Академический Документы

Профессиональный Документы

Культура Документы

Torsional Analysis of Steel Members (American Institute of Steel Construction, 1983)

Загружено:

Raul Mendoza SubiaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Torsional Analysis of Steel Members (American Institute of Steel Construction, 1983)

Загружено:

Raul Mendoza SubiaАвторское право:

Доступные форматы

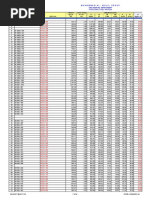

TORSION PROPERTIES 1 - 145

TORSION PROPERTIES

Torsional analysis is not required for the routine design of most structural steel members.

When torsional analysis is required, the Table of Torsion Properties will be of assistance

in utilizing current analysis methods. The reader is referred to the AISC publication

Torsional Analysis of Steel Members (American Institute of Steel Construction, 1983) for

additional information and appropriate design aids.

Torsion Properties are also required to determine the design compressive strength for

torsional and flexural-torsional buckling as specified in the AISC LRFD Specification

Appendix E3.

Nomenclature

Cw = warping constant for section, in.6*

E = modulus of elasticity of steel (29,000 ksi)

G = shear modulus of elasticity of steel (11,200 ksi)

H = flexural constant in Equation E3-1, LRFD Specification

J = torsional constant for a section, in.4

Qf = statical moment for a point in the flange directly above the vertical edge of the

web, in.3

3

_Qw = statical moment at mid-depth of the section, in.

ro = polar radius of gyration about the shear center, in.

Sw = warping statical moment at a point in the section, in.4

Wno = normalized warping function at a point at the flange edge, in.2

*Calculated values of Cw are given for all tabulated shapes. However, for many angles and T shapes, Cw is so small that for

practical purposes it can be taken as zero.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 146 DIMENSIONS AND PROPERTIES

TORSION PROPERTIES

W shapes

Normalized Warping Statical

Torsional Warping Warping Statical Moment

Constant Constant √

EC

w

GJ

Constant Moment

J Cw Wno Sw Qf Qw

4 6 2 4 3

Designation in. in. in. in. in. in. in.3

W44×335 74.4 536000 137 168 1190 282 811

W ×290 51.5 463000 153 166 1040 251 709

W ×262 37.7 406000 167 165 922 225 636

W ×230 24.9 346000 190 164 789 194 551

W40×593 451 989000 75.4 166 2240 484 1380

W ×503 186 649000 95.1 158 1540 354 992

W ×431 142 577000 103 156 1380 323 894

W ×372 109 511000 110 154 1240 294 813

W ×321 79.4 446000 121 152 1100 264 730

W ×297 61.2 397000 130 151 986 240 665

W ×277 51.1 378000 138 151 940 230 624

W ×249 37.7 333000 151 149 836 208 560

W ×215 24.4 283000 173 149 714 179 481

W ×199 18.1 245000 187 148 621 157 434

W ×174 11.2 189000 209 147 481 119 364

W40×466 277 393000 60.6 125 1160 322 1030

W ×392 172 306000 67.9 121 940 272 856

W ×331 106 242000 76.8 118 762 228 715

W ×278 64.7 192000 87.6 115 622 192 596

W ×264 56.1 181000 91.3 114 589 184 566

W ×235 41.3 161000 101 113 530 168 506

W ×211 30.4 140000 109 112 468 151 453

W ×183 19.6 119000 125 111 402 134 391

W ×167 14.0 99300 136 111 336 113 346

W ×149 9.60 79600 147 110 270 92.0 299

W36×848 1270 1620000 57.5 172 3530 674 1910

W ×798 1070 1480000 59.8 169 3270 634 1790

W ×650 600 1090000 68.6 162 2520 513 1420

W ×527 330 816000 80.0 156 1960 415 1130

W ×439 195 637000 92.0 152 1570 344 928

W ×393 143 554000 100 150 1390 309 830

W ×359 109 493000 108 148 1240 281 757

W ×328 84.5 441000 116 146 1130 258 691

W ×300 64.2 398000 127 146 1020 235 628

W ×280 52.6 366000 134 145 944 219 585

W ×260 41.5 330000 143 144 858 200 538

W ×245 34.6 306000 151 143 799 187 505

W ×230 28.6 282000 160 143 740 175 472

W36×256 53.3 168000 90.3 109 576 176 520

W ×232 39.8 148000 98.1 108 512 159 468

W ×210 28.0 128000 109 108 446 138 416

W ×194 22.2 116000 116 107 407 128 383

W ×182 18.4 107000 123 106 378 120 359

W ×170 15.1 98500 130 105 349 111 334

W ×160 12.4 90200 137 105 321 103 312

W ×150 10.1 82200 145 105 294 95.1 291

W ×135 6.99 68100 159 104 245 79.9 255

W33×354 115 408000 95.8 135 1130 263 709

W ×318 84.4 357000 105 133 1000 237 634

W ×291 65.0 319000 113 132 906 216 577

W ×263 48.5 281000 122 130 808 195 519

W ×241 35.8 250000 134 130 721 174 469

W ×221 27.5 224000 145 129 650 158 428

W ×201 20.5 198000 158 128 580 142 386

W33×169 17.7 82400 110 93.7 329 109 314

W ×152 12.4 71700 122 93.8 286 95.1 279

W ×141 9.70 64400 131 93.3 258 86.5 257

W ×130 7.37 56600 141 92.8 228 76.9 233

W ×118 5.30 48300 154 92.2 196 66.6 207

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 147

TORSION PROPERTIES

W shapes

Normalized Warping Statical

Torsional Warping Warping Statical Moment

Constant Constant √

EC

w

GJ

Constant Moment

J Cw Wno Sw Qf Qw

4 6 2 4 3

Designation in. in. in. in. in. in. in.3

W30×477 307 480000 63.6 124 1450 329 896

W ×391 174 364000 73.6 120 1140 268 716

W ×326 103 286000 84.8 117 919 223 595

W ×292 74.9 249000 92.8 115 812 200 530

W ×261 53.8 215000 102 114 710 177 470

W ×235 40.0 190000 111 112 633 160 422

W ×211 27.9 166000 124 112 556 141 374

W ×191 20.6 146000 135 111 494 126 337

W ×173 15.3 129000 148 110 439 113 303

W30×148 14.6 49400 93.6 77.3 239 86.8 250

W ×132 9.72 42100 106 77.3 204 74.0 219

W ×124 7.99 38600 112 76.9 188 68.8 204

W ×116 6.43 34900 119 76.5 171 62.8 189

W ×108 4.99 30900 127 76.1 152 56.1 173

W ×99 3.77 26800 136 75.7 133 49.5 156

W ×90 2.92 24000 146 75.0 119 45.0 142

W27×539 499 440000 47.8 111 1490 342 940

W ×448 297 336000 54.1 106 1190 283 766

W ×368 169 254000 62.4 102 930 231 620

W ×307 101 199000 71.4 99.4 750 192 511

W ×258 61.0 159000 82.2 98.2 613 161 424

W ×235 46.3 140000 88.5 96.0 548 146 384

W ×217 37.0 128000 94.6 95.0 503 135 354

W ×194 26.5 111000 104 93.9 442 120 314

W ×178 19.5 98300 114 93.7 393 107 284

W ×161 14.7 87300 124 92.9 352 96.6 256

W ×146 10.9 77200 135 92.2 314 87.0 231

W27×129 11.2 32500 86.7 66.4 183 69.5 197

W ×114 7.33 27600 98.7 66.4 155 59.2 171

W ×102 5.29 24000 108 65.7 137 52.7 153

W ×94 4.03 21300 117 65.4 122 47.3 139

W ×84 2.81 17900 128 64.9 103 40.6 122

W24×492 456 283000 40.1 92.1 1150 281 774

W ×408 271 214000 45.2 88.1 909 233 626

W ×335 154 160000 51.9 84.6 709 189 509

W ×279 91.7 125000 59.4 82.0 570 157 418

W ×250 67.3 108000 64.5 80.6 502 141 372

W ×229 51.8 95800 69.2 79.6 451 128 338

W ×207 38.6 83900 75.0 78.5 401 116 303

W ×192 31.0 76200 79.8 77.7 367 107 280

W ×176 24.1 68400 85.7 77.0 333 97.8 255

W ×162 18.5 62600 93.6 77.0 304 89.4 234

W ×146 13.4 54600 103 76.3 268 79.5 209

W ×131 9.50 47100 113 75.6 233 69.7 185

W ×117 6.72 40800 125 74.9 204 61.5 164

W ×104 4.72 35200 139 74.3 178 54.1 144

W24×103 7.10 16600 77.8 53.0 117 49.4 140

W ×94 5.26 15000 85.9 53.1 105 44.4 127

W ×84 3.70 12800 94.6 52.6 91.3 39.0 112

W ×76 2.68 11100 104 52.2 79.8 34.4 100

W ×68 1.87 9430 114 51.9 68.0 29.5 88.3

W24×62 1.71 4620 83.6 40.7 42.3 23.2 76.6

W ×55 1.18 3870 92.2 40.4 35.7 19.8 67.1

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 148 DIMENSIONS AND PROPERTIES

