Академический Документы

Профессиональный Документы

Культура Документы

Handbook of Reliability Prediction Procedures For Mechanical Equipment 15 May 2011 PP 235

Загружено:

kalam2k2Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Handbook of Reliability Prediction Procedures For Mechanical Equipment 15 May 2011 PP 235

Загружено:

kalam2k2Авторское право:

Доступные форматы

SEALING SENSE

Pressurized Seal System

What are the best practices for ensuring the reliability of API Piping Plan 53B?

By FSA member Mark Savage

W hen set up correctly, a Plan 53B pressurized seal

system has the ability to reliably deliver pressurized

barrier fluid to the mechanical seal, dissipate the heat load

• Method of pressurizing the barrier fluid—Unlike

Plan 53A, which uses an external pressure source

to pressurize the fluid in a pressure vessel, Plan 53B

absorbed into the barrier fluid from the mechanical seal generates pressure by pumping barrier fluid into

and provide an early indication of deterioration in the seal’s a hydraulic accumulator, where it squeezes a gas-

performance. charged rubber bladder. The advantage of this plan is

Plan 53B differs from Plan 53A in two main areas: that the pressurized gas is separated from the barrier

• Barrier fluid circulating loop—All the barrier fluid fluid by the rubber bladder, eliminating issues with

stored in a Plan 53A system flows through the solubility of gas into the barrier fluid. No external

mechanical seal barrier fluid cavity. However, in a utilities are required to maintain the pressure.

Plan 53B, only a portion of the total barrier fluid

volume flows through the barrier cavity. The remain- The pressure generated by the accumulator is determined

der is stored in the accumulator, ready to enter the by the initial pressure (pre-charge) of the gas-charged

circulation loop and replace any fluid lost through rubber bladder. As barrier fluid is pumped into the accu-

leakage that normally occurs with mechanical seals. mulator, the pressure increases from the initial precharge

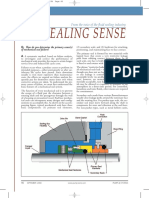

Stored Reservoir Stored

Barrier Fluid Bladder

Barrier Fluid

Volume Accumulator

Volume

Heat

Circulating Exchanger Circulating

Loop Loop Heat

Exchanger

Mecha nical Mecha nical

S eal S eal

Barrier fluid circulating

through mechanical seal

Barrier fluid separate from

circulating loop

Figure 1. Plan 53A (right) and 53B (left)

52 February 2013 www.pump-zone.com Pumps & Systems

pressure. Any temperature changes to the gas stored in the and a reasonable range in barrier pressure as the working

accumulator caused by variations in ambient temperatures volume is consumed.

can cause changes in the pressure. The pressure at any point This pressure variation is determined by the ratio of liquid

can be described by the combined gas law: to gas in the accumulator. The lower the ratio of liquid to gas,

the smaller the pressure variation and the more reliably the

P1 • V1 P2 • V2

= mechanical seal will perform. Typically, 15 to 25 percent of

T1 T2

the accumulator total volume is barrier fluid. Consideration

Where: must also be given to the compatibility of the bladder mate-

P = Pressure (in absolute pressure units of measure) rial with the selected barrier fluid.

T = Temperature (in Kelvin or Rankin)

V = Volume of gas in the accumulator bladder Heat Exchanger

(liquid volume = total accumulator volume less gas One of the main advantages of Plan 53B is the flexibility

volume) offered in choosing the heat exchanger style and capacity.

Subscript 1 represents the conditions when the bladder was The heat exchanger is no longer confined within the space of

pre-charged. a vessel as in traditional Plan 53A systems. This allows heat

Subscript 2 represents the conditions being evaluated. exchangers of larger cooling capacity to be selected, making

Plan 53B well suited to higher temperature applications.

