin GuptaАвторское право:

Доступные форматы

WWW.STUDENTS3K.COM | WWW.STUDENTS3K.COM | WWW.STUDENTS3K.COM | STUDENTS3K.

COM

Project Report

On

“ALTERNATE AND LOW COST

CONSTRUCTION MATERIALS

AND TECHNIQUES”

BY

WWW.STUDENTS3K.COM | WWW.STUDENTS3K.COM | WWW.STUDENTS3K.COM | STUDENTS3K.COM

SUBMITTED

TO

FOR DIPLOMA IN CIVIL ENGINEERING

SUBMITTED BY: GUIDED BY:

Downloaded from www.students3k.com

INTRODUCTION

The Council for Works and Housing (CWHR) is an R & D organization under the

aegis of the Ministry of Science and Technology. The main function of this council is to promote

scientific research on problems related to different types of civil engineering structures such as

buildings, roads, bridges, dams, harbors, treatment plants etc.

The CWHR has endeavored in R & D work for the development of durable,

economical and innovative materials for the construction industry with focus on the utilization of

local/ indigenous techniques and materials for import substitution of construction inputs.

Downloaded from www.students3k.com

SYNOPSIS

Environment friendly low cost demonstration model houses and rooms constructed by

CWHR.

Ferrocement products developed at CWHR as replacement of RCC, timber etc.

Mechanized pre-cast concrete water course lining units and construction of model channels.

Production of fiber cement sheets as replacement to asbestos cement at CWHR.

Common defects of clay bricks and different brick moulding systems developed at CWHR

for improving the quality of clay bricks.

Some innovative building products developed at CWHR

Some building components used in the construction of low cost housing unit.

Downloaded from www.students3k.com

CONSTRUCTION OF A LOW COST HOUSE USING RICE HUSK

ASHAND LIME AS PARTIAL REPLACEMENT OF CEMENT

For utilization of agro-wastes a house was constructed for the first time, using rice husk

ash and lime as partial replacement of cement in construction.

MATERIALS AND TECHNIQUES

Rice Husk Ash and Lime has been used as cement in the fabrication of hollow, load bearing

blocks and for mortar in plaster.

The roof is prefabricated and consists of battens tiles; here too port land cement has been

replaced by Rice Husk Ash to the extent of 30%.

The foundation and base course are made up with soil stabilized with cement.

The cost of construction was reduced by 37%as compared to cost of construction by conventional

methods.

Downloaded from www.students3k.com

CONSTRUCTION OF A ROOM USING GROUND

GRANULATED BLAST FURNANCE SLAG AS

PARTIAL REPLACEMENT OF CEMENT

For utilization of industrial waste material, a room was constructed, using ground

granulated blast furnace slag, (a waste product of Pakistan Steel Mills,) as partial replacement of

cement in construction.

MATERIALS AND TECHNIQUES

Load bearing walls are made of lime-slag-soil stabilized blocks.

The lime-slag mixture consists of 30% lime and 70% slag. The blocks contain 10% of this

mixture and 90% of soil by weight.

The roof is prefabricated and consists of battens and tiles.

30% Portland Cement has been saved in the tiles by replacing with it with slag.

The mosaic floor constitutes the mixture of slag, lime, cement and marble chips.

The cost of construction was reduced by 25% to 30% as compared to cost of construction

by conventional methods.

Downloaded from www.students3k.com

CONSTRUCTION OF A LOW COST SCHOOL USING SOIL

CEMENT STABILIZED BLOCKS FOR MASONRY WALLS AND

PRE-FABRICATED ROOF WITH SLAG CEMENT

For utilization of industrial wastes, a five room school was constructed using Soil-

Cement Stabilized blocks for masonry walls and pre-fabricated roof using slag as partial

replacement of cement in construction.

MATERIALS AND TECHNIQUES

The foundation and base course of the floor is made of soil cement stabilized material.