TORSION PROPERTIES

W shapes

Normalized Warping Statical

Torsional Warping Warping Statical Moment

Constant Constant √

EC

w

GJ

Constant Moment

J Cw Wno Sw Qf Qw

4 6 2 4 3

Designation in. in. in. in. in. in. in.3

W21×201 41.3 61800 62.2 67.0 345 102 265

W ×182 31.1 54300 67.2 66.0 307 92.3 238

W ×166 23.9 48500 72.5 65.6 277 84.4 216

W ×147 15.4 41100 83.1 65.4 235 71.4 187

W ×132 11.3 36000 90.8 64.7 208 64.0 167

W ×122 8.98 32700 97.1 64.2 191 59.2 154

W ×111 6.83 29200 105 63.7 172 53.7 139

W ×101 5.21 26200 114 63.2 155 49.0 127

W21×93 6.03 9940 65.3 43.6 85.3 38.2 110

W ×83 4.34 8630 71.8 43.0 75.0 34.2 98.0

W ×73 3.02 7410 79.7 42.5 65.2 30.3 86.2

W ×68 2.45 6760 84.5 42.3 59.9 28.0 79.9

W ×62 1.83 5960 91.8 42.0 53.2 25.1 72.2

W21×57 1.77 3190 68.3 33.4 35.6 20.9 64.3

W ×50 1.14 2570 76.4 33.1 28.9 17.2 55.0

W ×44 0.77 2110 84.2 32.8 24.0 14.5 47.7

W18×311 177 75700 33.3 58.8 483 141 376

W ×283 135 65600 35.5 57.5 427 127 338

W ×258 104 57400 37.8 56.4 382 116 306

W ×234 79.7 49900 40.3 55.2 339 105 274

W ×211 59.3 43200 43.4 54.2 299 94.3 245

W ×192 45.2 37900 46.6 53.3 267 85.7 221

W ×175 34.2 33200 50.1 52.5 237 77.2 199

W ×158 25.4 28900 54.3 51.6 210 69.4 178

W ×143 19.4 25700 58.6 51.0 189 63.2 161

W ×130 14.7 22700 63.2 50.4 169 57.1 145

W18×119 10.6 20300 70.4 50.4 151 50.6 131

W ×106 7.48 17400 77.6 49.8 131 44.6 115

W ×97 5.86 15800 83.6 49.4 120 41.2 105

W ×86 4.10 13600 92.7 48.9 104 36.3 92.8

W ×76 2.83 11700 103 48.4 90.7 31.9 81.4

W18×71 3.48 4700 59.1 33.7 52.1 25.8 72.7

W ×65 2.73 4240 63.4 33.4 47.5 23.8 66.6

W ×60 2.17 3850 67.8 33.1 43.5 22.1 61.4

W ×55 1.66 3430 73.1 32.9 39.0 19.9 55.9

W ×50 1.24 3040 79.7 32.6 34.9 18.0 50.4

W18×46 1.22 1710 60.2 26.4 24.2 15.3 45.3

W ×40 0.81 1440 67.8 26.1 20.6 13.3 39.2

W ×35 0.51 1140 76.1 25.9 16.5 10.7 33.2

W16×100 7.73 11900 63.1 41.7 107 39.0 99.0

W ×89 5.45 10200 69.6 41.1 93.3 34.4 87.3

W ×77 3.57 8590 78.9 40.6 79.3 29.7 75.0

W ×67 2.39 7300 88.9 40.1 68.2 25.9 64.9

W16×57 2.22 2660 55.7 28.0 35.6 19.0 52.6

W ×50 1.52 2270 62.2 27.6 30.8 16.7 46.0

W ×45 1.11 1990 68.1 27.4 27.2 15.0 41.1

W ×40 0.79 1730 75.3 27.1 23.9 13.4 36.5

W ×36 0.54 1460 83.7 26.9 20.2 11.4 32.0

W16×31 0.46 739 64.5 21.3 13.0 9.17 27.0

W ×26 0.26 565 75.0 21.1 10.0 7.20 22.1

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 149

TORSION PROPERTIES

W shapes

Normalized Warping Statical

Torsional Warping Warping Statical Moment

Constant Constant √

EC

w

GJ

Constant Moment

J Cw Wno Sw Qf Qw

4 6 2 4 3

Designation in. in. in. in. in. in. in.3

W14×808 1860 433000 24.6 82.2 1950 337 916

W ×730 1450 362000 25.4 78.3 1720 319 831

W ×665 1120 305000 26.6 75.5 1510 287 740

W ×605 870 258000 27.7 73.0 1320 259 660

W ×550 670 219000 29.1 70.6 1160 233 588

W ×500 514 187000 30.7 68.5 1020 209 524

W ×455 395 160000 32.4 66.5 899 189 468

W14×426 331 144000 33.6 65.3 827 176 434

W ×398 273 129000 35.0 64.1 756 163 401

W ×370 222 116000 36.8 62.9 689 151 368

W ×342 178 103000 38.7 61.6 623 138 336

W ×311 136 89100 41.2 60.3 553 125 301

W ×283 104 77700 44.0 59.1 493 113 271

W ×257 79.1 67800 47.1 57.9 438 102 243

W ×233 59.5 59000 50.7 56.9 389 91.7 218

W ×211 44.6 51500 54.7 55.9 345 82.3 195

W ×193 34.8 45900 58.4 55.1 312 75.4 177

W ×176 26.5 40500 62.9 54.4 279 68.0 160

W ×159 19.8 35600 68.2 53.7 248 61.3 143

W ×145 15.2 31700 73.5 53.0 224 55.8 130

W14×132 12.3 25500 73.3 50.2 190 49.9 117

W ×120 9.37 22700 79.2 49.7 171 45.3 106

W ×109 7.12 20200 85.7 49.1 154 41.2 95.9

W ×99 5.37 18000 93.2 48.7 138 37.2 86.6

W ×90 4.06 16000 101 48.3 125 33.7 78.3

W14×82 5.08 6710 58.5 34.1 73.8 28.1 69.3

W ×74 3.88 5990 63.2 33.7 66.6 25.7 62.8

W ×68 3.02 5380 67.9 33.4 60.4 23.5 57.3

W ×61 2.20 4710 74.5 33.1 53.3 21.0 51.1

W14×53 1.94 2540 58.2 26.7 35.5 17.3 43.6

W ×48 1.46 2240 63.0 26.5 31.6 15.6 39.2

W ×43 1.05 1950 69.3 26.2 27.8 13.9 34.8

W14×38 0.80 1230 63.1 23.0 20.0 11.5 30.7

W ×34 0.57 1070 69.7 22.8 17.5 10.2 27.3

W ×30 0.38 887 77.7 22.6 14.7 8.59 23.6

W14×26 0.36 405 54.0 16.9 8.94 6.98 20.1

W ×22 0.21 314 62.2 16.8 7.02 5.58 16.6

W12×336 243 57000 24.6 46.4 459 119 301

W ×305 185 48600 26.1 45.0 403 107 269

W ×279 143 42000 27.6 44.0 357 96.3 241

W ×252 108 35800 29.3 42.8 313 86.4 214

W ×230 83.8 31200 31.0 41.8 279 78.4 193

W ×210 64.7 27200 33.0 41.0 249 71.1 174

W ×190 48.8 23600 35.4 40.1 220 64.1 156

W ×170 35.6 20100 38.2 39.2 192 56.9 137

W ×152 25.8 17200 41.5 38.4 168 50.4 121

W ×136 18.5 14700 45.4 37.7 146 44.5 107

W ×120 12.9 12400 49.9 37.0 126 38.9 93.2

W ×106 9.13 10700 55.1 36.4 110 34.6 81.9

W ×96 6.86 9410 59.6 35.9 98.2 31.3 73.6

W ×87 5.10 8270 64.8 35.5 87.2 28.0 66.0

W ×79 3.84 7330 70.3 35.2 78.1 25.3 59.5

W ×72 2.93 6540 76.0 34.9 70.3 22.9 53.9

W ×65 2.18 5780 82.9 34.5 62.7 20.6 48.4

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 150 DIMENSIONS AND PROPERTIES

TORSION PROPERTIES

W shapes

Normalized Warping Statical

Torsional Warping Warping Statical Moment

Constant Constant √

EC

w

GJ

Constant Moment

J Cw Wno Sw Qf Qw

4 6 2 4 3

Designation in. in. in. in. in. in. in.3

W12×58 2.10 3570 66.3 28.9 46.3 18.2 43.2

W ×53 1.58 3160 72.0 28.7 41.2 16.3 39.0

W12×50 1.78 1880 52.3 23.3 30.2 14.7 36.2

W ×45 1.31 1650 57.1 23.1 26.7 13.1 32.4

W ×40 0.95 1440 62.6 22.9 23.6 11.8 28.8

W12×35 0.74 879 55.5 19.6 16.8 9.86 25.6

W ×30 0.46 720 63.7 19.4 13.9 8.30 21.6

W ×26 0.30 607 72.4 19.2 11.8 7.15 18.6

W12×22 0.29 164 38.3 12.0 5.13 4.87 14.7

W ×19 0.18 131 43.4 11.8 4.14 4.01 12.4

W ×16 0.10 96.9 50.1 11.7 3.09 3.04 10.0

W ×14 0.07 80.4 54.5 11.6 2.59 2.59 8.72

W10×112 15.1 6020 32.1 26.3 85.7 30.8 73.7

W ×100 10.9 5150 35.0 25.8 74.7 27.2 64.9

W ×88 7.53 4330 38.6 25.3 64.2 23.8 56.4

W ×77 5.11 3630 42.9 24.8 54.9 20.7 48.8

W ×68 3.56 3100 47.5 24.4 47.6 18.1 42.6

W ×60 2.48 2640 52.5 24.0 41.2 15.9 37.3

W ×54 1.82 2320 57.5 23.8 36.6 14.3 33.3

W ×49 1.39 2070 62.1 23.6 33.0 13.0 30.2

W10×45 1.51 1200 45.4 19.0 23.6 11.5 27.5

W ×39 0.98 992 51.2 18.7 19.8 9.77 23.4

W ×33 0.58 790 59.4 18.5 16.0 7.98 19.4

W10×30 0.62 414 41.6 14.5 10.7 7.09 18.3

W ×26 0.40 345 47.3 14.3 9.05 6.08 15.6

W ×22 0.24 275 54.5 14.1 7.30 4.95 13.0

W10×19 0.23 104 34.2 9.89 3.93 3.76 10.8

W ×17 0.16 85.1 37.1 9.80 3.24 3.13 9.33

W ×15 0.10 68.3 42.1 9.72 2.62 2.56 8.00

W ×12 0.05 50.9 51.3 9.56 1.99 2.00 6.32

W8×67 5.06 1440 27.1 16.7 32.3 14.7 35.1

W ×58 3.34 1180 30.2 16.3 27.2 12.5 29.9

W ×48 1.96 931 35.1 15.8 22.0 10.4 24.5

W ×40 1.12 726 41.0 15.5 17.5 8.42 19.9

W ×35 0.77 619 45.6 15.3 15.2 7.39 17.3

W ×31 0.54 530 50.4 15.1 13.1 6.46 15.2

W8×28 0.54 312 38.7 12.4 9.43 5.64 13.6

W ×24 0.35 259 43.8 12.2 7.94 4.83 11.6

W8×21 0.28 152 37.5 10.4 5.47 4.03 10.2

W ×18 0.17 122 43.1 10.3 4.44 3.31 8.52

W8×15 0.14 51.8 31.0 7.82 2.47 2.39 6.78

W ×13 0.09 40.8 34.3 7.74 1.97 1.93 5.70

W ×10 0.04 30.9 44.7 7.57 1.53 1.56 4.43

W6×25 0.46 150 29.1 9.01 6.23 3.92 9.46

W ×20 0.24 113 34.9 8.78 4.82 3.10 7.45

W ×15 0.10 76.5 44.5 8.58 3.34 2.18 5.39

W6×16 0.22 38.2 21.2 5.92 2.42 2.28 5.84

W ×12 0.09 24.7 26.7 5.75 1.61 1.55 4.15

W ×9 0.04 17.7 33.8 5.60 1.19 1.19 3.12

W5×19 0.31 50.8 20.6 5.94 3.21 2.44 5.81

W ×16 0.19 40.6 23.5 5.81 2.62 2.02 4.82

W4×13 0.15 14.0 15.5 3.87 1.36 1.27 3.14

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 151

TORSION PROPERTIES

M shapes

Normalized Warping Statical

Torsional Warping Warping Statical Moment

Constant Constant √

EC

w

GJ

Constant Moment

J Cw Wno Sw Qf Qw

4 6 2 4 3

Designation in. in. in. in. in. in. in.3

M12×11.8 0.05 34.0 42.0 9.02 1.56 1.98 7.14

M ×10.8 0.04 31.3 45.0 9.01 1.45 1.86 6.58

M10×9 0.03 14.6 35.5 6.59 0.91 1.32 4.60

M ×8 0.02 12.8 40.7 6.57 0.80 1.18 4.06

M8×6.5 0.02 5.23 26.0 4.45 0.48 0.82 2.72

M5×18.9 0.34 41.3 17.7 5.73 2.98 2.28 5.53

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 152 DIMENSIONS AND PROPERTIES

TORSION PROPERTIES

S shapes

Normalized Warping Statical

Torsional Warping Warping Statical Moment

Constant Constant √

EC

w

GJ

Constant Moment

J Cw Wno Sw Qf Qw

4 6 2 4 3

Designation in. in. in. in. in. in. in.3

S24×121 12.8 11400 48.0 47.1 103 47.1 154

S ×106 10.1 10600 52.1 46.1 98.8 47.1 141

S24×100 7.58 6380 46.7 41.9 66.0 33.5 121

S ×90 6.04 6000 50.7 41.2 63.8 33.5 112

S ×80 4.88 5640 54.7 40.5 61.6 33.5 103

S20×96 8.39 4710 38.1 34.9 57.8 29.2 99.7

S ×86 6.64 4390 41.4 34.2 55.5 29.2 92.5

S20×75 4.59 2750 39.4 30.7 38.9 22.6 77.0

S ×66 3.58 2550 42.9 30.0 37.3 22.6 70.5

S18×70 4.15 1800 33.5 27.0 29.2 17.1 63.0

S ×54.7 2.37 1560 41.3 26.0 26.9 17.1 52.9

S15×50 2.12 811 31.5 20.3 17.8 11.8 39.0

S ×42.9 1.54 744 35.4 19.8 16.9 11.8 35.1

S12×50 2.82 505 21.5 15.5 14.0 9.30 31.0

S ×40.8 1.75 437 25.4 14.9 12.9 9.30 26.9

S12×35 1.08 324 27.9 14.5 10.0 7.48 22.7

S ×31.8 0.90 307 29.7 14.3 9.74 7.48 21.3

S10×35 1.29 189 19.5 11.8 7.13 5.24 17.9

S ×25.4 0.60 153 25.7 11.1 6.34 5.24 14.4

S8×23 0.55 61.8 17.1 7.90 3.50 3.10 9.74

S ×18.4 0.34 53.5 20.2 7.58 3.22 3.10 8.38

S6×17.25 0.37 18.4 11.3 5.03 1.61 1.63 5.35

S ×12.5 0.17 14.5 14.9 4.70 1.41 1.63 4.30

S5×10 0.11 6.66 12.3 3.51 0.86 1.11 2.88

S4×9.5 0.12 3.10 8.18 2.59 0.53 0.70 2.05

S ×7.7 0.07 2.62 9.84 2.47 0.48 0.70 1.79

S3×7.5 0.09 1.10 5.63 1.72 0.28 0.40 1.20

S ×5.7 0.04 0.85 7.42 1.60 0.24 0.40 1.00

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 153

TORSION PROPERTIES

HP shapes

Normalized Warping Statical

Torsional Warping Warping Statical Moment

Constant Constant √

EC

w

GJ

Constant Moment

J Cw Wno Sw Qf Qw

4 6 2 4 3

Designation in. in. in. in. in. in. in.3

HP14×117 8.02 19900 80.2 49.9 149 38.5 97.2

HP ×102 5.40 16800 89.8 49.2 128 33.5 84.3

HP ×89 3.60 14200 101 48.5 110 29.1 72.9

HP ×73 2.01 11200 120 47.8 88.0 23.8 59.2

HP13×100 6.25 11300 68.4 40.9 103 29.9 76.3

HP ×87 4.12 9430 77.0 40.2 87.7 25.8 65.6

HP ×73 2.54 7680 88.5 39.6 72.8 21.8 55.2

HP ×60 1.39 6020 106 39.0 57.8 17.7 44.5

HP12×84 4.24 7160 66.1 35.6 75.0 23.5 59.8

HP ×74 2.98 6170 73.2 35.2 65.5 20.8 52.7

HP ×63 1.83 4990 84.0 34.6 54.1 17.5 44.2

HP ×53 1.12 4090 97.2 34.2 44.7 14.7 37.0

HP10×57 1.97 2240 54.3 24.1 34.8 13.1 33.2

HP ×42 0.81 1540 70.2 23.4 24.7 9.64 24.2

HP8×36 0.77 578 44.1 15.4 14.0 6.62 16.8

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 154 DIMENSIONS AND PROPERTIES

