Академический Документы

Профессиональный Документы

Культура Документы

The Case For Nitrogen Inerting of Flammable and Combustible Liquids

Загружено:

nrmello0 оценок0% нашли этот документ полезным (0 голосов)

60 просмотров4 страницыInertização com Nitrogênio

Оригинальное название

En Processing Solutions for the Process Industries

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документInertização com Nitrogênio

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

60 просмотров4 страницыThe Case For Nitrogen Inerting of Flammable and Combustible Liquids

Загружено:

nrmelloInertização com Nitrogênio

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

As seen in the May 2015 issue

The case for nitrogen inerting of

flammable and combustible liquids

Protection against gas, oxygen and ignition coming together —

unexpectedly, explosively

By Nathan Bowser and Derek Miller

Even when required practices possible flammable environments,

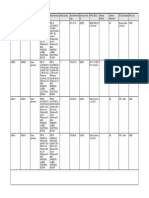

Table 1: Common Static-

such as bonding and grounding are particularly given unexpected or Accumulating Flammable

followed, flammable and combusti- off-spec operating conditions. Due Liquids That May Form

ble liquids can present the process to an abundance of variables that Ignitable Vapor-Air Mixtures

industries with complex, persistent may cause an ignition — e.g., static

hazards. electricity or other unforeseen spark VM&P Naptha

NFPA Class II and Class III com- generators — a focus on minimizing

bustible liquids heated above flash oxygen concentration by inerting is Cyclohexane

point, nonconductive flammable necessary in many cases.

and combustible liquids and special The U.S. Chemical Safety Board n-Heptane

situations — such as switch loading (USCSB) notes how complex, per-

— present significant risks equal sistently present and under-commu- Benzene

to those presented by flammable nicated flammable and combustible

liquids such as NFPA Class IB and material hazards can be. It points Toluene

IC and API Intermediate Vapor out that standard protections such

Pressure products. as bonding and grounding might n-Hexane

A review of several industrial fires not prevent accidents in cases

and explosions includes examples involving nonconductive flammable Xylene

of hazards that were either unmit- liquids, which include many com-

igated or improperly controlled. mon materials (see Table 1). Ethyl Benzene

The examples demonstrate the role Inerting practices mitigate these

proper inerting applications can hazards, and are a benefit partic- Styrene

play in hazard protection. ularly where it is challenging or

It’s impossible to eliminate all impractical to eliminate all ignition Source: US CSB Case Study on Barton

possible ignition sources in all sources. Solvents Explosion (No. 2007-06-I-KS)

Petrochemical Industry

Done properly, inerting prevents transfer rag wax from the heated air (21 percent), adequate to sup-

fires and explosions above and holding tanks. This same nitrogen port combustion. Given this oxygen

beyond that of normal bonding and system, properly used, could have concentration and the flammable

grounding and can even protect avoided explosion of the rag-wax rag-wax vapors in the holding ves-

product quality. holding vessel. sels, two of the three elements nec-

Unfortunately, the facility nitrogen essary for a fire were present.

Heated above flash point generator pressure occasionally When the third element—an igni-

Contributing factors in an explo- dropped below that required to tion source—manifested itself, the

sion at a polyethylene wax-process- transfer the rag wax. To maintain inevitable result was the accident

ing facility included combustible sufficient pressure to sustain opera- described.

liquid heated above flash point, tions, a compressed-air connection Many industrial accidents involve

improper nitrogen-inerting system downstream of the nitrogen gener- root causes that are occasional-

operation and improper pres- ator allowed mixing compressed air ly unique, but often unforeseen

sure-vessel alterations. The explo- with the nitrogen stream. because no one is consistently

sion caused structural damage up “overlooking.”

to one-quarter of a mile away from Investigation determination Done correctly, inerting can pre-

the plant. Investigation determined that the vent the escalations that lead to

Processing polyethylene wax nitrogen system typically generated further failures. Inerting the rag wax

includes removing impurities, 92 - 96 percent nitrogen with 4 - 8 holding vessels may have prevent-

referred to as “rag,” where the rag percent oxygen. Post-accident gas ed the flash-back into a vessel and

wax is heated to about 300 F using samples taken downstream of the the catastrophe that immediately

holding-tank steam piping. Post- generator and compressed-air con- ensued.