The load bearing walls have been constructed using soil cement stabilized blocks.

The roof is constructed with precast batten tiles wherein 30% Portland cement has been

replaced with finely ground granular slag.

Air cooled slag was used in all the roofing elements as coarse aggregate.

The cost of construction was reduced by 43% as compared to cost of construction by

conventional methods.

Downloaded from www.students3k.com

CONSTRUCTION OF LOW COST HOUSING UNIT

A demonstration and experimental low cost housing unit was constructed by utilization

of alternative low cost construction materials and techniques including wastes. The overall saving

of this house is 24% as compared to cost of construction by conventional methods.

MATERIALS AND TECHNIQUES

Masonry walls have been constructed using irregular stone pieces, cast in low grade

concrete to obtain shape of regular block masonry.

Saving in the cost of shuttering has been achieved by using pre-cast U-Shaped Channel

Blocks as lintels. The hollow spaces are filled with concrete with reinforcement bars.

Arches have been constructed by using old truck tyres to save shuttering and labour cost.

Cost of doors, windows, and their frames has been reduced by casting them with

ferrocement.

i. Reinforced burnt clay pot slab tiles,

ii. Reinforced burnt clay brick slab tile,

iii. Precast RCC battens and ferrocement barrel shell planks.

Downloaded from www.students3k.com

SOME BUILDING COMPONENTS USED IN THE

CONSTRUCTION LOW COST HOUSING UNIT

PRE-CAST REINFORCEMENTVBURNT CLAY FERROCEMENT BARREL

BRICK WAFFLE SLAB TILES FOR ROOFING SHELL ROOFING SYSTEM

PRE-CAST CONCRETE STONE U-SHAPED CHANNEL BLOCKS FOR LINTELS

MASONRY BLOCKS

Downloaded from www.students3k.com

A MODEL ROOM BUILT WITH WHEAT STRAW

CONCRETE BLOCK MASONARY WALLS AND

PRECAST BATTEN TILE ROOF

A model room is constructed by using wheat straw concrete block masonry for load

bearing walls with lightweight R.C.C. Tile Batten-Roofing system. This type of construction is

economical and thermally comfortable for rural houses. The construction is simple, low cost and

can be constructed on self help basis.

Mold Release Agents have been developed to provide the very best concrete stamp

release and still allow optimum color retention in decorative concrete. It can be used in

conjunction with Concrete Stamping Store Color Hardener to insure the best combination on the

market today. Concrete Stamping Store Release Agents give a beautiful antique finish to the

surface of stamped concrete. When used alone, it highlights the natural gray concrete with the

defining lines of the concrete stamp. When used together, the color hardener and release agent

create a very pleasing contrast.

Downloaded from www.students3k.com

Вам также может понравиться

- Civil EngineeringProjectДокумент9 страницCivil EngineeringProjectMitendra Singh100% (1)

- Low Cost HousingДокумент9 страницLow Cost HousingAli Fayyaz SiddiqiОценок пока нет

- Experimental Study of Waste Plastic Used in Paying Block: Project Synopsis ONДокумент13 страницExperimental Study of Waste Plastic Used in Paying Block: Project Synopsis ONAwanish PandeyОценок пока нет

- Alternate and Low Cost Construction Materials & Techniques Developed Through R & D Efforts at Council For Works and Housing ResearchДокумент45 страницAlternate and Low Cost Construction Materials & Techniques Developed Through R & D Efforts at Council For Works and Housing ResearchbuilconsОценок пока нет

- Low Cost School Building DesignДокумент29 страницLow Cost School Building DesignDebashishParida0% (1)

- Science and Technology Civil EngineeringДокумент2 страницыScience and Technology Civil Engineeringsri1110Оценок пока нет

- Alternate Techniques and Low Cost Construction Materials: AbstractДокумент1 страницаAlternate Techniques and Low Cost Construction Materials: AbstractJohn AjishОценок пока нет