FLEXURAL-TORSIONAL PROPERTIES

Channels

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

C15×50 2.67 492 5.49 .937

C15×40 1.46 411 5.72 .927

C15×33.9 1.02 358 5.94 .920

C12×30 0.87 151 4.55 .919

C15×25 0.54 130 4.72 .909

C15×20.7 0.37 112 4.93 .899

C10×30 1.23 79.3 3.63 .921

C1××25 0.69 68.4 3.75 .912

C5××20 0.37 56.9 3.93 .900

C10×15.3 0.21 45.6 4.19 .883

C9×20 0.43 39.4 3.46 .899

C9×15 0.21 31.0 3.69 .882

C9×13.4 0.17 28.2 3.79 .874

C8×18.75 0.44 25.1 3.06 .894

C9×13.75 0.19 19.2 3.27 .874

C9×11.5 0.13 16.5 3.42 .862

C7×12.25 0.16 11.2 2.87 .862

C9×9.8 0.10 9.18 3.02 .846

C6×13 0.24 7.22 2.37 .858

C9×10.5 0.13 5.95 2.49 .843

C9×8.2 0.08 4.72 2.65 .824

C5×9 0.11 2.93 2.10 .814

C9×6.7 0.06 2.22 2.26 .790

C4×7.25 0.08 1.24 1.75 .768

C9×5.4 0.04 0.92 1.89 .741

C3×6 0.07 0.46 1.39 .689

C9×5 0.04 0.38 1.45 .674

C9×4.1 0.03 0.31 1.53 .656

*See LRFD Specification Appendix E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 155

FLEXURAL-TORSIONAL PROPERTIES

Channels

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

MC18×58 2.81 1070 6.56 .944

MC10×51.9 2.03 986 6.70 .939

MC10×45.8 1.45 897 6.88 .933

MC10×42.7 1.23 852 6.97 .930

MC13×50 2.98 558 5.07 .875

MC10×40 1.57 463 5.33 .860

MC10×35 1.14 413 5.50 .849

MC10×31.8 0.94 380 5.64 .842

MC12×50 3.24 411 4.77 .859

MC10×45 2.35 374 4.87 .851

MC10×40 1.70 336 5.01 .842

MC10×35 1.25 297 5.18 .832

MC10×31 1.01 268 5.34 .821

MC10×10.6 0.06 11.7 4.27 .983

MC10×41.1 2.27 270 4.26 .790

MC10×33.6 1.21 224 4.47 .771

MC10×28.5 0.79 194 4.68 .752

MC10×25 0.64 125 4.46 .802

MC10×22 0.51 111 4.63 .790

MC10×8.4 0.04 7.01 3.68 .972

MC9×25.4 0.69 104 4.08 .770

MC9×23.9 0.60 98.2 4.15 .763

MC8×22.8 0.57 75.3 3.85 .716

MC9×21.4 0.50 70.9 3.91 .709

MC9×20 0.44 47.9 3.59 .780

MC9×18.7 0.38 45.1 3.65 .773

MC9×8.5 0.06 8.22 3.24 .910

MC7×22.7 0.63 58.5 3.53 .662

MC9×19.1 0.41 49.4 3.71 .638

MC6×18 0.38 34.6 3.46 .562

MC6×16.3 0.34 22.1 3.11 .643

MC9×15.1 0.29 20.6 3.18 .634

MC6×12 0.15 11.2 2.80 .740

*See LRFD Specification Appendix E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 156 DIMENSIONS AND PROPERTIES

FLEXURAL-TORSIONAL PROPERTIES

Single Angles

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

L8×8×11⁄8 7.13 32.5 4.31 0.632

L × ×1 5.08 23.4 4.35 0.630

L × ×17⁄8 3.46 16.1 4.37 0.629

L × ×13⁄4 2.21 10.4 4.41 0.627

L × ×15⁄8 1.30 6.16 4.45 0.627

L × ×19⁄16 0.960 4.55 4.47 0.627

L × ×11⁄2 0.682 3.23 4.48 0.624

L8×6×1 4.35 16.3 3.89 —

L × × 3⁄4 1.90 7.28 3.96 —

L × ×19⁄16 0.822 3.20 4.01 —

L × ×11⁄2 0.584 2.28 4.02 —

L × ×17⁄16 0.396 1.55 4.04 —

L8×4×1 3.68 12.9 3.77 —

L8×4×17⁄8 2.48 8.89 3.79 —

L × ×13⁄4 1.61 5.75 3.82 —

L8×4×15⁄8 0.933 3.42 3.85 —

L × ×19⁄16 0.704 2.53 3.86 —

L × ×11⁄2 0.501 1.80 3.88 —

L8×4×17⁄16 0.328 1.22 3.89 —

L7×4×3⁄4 1.47 3.97 3.33 —

L × ×5⁄8 0.873 2.37 3.36 —

L × ×1⁄2 0.459 1.25 3.38 —

L7×4×7⁄16 0.300 0.851 3.40 —

L × ×3⁄8 0.200 0.544 3.42 —

*See LRFD Specification Appendix E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 157

FLEXURAL-TORSIONAL PROPERTIES

Single Angles

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

L6×6×1 3.68 9.24 3.19 0.637

L6×6×17⁄8 2.51 6.41 3.22 0.632

L6×6×13⁄4 1.61 4.17 3.26 0.629

L6×6×15⁄8 0.954 2.50 3.29 0.628

L6×6×19⁄16 0.704 1.85 3.31 0.627

L6×6×11⁄2 0.501 1.32 3.32 0.627

L6×6×17⁄16 0.340 0.899 3.34 0.627

L6×6×13⁄8 0.218 0.575 3.36 0.626

L6×6×15⁄16 0.129 0.338 3.38 0.625

L6×4×3⁄4 1.33 2.64 2.86 —

L6×4×5⁄8 0.792 1.59 2.89 —

L6×4×9⁄16 0.585 1.18 2.9 —

L6×4×1⁄2 0.417 0.843 2.92 —

L6×4×7⁄16 0.284 0.575 2.94 —

L6×4×3⁄8 0.183 0.369 2.96 —

L6×4×5⁄16 0.108 0.217 2.97 —

L6×31⁄2×1⁄2 0.396 0.779 2.88 —

L6×31⁄2×3⁄8 0.174 0.341 2.92 —

L6×31⁄2×5⁄16 0.103 0.201 2.93 —

L5×5×7⁄8 2.07 3.53 2.65 0.634

L6×4×3⁄4 1.33 2.32 2.68 0.634

L6×4×5⁄8 0.792 1.40 2.71 0.630

L6×4×1⁄2 0.417 0.744 2.74 0.630

L6×4×7⁄16 0.284 0.508 2.77 0.629

L6×4×3⁄8 0.183 0.327 2.79 0.627

L6×4×5⁄16 0.108 0.193 2.81 0.626

*See LRFD Specification Appendix E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 158 DIMENSIONS AND PROPERTIES

FLEXURAL-TORSIONAL PROPERTIES

Single Angles

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

L5×31⁄2×3⁄4 1.11 1.52 2.37 —

L5×31⁄2×5⁄8 0.660 0.918 2.40 —

L5×31⁄2×1⁄2 0.348 0.491 2.44 —

L5×31⁄2×3⁄8 0.153 0.217 2.47 —

L5×31⁄2×5⁄16 0.0905 0.128 2.49 —

L5×31⁄2×1⁄4 0.0479 0.0670 2.50 —

L5×3×1⁄2 0.322 0.444 2.39 —

L5×3×7⁄16 0.219 0.304 2.41 —

L5×3×3⁄8 0.141 0.196 2.42 —

L5×3×5⁄16 0.0832 0.116 2.43 —

L5×3×1⁄4 0.0438 0.0606 2.45 —

L4×4×3⁄4 1.02 1.12 2.11 0.639

L5×3×5⁄8 0.610 0.680 2.14 0.631

L5×3×1⁄2 0.322 0.366 2.17 0.632

L5×3×7⁄16 0.219 0.252 2.19 0.631

L5×3×3⁄8 0.141 0.162 2.20 0.625

L5×3×5⁄16 0.0832 0.0963 2.22 0.623

L5×3×1⁄4 0.0438 0.0505 2.23 0.627

L4×31⁄2×1⁄2 0.301 0.302 2.04 —

L5×31⁄2×3⁄8 0.132 0.134 2.08 —

L5×31⁄2×5⁄16 0.0782 0.0798 2.09 —

L5×31⁄2×1⁄4 0.0412 0.0419 2.11 —

*See LRFD Specification Appendix E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 159

FLEXURAL-TORSIONAL PROPERTIES

Single Angles

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

L4×3×5⁄8 0.529 0.472 1.91 —

L4×3×1⁄2 0.281 0.255 1.95 —

L4×3×7⁄16 0.192 0.176 1.96 —

L4×3×3⁄8 0.123 0.114 1.98 —

L4×3×5⁄16 0.0731 0.0676 2.00 —

L4×3×1⁄4 0.0386 0.0356 2.01 —

L31⁄2×31⁄2×1⁄2 0.281 0.238 1.89 0.631

L31⁄2×31⁄2×7⁄16 0.192 0.164 1.91 0.629

L31⁄2×31⁄2×3⁄8 0.123 0.106 1.91 0.628

L31⁄2×31⁄2×5⁄16 0.0731 0.0634 1.93 0.627

L31⁄2×31⁄2×1⁄4 0.0386 0.0334 1.95 0.626

L31⁄2×3×1⁄2 0.260 0.191 1.76 —

L31⁄2×3×3⁄8 0.114 0.0858 1.79 —

L31⁄2×3×5⁄16 0.0680 0.0512 1.81 —

L31⁄2×3×1⁄4 0.0360 0.0270 1.83 —

L31⁄2×21⁄2×1⁄2 0.234 0.159 1.67 —

L31⁄2×31⁄2×3⁄8 0.103 0.0714 1.70 —

L31⁄2×31⁄2×1⁄4 0.0322 0.0225 1.73 —

L3×3×1⁄2 0.234 0.144 1.60 0.634

L4×3×7⁄16 0.160 0.100 1.61 0.632

L4×3×3⁄8 0.103 0.0652 1.63 0.629

L4×3×5⁄16 0.0611 0.0390 1.65 0.628

L4×3×1⁄4 0.0322 0.0206 1.66 0.627

L4×3×3⁄16 0.0142 0.00899 1.68 0.626

*See LRFD Specification Appendix E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 160 DIMENSIONS AND PROPERTIES

FLEXURAL-TORSIONAL PROPERTIES

Single Angles

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

L3×21⁄2×1⁄2 0.213 0.112 1.47 —

L3×21⁄2×7⁄16 0.146 0.0777 1.49 —

L3×21⁄2×3⁄8 0.0943 0.0507 1.50 —

L3×21⁄2×5⁄16 0.0560 0.0304 1.52 —

L3×21⁄2×1⁄4 0.0296 0.0161 1.54 —

L3×21⁄2×3⁄16 0.0131 0.00705 1.55 —

L3×2×1⁄2 0.192 0.0908 1.40 —

L2×2×3⁄8 0.0855 0.0413 1.43 —

L2×2×5⁄16 0.0509 0.0248 1.45 —

L2×2×1⁄4 0.0270 0.0132 1.46 —

L2×2×3⁄16 0.0120 0.00576 1.48 —

L21⁄2×21⁄2×1⁄2 0.185 0.0791 1.31 0.639

L21⁄2×21⁄2×3⁄8 0.0816 0.0362 1.34 0.632

L21⁄2×21⁄2×5⁄16 0.0483 0.0218 1.36 0.630

L21⁄2×21⁄2×1⁄4 0.0253 0.0116 1.37 0.628

L21⁄2×21⁄2×3⁄16 0.0110 0.00510 1.39 0.627

L21⁄2×2×3⁄8 0.0728 0.0268 1.22 —

L3×21⁄2×5⁄16 0.0432 0.0162 1.24 —

L3×21⁄2×1⁄4 0.0227 0.00868 1.25 —

L3×21⁄2×3⁄16 0.00990 0.00382 1.27 —

L2×2×3⁄8 0.0640 0.0174 1.05 0.637

L2×2×5⁄16 0.0381 0.0106 1.07 0.633

L2×2×1⁄4 0.0201 0.00572 1.09 0.630

L2×2×3⁄16 0.00880 0.00254 1.10 0.628

L2×2×1⁄8 0.00274 0.00079 1.12 0.626

*See LRFD Specification Appendix E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 161