accident testing by the CSB found nection tested 82-percent nitrogen Something safer than the com-

the rag wax to have a flash point with 18-percent oxygen. pressed air connection, such as

of 230 F, which classifies it as an USCSB found this oxygen concen- liquid nitrogen backup or a differ-

NFPA Class IIIB combustible liquid. tration, although lower than that of ent generator system, would have

Heating the material above flash

point generated sufficient vapor to

produce an ignitable environment,

when mixed with a sufficient con-

centration of oxygen.

When failure of a weld on a pres-

surized holding tank led to spark

generation, it initiated a flame that

flashed back into the vessel, result-

ing in an internal deflagration and

vessel failure.

The accident’s several root caus-

es included improper rag-wax

holding-vessel inerting. The facility

generated nitrogen to prevent wax

oxidation, as well as pneumatically

Petrochemical Industry

precluded attaining oxygen levels static electricity. Decay of that static hazard but, in many cases, it may

sufficient for combustion. Matching charge depends on the liquid’s con- not be enough.

an inert gas supply system to the ductivity and dielectric constant, so Although the USCSB determined

process utilization rates and flow that even the liquid surface in con- the loose linkage was the most

patterns is important and can be tact with a bonded and grounded likely spark location, a spark from a

accomplished either by an on-site tank wall can have static potential. brush discharge could not be ruled

generator, liquid supply, or combi- The fire and explosion occurred out. According to Britton, brush

nation of both. while a tanker-trailer was loading discharges can occur even when

naphtha into an above-ground stor- equipment is properly bonded

Non-conductive liquids age tank. Witnesses confirm the and grounded during loading and

Another noteworthy incident tanker-trailer, pump, piping, and unloading operations. In this case,

involving unexpected spark gen- storage tank were all bonded and two legs of the fire triangle — fuel

eration, ignition, and explosion grounded at the time. The tank and an ignition source — can be

occurred in a storage tank contain- included a level float with a loose present, and a focus on eliminating

ing Varnish Makers’ and Painters’ linkage that could interrupt ground- the oxygen content is needed. The

naphtha. The naphtha’s flash point ing by slightly separating near the USCSB specifically noted in this

was found to be 58 F, and USCSB float. incident investigation that extra

determined that at the handling precautions should be taken by

temperature during the incident What had transpired companies that store, transfer, and

(approximately 77 F), there was like- USCSB determined that static handle nonconductive flammable

ly an ignitable mixture in the tank- charge accumulation occurred on liquids due to these risks.

head space. Many materials, such the nonconductive liquid surface For those companies, inerting

as NFPA Class IB and IC flammable inside the tank and that a spark, solutions exist to protect against

liquids, and API Intermediate Vapor likely generated by the loose the unexpected. Storage tanks

Pressure Products, are capable of linkage and intermittent loss of can be blanketed using a form of

evolving flammable vapor-air mix- grounding, ignited the flammable concentration or pressure control,

tures at ambient conditions. vapor-air mixture in the tank head which can be more economical than

According to Britton, the naph- space. The result was a fire and blanketing via continuous purging.

tha involved also had a low electri- explosion that destroyed the tank Based on the material’s limiting oxy-

cal conductivity of 3 picosiemens farm and sent eleven residents and gen concentration, process operat-

per meter (pS/m), which allowed one firefighter for medical treat- ing pattern and flow rate needs, an

for a potentially hazardous accumu- ment. inert-gas purity and supply mode

lation of static electricity. Materials A key investigation finding was (or combination of supply modes)

with conductivities below 100 pS/m that the tank had an ignitable can be recommended. Nitrogen is

are generally considered to be vapor-air mixture in its head space. the most commonly used inerting

non-conductive. Many very com- Proper inerting techniques could gas, but carbon dioxide or argon

mon liquids fall within this category have mitigated this hazard by can be used where nitrogen is not

(see Table 1). reducing oxygen concentration to appropriate.