Accumulator Selection When matching the heat exchanger cooling capacity to

The accumulator size is selected to provide sufficient barrier the heat load placed on the barrier fluid, consider the effect

fluid working volume (the volume of barrier fluid con- of increases in the resistance to barrier fluid flow com-

sumed by normal leakage over a period of time, typically monly associated with larger heat exchangers. Undersized

one month) together with a small safety reserve volume heat exchangers will result in excessively high barrier fluid

Peak performance

from the market

leader

Our Pump • Higher productivity,

Systems Do lower cost of ownership

What Other’s Can’t • Scalability from 0.7 GPM

to 317 GPM flow

Maag gear pumps are engineered for some of the • Robust and compact

most demanding conditions to which a pump can be direct-coupled design

subjected:

s� pressures to 5,075 psi APEX , the

TM

s� temperatures to 600 °F revolutionary

s� viscosities to 4,000,000 cP hose pump

Clearances in four different pump areas are chosen

for the particular application. Pumps can also be sup-

plied stand-alone. Call to learn more.

Maag Automatik Inc.

Charlotte, NC wmpg.com/apex

MaagAmericas@maag.com

704-716-9000 800-282-8823

circle 137 on card or go to psfreeinfo.com circle 139 on card or go to psfreeinfo.com

PUMPS & SYSTEMS www.pump-zone.com February 2013 53

SEALING SENSE

temperature, which rapidly decreases mechanical seal to and a short distance above the mechanical seal’s centerline

reliability. (without obscuring access for pump maintenance). Tube or

piping connecting the mechanical seal to the heat exchanger

Barrier Fluid Flow Rate should be selected to produce minimal resistance to barrier

The barrier fluid flow produced by the mechanical seal flow. Large diameter bores, smooth radius bends, short dis-

pumping ring needs to be sufficient to enable the transfer tances and minimal ancillary equipment added into the cir-

of the heat absorbed into the barrier fluid—mostly seal fric- culating loop all help lower the resistance to barrier fluid flow.

tional heat generation and heat soak from the pump—to The accumulator can be mounted a substantial distance

the heat exchanger. An insufficient flow rate will result in from the barrier fluid circulating loop without any impact

large differential temperatures between the barrier fluid in on the system’s performance. Many installations will mount

and out connections at the mechanical seal and an increase the heat exchanger and accumulator together on the same

in the overall temperature of the barrier fluid. stand, provided it does not detrimentally impact the posi-

Excessively high barrier fluid temperatures result in a tioning of the heat exchanger relative to the mechanical seal.

number of problems that can affect the performance and reli- A shade hood or insulation should be fitted to the accu-

ability of the mechanical seal. Pumps with shaft speeds below mulator for installations in which large variations in ambi-

1,800 rpm need a more thorough assessment of the barrier ent temperatures occur. Changing the accumulator’s color

flow rate due to the decreased performance of pumping rings to white or silver should also be considered. Excessive tem-

at lower speeds. perature variations can impact the maximum barrier pres-

sure and minimum barrier pressure margin above the seal

Installation chamber pressure. Such variations can also reduce the effec-

The position of the heat exchanger relative to the mechani- tive barrier fluid working volume when the refill alarm is

cal seal is important. It should be located as close as possible activated.

Fluid Sealing Association

The following members of the

Pump Swap

Mechanical Seal Division sponsored this

“Sealing Sense”:

Advanced Sealing International (ASI)

Ashbridge & Roseburgh Inc.

Install a brand new Vogelsang Rotary A.W. Chesterton Co.

Lobe Pump for the cost of rebuilding Daikin America, Inc.

your Progressing Cavity Pump. EagleBurgmann Mechanical Seals

Plus, our Rotary Lobe Pumps are easy to Flex-A-Seal, Inc.

maintain and can be rebuilt in an hour. Flowserve, Flow Solutions Group

Get a brand new pump while reducing Garlock Sealing Technologies

your maintenance budget! Hydro-Ergoseal, Inc.

You can even typically use your current Industrias Vago de Mexico SA de CV

baseplate, motor and coupling. John Crane

Latty International S.A.

Metallized Carbon Corp.

Morgan AM&T

Nippon Pillar Corp. of America

Scenic Precise Element Inc.

SEPCO - Sealing Equipment Products Co.