FLEXURAL-TORSIONAL PROPERTIES

Structural Tees

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

WT22×167.5 37.2 434 8.81 0.724

WT ×145 25.7 279 8.67 0.733

WT ×131 18.9 204 8.65 0.731

WT ×115 12.4 139 8.67 0.723

WT20×296.5** 223 2340 8.30 0.761

WT ×251.5** 140 1420 8.17 0.760

WT ×215.5 88.5 881 8.09 0.756

WT ×186 58.2 559 8.00 0.756

WT ×160.5 37.7 350 7.92 0.756

WT ×148.5 30.6 279 7.88 0.756

WT ×138.5 25.8 218 7.75 0.770

WT ×124.5 19.1 158 7.71 0.770

WT ×107.5 12.4 101 7.66 0.770

WT ×99.5 9.14 83.5 7.83 0.746

WT ×87 5.60 65.3 8.12 0.699

WT20×233** 139 1360 8.39 0.680

WT ×196** 86.1 802 8.27 0.678

WT ×165.5 53.0 485 8.19 0.674

WT ×139 32.4 278 8.07 0.676

WT ×132 28.0 233 8.02 0.680

WT ×117.5 20.6 156 7.88 0.690

WT ×105.5 15.2 113 7.84 0.690

WT ×91.5 10.0 72.1 7.79 0.691

WT ×83.5 7.01 62.9 8.02 0.658

WT ×74.5 4.68 51.9 8.24 0.626

WT18×424** 622 6880 8.08 0.802

WT ×399** 527 5700 8.02 0.801

WT ×325** 295 3010 7.82 0.797

WT ×263.5** 163 1570 7.63 0.797

WT ×219.5** 96.7 894 7.52 0.794

WT ×196.5** 70.7 637 7.44 0.796

WT ×179.5** 54.3 480 7.38 0.797

WT ×164** 42.1 363 7.32 0.799

WT ×150 32.0 278 7.30 0.797

WT ×140 26.2 226 7.27 0.796

WT ×130 20.7 181 7.28 0.791

WT ×122.5 17.3 151 7.28 0.788

WT ×115 14.3 125 7.27 0.784

*See LRFD Specification Section E3.

**Group 4 or Group 5 shape. See Notes in Table 1-2.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 162 DIMENSIONS AND PROPERTIES

FLEXURAL-TORSIONAL PROPERTIES

Structural Tees

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

WT18×128 26.6 205 7.43 0.703

WT ×116 19.8 151 7.40 0.703

WT ×105 13.9 119 7.49 0.687

WT ×97 11.1 92.7 7.45 0.687

WT ×91 9.19 77.6 7.45 0.686

WT ×85 7.51 63.2 7.44 0.684

WT ×80 6.17 53.6 7.46 0.678

WT ×75 5.04 46.0 7.50 0.670

WT ×67.5 3.48 37.3 7.65 0.644

WT16.5×177** 57.2 468 7.00 0.802

WT ×159** 42.1 335 6.94 0.803

WT ×145.5** 32.4 256 6.90 0.801

WT ×131.5** 24.2 188 6.86 0.802

WT ×120.5 17.9 146 6.91 0.792

WT ×110.5 13.7 113 6.90 0.788

WT ×100.5 10.2 84.9 6.89 0.784

WT16.5×84.5 8.83 55.4 6.74 0.714

WT ×76 6.16 43.0 6.82 0.700

WT ×70.5 4.84 35.4 6.85 0.691

WT ×65 3.67 29.3 6.93 0.678

WT ×59 2.64 23.4 7.02 0.659

WT15×238.5** 151 1170 6.65 0.819

WT ×195.5** 85.9 636 6.54 0.815

WT ×163** 50.8 361 6.40 0.817

WT ×146** 37.2 257 6.34 0.818

WT ×130.5 26.7 184 6.31 0.815

WT ×117.5 19.9 132 6.25 0.817

WT ×105.5 13.9 96.4 6.27 0.809

WT ×95.5 10.3 71.2 6.25 0.806

WT ×86.5 7.61 53.0 6.25 0.802

WT15×74 7.27 37.6 6.10 0.716

WT ×66 4.85 28.5 6.19 0.698

WT ×62 3.98 23.9 6.20 0.693

WT ×58 3.21 20.5 6.24 0.683

WT ×54 2.49 17.3 6.31 0.669

WT ×49.5 1.88 14.3 6.38 0.654

WT ×45 1.42 10.5 6.34 0.655

*See LRFD Specification Section E3.

**Group 4 or Group 5 shape. See Notes in Table 1-2.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 163

FLEXURAL-TORSIONAL PROPERTIES

Structural Tees

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

WT13.5×269.5** 245 1740 6.27 0.830

WT ×224** 146 977 6.11 0.829

WT ×184** 83.6 532 5.97 0.828

WT ×153.5** 49.8 304 5.85 0.828

WT ×140.5** 39.0 232 5.80 0.830

WT ×129 30.2 178 5.77 0.828

WT ×117.5 23.0 135 5.74 0.825

WT ×108.5 18.5 105 5.72 0.830

WT ×97 13.2 74.3 5.66 0.826

WT ×89 9.74 57.7 5.70 0.815

WT ×80.5 7.31 42.7 5.67 0.813

WT ×73 5.44 31.7 5.65 0.810

WT13.5×64.5 5.60 24.0 5.48 0.731

WT ×57 3.65 17.5 5.54 0.716

WT ×51 2.64 12.6 5.52 0.714

WT ×47 2.01 10.2 5.57 0.703

WT ×42 1.40 7.79 5.63 0.685

WT12×246** 223 1340 5.71 0.838

WT ×204** 133 748 5.55 0.836

WT ×167.5** 76.0 405 5.40 0.837

WT ×139.5** 45.3 230 5.28 0.837

WT ×125** 33.3 165 5.22 0.838

WT ×114.5 25.7 125 5.19 0.836

WT ×103.5 19.1 91.3 5.14 0.836

WT ×96 15.4 72.5 5.11 0.836

WT ×88 12.0 55.8 5.09 0.835

WT ×81 9.22 43.8 5.09 0.831

WT ×73 6.70 31.9 5.08 0.827

WT ×65.5 4.74 23.1 5.09 0.818

WT ×58.5 3.35 16.4 5.08 0.813

WT ×52 2.35 11.6 5.07 0.809

WT12×51.5 3.54 12.3 4.88 0.733

WT ×47 2.62 9.57 4.89 0.727

WT ×42 1.84 6.90 4.89 0.721

WT ×38 1.34 5.30 4.93 0.709

WT ×34 0.932 4.08 4.99 0.692

WT12×31 0.850 3.92 5.13 0.619

WT ×27.5 0.588 2.93 5.18 0.606

*See LRFD Specification Section E3.

**Group 4 or Group 5 shape. See Notes in Table 1-2.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 164 DIMENSIONS AND PROPERTIES

FLEXURAL-TORSIONAL PROPERTIES

Structural Tees

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

WT10.5×100.5 20.6 85.4 4.67 0.859

WT10.5×91 15.4 63.0 4.64 0.859

WT10.5×83 11.9 47.3 4.59 0.861

WT10.5×73.5 7.69 32.5 4.64 0.847

WT10.5×66 5.62 23.4 4.61 0.845

WT10.5×61 4.47 18.4 4.58 0.846

WT10.5×55.5 3.40 13.8 4.56 0.846

WT10.5×50.5 2.60 10.4 4.54 0.846

WT10.5×46.5 3.01 9.33 4.37 0.729

WT10.5×41.5 2.16 6.50 4.33 0.732

WT10.5×36.5 1.51 4.42 4.31 0.732

WT10.5×34 1.22 3.62 4.31 0.727

WT10.5×31 0.513 2.78 4.31 0.722

WT10.5×28.5 0.884 2.50 4.36 0.665

WT10.5×25 0.570 1.89 4.44 0.640

WT10.5×22 0.383 1.40 4.49 0.623

WT9×155.5** 87.2 339 4.42 0.875

WT9×141.5** 66.5 251 4.36 0.873

WT9×129** 51.5 189 4.30 0.874

WT9×117** 39.4 140 4.23 0.875

WT9×105.5** 29.4 102 4.19 0.873

WT9×96 22.4 75.7 4.14 0.875

WT9×87.5 17.0 56.5 4.10 0.872

WT9×79 12.6 41.2 4.06 0.872

WT9×71.5 9.70 30.7 4.03 0.874

WT9×65 7.30 22.8 3.99 0.874

WT9×59.5 5.30 17.4 4.03 0.862

WT9×53 3.73 12.1 4.00 0.860

WT9×48.5 2.92 9.29 3.97 0.862

WT9×43 2.04 6.42 3.95 0.860

WT9×38 1.41 4.37 3.92 0.862

WT9×35.5 1.74 3.96 3.72 0.751

WT9×32.5 1.36 3.01 3.69 0.755

WT9×30 1.08 2.35 3.67 0.756

WT9×27.5 0.829 1.84 3.68 0.749

WT9×25 0.613 1.36 3.66 0.748

WT9×23 0.609 1.20 3.67 0.694

WT9×20 0.403 0.788 3.65 0.692

WT9×17.5 0.252 0.598 3.74 0.662

*See LRFD Specification Section E3.

**Group 4 or Group 5 shape. See Notes in Table 1-2.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 165

FLEXURAL-TORSIONAL PROPERTIES

Structural Tees

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

WT8×50 3.85 10.4 3.62 0.877

WT ×44.5 2.72 7.19 3.60 0.877

WT ×38.5 1.78 4.61 3.56 0.877

WT ×33.5 1.19 3.01 3.53 0.879

WT8×28.5 1.10 1.99 3.30 0.770

WT ×25 0.760 1.34 3.28 0.770

WT ×22.5 0.655 0.974 3.27 0.767

WT ×20 0.396 0.673 3.24 0.769

WT ×18 0.271 0.516 3.30 0.745

WT8×15.5 0.229 0.366 3.26 0.695

WT ×13 0.130 0.243 3.32 0.667

WT7×404** 918 6970 5.67 0.959

WT ×365** 714 5250 5.47 0.966

WT ×332.5** 555 3920 5.36 0.966

WT ×302.5** 430 2930 5.25 0.966

WT ×275** 331 2180 5.15 0.967

WT ×250** 255 1620 5.06 0.967

WT ×227.5** 196 1210 4.98 0.967

WT7×213** 164 991 4.92 0.968

WT ×199** 135 801 4.87 0.968

WT ×185** 110 640 4.81 0.968

WT ×171** 88.3 502 4.77 0.968

WT ×155.5** 67.5 375 4.71 0.968

WT ×141.5** 51.8 281 4.66 0.969

WT ×128.5** 39.3 209 4.61 0.969

WT ×116.5** 29.6 154 4.56 0.970

WT ×105.5 22.2 113 4.52 0.970

WT ×96.5 17.3 87.2 4.49 0.971

WT ×88 13.2 65.2 4.46 0.971

WT ×79.5 9.84 47.9 4.42 0.971

WT ×72.5 7.56 36.3 4.40 0.971

*See LRFD Specification Section E3.