Processing these liquid materials below ignition-support levels. As

through piping, tubing, or filters; previously mentioned, bonding and Those special cases

splash filling; or stirring with splash- grounding typically employed to Several additional, special cases

ing can cause them to accumulate mitigate static- charge accumulation present significant flammability haz-

Petrochemical Industry

ards. Examples include off-gassing since any static charge build-up will out additional oxygen. Therefore,

of abnormal volatile components not be bled off as easily via bonding proper design of an inerting system

in a low-vapor pressure liquid; fine and grounding. This practice has and its supply mode are based on

droplets, mist, or foam on the liq- resulted in numerous fires in indus- the facility, processes, and hazards

uid surface; processing liquids at try. Sufficient vessel inerting prior at hand. Experts in applying inert

non-standard temperatures or pres- to loading the low-vapor pressure gas solutions are essential resourc-

sures capable of creating ignitable liquid can protect against these haz- es when designing an application

vapors; or practices such as switch ards by eliminating the oxygen con- and can help facilities improve their

loading. tent as well as the ignitable vapors understanding as well as their pro-

“Switch loading,” as defined by from the previous liquid. cess safety.

API 2003, refers to the practice of

loading a low-vapor pressure liquid Final words Nathan Bowser is an Industrial

into a container, e.g., trailer, tank or Combustible liquids heated above Gases Applications Engineer at Air

vessel, which previously contained their flash point, nonconductive Products covering the chemical pro-

a high or intermediate vapor pres- flammable and combustible liquids, cessing, biotech, rubber, and plastics

sure product. The hazard exists and special situations such as switch industries.

because the head space, which is loading present significant risks Derek Miller is Process Safety

often above the upper-flammability that warrant additional precautions. Technical Director at Air Products.

limit with the high or intermediate Inerting is a powerful and flexible He has responsibility for the meth-

vapor-pressure product, may drop solution that can mitigate fires and ods and tools used to manage pro-

into the flammable range while load- explosions for these situations. Inert cess safety hazards associated with

ing the low-vapor pressure product. gases can present the risk of asphyx- the production and application of

In the event of a spark or static iation if not used properly. Therefore the company’s gas and chemical

discharge from liquid loading, the safe handling procedures must be products.

flammable mixture in the head space understood and followed. In addi-

could ignite, resulting in fire, explo- tion, materials such as ethylene

sion or both. Switch loading of non- oxide contain oxygen in the mole-

conductive liquids increases this risk cule that can yield flammability, with-

For more information, please contact us at:

Corporate Headquarters Asia Europe

Air Products and Chemicals, Inc. Air Products Asia, Inc. Air Products PLC

7201 Hamilton Boulevard Floor 4&5, Building 72 2 Millennium Gate

Allentown, PA 18195-1501 U.S.A. Lane 887, Zu Chong Zhi Road Westmere Drive

T 800-654-4567 or 610-706-4730 Zhangjiang Hi-tech Park Crewe CW16AP

T 514-353-4331 (Francais) Shanghai, China United Kingdom

F 800-272-4449 T +86-21-3896-2000 T +44(0)800 389 0202

gigmrktg@airproducts.com F +86-21-5080-5575 F +44-1932-258652

Merchant Gases Hotline: 400-888-7662 apbulkuk@airproducts.com

tell me more

airproducts.com/inert

©Air Products and Chemicals, Inc., 2015 312-15-020-US

Вам также может понравиться

- P&id NGSS PDFДокумент7 страницP&id NGSS PDFHBNBILОценок пока нет

- Turbo ExpanderДокумент105 страницTurbo Expandermartinandrei100% (11)

- Vacuum Engineering FundamentalsДокумент33 страницыVacuum Engineering FundamentalsChristian Vargas100% (3)

- Make List - Fire FightingДокумент3 страницыMake List - Fire FightingsureshkanuboyinaОценок пока нет

- Water Mist System PDFДокумент12 страницWater Mist System PDFNguyễn Ngọc100% (1)

- Catastrophic Failure of Storage TanksДокумент6 страницCatastrophic Failure of Storage Tanksdga51Оценок пока нет

