Академический Документы

Профессиональный Документы

Культура Документы

Tapcoenpro: The Value of A Trusted Partner

Загружено:

Inspection Engineer0 оценок0% нашли этот документ полезным (0 голосов)

130 просмотров4 страницыTapcoEnpro-A4-4pp

Оригинальное название

TapcoEnpro-A4-4pp

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документTapcoEnpro-A4-4pp

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

130 просмотров4 страницыTapcoenpro: The Value of A Trusted Partner

Загружено:

Inspection EngineerTapcoEnpro-A4-4pp

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

DAWCUL PARTNER PROFILE

TAPCOENPRO

THE VALUE OF A TRUSTED PARTNER

For over 60 years, TapcoEnpro has been a world

leader in the design and manufacture of critical

service valves, equipment and services for fluid

catalytic cracking (FCC).

We offer a full range of products including FCC slide

valves, diverter valves, high performance butterfly

valves, hydraulic power units, digital controllers and

actuators. These products along with our ability to

supply heavy-wall reactors, regenerators, risers, orifice

chambers and FCC components make us a true

single source supplier for all your FCC requirements. TapcoEnpro manufacturing and service facility Channelview, Texas

Our extensive experience in designing and building

engineered severe-service industrial valves and

equipment for FCC units has made us one of the

premier valve manufacturers in the industry today. We

listen to our customers’ needs and strive to provide

innovative products that meet the critical demands of

the FCCU.

As a trusted partner, we deliver safe, reliable products

while providing the best value for our customers.

From the moment a customer contacts us, through

delivery, installation, support and service we’re

there to provide unparalleled products, service and

support. We continually strive to make our products

the best, most reliable in the industry.

PETROCHEMICAL EXPERTISE & SUPPLY SINCE 1977

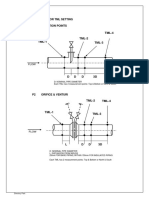

COLD SHELL BOLTED SLIDE

VALVES

MAXIMUM TEMPERATURE RESISTANCE

Each of our valves are custom designed to

your operating conditions including applicable

codes, FCC licensor specifications, customer

supplied requirements and our own in-house

standards for maximum temperature and

abrasion resistance.

Cold shell slide valve body material is carbon

steel (SA516-70), while internal parts material

will be selected based on design temperatures

(304H or SA387-GR11) up to 1800°F (980°C)

to provide maximum resistance to high

temperatures and erosion.

Our cold shell slide valve design includes

special refractory linings to protect the valve

body and internals from high temperatures and

erosion. The disc and orifice plate are refractory

lined specifically to protect against erosion.

Our suspended internal cone is welded to the

body shell with bimetallic weld located in the

straight section of the cone itself.

Slide valve internals are easily removable

through the valve bonnet for easy

maintenance. We designed their internal

components to withstand high temperatures,

pressure drops and erosive properties of the

flowing catalyst. Internal components centre

catalyst flow through the valve to minimise

erosion of internal valve body surfaces.

Whatever your needs might be in the FCCU,

our slide valves are available for the following

applications:

• Regenerated catalyst

• Spent catalyst

• Recirculation catalyst

• Catalyst cooler

• Double disc flue gas

• Flue gas diversion

• Expander flue gas

• Flue gas bypass

• Flue gas isolation

ELECTRO-HYDRAULIC

CONTROLS

DIGITAL AND ANALOG SERIES PIONEERS IN HYDRAULIC POSITIONING SYSTEMS

TapcoEnpro’s digital and analog actuators keep scheduled TapcoEnpro was the first to:

maintenance as routine as possible. Unlike other • Mount an electro-hydraulic actuator on a slide valve in

companies that build their systems using highpriced, the 1970s

proprietary, custom parts, TapcoEnpro designs its • Become a single source actuator, HPU and valve

actuators with quality-proven components. So, your initial supplier on a FCCU

investment in a superior TapcoEnpro actuator pays for • Design the system to use off-the-shelf components for

itself with affordable, convenient maintenance. simplicity, ease of maintenance and repair with parts

Replacement parts from recognised manufacturers, like that are available worldwide

Vickers and Parker, are available worldwide through

authorised distributors or from TapcoEnpro warehouses DIGITAL TA3000 CONTROL UNIT

in Houston, Texas, USA or Barnsley, South Yorkshire, U.K.