ENGINEERED TO WORK

SGL Technic Polycarbon Division

SLUDGE PUMPING SLUDGE GRINDING SLUDGE LYSING

(800) 984-9400 | vogelsangusa.com | sales@vogelsangusa.com Turmond SpA

circle 133 on card or go to psfreeinfo.com

54 February 2013 www.pump-zone.com Pumps & Systems

Commissioning the barrier system, such as inspecting or replacing the accu-

Filling the system with clean, fresh barrier fluid and remov- mulator’s bladder.

ing all air from the system is critical to ensuring a success-

ful startup. Vent valves must be positioned so that all high Conclusion

points within the system can be effectively vented. Many Plan 53B pressurized seal systems offer a safe and reliable

installations require multiple vent valves to be installed to solution for a wide range of applications exceeding the

ensure that all air can be removed from the system. The bar- scope of traditional Plan 53A systems. The correct sizing

rier fluid should be added into the system from the lowest of the accumulator, the heat exchanger and the barrier fluid

point in the circulating loop to promote venting. When flow rate together with best installation and operational

possible, the shaft should be rotated by hand to assist with practices are the keys to years of reliable performance from a

purging the mechanical seal barrier cavity of air. Bleed all Plan 53B system. P&S

instrument block and bleed valves. Bleed the vent connec-

tion in the accumulator fluid port to ensure that no air is Next Month:

trapped in the accumulator. Never pressurize the pump What are grooved metal gaskets, and where are

casing until the barrier system is completely purged of air they applied?

and at operating pressure.

We invite your suggestions for article topics as well as questions

Ongoing Maintenance on sealing issues so we can better respond to the needs of the

Periodically replenishing the barrier fluid is required to industry. Please direct your

replace fluid that is consumed because of normal leakage. suggestions and questions to

Fresh, clean barrier fluid is added to the system by pumping sealingsensequestions@

fluid into the accumulator. This is typically accomplished fluidsealing.com.

with a mobile trolley fitted with a res-

ervoir and a hand/pneumatic pump.

Another option is a dedicated reser-

voir and pump mounted adjacent to

the accumulator.

When using oil as a barrier fluid,

moisture is a potential source of con-

tamination. This can occur when

moisture enters the reservoir through

the breather/vent as a result of expo-

sure to the weather or air exchange as

the vapor space expands and contracts

between day and night. A coalescing

breather can help solve these issues.

The accumulator shell is a pressure

vessel. Therefore, it requires periodic

inspection as specified by the owner

or by regulatory requirements. The

accumulator bladder is an elastomeric

component and should be replaced

periodically as recommended by the

bladder manufacturer.

The pump casing must be depressur-

ized prior to any maintenance activi-

ties that require depressurization of

circle 132 on card or go to psfreeinfo.com

PUMPS & SYSTEMS www.pump-zone.com February 2013 55

Вам также может понравиться

- 53C - FsaДокумент5 страниц53C - FsaSulaiman Kadher KОценок пока нет

- Api 23Документ3 страницыApi 23sapu11jagat5855Оценок пока нет

- Mar14 PDFДокумент2 страницыMar14 PDFsudhindra_tiwariОценок пока нет

- Sealing Sense: Where Mechanical Seals Meet Pumps: What Is The Next Generation?Документ3 страницыSealing Sense: Where Mechanical Seals Meet Pumps: What Is The Next Generation?madairkifОценок пока нет

- Module 04.4 - Seal ArrangementsДокумент15 страницModule 04.4 - Seal ArrangementsMostafaОценок пока нет

- Flowserve Pump Gas SealsДокумент37 страницFlowserve Pump Gas Sealsmujeebmehar50% (2)

- Mech Seal System Difference 53 A B CДокумент3 страницыMech Seal System Difference 53 A B CAmol Patki100% (1)

- L Uk SugarДокумент16 страницL Uk SugarnarupvОценок пока нет

- Explosive DecompressionДокумент11 страницExplosive DecompressionAndrey EkkertОценок пока нет

- John CraneДокумент16 страницJohn CraneMenta Basita Bangun100% (1)

- TF Seal SelectionДокумент42 страницыTF Seal SelectionPete PompesОценок пока нет

- Mechanical Seals According To StandardsДокумент6 страницMechanical Seals According To StandardsSunit MishraОценок пока нет

- Mechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocusДокумент21 страницаMechanical Seal and Support System Considerations For Negative Temperature Hydrocarbon Services: NGL Processing and Ethylene Production FocuspratapОценок пока нет

- Root Cause On Seal Failure RefineryДокумент8 страницRoot Cause On Seal Failure RefineryVaibhav SinghОценок пока нет

- 7secrets Pump RelyДокумент2 страницы7secrets Pump RelyRichard S. BabanОценок пока нет

- Pitfalls of Pump PipingДокумент3 страницыPitfalls of Pump PipingChris PeramunugamaОценок пока нет

- Solving API Seal Flush 11Документ7 страницSolving API Seal Flush 11Linh ThùyОценок пока нет

- ISOMAG - Pump - Zone - Reprint-Bearing Protection DevicesДокумент5 страницISOMAG - Pump - Zone - Reprint-Bearing Protection DevicesChandra SimanjuntakОценок пока нет

- Sealing Extreme Cold Application - FSAДокумент3 страницыSealing Extreme Cold Application - FSASulaiman Kadher KОценок пока нет

- Eagle Report 4Документ34 страницыEagle Report 4Priya Pawar100% (1)

- Api 23 02Документ4 страницыApi 23 02montsegranОценок пока нет

- Improving Mechanical Seal ReliabilityДокумент4 страницыImproving Mechanical Seal ReliabilityBala MuruganОценок пока нет

- Why Mech Seal FailДокумент5 страницWhy Mech Seal FailMunam AhmedОценок пока нет

- Mechanical Seals Reliability TQ-PJNДокумент6 страницMechanical Seals Reliability TQ-PJNPete PompesОценок пока нет

- Fitting InstructionДокумент6 страницFitting InstructionAan Sarkasi AmdОценок пока нет

- Diamondfaces The New Dimension in Mechanical Seal TechnologyДокумент20 страницDiamondfaces The New Dimension in Mechanical Seal TechnologyadamОценок пока нет

- What Determines Seal Leakage?Документ3 страницыWhat Determines Seal Leakage?Pradeep MotaparthyОценок пока нет

- Calculating Stuffing Box PressuresДокумент2 страницыCalculating Stuffing Box PressuresSuresh Kumar MittapalliОценок пока нет

- Overview of ElastomersДокумент2 страницыOverview of ElastomersRuilin TanОценок пока нет

- Burgmann Quick Guide To Identifying Mechanical Seal FailuresДокумент1 страницаBurgmann Quick Guide To Identifying Mechanical Seal FailuresakabbaraОценок пока нет

- Schroedahl ArvДокумент19 страницSchroedahl ArvfadzilharmanОценок пока нет

- MECO HB Leaflet ENG PDFДокумент4 страницыMECO HB Leaflet ENG PDFdilgo02Оценок пока нет

- Double Mechanical Seal For PumpsДокумент7 страницDouble Mechanical Seal For PumpsNikeshОценок пока нет

- Royal Purple BarrierДокумент14 страницRoyal Purple BarrierAnonymous H3I29yjОценок пока нет

- Pump SealsДокумент10 страницPump Sealspaul_brightОценок пока нет

- Pressurized Mech Seals Piping PlansДокумент9 страницPressurized Mech Seals Piping PlanssachinumaryeОценок пока нет

- KTR Magnetic Coupling CatalogДокумент10 страницKTR Magnetic Coupling CatalogHyungTae JangОценок пока нет

- Double Mechanical Seals, Tandem ArrangementДокумент10 страницDouble Mechanical Seals, Tandem ArrangementViwek MertiyaОценок пока нет

- SUBJECT: A Quick Reference Guide For Mechanical Seal Failure 4-11Документ5 страницSUBJECT: A Quick Reference Guide For Mechanical Seal Failure 4-11Liz Lynn LimОценок пока нет

- FSD101eng FSG Seals Catalog A4Документ64 страницыFSD101eng FSG Seals Catalog A4ASHOKОценок пока нет

- Mechanical SealsДокумент2 страницыMechanical Sealscuraaj100% (1)