- Flare SystemДокумент68 страницFlare SystemMihir JhaОценок пока нет

- 08 Doosan TIER 4I Engine (120425)Документ13 страниц08 Doosan TIER 4I Engine (120425)Jose Rafael Ramos ChiquilloОценок пока нет

- Tank Blanketing Helps Keep Hydrocarbon Processing Facilities SafeДокумент4 страницыTank Blanketing Helps Keep Hydrocarbon Processing Facilities SafeKrishnamoorthyОценок пока нет

- Department of Defense Design Criteria StandardДокумент30 страницDepartment of Defense Design Criteria StandardAlvaro Rojas AnzolaОценок пока нет

- Failure Scenarios For VesselsДокумент24 страницыFailure Scenarios For VesselsJim WesnorОценок пока нет

- Steam From Cavitation PDFДокумент4 страницыSteam From Cavitation PDFNiculae George RazvanОценок пока нет

- Nitrogen: A Security Blanket For The Chemical Industry: Fluids and Solids HandlingДокумент6 страницNitrogen: A Security Blanket For The Chemical Industry: Fluids and Solids HandlingSubramanian RavichandranОценок пока нет

- Safety Valve Sizing Calculations As Per IBR 1950Документ2 страницыSafety Valve Sizing Calculations As Per IBR 1950santoshmane2389% (9)

- Cs15 Gas Tank Cleaning Degassing 1997Документ12 страницCs15 Gas Tank Cleaning Degassing 1997kirandevi1981100% (2)

- GTC Waste To EnergyДокумент14 страницGTC Waste To EnergyaleedibuiОценок пока нет

- Oxygen Plant Safety PrinciplesДокумент10 страницOxygen Plant Safety Principleshwang2Оценок пока нет

- Explosion Protection For Coal Grinding PlantДокумент36 страницExplosion Protection For Coal Grinding PlantMike WoodwardОценок пока нет

- Dust Testing For DSEAR and ATEX Complian PDFДокумент16 страницDust Testing For DSEAR and ATEX Complian PDFSawita LertsupochavanichОценок пока нет

- Warsash - AFF Course PDFДокумент103 страницыWarsash - AFF Course PDFrenzwar100% (3)

- Flashback Mechanisms in Lean Premixed Gas Turbine CombustionОт EverandFlashback Mechanisms in Lean Premixed Gas Turbine CombustionОценок пока нет

- DSEAR Dust ExplosionsДокумент16 страницDSEAR Dust ExplosionsSaqib Nazir100% (1)

- IAC PAC Power Plant BarhДокумент19 страницIAC PAC Power Plant BarhMohammad AtaullahОценок пока нет

- Case Study: Barton SolventsДокумент14 страницCase Study: Barton SolventsVan Sot100% (1)

- Q1 Catalyst CatastrophesДокумент6 страницQ1 Catalyst CatastrophesGhulam RasoolОценок пока нет

- Protect Tanks From Overpressure and Vacuum PDFДокумент7 страницProtect Tanks From Overpressure and Vacuum PDFJohn SmithОценок пока нет

- Water Deluge Protection of LPGДокумент20 страницWater Deluge Protection of LPGVivi OktaviantiОценок пока нет

- Lesson Learned in SafetyДокумент7 страницLesson Learned in Safetybilalabdulmajeed100% (1)

- NRG 200Документ64 страницыNRG 200Rahul LavandОценок пока нет

- LNG Safety ReportДокумент14 страницLNG Safety ReportDavid Lincoln100% (2)

- ANSUL - Fire Protection Solutions For LNGДокумент29 страницANSUL - Fire Protection Solutions For LNGErwinОценок пока нет

- Flare Deflagration Incident at Rohm and Haas: DesaiДокумент2 страницыFlare Deflagration Incident at Rohm and Haas: DesaiNoel Federer SarkarОценок пока нет

- Prugh ModelДокумент17 страницPrugh ModelakilanОценок пока нет

- Parker Tank Blanketing White Paper PDFДокумент4 страницыParker Tank Blanketing White Paper PDFshashi kant kumarОценок пока нет

- BlanketingДокумент5 страницBlanketingasmiОценок пока нет

- The Evaluation and Control of Hazard DT Self HeatingДокумент9 страницThe Evaluation and Control of Hazard DT Self HeatingNyhcnawОценок пока нет