• One of the true digital controllers FCCU slide valves

Usually, these parts can be easily installed by your own

• Built in diagnostics for ease of maintenance and

personnel. If you are unable to find a part readily, we will

preventative maintenance

overnight it to you from one of our warehouses.

• Programmable so each application can be customised

• Data and event logging for history logs

CUSTOM CONFIGURATION • Self-contained health monitoring

Every valve demands unique capabilities from its actuator

counterpart. So TapcoEnpro offers total flexibility in your DIGITAL PLC3000 CONTROL UNIT

configuration upon installation. Available for all types • Simplex and redundant PLC configurations

of valves, TapcoEnpro actuators are available in several • Configurative parameters

packages that fit the requirements of most plants. But, • Built in diagnostics

if you have specific needs, no problem. TapcoEnpro • Data logging

completes each package with components tailored to

your situation. TapcoEnpro’s everimproving actuator

ANALOG TA2000 CONTROL UNIT

technology offers increasing operational capabilities, such

as on-stream fluid conditioning and greater redundancies, • Proven technology in this analog system that has been

to whatever degree you specify. in service for over 25 years

• Meets all requirements and specifications of industry

standards and best practices

CUSTOM SPECIFICATIONS

Not only will your configuration be customised to your

operation, your written specification can be too. If your

personnel aren’t familiar with actuator parameters,

we’ll write specifications for you to help set operational

standards. Or if you have experienced instrumentation and

operations people, we’ll provide detailed specifications

for their professional review and refinement.

For smaller companies with limited engineering resources,

TapcoEnpro will design the actuator system to comply

with industry requirements. TapcoEnpro innovates to keep

at the forefront of flow control technology for

severe conditions.

FIELD SERVICES

Our field service technicians provide a superior level of

service, providing 24-7 coverage and responding to our

customers’ needs in a timely and efficient manner.

TapcoEnpro’s network of technicians are highly trained

to evaluate, troubleshoot and resolve issues. They are

backed by our engineering group allowing for quick

access to technical expertise, drawings, bills of materials

and other data to expedite practical and reliable solutions.

Core services of the TapcoEnpro field service team are:

• Equipment installations

• Site acceptance tests

• Commissioning supervision

• Site audits

• Turnaround service

• Maintenance and repair

• Equipment rebuilds

• Storage

• Hydraulic flush services

• Electrical loop checks

• On-site training

• Bolt/tensioning/torquing

• Spare parts

• High performance hydraulic fluids

In order to respond to our customers’ requirements,

TapcoEnpro has sizeable service facilities staffed with

our certified, dedicated technicians in the United States,

Canada and Europe. We are also planning such facilities

globally to meet the demands of our growing list of

worldwide customers.

For additional information Dawcul Head Office T: +44 (0)118 932 0520

Number 8 Beech Court, Wokingham Road F: + 44 (0)118 924 1919

feel free to contact us or visit: Hurst, Reading, Berkshire RG10 0RQ E: sales@dawcul.co.uk

www.dawcul.com United Kingdom W: www.dawcul.com

Вам также может понравиться

- Type PR Online Assurance Program: Success StoryДокумент2 страницыType PR Online Assurance Program: Success Storyvarun sharmaОценок пока нет

- Plant Engineering and Design The Ultimate Step-By-Step GuideОт EverandPlant Engineering and Design The Ultimate Step-By-Step GuideОценок пока нет

- Belco Edv Wet Scrubbing System: Best Available Control Technology (Bact) For Fccu Emission ControlДокумент16 страницBelco Edv Wet Scrubbing System: Best Available Control Technology (Bact) For Fccu Emission ControlBharavi K S100% (1)

- Chemical Process Retrofitting and Revamping: Techniques and ApplicationsОт EverandChemical Process Retrofitting and Revamping: Techniques and ApplicationsGade Pandu RangaiahОценок пока нет

- ECAT Analysis GuideДокумент12 страницECAT Analysis GuideElder RuizОценок пока нет