- Low Cost ConstructionДокумент11 страницLow Cost ConstructionSanjoli JainОценок пока нет

- AbstractДокумент24 страницыAbstractAslam KtОценок пока нет

- Bamboo Crete HouseДокумент2 страницыBamboo Crete HouseChandan Bose100% (1)

- LOW COST BUILDING TECHNIQUES AND MATERIALSДокумент28 страницLOW COST BUILDING TECHNIQUES AND MATERIALSKriti ModiОценок пока нет

- Sustainable Planning & Architecture (Unit - 3)Документ51 страницаSustainable Planning & Architecture (Unit - 3)Minni ImmanuelОценок пока нет

- Alternate Building MaterialsДокумент26 страницAlternate Building Materialsapi-27477209100% (1)

- Interlocking Bricks ReportДокумент13 страницInterlocking Bricks ReportSandeep Sampth RamОценок пока нет

- Low Cost HousingДокумент11 страницLow Cost HousingSano SanojОценок пока нет

- Advanced Construction Techniques and Materials PresentationДокумент59 страницAdvanced Construction Techniques and Materials PresentationVikrant KothariОценок пока нет

- Modern Construction Methods Using Sustainable MaterialsДокумент27 страницModern Construction Methods Using Sustainable MaterialsDevendra SharmaОценок пока нет

- Precast Concrete PanelsДокумент37 страницPrecast Concrete PanelsAniket Chaudhari100% (1)

- RRL - FerrrocksДокумент4 страницыRRL - FerrrocksSimОценок пока нет

- A Seminar Report OnДокумент14 страницA Seminar Report OnDevesh SharmaОценок пока нет

- Autoclaved Aerated Concrete Block Machine Manufacturers - 2k TechnologiesДокумент10 страницAutoclaved Aerated Concrete Block Machine Manufacturers - 2k TechnologiesPriyaОценок пока нет

- Comparative Study About AAC Block With Porotherm BrickДокумент8 страницComparative Study About AAC Block With Porotherm BrickIJRASETPublicationsОценок пока нет

- Comparison of The Classical Method in Wastewater Treatment With New Cutting Edge TechnologyДокумент22 страницыComparison of The Classical Method in Wastewater Treatment With New Cutting Edge TechnologyNicolai CobzariОценок пока нет

- New Construction Materials Types and UsesДокумент17 страницNew Construction Materials Types and UsesRavindra MRОценок пока нет

- BMTPC July15 PDFДокумент62 страницыBMTPC July15 PDFRameshОценок пока нет

- Studying Cement Kiln Dust to Make Cost-Efficient Interlock PaversДокумент11 страницStudying Cement Kiln Dust to Make Cost-Efficient Interlock PaversAnonymous 2FDTST37uОценок пока нет

- Research Paper On BrickДокумент8 страницResearch Paper On Brickfvf2nnj9100% (1)

- Foam Concrete Benefits and UsesДокумент2 страницыFoam Concrete Benefits and UsesKhalid AlameerОценок пока нет

- Precast Concrete and Prefabricated TechnologyДокумент45 страницPrecast Concrete and Prefabricated TechnologyAzrina MadihiОценок пока нет

- AAC Vs CLCДокумент23 страницыAAC Vs CLCsandipgargОценок пока нет

- 2022-V13I12030_AAC BlocksДокумент11 страниц2022-V13I12030_AAC Blockszuber shaikhОценок пока нет

- PE003Документ38 страницPE003Gogireddy Srinivasareddy1346Оценок пока нет

- Low Cost Housing PDFДокумент4 страницыLow Cost Housing PDFHarsh VermaОценок пока нет

- Cost Effective ArchitectureДокумент12 страницCost Effective ArchitectureAaliyaWadhwaОценок пока нет

- Casting Yard and Expansion JointДокумент69 страницCasting Yard and Expansion Jointkaushikreja100% (2)