- CNF 1994autoignitioncombustiblefluidsДокумент11 страницCNF 1994autoignitioncombustiblefluidstiger sharkОценок пока нет

- Lessons Learned From Recent Process Safety IncidentsДокумент7 страницLessons Learned From Recent Process Safety IncidentsMohamed AhmedОценок пока нет

- Flammable Hazards in Sewerage SystemsДокумент81 страницаFlammable Hazards in Sewerage SystemsKarel OstenОценок пока нет

- PPS - Static ElectricityДокумент5 страницPPS - Static ElectricityMANISHОценок пока нет

- 2001 Meessen Stamicarbon Safety Aspects in Urea Plants Y2KДокумент20 страниц2001 Meessen Stamicarbon Safety Aspects in Urea Plants Y2Kjesus_manrique2753Оценок пока нет

- SPE Paper 69679Документ11 страницSPE Paper 69679Nicholas Garrett100% (2)

- Vess FireДокумент21 страницаVess FirecsОценок пока нет

- Flame Temperature in Oil Fired Fuel Burning Equipment and Its Relationship To Carbonaceous Particulate EmissionsДокумент5 страницFlame Temperature in Oil Fired Fuel Burning Equipment and Its Relationship To Carbonaceous Particulate EmissionsazmanОценок пока нет

- Electrostatic Hazards in Brief - pp13-16Документ4 страницыElectrostatic Hazards in Brief - pp13-16Soeryanto SlametОценок пока нет

- Is9 2008Документ5 страницIs9 2008eng.tomasoniОценок пока нет

- Buncefield XXI Paper 094Документ12 страницBuncefield XXI Paper 094Ricardo CarrerОценок пока нет

- Modelling The Environmental Consequences of Fires in WarehousesДокумент12 страницModelling The Environmental Consequences of Fires in WarehousesArcangelo Di TanoОценок пока нет

- APL 13 04 McClure - CombДокумент8 страницAPL 13 04 McClure - CombscgmzhtftyОценок пока нет

- JournalOfLossPreventionInTheProcessIndustries v14 P475to487Документ13 страницJournalOfLossPreventionInTheProcessIndustries v14 P475to487SapphireОценок пока нет

- Chapter2 Basics ExДокумент6 страницChapter2 Basics Exiin sukniaОценок пока нет

- Tank Washing RisksДокумент5 страницTank Washing RisksmavericksailorОценок пока нет

- Safetygram #33: The Hazards of Oxygen and Oxygen-Enriched MixturesДокумент5 страницSafetygram #33: The Hazards of Oxygen and Oxygen-Enriched MixturesPrakash22462Оценок пока нет

- 1 s2.0 S001021802100328X MainДокумент11 страниц1 s2.0 S001021802100328X Mainraphael.lomonacoОценок пока нет

- j13 09 8hhgtДокумент22 страницыj13 09 8hhgtJuan PozoОценок пока нет

- Paper46 Hazards 23Документ9 страницPaper46 Hazards 23Nadia AfifahОценок пока нет

- Price 1998Документ11 страницPrice 1998LỢI NGUYỄN CÔNGОценок пока нет

- Halm 2017Документ15 страницHalm 2017anuragОценок пока нет

- Safety Risks in Vocs Treatment Process of Oil Storage Tank FarmsДокумент7 страницSafety Risks in Vocs Treatment Process of Oil Storage Tank FarmsPriyo DjatmikoОценок пока нет

- Potential For Major Explosions From Crude Oil Pipeline Releases in Varied TerrainДокумент6 страницPotential For Major Explosions From Crude Oil Pipeline Releases in Varied TerrainSubhradeb PramanikОценок пока нет

- Evaluation of Firepots and Gel Fuels: NIST Technical Note 1791Документ13 страницEvaluation of Firepots and Gel Fuels: NIST Technical Note 1791jkhgvdj mnhsnjkhgОценок пока нет

- Nitrogen and Its Use in Bulk Liquid Transport: Standard Safety, Tankers May 2016Документ2 страницыNitrogen and Its Use in Bulk Liquid Transport: Standard Safety, Tankers May 2016sajjadyasinОценок пока нет