**Group 4 or Group 5 shape. See Notes in Table 1-2.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 166 DIMENSIONS AND PROPERTIES

FLEXURAL-TORSIONAL PROPERTIES

Structural Tees

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

WT7×66 6.13 26.6 4.21 0.966

WT ×60 4.67 20.0 4.18 0.966

WT ×54.5 3.55 15.0 4.16 0.968

WT ×49.5 2.68 11.1 4.14 0.968

WT ×45 2.03 8.31 4.12 0.968

WT7×41 2.53 5.63 3.25 0.912

WT ×37 1.94 4.19 3.21 0.917

WT ×34 1.51 3.21 3.19 0.915

WT ×30.5 1.10 2.29 3.18 0.915

WT7×26.5 0.970 1.46 2.89 0.868

WT ×24 0.726 1.07 2.87 0.866

WT ×21.5 0.524 0.751 2.85 0.866

WT7×19 0.398 0.554 2.87 0.800

WT ×17 0.284 0.400 2.86 0.793

WT ×15 0.190 0.287 2.90 0.772

WT7×13 0.179 0.207 2.82 0.713

WT ×11 0.104 0.134 2.86 0.691

*See LRFD Specification Section E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 167

FLEXURAL-TORSIONAL PROPERTIES

Structural Tees

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

WT6×168** 120 481 4.07 0.958

WT ×152.5** 92.0 356 4.00 0.959

WT ×139.5** 70.9 267 3.94 0.957

WT ×126** 53.5 195 3.88 0.958

WT ×115** 41.6 148 3.84 0.958

WT ×105** 32.2 112 3.79 0.958

WT ×95 24.4 82.1 3.74 0.959

WT ×85 17.7 58.3 3.69 0.960

WT ×76 12.8 41.3 3.65 0.960

WT ×68 9.22 28.9 3.61 0.960

WT ×60 6.43 19.7 3.58 0.959

WT ×53 4.55 13.6 3.54 0.961

WT ×48 3.42 10.1 3.51 0.961

WT ×43.5 2.54 7.34 3.49 0.960

WT ×39.5 1.92 5.43 3.46 0.960

WT ×36 1.46 4.07 3.45 0.961

WT ×32.5 1.09 2.97 3.43 0.960

WT6×29 1.05 2.08 3.01 0.944

WT ×26.5 0.788 1.53 3.00 0.940

WT6×25 0.889 1.23 2.67 0.899

WT ×22.5 0.656 0.885 2.64 0.898

WT ×20 0.476 0.620 2.62 0.901

WT6×17.5 0.369 0.437 2.56 0.835

WT ×15 0.228 0.267 2.55 0.830

WT ×13 0.150 0.174 2.54 0.826

WT6×11 0.146 0.137 2.52 0.683

WT ×9.5 0.0899 0.0934 2.54 0.663

WT ×8 0.0511 0.0678 2.62 0.624

WT ×7 0.0350 0.0493 2.64 0.610

*See LRFD Specification Section E3.

**Group 4 or Group 5 shape. See Notes in Table 1-2.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 168 DIMENSIONS AND PROPERTIES

FLEXURAL-TORSIONAL PROPERTIES

Structural Tees

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

WT5×56 7.50 16.9 3.04 0.963

WT5×50 5.41 11.9 3.00 0.964

WT5×44 3.75 8.02 2.98 0.964

WT5×38.5 2.55 5.31 2.93 0.964

WT5×34 1.78 3.62 2.92 0.965

WT5×30 1.23 2.46 2.89 0.965

WT5×27 0.909 1.78 2.87 0.966

WT5×24.5 0.693 1.33 2.85 0.966

WT5×22.5 0.753 0.981 2.44 0.940

WT5×19.5 0.487 0.616 2.42 0.936

WT5×16.5 0.291 0.356 2.40 0.927

WT5×15 0.310 0.273 2.17 0.848

WT5×13 0.201 0.173 2.15 0.848

WT5×11 0.119 0.107 2.17 0.831

WT5×9.5 0.116 0.0796 2.08 0.728

WT5×8.5 0.0776 0.061 2.12 0.702

WT5×7.5 0.0518 0.0475 2.16 0.672

WT5×6 0.0272 0.0255 2.16 0.662

*See LRFD Specification Section E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 169

FLEXURAL-TORSIONAL PROPERTIES

Structural Tees

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

WT4×33.5 2.52 3.56 2.41 0.962

WT ×29 1.66 2.28 2.39 0.961

WT ×24 0.979 1.30 2.34 0.966

WT ×20 0.559 0.715 2.31 0.961

WT ×17.5 0.385 0.480 2.29 0.963

WT ×15.5 0.268 0.327 2.29 0.961

WT4×14 0.268 0.230 1.97 0.935

WT ×12 0.173 0.144 1.96 0.936

WT4×10.5 0.141 0.0916 1.80 0.877

WT ×9 0.0855 0.0562 1.81 0.863

WT4×7.5 0.0679 0.0382 1.72 0.762

WT ×6.5 0.0433 0.0269 1.74 0.732

WT ×5 0.0212 0.0114 1.69 0.748

WT3×12.5 0.229 0.171 1.76 0.952

WT ×10 0.120 0.0858 1.73 0.952

WT ×7.5 0.0504 0.0342 1.71 0.937

WT3×8 0.111 0.0426 1.37 0.880

WT ×6 0.0449 0.0178 1.37 0.846

WT ×4.5 0.0202 0.0074 1.34 0.852

WT2.5×9.5 0.154 0.0775 1.44 0.964

WT ×8 0.0930 0.0453 1.43 0.962

WT2×6.5 0.0750 0.0213 1.16 0.947

*See LRFD Specification Section E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 170 DIMENSIONS AND PROPERTIES

FLEXURAL-TORSIONAL PROPERTIES

Structural Tees

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

MT6×5.9 0.0307 0.0330 2.69 0.564

MT ×5.4 0.0196 0.0252 2.67 0.572

MT5×4.5 0.0213 0.0133 2.21 0.584

MT ×4 0.0116 0.00916 2.21 0.582

MT4×3.25 0.0146 0.00421 1.73 0.611

MT2.5×9.45** 0.165 0.0732 1.37 0.951

*See LRFD Specification Section E3.

**This shape has tapered flanges while other MT shapes have parallel flanges.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 171

FLEXURAL-TORSIONAL PROPERTIES

Structural Tees

Polar

Torsional Warping Radius of Flexural

Constant Constant Gyration

_ Constant

J Cw ro* H*

Designation in.4 in.6 in. No Units

ST12×60.5 6.38 27.5 5.14 0.640

ST ×53 5.04 15.0 4.87 0.685

ST12×50 3.76 19.5 5.27 0.584

ST ×45 3.01 12.1 5.12 0.616

ST ×40 2.43 6.94 4.89 0.657

ST10×48 4.15 15.0 4.36 0.625

ST ×43 3.30 9.17 4.20 0.661

ST10×37.5 2.28 7.21 4.28 0.612

ST ×33 1.78 4.02 4.10 0.655

ST9×35 2.05 7.03 4.01 0.583

ST ×27.35 1.18 2.26 3.71 0.662

ST7.5×25 1.05 2.02 3.22 0.637

ST ×21.45 0.767 0.995 3.04 0.689

ST6×25 1.39 1.97 2.60 0.663

ST ×20.4 0.872 0.787 2.42 0.733

ST6×17.5 0.538 0.556 2.49 0.697

ST ×15.9 0.449 0.364 2.39 0.731

ST5×17.5 0.633 0.725 2.23 0.653

ST ×12.7 0.300 0.173 1.98 0.768

ST4×11.5 0.271 0.168 1.74 0.707

ST ×9.2 0.167 0.0642 1.59 0.789

ST3×8.625 0.182 0.0772 1.36 0.706

ST ×6.25 0.0838 0.0197 1.21 0.820

ST2.5×5 0.0568 0.0100 1.02 0.842

ST2×4.75 0.0589 0.00995 0.907 0.800

ST ×3.85 0.0364 0.00457 0.841 0.872

ST1.5×3.75 0.0440 0.00496 0.737 0.832

ST ×2.85 0.0220 0.00189 0.672 0.913

*See LRFD Specification Section E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 172 DIMENSIONS AND PROPERTIES

FLEXURAL-TORSIONAL PROPERTIES

Double Angles

Long Legs Vertical Short Legs Vertical

Back to Back of Angles, in. Back to Back of Angles, in.

0 3⁄ 3⁄ 0 3⁄ 3⁄

8 4 8 4

Designation ro* H* ro* H* ro* H* ro* H* ro* H* ro* H*

L8×8×11⁄8 4.58 0.837 4.68 0.844 4.79 0.851 4.58 0.837 4.68 0.844 4.79 0.851

L × ×1 4.58 0.833 4.68 0.840 4.79 0.847 4.58 0.833 4.68 0.840 4.79 0.847

L × × 7⁄8 4.58 0.831 4.68 0.838 4.78 0.845 4.58 0.831 4.68 0.838 4.78 0.845

L × × 3⁄4 4.58 0.828 4.68 0.835 4.78 0.842 4.58 0.828 4.68 0.835 4.78 0.842

L × × 5⁄8 4.58 0.825 4.68 0.832 4.78 0.839 4.58 0.825 4.68 0.832 4.78 0.839

L × × 1⁄2 4.59 0.822 4.69 0.829 4.78 0.836 4.59 0.822 4.69 0.829 4.78 0.836

L8×6×1 4.07 0.721 4.15 0.731 4.23 0.742 4.19 0.925 4.31 0.929 4.44 0.933

L × × 3⁄4 4.08 0.714 4.16 0.724 4.24 0.735 4.17 0.919 4.29 0.924 4.41 0.928

L × × 1⁄2 4.11 0.708 4.18 0.718 4.26 0.728 4.17 0.914 4.28 0.919 4.40 0.923

L8×4×1 3.87 0.566 3.93 0.578 3.99 0.591 4.12 0.982 4.26 0.983 4.41 0.984

L × × 3⁄4 3.89 0.562 3.94 0.573 4.00 0.586 4.08 0.980 4.22 0.981 4.36 0.982

L × × 1⁄2 3.93 0.558 3.97 0.568 4.03 0.580 4.05 0.977 4.19 0.979 4.33 0.980

L7×4×3⁄4 3.42 0.609 3.48 0.623 3.55 0.637 3.58 0.968 3.71 0.971 3.85 0.973

L × ×1⁄2 3.45 0.604 3.5 0.616 3.57 0.629 3.55 0.965 3.68 0.967 3.82 0.969

L × ×3⁄8 3.46 0.602 3.51 0.614 3.57 0.627 3.54 0.963 3.67 0.965 3.80 0.968

L6×6×1 3.43 0.843 3.54 0.852 3.65 0.861 3.43 0.843 3.54 0.852 3.65 0.861

L × × 7⁄8 3.43 0.838 3.54 0.847 3.65 0.856 3.43 0.838 3.54 0.847 3.65 0.856

L × × 3⁄4 3.44 0.833 3.54 0.842 3.65 0.852 3.44 0.833 3.54 0.842 3.65 0.852

L × × 5⁄8 3.44 0.830 3.54 0.839 3.64 0.848 3.44 0.830 3.54 0.839 3.64 0.848

L × × 1⁄2 3.44 0.827 3.54 0.836 3.64 0.845 3.44 0.827 3.54 0.836 3.64 0.845

L × × 3⁄8 3.44 0.822 3.54 0.831 3.64 0.841 3.44 0.822 3.54 0.831 3.64 0.841

L6×4×3⁄4 2.98 0.672 3.05 0.687 3.13 0.704 3.10 0.948 3.23 0.952 3.36 0.956

L × ×5⁄8 2.98 0.668 3.05 0.683 3.13 0.699 3.09 0.946 3.21 0.950 3.34 0.954

L × ×1⁄2 3.00 0.663 3.06 0.678 3.14 0.693 3.08 0.943 3.20 0.947 3.34 0.951

L × ×3⁄8 3.01 0.661 3.07 0.675 3.15 0.690 3.07 0.940 3.19 0.944 3.32 0.948

L6×31⁄2×3⁄8 2.97 0.610 3.02 0.624 3.09 0.640 3.05 0.961 3.17 0.964 3.31 0.967

L × 1⁄2×5⁄16 2.97 0.610 3.02 0.624 3.09 0.639 3.03 0.960 3.16 0.963 3.29 0.966

L5×5×7⁄8 2.87 0.844 2.97 0.855 3.09 0.865 2.87 0.844 2.97 0.855 3.09 0.865

L × ×3⁄4 2.85 0.839 2.96 0.850 3.07 0.861 2.85 0.839 2.96 0.850 3.07 0.861

L × ×1⁄2 2.86 0.830 2.96 0.841 3.07 0.852 2.86 0.830 2.96 0.841 3.07 0.852

L × ×3⁄8 2.87 0.824 2.96 0.835 3.07 0.846 2.87 0.824 2.96 0.835 3.07 0.846

L × ×5⁄16 2.87 0.821 2.97 0.833 3.07 0.844 2.87 0.821 2.97 0.833 3.07 0.844

*See LRFD Specification Section E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

TORSION PROPERTIES 1 - 173

FLEXURAL-TORSIONAL PROPERTIES

Double Angles

Long Legs Vertical Short Legs Vertical

Back to Back of Angles, in. Back to Back of Angles, in.