- L Uk General Product RangeДокумент20 страницL Uk General Product RangesanjeevvangeОценок пока нет

- How To Determine Primary Cause of Mechanical Seal FailureДокумент2 страницыHow To Determine Primary Cause of Mechanical Seal Failurerizki akhadiОценок пока нет

- S 28AT XP EXP EngДокумент6 страницS 28AT XP EXP EngpramodtryОценок пока нет

- Safe MaticДокумент4 страницыSafe Maticsulai2000Оценок пока нет

- Velan Pressure Seal Valve CatalogДокумент4 страницыVelan Pressure Seal Valve CatalogulfatОценок пока нет

- 4 Ways To Prevent Seal FailureДокумент5 страниц4 Ways To Prevent Seal FailureGlobe Star Engineers Pvt LtdОценок пока нет

- Troubleshooting of Mechanical Seals PDFДокумент5 страницTroubleshooting of Mechanical Seals PDFNasser KhattabОценок пока нет

- Dry Gas Seal System StandarДокумент8 страницDry Gas Seal System StandarRonny AjaОценок пока нет

- Gas SealsДокумент38 страницGas SealskbogeshwaranОценок пока нет

- Flowserve Pusher Seal ManualДокумент16 страницFlowserve Pusher Seal ManualNikhil Princeton AndradeОценок пока нет

- Bomba CPKДокумент20 страницBomba CPKPatricio Andres Silva SanzanaОценок пока нет

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreОт EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreОценок пока нет

- Catalog C-1 AccumulatorsДокумент12 страницCatalog C-1 AccumulatorsTrg SiltarОценок пока нет

- Consolidated Piloting Boiler Start-Pp at Lightspeed 2019 Article (English)Документ2 страницыConsolidated Piloting Boiler Start-Pp at Lightspeed 2019 Article (English)mohdfirdausОценок пока нет

- 608 - VLB Steam Conditioning ValveДокумент4 страницы608 - VLB Steam Conditioning Valvebk1202 sk100% (1)

- C&I Part of SCДокумент28 страницC&I Part of SCLakshmi Narayan100% (1)

- Flyer-Heliflow Pump Seal CoolerДокумент2 страницыFlyer-Heliflow Pump Seal Coolerumesh shelkeОценок пока нет

- BFS Power Plant ValvesДокумент24 страницыBFS Power Plant ValvesAnonymous lmCR3SkPrKОценок пока нет

- PRR Engineering, DataДокумент4 страницыPRR Engineering, DataMauricio CamposОценок пока нет

- Technical WritingДокумент37 страницTechnical Writingkalam2k2Оценок пока нет

- Catalog FPJ Kinsburry PDFДокумент10 страницCatalog FPJ Kinsburry PDFkalam2k2Оценок пока нет

- Handbook of Reliability Prediction Procedures For Mechanical Equipment 15 May 2011 PP 235 PDFДокумент1 страницаHandbook of Reliability Prediction Procedures For Mechanical Equipment 15 May 2011 PP 235 PDFkalam2k2Оценок пока нет

- Basic SPC Training For SupplierДокумент44 страницыBasic SPC Training For Supplierkalam2k2Оценок пока нет

- Bently NevadaДокумент2 страницыBently Nevadakalam2k2Оценок пока нет

- MaterialsДокумент1 страницаMaterialskalam2k2Оценок пока нет

- Using Rod Drop Monitor To Prevent Cyliner and Piston Rod RepairДокумент2 страницыUsing Rod Drop Monitor To Prevent Cyliner and Piston Rod Repairkalam2k2Оценок пока нет

- Kingsbury BearingДокумент28 страницKingsbury Bearingkalam2k2100% (1)

- Vibration Analysis Rotating EquipmentДокумент161 страницаVibration Analysis Rotating Equipmentronfrend100% (17)

- Technical Schedule World BankДокумент249 страницTechnical Schedule World BankPramod ShastryОценок пока нет

- LTE Radio Network Design Guideline (FDD)Документ33 страницыLTE Radio Network Design Guideline (FDD)Tri Frida NingrumОценок пока нет