- AB AA-92-8338: As AsДокумент1 страницаAB AA-92-8338: As AsKumbamОценок пока нет

- Myths and Facts About Hydrogen Hazards: C H E M I C A L E N G I N E E R I N GДокумент6 страницMyths and Facts About Hydrogen Hazards: C H E M I C A L E N G I N E E R I N GZbigОценок пока нет

- 6 - Mine Fires and ExplosionsДокумент38 страниц6 - Mine Fires and ExplosionsSude Yağmur ÇalışırОценок пока нет

- Case Histories of Incidents in Heated Bitumen Storage TanksДокумент5 страницCase Histories of Incidents in Heated Bitumen Storage TanksJohn SmithОценок пока нет

- Technology: Handbook of Vacuum PhysicsОт EverandTechnology: Handbook of Vacuum PhysicsA. H. BeckОценок пока нет

- Steam Turbines PDFДокумент8 страницSteam Turbines PDFIndra PratamaОценок пока нет

- Numerical Analysis of A Hypersonic Turbulent and LДокумент13 страницNumerical Analysis of A Hypersonic Turbulent and LDANUSH DATTHATHIREYAN KОценок пока нет

- PG Si 0039 en WebДокумент2 страницыPG Si 0039 en Webb82monicaОценок пока нет

- Process OperatorДокумент2 страницыProcess Operatorapi-78201706Оценок пока нет

- Nomenclature For Gpsa Engineering Data Book, 12 Ed - Section 9, Heat ExchangersДокумент8 страницNomenclature For Gpsa Engineering Data Book, 12 Ed - Section 9, Heat ExchangerstizeskiОценок пока нет

- Gail India LTD VijaipurДокумент13 страницGail India LTD Vijaipuranshul21Оценок пока нет

- Mini VRF specification-AHRДокумент1 страницаMini VRF specification-AHRКирилл ЛевкевичОценок пока нет

- L2 Transmission of Power by PipelineДокумент15 страницL2 Transmission of Power by PipelineOPOОценок пока нет

- Refrigeration & Air Conditioning: ME 170: Fundamentals of Mechanical Engineering (Model Lab)Документ52 страницыRefrigeration & Air Conditioning: ME 170: Fundamentals of Mechanical Engineering (Model Lab)Umair MueedОценок пока нет

- Proyecto de InglesДокумент2 страницыProyecto de InglesDiego Manosalva OrtizОценок пока нет

- Model 4Wg 100 - 800 HP Boilers: Table A3-8. 4Wg Low Nox Dimensions - Hot WaterДокумент4 страницыModel 4Wg 100 - 800 HP Boilers: Table A3-8. 4Wg Low Nox Dimensions - Hot WatersebaversaОценок пока нет

- VPARL1998 99no61Документ292 страницыVPARL1998 99no61chemsac2Оценок пока нет

- Introduction To MatlabДокумент182 страницыIntroduction To MatlabGopik AnandОценок пока нет

- General Design ProcedureДокумент5 страницGeneral Design ProcedureMutiaraОценок пока нет

- Ramson Steam Boiler RateДокумент9 страницRamson Steam Boiler Ratenagagop930Оценок пока нет

- Answer: AДокумент6 страницAnswer: AAduchelab AdamsonuniversityОценок пока нет

- Bahan Kuliah Fluida (2016) PDFДокумент86 страницBahan Kuliah Fluida (2016) PDFReinhard Tetap SemangatОценок пока нет

- Electrical Driven 2 Stage T 30 Series High Pressure Compressor enДокумент3 страницыElectrical Driven 2 Stage T 30 Series High Pressure Compressor enemmanuel slimОценок пока нет

- S. No Dept Equiment Name Equip. ID Calibration FreqДокумент20 страницS. No Dept Equiment Name Equip. ID Calibration FreqPrasad KasettiОценок пока нет

- Hydraulics Course FileДокумент81 страницаHydraulics Course FileSwarna LathaОценок пока нет

- AcknowledgmentsДокумент2 страницыAcknowledgmentsFernandoОценок пока нет