0 3⁄ 3⁄ 0 3⁄ 3⁄

8 4 8 4

Designation ro* H* ro* H* ro* H* ro* H* ro* H* ro* H*

L5×31⁄2×3⁄4 2.50 0.697 2.58 0.715 2.67 0.734 2.61 0.943 2.74 0.948 2.87 0.953

L5×31⁄2×1⁄2 2.51 0.685 2.59 0.703 2.67 0.722 2.59 0.936 2.71 0.941 2.84 0.947

L5×31⁄2×3⁄8 2.52 0.682 2.59 0.699 2.67 0.717 2.58 0.932 2.70 0.938 2.83 0.943

L5×31⁄2×5⁄16 2.53 0.679 2.60 0.695 2.68 0.713 2.58 0.930 2.70 0.936 2.82 0.942

L5×3×1⁄2 2.45 0.626 2.52 0.645 2.59 0.665 2.55 0.962 2.69 0.965 2.82 0.969

L3×3×3⁄8 2.46 0.623 2.52 0.641 2.60 0.661 2.54 0.959 2.67 0.963 2.80 0.966

L3×3×5⁄16 2.47 0.621 2.53 0.638 2.60 0.657 2.54 0.957 2.67 0.961 2.80 0.965

L3×3×1⁄4 2.48 0.618 2.54 0.634 2.61 0.653 2.53 0.956 2.66 0.960 2.79 0.964

L4×4×3⁄4 2.29 0.847 2.40 0.861 2.52 0.873 2.29 0.847 2.40 0.861 2.52 0.873

L3×3×5⁄8 2.29 0.839 2.40 0.853 2.51 0.867 2.29 0.839 2.40 0.853 2.51 0.867

L3×3×1⁄2 2.29 0.834 2.39 0.848 2.50 0.862 2.29 0.834 2.39 0.848 2.50 0.862

L3×3×3⁄8 2.29 0.827 2.39 0.841 2.50 0.855 2.29 0.827 2.39 0.841 2.50 0.855

L3×3×5⁄16 2.29 0.824 2.39 0.838 2.50 0.852 2.29 0.824 2.39 0.838 2.50 0.852

L3×3×1⁄4 2.29 0.823 2.39 0.837 2.49 0.850 2.29 0.823 2.39 0.837 2.49 0.850

L4×31⁄2×1⁄2 2.15 0.783 2.24 0.801 2.34 0.818 2.17 0.881 2.29 0.892 2.41 0.903

L5×31⁄2×3⁄8 2.15 0.774 2.24 0.792 2.34 0.809 2.17 0.875 2.28 0.887 2.40 0.898

L5×31⁄2×5⁄16 2.15 0.774 2.24 0.791 2.34 0.808 2.17 0.872 2.28 0.884 2.40 0.895

L5×31⁄2×1⁄4 2.16 0.770 2.24 0.787 2.34 0.805 2.17 0.870 2.28 0.882 2.39 0.893

L4×3×1⁄2 2.04 0.719 2.12 0.740 2.22 0.762 2.10 0.924 2.22 0.933 2.35 0.940

L3×3×3⁄8 2.04 0.714 2.12 0.735 2.21 0.757 2.09 0.919 2.21 0.928 2.34 0.935

L3×3×5⁄16 2.05 0.710 2.13 0.731 2.22 0.752 2.09 0.917 2.21 0.925 2.33 0.933

L3×3×1⁄4 2.06 0.706 2.13 0.726 2.22 0.747 2.09 0.914 2.20 0.923 2.33 0.931

L31⁄2×31⁄2×3⁄8 2.00 0.831 2.10 0.847 2.22 0.862 2.00 0.831 2.10 0.847 2.22 0.862

L31⁄2×31⁄2×1⁄4 2.01 0.824 2.10 0.839 2.21 0.855 2.01 0.824 2.10 0.839 2.21 0.855

L31⁄2×3×3⁄8 1.86 0.771 1.95 0.791 2.06 0.812 1.89 0.884 2.00 0.897 2.13 0.909

L5×31⁄2×5⁄16 1.87 0.766 1.96 0.787 2.06 0.807 1.89 0.881 2.00 0.894 2.12 0.906

L5×31⁄2×1⁄4 1.87 0.762 1.96 0.782 2.06 0.803 1.89 0.878 2.00 0.891 2.12 0.903

L31⁄2×21⁄2×3⁄8 1.76 0.696 1.84 0.721 1.94 0.748 1.82 0.932 1.94 0.941 2.08 0.948

L31⁄2×31⁄2×1⁄4 1.77 0.691 1.85 0.715 1.93 0.740 1.81 0.927 1.93 0.936 2.06 0.944

L3×3×1⁄2 1.72 0.842 1.83 0.860 1.95 0.877 1.72 0.842 1.83 0.860 1.95 0.877

L3×3×3⁄8 1.72 0.834 1.82 0.852 1.94 0.869 1.72 0.834 1.82 0.852 1.94 0.869

L3×3×5⁄16 1.72 0.830 1.82 0.848 1.93 0.866 1.72 0.830 1.82 0.848 1.93 0.866

L3×3×1⁄4 1.72 0.825 1.82 0.844 1.93 0.862 1.72 0.825 1.82 0.844 1.93 0.862

L3×3×3⁄16 1.72 0.822 1.82 0.841 1.93 0.858 1.72 0.822 1.82 0.841 1.93 0.858

*See LRFD Specification Section E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 174 DIMENSIONS AND PROPERTIES

FLEXURAL-TORSIONAL PROPERTIES

Double Angles

Long Legs Vertical Short Legs Vertical

Back to Back of Angles, in. Back to Back of Angles, in.

0 3⁄ 3⁄ 0 3⁄ 3⁄

8 4 8 4

Designation ro* H* ro* H* ro* H* ro* H* ro* H* ro* H*

L3×21⁄2×3⁄8 1.58 0.763 1.67 0.789 1.78 0.813 1.61 0.896 1.73 0.910 1.86 0.922

L3×21⁄2×1⁄4 1.59 0.754 1.67 0.779 1.78 0.804 1.61 0.889 1.72 0.903 1.84 0.916

L3×21⁄2×3⁄16 1.59 0.750 1.67 0.775 1.77 0.800 1.61 0.885 1.72 0.899 1.84 0.912

L3×2×3⁄8 1.49 0.672 1.57 0.704 1.66 0.737 1.55 0.949 1.68 0.956 1.82 0.963

L3×2×5⁄16 1.50 0.667 1.57 0.698 1.66 0.730 1.55 0.946 1.68 0.954 1.82 0.961

L3×2×1⁄4 1.50 0.664 1.57 0.694 1.66 0.726 1.54 0.943 1.67 0.951 1.80 0.958

L3×2×3⁄16 1.50 0.661 1.57 0.690 1.66 0.721 1.54 0.940 1.66 0.949 1.80 0.956

L21⁄2×21⁄2×3⁄8 1.43 0.839 1.54 0.861 1.66 0.880 1.43 0.839 1.54 0.861 1.66 0.880

L21⁄2×21⁄2×5⁄16 1.43 0.834 1.54 0.856 1.66 0.876 1.43 0.834 1.54 0.856 1.66 0.876

L21⁄2×21⁄2×1⁄4 1.43 0.829 1.53 0.851 1.65 0.871 1.43 0.829 1.53 0.851 1.65 0.871

L21⁄2×21⁄2×3⁄16 1.43 0.825 1.53 0.847 1.65 0.867 1.43 0.825 1.53 0.847 1.65 0.867

L21⁄2×2×3⁄8 1.29 0.752 1.39 0.785 1.50 0.816 1.33 0.912 1.45 0.927 1.59 0.939

L3×21⁄2×5⁄16 1.30 0.746 1.39 0.779 1.50 0.810 1.33 0.908 1.45 0.923 1.58 0.935

L3×21⁄2×1⁄4 1.30 0.741 1.39 0.773 1.50 0.804 1.33 0.903 1.45 0.919 1.58 0.932

L3×21⁄2×3⁄16 1.31 0.736 1.39 0.767 1.49 0.798 1.32 0.899 1.44 0.915 1.57 0.928

L2×2×3⁄8 1.15 0.846 1.26 0.873 1.39 0.896 1.15 0.846 1.26 0.873 1.39 0.896

L3×2×5⁄16 1.15 0.840 1.26 0.867 1.38 0.890 1.15 0.840 1.26 0.867 1.38 0.890

L3×2×1⁄4 1.15 0.834 1.25 0.861 1.38 0.885 1.15 0.834 1.25 0.861 1.38 0.885

L3×2×3⁄16 1.15 0.828 1.25 0.855 1.37 0.880 1.15 0.828 1.25 0.855 1.37 0.880

L3×2×1⁄8 1.15 0.822 1.25 0.850 1.37 0.875 1.15 0.822 1.25 0.850 1.37 0.875

*See LRFD Specification Section E3.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

SURFACE AREAS AND BOX AREAS 1 - 175

SURFACE AREAS AND BOX AREAS

W shapes

Square feet per foot of length

Case A Case B Case C Case D Case A Case B Case C Case D

Desig- Desig-

nation nation

W44×335 11.0 12.4 8.67 10.0 W36×256 9.02 10.0 7.26 8.27

W44×290 11.0 12.3 8.59 9.91 W44×232 8.96 9.97 7.20 8.21

W44×262 10.9 12.2 8.53 9.84 W44×210 8.91 9.93 7.13 8.15

W44×230 10.9 12.2 8.46 9.78 W44×194 8.88 9.89 7.09 8.10

W44 W36×182 8.85 9.85 7.06 8.07

W40×593 10.9 12.3 8.56 9.95 W36×170 8.82 9.82 7.03 8.03

W44×503 10.7 12.1 8.38 9.75 W36×160 8.79 9.79 7.00 8.00

W44×431 10.5 11.9 8.23 9.58 W36×150 8.76 9.76 6.97 7.97

W44×372 10.4 11.8 8.11 9.45 W36×135 8.71 9.70 6.92 7.92

W44×321 10.3 11.6 8.01 9.33

W44×297 10.3 11.6 7.96 9.28 W33×354 9.66 11.0 7.27 8.61

W44×277 10.3 11.6 7.93 9.25 W36×318 9.58 10.9 7.19 8.52

W44×249 10.2 11.5 7.88 9.19 W36×291 9.52 10.8 7.13 8.46

W44×215 10.2 11.5 7.81 9.12 W36×263 9.46 10.8 7.07 8.39

W44×199 10.1 11.4 7.76 9.07 W36×241 9.42 10.7 7.02 8.34

W44×174 10.0 11.3 7.68 8.99 W36×221 9.38 10.7 6.97 8.29

W33×201 9.33 10.6 6.93 8.24

W40×466 9.79 10.8 8.13 9.18

W44×392 9.61 10.6 7.96 8.99 W33×169 8.30 9.26 6.60 7.55

W44×331 9.47 10.5 7.81 8.83 W36×152 8.27 9.23 6.55 7.51

W44×278 9.35 10.3 7.69 8.69 W36×141 8.23 9.19 6.51 7.47

W44×264 9.32 10.3 7.66 8.66 W36×130 8.20 9.15 6.47 7.43

W44×235 9.28 10.3 7.61 8.60 W36×118 8.15 9.11 6.43 7.39

W36×211 9.22 10.2 7.55 8.53

W36×183 9.17 10.2 7.48 8.47 W30×477 9.30 10.6 7.02 8.35

W36×167 9.11 10.1 7.42 8.40 W36×391 9.11 10.4 6.83 8.13

W36×149 9.05 10.0 7.35 8.34 W36×326 8.96 10.2 6.68 7.96

W36×292 8.88 10.2 6.61 7.88

W36×848 11.1 12.6 8.59 10.1 W36×261 8.81 10.1 6.53 7.79

W36×798 11.0 12.5 8.49 9.99 W36×235 8.75 10.0 6.47 7.73

W36×650 10.7 12.1 8.21 9.67 W36×211 8.71 9.97 6.42 7.67

W36×527 10.4 11.9 7.97 9.41 W36×191 8.66 9.92 6.37 7.62

W36×439 10.3 11.7 7.79 9.20 W36×173 8.62 9.87 6.32 7.57

W36×393 10.2 11.6 7.70 9.10

W36×359 10.1 11.5 7.63 9.02 W30×148 7.53 8.40 5.99 6.86

W36×328 10.0 11.4 7.57 8.95 W36×132 7.49 8.37 5.93 6.81

W36×300 9.99 11.4 7.51 8.90 W36×124 7.47 8.34 5.90 6.78

W36×280 9.95 11.3 7.47 8.85 W36×116 7.44 8.31 5.88 6.75

W36×260 9.90 11.3 7.42 8.80 W36×108 7.41 8.28 5.84 6.72

W36×245 9.87 11.2 7.39 8.77 W36×99 7.37 8.25 5.81 6.68

W36×230 9.84 11.2 7.36 8.73 W36×90 7.35 8.22 5.79 6.66

Case A: Shape perimeter, minus one flange surface.

Case B: Shape perimeter.

Case C: Box perimeter, equal to one flange surface plus twice the depth.