- Srikanth ReviewДокумент8 страницSrikanth ReviewMallela SrikanthОценок пока нет

- Project Report On Pavers Block ManufacturingДокумент11 страницProject Report On Pavers Block ManufacturingEIRI Board of Consultants and Publishers100% (2)

- Recent Trends in Concrete TechnologyДокумент13 страницRecent Trends in Concrete TechnologyAntony Kishore100% (3)

- Proposal For Ibrahim HyderiДокумент12 страницProposal For Ibrahim HyderisuhailgeniousОценок пока нет

- Eco-Frendly Materials and TechniqesДокумент69 страницEco-Frendly Materials and TechniqesNupur BhadraОценок пока нет

- Low Cost HousesДокумент14 страницLow Cost HousesskyduckОценок пока нет

- Interlocking Block TechnologyДокумент15 страницInterlocking Block TechnologyChaula Trivedi100% (4)

- Module 6 - High Performance Concretes PDFДокумент32 страницыModule 6 - High Performance Concretes PDFabinash choudharyОценок пока нет

- Ar Bricks-21Документ34 страницыAr Bricks-21ManishaChary100% (1)

- Cost Analysis in Low Cost Buildings: Submitted By:-Meenu Nashier Nancy NeerajДокумент32 страницыCost Analysis in Low Cost Buildings: Submitted By:-Meenu Nashier Nancy NeerajAditya VermaОценок пока нет

- WasteДокумент7 страницWasteManishaDhimanОценок пока нет

- Precast Concrete ReportДокумент28 страницPrecast Concrete ReportAchyutam Khajuria50% (2)

- Project Report On Cellular Light Weight ConcreteДокумент21 страницаProject Report On Cellular Light Weight ConcreteVishal Kumar100% (1)

- Fabrication of Mortar Mixer and CHB Filler PumpДокумент15 страницFabrication of Mortar Mixer and CHB Filler PumpRenjo Kim VenusОценок пока нет

- Unit 7 Modern Trends in Construction: StructureДокумент27 страницUnit 7 Modern Trends in Construction: StructureRaj BakhtaniОценок пока нет

- Box Culverts SДокумент0 страницBox Culverts Sjs kalyana ramaОценок пока нет

- Prefabrication Construction MethodsДокумент26 страницPrefabrication Construction MethodsDhananjay GajendraОценок пока нет

- H U D C L .: Ousing and Rban Evelopment Orporation ImitedДокумент16 страницH U D C L .: Ousing and Rban Evelopment Orporation ImitedAkash KarwaОценок пока нет

- CBM Unit1 Part1Документ26 страницCBM Unit1 Part1RajeshОценок пока нет

- Eco-Friendly Construction Materials Gain ImportanceДокумент8 страницEco-Friendly Construction Materials Gain ImportanceManojlovic Vaso100% (1)

- Precast ConcreteДокумент2 страницыPrecast ConcreteShokhieb Showbad CarriebОценок пока нет

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringОт EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringРейтинг: 4 из 5 звезд4/5 (5)

- Concrete Construction for the Home and the FarmОт EverandConcrete Construction for the Home and the FarmОценок пока нет

- How to Build a Simple Three Bedroom Shipping Container HouseОт EverandHow to Build a Simple Three Bedroom Shipping Container HouseРейтинг: 4 из 5 звезд4/5 (2)

- Wight FdbsДокумент3 страницыWight FdbsClarenz BragaОценок пока нет

- Chapter 6 - Durability of Concrete MaterialДокумент32 страницыChapter 6 - Durability of Concrete Materialeyob yohannesОценок пока нет

- TDS - Glenium 51Документ3 страницыTDS - Glenium 51Alexi ALfred H. TagoОценок пока нет

- Building and Design CodesДокумент15 страницBuilding and Design CodesKeangsinh TaingОценок пока нет