- Tugas-MPSI-P1-P14 - Kelompok 2 - 19.4A.04Документ29 страницTugas-MPSI-P1-P14 - Kelompok 2 - 19.4A.04gilang putraОценок пока нет

- Rhea Huddleston For Supervisor - 17467 - DR2Документ1 страницаRhea Huddleston For Supervisor - 17467 - DR2Zach EdwardsОценок пока нет

- System Error Codes (0-499)Документ33 страницыSystem Error Codes (0-499)enayuОценок пока нет

- BPV ApproachДокумент13 страницBPV ApproachfwfsdОценок пока нет

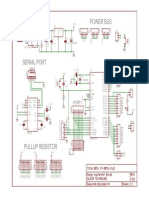

- 8051 Development Board Circuit DiagramДокумент1 страница8051 Development Board Circuit DiagramRohan DharmadhikariОценок пока нет

- VLLAR2019Документ81 страницаVLLAR2019Christian MallorcaОценок пока нет

- Writing White PapersДокумент194 страницыWriting White PapersPrasannaYalamanchili80% (5)

- Assignment On Industrial Relation of BDДокумент12 страницAssignment On Industrial Relation of BDKh Fahad Koushik50% (6)

- Lynette Hawkins, BMG Awesome InsightДокумент2 страницыLynette Hawkins, BMG Awesome Insightawesomei100% (1)

- 02 - STD - Bimetal Overload Relay - (2.07 - 2.08)Документ2 страницы02 - STD - Bimetal Overload Relay - (2.07 - 2.08)ThilinaОценок пока нет

- Vbulletin 5 Connect: Quick Start Guide (Ver 1.0)Документ21 страницаVbulletin 5 Connect: Quick Start Guide (Ver 1.0)dantevasquezОценок пока нет

- Ge Washing Machine ManualДокумент52 страницыGe Washing Machine Manuallillith1723Оценок пока нет

- BeechДокумент1 страницаBeechperovojОценок пока нет

- Chapter 9 CompensationДокумент24 страницыChapter 9 CompensationSophie CheungОценок пока нет

- Reemployment Assistance Application EngДокумент6 страницReemployment Assistance Application EngMelissa RatliffОценок пока нет

- Taxicab Operators V BOTДокумент2 страницыTaxicab Operators V BOTHazel P.Оценок пока нет

- RMU With Eco-Efficient Gas Mixture-Evaluation After Three Years of Field ExperienceДокумент5 страницRMU With Eco-Efficient Gas Mixture-Evaluation After Three Years of Field ExperienceZineddine BENOUADAHОценок пока нет

- Lust V Animal Logic MSJ OppositionДокумент34 страницыLust V Animal Logic MSJ OppositionTHROnlineОценок пока нет

- Principles of Care-Nursing For Children: Principle DescriptionДокумент3 страницыPrinciples of Care-Nursing For Children: Principle DescriptionSanthosh.S.UОценок пока нет

- The Study of Challenges Faced by Paper IndustryДокумент92 страницыThe Study of Challenges Faced by Paper IndustryPrachi 21Оценок пока нет

- 1.3.2 SIC/XE Machine Architecture: 1 Megabytes (1024 KB) in Memory 3 Additional Registers, 24 Bits in LengthДокумент8 страниц1.3.2 SIC/XE Machine Architecture: 1 Megabytes (1024 KB) in Memory 3 Additional Registers, 24 Bits in LengthSENTHILKUMAR PОценок пока нет

- EC1002 Commentary 2022Документ32 страницыEC1002 Commentary 2022Xxx V1TaLОценок пока нет

- Auto Setting DataДокумент6 страницAuto Setting Datahalo91Оценок пока нет

- SDS enДокумент6 страницSDS enAnup BajracharyaОценок пока нет

- Product Sold by APPLE AustraliaДокумент1 страницаProduct Sold by APPLE AustraliaImran KhanОценок пока нет

- LTE ID RNP StandardizationДокумент9 страницLTE ID RNP Standardizationahdanizar100% (1)

- HSTE User GuideДокумент26 страницHSTE User GuideAnca ToleaОценок пока нет

- Bp344 RampДокумент29 страницBp344 RampmaeОценок пока нет