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationОт EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosОценок пока нет

- ABB Ie2 High EfficiencyДокумент4 страницыABB Ie2 High EfficiencyPARBATIОценок пока нет

- SSW - April 2020 - Lowres Pages 42 45 PDFДокумент4 страницыSSW - April 2020 - Lowres Pages 42 45 PDFBaher ElsheikhОценок пока нет

- Coke Drum Remaining LifeДокумент4 страницыCoke Drum Remaining Lifeash1968Оценок пока нет

- Oil Refinery ProcessДокумент44 страницыOil Refinery ProcessJunaid IqbalОценок пока нет

- Assignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsДокумент6 страницAssignment NO 3:: Question 1: Define Cracking. Classify Cracking OperationsMilan MoradiyaОценок пока нет

- Process Engineering Properly Protect Centrifugal Pumps Chemical Processing PDFДокумент2 страницыProcess Engineering Properly Protect Centrifugal Pumps Chemical Processing PDFAndri SaputraОценок пока нет

- HSFCCДокумент22 страницыHSFCCdonald55555100% (1)

- T2091 100 PDFДокумент10 страницT2091 100 PDFRICKY ECHANOОценок пока нет

- CorrosionДокумент9 страницCorrosionhesampirОценок пока нет

- AcquaconvertionДокумент10 страницAcquaconvertionGreysi N. Moreno CedeñoОценок пока нет

- ROSE® Process Offers Energy Savings For Solvent ExtractionДокумент14 страницROSE® Process Offers Energy Savings For Solvent Extractiona_abbaspourОценок пока нет

- CHEN4018 Natural Gas Processing Semester 1 2021 Bentley Campus INTДокумент9 страницCHEN4018 Natural Gas Processing Semester 1 2021 Bentley Campus INTfahadnbОценок пока нет

- Orbit Article Molecular Sieve Dehydration Switching ValvesДокумент12 страницOrbit Article Molecular Sieve Dehydration Switching ValvesPasquale Sessa0% (1)

- SCORE Furnace Erection SequenceДокумент12 страницSCORE Furnace Erection SequenceAleem QureshiОценок пока нет

- 02.understanding Process Equipment For Operators & Engineers-68Документ5 страниц02.understanding Process Equipment For Operators & Engineers-68rahulОценок пока нет

- 1998 Irving Refinery Hydrocracker Furnace Accident ReportДокумент18 страниц1998 Irving Refinery Hydrocracker Furnace Accident Reportbazil17Оценок пока нет

- Steam Reforming Common ProblemsДокумент61 страницаSteam Reforming Common ProblemsBilalОценок пока нет

- Safety Valve LaserДокумент15 страницSafety Valve Lasersajjad_naghdi241Оценок пока нет

- IFC Inflow UK-Loading Arms & SkidsДокумент16 страницIFC Inflow UK-Loading Arms & SkidslpczyfansОценок пока нет

- Refractory Dryout by Electrical Coil Heating 2Документ1 страницаRefractory Dryout by Electrical Coil Heating 2choksОценок пока нет

- Bimetallic Steam Traps (Velan)Документ36 страницBimetallic Steam Traps (Velan)Ebn egg100% (1)

- Refinery Training Courses by PertecnicaДокумент7 страницRefinery Training Courses by PertecnicapertecstudentОценок пока нет

- Composition Gas OilДокумент14 страницComposition Gas OilRavikant KumarОценок пока нет

- Refining-Petrochemical Integration-FCC Gasoline To PetrochemicalsДокумент4 страницыRefining-Petrochemical Integration-FCC Gasoline To PetrochemicalsKwangsjungОценок пока нет

- CBI Welding Journal Vert Plate Apr04Документ0 страницCBI Welding Journal Vert Plate Apr04Mahendra RathoreОценок пока нет

- Corrosion Control in The Refining Industry: Petrosync LecturerДокумент8 страницCorrosion Control in The Refining Industry: Petrosync LecturerYaraKanawati100% (1)

- Boiler Performance & Technical Data JT-K13467-E01-0Документ15 страницBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- Installation, Operation, and Maintenance ManualДокумент54 страницыInstallation, Operation, and Maintenance ManualIsmael Berlanga ResОценок пока нет