Case D: Box perimeter, equal to two flange surfaces plus twice the depth.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 176 DIMENSIONS AND PROPERTIES

SURFACE AREAS AND BOX AREAS

W shapes

Square feet per foot of length

Case A Case B Case C Case D Case A Case B Case C Case D

Desig- Desig-

nation nation

W27×539 8.82 10.09 6.69 7.96 W21×201 6.75 7.80 4.89 5.93

W ×448 8.61 9.86 6.48 7.73 W18×182 6.69 7.74 4.83 5.87

W ×368 8.42 9.64 6.29 7.51 W18×166 6.65 7.68 4.78 5.82

W ×307 8.27 9.47 6.14 7.34 W18×147 6.61 7.66 4.72 5.76

W ×281 8.21 9.40 6.08 7.27 W18×132 6.57 7.61 4.68 5.71

W ×258 8.15 9.34 6.02 7.21 W18×122 6.54 7.57 4.65 5.68

W ×235 8.09 9.27 5.96 7.14 W18×111 6.51 7.54 4.61 5.64

W ×217 8.04 9.22 5.91 7.09 W18×101 6.48 7.50 4.58 5.61

W ×194 7.98 9.15 5.85 7.02

W ×178 7.95 9.12 5.81 6.98 W21×93 5.54 6.24 4.31 5.01

W ×161 7.91 9.08 5.77 6.94 W18×83 5.50 6.20 4.27 4.96

W ×146 7.87 9.03 5.73 6.89 W18×73 5.47 6.16 4.23 4.92

W ×68 5.45 6.14 4.21 4.90

W27×129 6.92 7.75 5.44 6.27 W18×62 5.42 6.11 4.19 4.87

W ×114 6.88 7.72 5.39 6.23

W ×102 6.85 7.68 5.35 6.18 W21×57 5.01 5.56 4.06 4.60

W ×94 6.82 7.65 5.32 6.15 W18×50 4.97 5.51 4.02 4.56

W ×84 6.78 7.61 5.28 6.11 W18×44 4.94 5.48 3.99 4.53

W24×492 8.07 9.25 6.12 7.29 W18×311 6.41 7.41 4.72 5.72

W ×408 7.86 9.01 5.91 7.06 W18×283 6.32 7.31 4.63 5.62

W ×335 7.66 8.79 5.71 6.84 W18×258 6.24 7.23 4.56 5.54

W ×279 7.51 8.62 5.56 6.67 W18×234 6.17 7.14 4.48 5.45

W ×250 7.44 8.54 5.49 6.59 W18×211 6.10 7.06 4.41 5.37

W ×229 7.38 8.47 5.43 6.52 W18×192 6.03 6.99 4.35 5.30

W ×207 7.32 8.40 5.37 6.45 W18×175 5.97 6.92 4.29 5.24

W ×192 7.27 8.35 5.32 6.40 W18×158 5.92 6.86 4.23 5.17

W ×176 7.23 8.31 5.28 6.35 W18×143 5.87 6.81 4.18 5.12

W ×162 7.22 8.30 5.25 6.33 W18×130 5.83 6.76 4.14 5.07

W ×146 7.17 8.24 5.20 6.27

W ×131 7.12 8.19 5.15 6.22 W18×119 5.81 6.75 4.10 5.04

W ×117 7.08 8.15 5.11 6.18 W18×106 5.77 6.70 4.06 4.99

W ×104 7.04 8.11 5.07 6.14 W18×97 5.74 6.67 4.03 4.96

W ×86 5.70 6.62 3.99 4.91

W24×103 6.18 6.93 4.84 5.59 W18×76 5.67 6.59 3.95 4.87

W ×94 6.16 6.92 4.81 5.56

W ×84 6.12 6.87 4.77 5.52 W18×71 4.85 5.48 3.71 4.35

W ×76 6.09 6.84 4.74 5.49 W18×65 4.82 5.46 3.69 4.32

W ×68 6.06 6.80 4.70 5.45 W18×60 4.80 5.43 3.67 4.30

W ×55 4.78 5.41 3.65 4.27

W24×62 5.57 6.16 4.54 5.13 W18×50 4.76 5.38 3.62 4.25

W ×55 5.54 6.13 4.51 5.10

Case A: Shape perimeter, minus one flange surface.

Case B: Shape perimeter.

Case C: Box perimeter, equal to one flange surface plus twice the depth.

Case D: Box perimeter, equal to two flange surfaces plus twice the depth.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

SURFACE AREAS AND BOX AREAS 1 - 177

SURFACE AREAS AND BOX AREAS

W shapes

Square feet per foot of length

Case A Case B Case C Case D Case A Case B Case C Case D

Desig- Desig-

nation nation

W18×46 4.41 4.91 3.51 4.02 W14×82 4.75 5.59 3.23 4.07

W ×40 4.38 4.88 3.48 3.99 W14×74 4.72 5.56 3.20 4.04

W ×35 4.34 4.84 3.45 3.95 W14×68 4.69 5.53 3.18 4.01

W ×61 4.67 5.50 3.15 3.98

W16×100 5.28 6.15 3.70 4.57

W ×89 5.24 6.10 3.66 4.52 W14×53 4.19 4.86 2.99 3.66

W ×77 5.19 6.05 3.61 4.47 W14×48 4.16 4.83 2.97 3.64

W ×67 5.16 6.01 3.57 4.43 W14×43 4.14 4.80 2.94 3.61

W16×57 4.39 4.98 3.33 3.93 W14×38 3.93 4.50 2.91 3.48

W ×50 4.36 4.95 3.30 3.89 W14×34 3.91 4.47 2.89 3.45

W ×45 4.33 4.92 3.27 3.86 W14×30 3.89 4.45 2.87 3.43

W ×40 4.31 4.89 3.25 3.83

W ×36 4.28 4.87 3.23 3.81 W14×26 3.47 3.89 2.74 3.16

W ×22 3.44 3.86 2.71 3.12

W16×31 3.92 4.39 3.11 3.57

W ×26 3.89 4.35 3.07 3.53 W12×336 5.77 6.88 3.92 5.03

W ×305 5.67 6.77 3.82 4.93

W14×808 7.74 9.28 5.35 6.90 W14×279 5.59 6.68 3.74 4.83

W ×730 7.61 9.10 5.23 6.72 W14×252 5.50 6.58 3.65 4.74

W ×665 7.46 8.93 5.08 6.55 W14×230 5.43 6.51 3.58 4.66

W ×605 7.32 8.77 4.94 6.39 W14×210 5.37 6.43 3.52 4.58

W ×550 7.19 8.62 4.81 6.24 W14×190 5.30 6.36 3.45 4.51

W ×500 7.07 8.49 4.68 6.10 W14×170 5.23 6.28 3.39 4.43

W ×455 6.96 8.36 4.57 5.98 W14×152 5.17 6.21 3.33 4.37

W ×136 5.12 6.15 3.27 4.30

W14×426 6.89 8.28 4.50 5.89 W14×120 5.06 6.09 3.21 4.24

W ×398 6.81 8.20 4.43 5.81 W14×106 5.02 6.03 3.17 4.19

W ×370 6.74 8.12 4.36 5.73 W14×96 4.98 5.99 3.13 4.15

W ×342 6.67 8.03 4.29 5.65 W14×87 4.95 5.96 3.10 4.11

W ×311 6.59 7.94 4.21 5.56 W14×79 4.92 5.93 3.07 4.08

W ×283 6.52 7.86 4.13 5.48 W14×72 4.89 5.90 3.05 4.05

W ×257 6.45 7.78 4.06 5.40 W14×65 4.87 5.87 3.02 4.02

W ×233 6.38 7.71 4.00 5.32

W ×211 6.32 7.64 3.94 5.25 W12×58 4.39 5.22 2.87 3.70

W ×193 6.27 7.58 3.89 5.20 W14×53 4.37 5.20 2.84 3.68

W ×176 6.22 7.53 3.84 5.15

W ×159 6.18 7.47 3.79 5.09 W12×50 3.90 4.58 2.71 3.38

W ×145 6.14 7.43 3.76 5.05 W14×45 3.88 4.55 2.68 3.35

W ×40 3.86 4.52 2.66 3.32

W14×132 5.93 7.16 3.67 4.90

W ×120 5.90 7.12 3.64 4.86

W ×109 5.86 7.08 3.60 4.82

W ×99 5.83 7.05 3.57 4.79

W ×90 5.81 7.02 3.55 4.76

Case A: Shape perimeter, minus one flange surface.

Case B: Shape perimeter.

Case C: Box perimeter, equal to one flange surface plus twice the depth.

Case D: Box perimeter, equal to two flange surfaces plus twice the depth.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

1 - 178 DIMENSIONS AND PROPERTIES

SURFACE AREAS AND BOX AREAS

W shapes

Square feet per foot of length

Case A Case B Case C Case D Case A Case B Case C Case D

Desig- Desig-

nation nation

W12×35 3.63 4.18 2.63 3.18 W8×21 2.61 3.05 1.82 2.26

W12×30 3.60 4.14 2.60 3.14 W8×18 2.59 3.03 1.79 2.23

W12×26 3.58 4.12 2.58 3.12

W8×15 2.27 2.61 1.69 2.02

W12×22 2.97 3.31 2.39 2.72 W8×13 2.25 2.58 1.67 2.00

W12×19 2.95 3.28 2.36 2.69 W8×10 2.23 2.56 1.64 1.97

W12×16 2.92 3.25 2.33 2.66

W12×14 2.90 3.23 2.32 2.65 W6×25 2.49 3.00 1.57 2.08

W ×20 2.46 2.96 1.54 2.04

W10×112 4.30 5.17 2.76 3.63 W8×15 2.42 2.92 1.50 2.00

W12×100 4.25 5.11 2.71 3.57

W12×88 4.20 5.06 2.66 3.52 W6×16 1.98 2.31 1.38 1.72

W12×77 4.15 5.00 2.62 3.47 W8×12 1.93 2.26 1.34 1.67

W12×68 4.12 4.96 2.58 3.42 W8×9 1.90 2.23 1.31 1.64

W12×60 4.08 4.92 2.54 3.38

W12×54 4.06 4.89 2.52 3.35 W5×19 2.04 2.45 1.28 1.70

W12×49 4.04 4.87 2.50 3.33 W8×16 2.01 2.43 1.25 1.67

W10×45 3.56 4.23 2.35 3.02 W4×13 1.63 1.96 1.03 1.37

W12×39 3.53 4.19 2.32 2.98

W12×33 3.49 4.16 2.29 2.95

W10×30 3.10 3.59 2.23 2.71

W12×26 3.08 3.56 2.20 2.68

W12×22 3.05 3.53 2.17 2.65

W10×19 2.63 2.96 2.04 2.38

W12×17 2.60 2.94 2.02 2.35

W12×15 2.58 2.92 2.00 2.33

W12×12 2.56 2.89 1.97 2.30

W8×67 3.42 4.11 2.19 2.88

W8×58 3.37 4.06 2.14 2.83

W8×48 3.32 4.00 2.09 2.77

W8×40 3.28 3.95 2.05 2.72

W8×35 3.25 3.92 2.02 2.69

W8×31 3.23 3.89 2.00 2.67

W8×28 2.87 3.42 1.89 2.43

W8×24 2.85 3.39 1.86 2.40

Case A: Shape perimeter, minus one flange surface.

Case B: Shape perimeter.

Case C: Box perimeter, equal to one flange surface plus twice the depth.

Case D: Box perimeter, equal to two flange surfaces plus twice the depth.

AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Вам также может понравиться

- ESM 425 Lab Wk1 Units WatershedsДокумент5 страницESM 425 Lab Wk1 Units WatershedsOcto ChowОценок пока нет

- D502Документ5 страницD502Gustavo Adolfo Quintero RuizОценок пока нет

- API-650 Design Procedure ExampleДокумент21 страницаAPI-650 Design Procedure Examplegdwvcd93% (14)

- HY 200 - ESR-3187 Hilti HIT-ZДокумент38 страницHY 200 - ESR-3187 Hilti HIT-Zdrac_dracОценок пока нет

- Icbo Es Report-Er2078pДокумент65 страницIcbo Es Report-Er2078peltorro-tОценок пока нет

- AREMA Estructuras ART. 2.30 Al 39Документ18 страницAREMA Estructuras ART. 2.30 Al 39pepegrillo891100% (1)

- Solver Vinnakota Cap 11 PDFДокумент57 страницSolver Vinnakota Cap 11 PDFJunior Tejada SanchezОценок пока нет

- RC 19Документ8 страницRC 19ianiroy13Оценок пока нет

- Ebook Introduction Gala4.1Документ24 страницыEbook Introduction Gala4.1Lê Ngọc-HàОценок пока нет

- Recommendations For Shear Lag Factors For Longitudinally Welded Tension MembersДокумент22 страницыRecommendations For Shear Lag Factors For Longitudinally Welded Tension MembersSergioAlcantaraОценок пока нет

- The Next Generation of Codes For Seismic Isolation in The United States and Regulatory Barriers To Seismic Isolation DevelopmentДокумент12 страницThe Next Generation of Codes For Seismic Isolation in The United States and Regulatory Barriers To Seismic Isolation DevelopmentfaisaladeОценок пока нет

- Wide Flange Beam DataДокумент10 страницWide Flange Beam DataapgoslingОценок пока нет

- Gold 09 11 SCR PDFДокумент64 страницыGold 09 11 SCR PDFRaul Mendoza Subia100% (1)

- Netxknx Opc 3 - 5 - 4 EngДокумент93 страницыNetxknx Opc 3 - 5 - 4 Engtai_sao_khong_1307Оценок пока нет

- Design of Pallet Rack Upright Frames Subject To CompressionДокумент107 страницDesign of Pallet Rack Upright Frames Subject To CompressionssierroОценок пока нет

- AISI Standards For Cold-Formed Steel FramingДокумент19 страницAISI Standards For Cold-Formed Steel Framingnicole pampangaОценок пока нет

- Mathcad - Butter Worth PLCДокумент4 страницыMathcad - Butter Worth PLCRicardo AtaídeОценок пока нет

- ACI 318-14 Building Code Requirements For Structural Concrete. Units: In., PsiДокумент5 страницACI 318-14 Building Code Requirements For Structural Concrete. Units: In., PsiOscarCVОценок пока нет

- Center of Mass and Rigidity EtabsДокумент2 страницыCenter of Mass and Rigidity EtabsBejil Shrestha100% (1)

- Design Failure AnalysisДокумент8 страницDesign Failure AnalysisHamzaОценок пока нет

- Advanced Design of Concrete Structures - UPCДокумент5 страницAdvanced Design of Concrete Structures - UPCRodrigo LameirasОценок пока нет

- Advanced Structural Steel Design Advanced Structural Steel DesignДокумент10 страницAdvanced Structural Steel Design Advanced Structural Steel DesignMasudОценок пока нет

- 612 - ACI STRUCTURAL JOURNAL by Wiryanto Dewobroto PDFДокумент168 страниц612 - ACI STRUCTURAL JOURNAL by Wiryanto Dewobroto PDFchaval01Оценок пока нет

- Encased ColumnsДокумент14 страницEncased ColumnsjimmyfontanaОценок пока нет

- Rigid Frames - Compression & Buckling: NotationДокумент12 страницRigid Frames - Compression & Buckling: Notationdarebusi1Оценок пока нет

- Ej 2019 q3 Issue PDFДокумент58 страницEj 2019 q3 Issue PDFRonny HurtadoОценок пока нет

- Steel DeckДокумент13 страницSteel Deckrini100% (1)

- Unclassified Ad Number Limitation Changes TOДокумент837 страницUnclassified Ad Number Limitation Changes TOVo Dinh ThaoОценок пока нет

- Circular Column Design Based On ACI 318-14: Project: Client: Design By: Job No.: Date: Review byДокумент1 страницаCircular Column Design Based On ACI 318-14: Project: Client: Design By: Job No.: Date: Review byJuanAlfaroRodríguezОценок пока нет

- FIU Bridge Collapse Investigative ReportДокумент2 страницыFIU Bridge Collapse Investigative ReportGary DetmanОценок пока нет

- Baa2213 - Reinforced Concrete Design I 21516 PDFДокумент7 страницBaa2213 - Reinforced Concrete Design I 21516 PDFAizat HermanОценок пока нет

- D 243 AstmДокумент3 страницыD 243 AstmNuMbОценок пока нет

- Composite Steel JoistsДокумент10 страницComposite Steel Joistsv2299100% (1)

- Joist - Canam (05-2005)Документ122 страницыJoist - Canam (05-2005)lostprophet1301Оценок пока нет

- Light Gauge Galvanized Steel Framing: HomesteelДокумент18 страницLight Gauge Galvanized Steel Framing: HomesteelhalawallaОценок пока нет

- Use of Shear Lugs For Anchorage To Concrete: January 2009Документ9 страницUse of Shear Lugs For Anchorage To Concrete: January 2009Sandeep BhatiaОценок пока нет

- Sudden Collapse of The 27-Story Space Building in Medellin, Colombia, Yamin Et Al 2018Документ13 страницSudden Collapse of The 27-Story Space Building in Medellin, Colombia, Yamin Et Al 2018Tránsito SUDEN SASОценок пока нет

- Arcelormittal - Catalogo General de Tablestacas 2019 PDFДокумент64 страницыArcelormittal - Catalogo General de Tablestacas 2019 PDFCarloz JozeОценок пока нет

- ACI 350R Vs 318 - RevisedДокумент76 страницACI 350R Vs 318 - RevisedtroyscribdОценок пока нет

- CB Value Significance PDFДокумент5 страницCB Value Significance PDFArchitjОценок пока нет

- Structural Capacity and Failure Mechanisms of Transmission Towers Under High Intensity Wind LoadingДокумент9 страницStructural Capacity and Failure Mechanisms of Transmission Towers Under High Intensity Wind LoadingRm1262Оценок пока нет

- Section - 05520 - Handrails and RailingsДокумент3 страницыSection - 05520 - Handrails and RailingsNana DelgadoОценок пока нет

- AISC Design Guide 1 - Errata-Column Base Plates - 2nd Edition PDFДокумент6 страницAISC Design Guide 1 - Errata-Column Base Plates - 2nd Edition PDFसौरव डेОценок пока нет

- Behavior of Partially Encased Slender Composite Columns in Eccentric Loading by Saima Ali, Mahbuba Begum PDFДокумент10 страницBehavior of Partially Encased Slender Composite Columns in Eccentric Loading by Saima Ali, Mahbuba Begum PDFgulilero_yoОценок пока нет

- WinFlume Guide PDFДокумент17 страницWinFlume Guide PDFカーン アブドゥルラヒムОценок пока нет

- Postensioning TIANJINДокумент25 страницPostensioning TIANJINViviana Sofia100% (1)

- HB - 10 - 11 Ayudas de DiseñoДокумент32 страницыHB - 10 - 11 Ayudas de DiseñoSergio NinaОценок пока нет

- 4a. Nonlinear Structural Analysis For Seismic Design - Spring 2018 - v2Документ30 страниц4a. Nonlinear Structural Analysis For Seismic Design - Spring 2018 - v2Nguyen DuyОценок пока нет

- Structural Engineering VUДокумент6 страницStructural Engineering VUshan kumarОценок пока нет

- FMДокумент6 страницFMdist2235Оценок пока нет

- ArchBridgeBuckling PDFДокумент31 страницаArchBridgeBuckling PDFjayaramanrathnamОценок пока нет

- Seismic Masonry Guide 2nd Edition Oct 2018 R1 Split 4Документ71 страницаSeismic Masonry Guide 2nd Edition Oct 2018 R1 Split 4Eduardo Martinez CaleroОценок пока нет

- 2001 Darendeli - Normalized Shear Modulus and Damping PHD ThesisДокумент395 страниц2001 Darendeli - Normalized Shear Modulus and Damping PHD ThesisEderEnzoTapiaBañezОценок пока нет

- Beamanal (Metric)Документ1 страницаBeamanal (Metric)Tri TruongОценок пока нет

- Errata: Transportation OfficialsДокумент24 страницыErrata: Transportation OfficialsHector Enrique Reza ReyesОценок пока нет

- Shear KeyДокумент43 страницыShear KeyMd Shamsul IslamОценок пока нет

- Bracind of Steel Beams in Bridges PDFДокумент96 страницBracind of Steel Beams in Bridges PDFAndré Luiz NogueiraОценок пока нет

- 05-Mathcad Wall PilesДокумент17 страниц05-Mathcad Wall PilesIndika Jagath KumaraОценок пока нет

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОт EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОценок пока нет

- Wide Flange SizesДокумент18 страницWide Flange SizesKaloyОценок пока нет

- Steel Sections Std.Документ64 страницыSteel Sections Std.Sayavi Nicole Sayavi Nick100% (3)

- Wide FlangeДокумент8 страницWide FlangeEvangie PaguiriganОценок пока нет

- Mosclrfd (Beams)Документ7 страницMosclrfd (Beams)Hafiz ZulfajarОценок пока нет

- Drawing1 Layout2Документ1 страницаDrawing1 Layout2Raul Mendoza SubiaОценок пока нет

- Drawing1 Layout1Документ1 страницаDrawing1 Layout1Raul Mendoza SubiaОценок пока нет

- XS4921 2300XPC DC BroДокумент8 страницXS4921 2300XPC DC BroRaul Mendoza Subia100% (1)

- XS4921 2300XPC DC BroДокумент8 страницXS4921 2300XPC DC BroRaul Mendoza Subia100% (1)

- TFT SDK ManualДокумент107 страницTFT SDK ManualRenier ServenОценок пока нет

- Diagnosis and Testing: Four Wheel Drive (4WD) Systems - Electronic ShiftДокумент38 страницDiagnosis and Testing: Four Wheel Drive (4WD) Systems - Electronic ShiftLojan Coronel José Humberto100% (1)

- B28 VivaДокумент27 страницB28 VivashubhamОценок пока нет

- Earthquake EnginneringДокумент11 страницEarthquake EnginneringkkkОценок пока нет

- Tarea Stereonet-HelpДокумент32 страницыTarea Stereonet-HelpJosueHuillcaPortilloОценок пока нет

- Proportional Directional Valves: Series LVS08 and LVS12 - Preferred Products ProgrammeДокумент66 страницProportional Directional Valves: Series LVS08 and LVS12 - Preferred Products ProgrammealeksandrОценок пока нет

- Design of Machine Elements II PDFДокумент6 страницDesign of Machine Elements II PDFRavi RanjanОценок пока нет

- Pedestrian Safety AnalysisДокумент12 страницPedestrian Safety Analysispartha sreekarОценок пока нет

- The Effect of Axial Flow Velocity On Annular Gap Windage Power LossДокумент12 страницThe Effect of Axial Flow Velocity On Annular Gap Windage Power Losskien nguyenОценок пока нет

- Yr 6 Maths G-6 E P-I PDFДокумент168 страницYr 6 Maths G-6 E P-I PDFdina171279Оценок пока нет

- DefaultДокумент49 страницDefaultmaruka33100% (1)

- Calcium Ethoxide As A Solid Base Catalyst For The PDFДокумент15 страницCalcium Ethoxide As A Solid Base Catalyst For The PDFHelmi BaharОценок пока нет

- BMG Idle CatlogueДокумент20 страницBMG Idle Catloguechintan mistryОценок пока нет

- UNIT1-Demand Management in Supply Chain Demand Planning and ForecastingДокумент20 страницUNIT1-Demand Management in Supply Chain Demand Planning and Forecastingshenbha50% (2)

- ISG Services OverviewДокумент12 страницISG Services OverviewsdonОценок пока нет

- Unit 10 Lesson 3 Activity Guide - Unreasonable TimeДокумент2 страницыUnit 10 Lesson 3 Activity Guide - Unreasonable Timetrivediom427Оценок пока нет

- Sc3 Lecture Short CKT Currents BMR Feb.03, 2021Документ11 страницSc3 Lecture Short CKT Currents BMR Feb.03, 2021Khizer AminОценок пока нет

- Cobol Language Fundamentals: Structured COBOL Programming, Stern & Stern, 9th Ed ItionДокумент53 страницыCobol Language Fundamentals: Structured COBOL Programming, Stern & Stern, 9th Ed ItionAsk NameОценок пока нет

- Kraken Intelligence's Taproot Primer - An Upgrade For The AgesДокумент37 страницKraken Intelligence's Taproot Primer - An Upgrade For The AgesT. CC ElficОценок пока нет

- ReadmeRC8007 PDFДокумент2 страницыReadmeRC8007 PDFمنير أحمدОценок пока нет

- Midterm rp - Nguyễn Phú Minh Nhật - 20202795Документ1 страницаMidterm rp - Nguyễn Phú Minh Nhật - 20202795Minh Nhật100% (1)

- Deductive ReasoningДокумент2 страницыDeductive ReasoningMariel C. BombitaОценок пока нет

- Back To Basics in Optical Communications TechnologyДокумент178 страницBack To Basics in Optical Communications TechnologyAyanОценок пока нет

- Inform: Extending PhoenicsДокумент42 страницыInform: Extending PhoenicsrsigorОценок пока нет

- Condensation and BoilingДокумент14 страницCondensation and BoilingCrislyn Akilit Bayawa100% (1)

- Grade 9 Cells and Cell Movements Formative WorksheetДокумент8 страницGrade 9 Cells and Cell Movements Formative WorksheetHari PatelОценок пока нет

- IECEx INE 12.0010X 002Документ9 страницIECEx INE 12.0010X 002Marcos SiqueiraОценок пока нет

- Yohimbine InjectionДокумент1 страницаYohimbine InjectionKasidit SornchaiОценок пока нет