- Is 6461 8 1973Документ16 страницIs 6461 8 1973VijayKatariaОценок пока нет

- OPSS 410 Nov12Документ15 страницOPSS 410 Nov12pouyaОценок пока нет

- Specifying and Selecting Coatings April - 2015 SWr3Документ60 страницSpecifying and Selecting Coatings April - 2015 SWr3arun3kumar00_7691821Оценок пока нет

- Bom BoqДокумент4 страницыBom BoqRenzel EstebanОценок пока нет

- Is 459Документ10 страницIs 459AmbrishОценок пока нет

- Analysis of Increasing of Concrete Compression Strength To Concrete'S Age Due To Adding Admixture of Sikament-163Документ6 страницAnalysis of Increasing of Concrete Compression Strength To Concrete'S Age Due To Adding Admixture of Sikament-163Mahnoor asadОценок пока нет

- Mechanical Properties and Durability Performance of Concretes With Limestone Calcined Clay Cement (LC3) PDFДокумент16 страницMechanical Properties and Durability Performance of Concretes With Limestone Calcined Clay Cement (LC3) PDFCheruku Manohar0% (1)

- WTC 2020 - Full Paper 4 (REM Lining) - 414 - FinalДокумент8 страницWTC 2020 - Full Paper 4 (REM Lining) - 414 - FinalMehdi BakhshiОценок пока нет

- Concrete CubesДокумент5 страницConcrete CubesDipti Ranjan Swain100% (1)

- PDH Post Tensioned Concrete Design PDFДокумент8 страницPDH Post Tensioned Concrete Design PDFabdulmananОценок пока нет

- Manual of Cement Testing: For Safety PrecautionsДокумент18 страницManual of Cement Testing: For Safety PrecautionsDIAZCORDOBAОценок пока нет

- Method StatementДокумент5 страницMethod StatementMalith De SilvaОценок пока нет

- Khodaie Et Al-ACI Spring 2016Документ13 страницKhodaie Et Al-ACI Spring 2016erosОценок пока нет

- 4) Work Method Statement Upper Floor Beam & SlabДокумент2 страницы4) Work Method Statement Upper Floor Beam & Slabhks1209Оценок пока нет

- Is 2250 1981 PDFДокумент36 страницIs 2250 1981 PDFChockalingamОценок пока нет

- Isorod Guide SpecДокумент8 страницIsorod Guide SpecmarkicivanОценок пока нет

- Internship Report FormatДокумент19 страницInternship Report FormatGeo Mapl Infra67% (3)

- MScCE AY20182019 PDFДокумент3 страницыMScCE AY20182019 PDFYuki GitaraОценок пока нет

- Mesh Specific22354Документ19 страницMesh Specific22354hansenОценок пока нет

- Bison Guide HCFДокумент68 страницBison Guide HCFjohnsmith1980Оценок пока нет

- Experimental Study On Partial Replacement of Cement in Concrete by Incineration Ash of Municipal SolidДокумент4 страницыExperimental Study On Partial Replacement of Cement in Concrete by Incineration Ash of Municipal SolidInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- 11 2Документ4 страницы11 2Logadhasan SuwedanОценок пока нет

- Fosroc Cemtop 400SD: Constructive SolutionsДокумент4 страницыFosroc Cemtop 400SD: Constructive SolutionsVincent JavateОценок пока нет

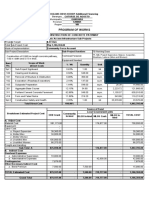

- Program of Works - PathwayДокумент43 страницыProgram of Works - PathwayJonnel CatadmanОценок пока нет

- CAPE BMED Option B Bdraw 2019 U2 P2Документ10 страницCAPE BMED Option B Bdraw 2019 U2 P2Solomon ThomasОценок пока нет

- A Review On Seismic Behavior of Ultra-High Performance Concrete MembersДокумент16 страницA Review On Seismic Behavior of Ultra-High Performance Concrete Membersdragon HОценок пока нет