- Diaphragm Elimination Using Taper-Lok - NPRAДокумент11 страницDiaphragm Elimination Using Taper-Lok - NPRAAntonio PerezОценок пока нет

- HydroCracker UnitДокумент5 страницHydroCracker UnitPassmore Dube100% (1)

- Coking and Thermal ProcessesДокумент8 страницCoking and Thermal ProcessesWulandariОценок пока нет

- Forged Components Catalog For Pressure Vessel ConnectionsДокумент72 страницыForged Components Catalog For Pressure Vessel ConnectionsForged ComponentsОценок пока нет

- Valve Material Application PDFДокумент16 страницValve Material Application PDFSudherson Jagannathan100% (1)

- ACTUATORSДокумент6 страницACTUATORSMohamed Arriff100% (1)

- UOP Separex Membrane Technology Tech PresentationДокумент44 страницыUOP Separex Membrane Technology Tech PresentationKarunakarОценок пока нет

- Compressors How To Achieve High Reliability & Availability (Electronics)Документ55 страницCompressors How To Achieve High Reliability & Availability (Electronics)Anonymous IGtWHoi0Оценок пока нет

- 41000Документ36 страниц41000tetiospamОценок пока нет

- Monitoreo de BombasДокумент6 страницMonitoreo de Bombasroberdani12Оценок пока нет

- A Complete Analysis of Your Reformer: Bill Cotton and Barry FisherДокумент9 страницA Complete Analysis of Your Reformer: Bill Cotton and Barry Fishersalvatore raffaОценок пока нет

- 1 - CL619 RPD - Properties Calculation PDFДокумент166 страниц1 - CL619 RPD - Properties Calculation PDFPankaj Kumar SainiОценок пока нет

- 9 Storage TanksДокумент10 страниц9 Storage TanksFebriannada Abiyyu100% (1)

- Presentation Q2 APE-1Документ24 страницыPresentation Q2 APE-1mts1234Оценок пока нет

- OilFieldArtificialLiftISP Report FinalДокумент32 страницыOilFieldArtificialLiftISP Report FinalWessam HashemОценок пока нет

- Optimising Crude Unit Design PDFДокумент7 страницOptimising Crude Unit Design PDFvedadonОценок пока нет

- Flatlapping Polishing-Lamplan 2016 Indep-Mdef PDFДокумент64 страницыFlatlapping Polishing-Lamplan 2016 Indep-Mdef PDFGowtham VishvakarmaОценок пока нет

- Columns: An Introductory Guide To Columns For Chemical EngineersДокумент53 страницыColumns: An Introductory Guide To Columns For Chemical EngineersHerawan Mulyanto100% (1)

- Fluid Catalytic Cracking Unit (FCCU)Документ1 страницаFluid Catalytic Cracking Unit (FCCU)Billy BlinksОценок пока нет

- Energy Optimization of Crude Oil Distillation Using Different Designs of Pre-Flash Drums PDFДокумент7 страницEnergy Optimization of Crude Oil Distillation Using Different Designs of Pre-Flash Drums PDFGabriela Urdaneta100% (1)

- Coker Ball Valve of Velan PDFДокумент8 страницCoker Ball Valve of Velan PDFmujeebtalibОценок пока нет

- MEL470-L12 Knocking in SI EngineДокумент31 страницаMEL470-L12 Knocking in SI EngineGaurav GuptaОценок пока нет

- Chemical Process Calculations - Short TutorialДокумент5 страницChemical Process Calculations - Short TutorialMohammad AtifОценок пока нет

- 5 Oil Refinery ProcessesДокумент111 страниц5 Oil Refinery ProcessesMohamed Sayed AbdoОценок пока нет

- VesselsДокумент16 страницVesselsRonald TysonОценок пока нет

- 300 SS Bolting FailureДокумент3 страницы300 SS Bolting FailureInspection EngineerОценок пока нет

- ML040150682 PDFДокумент406 страницML040150682 PDFjimmy_bikerОценок пока нет

- Relief Valves: Gases and Gas EquipmentДокумент22 страницыRelief Valves: Gases and Gas EquipmentInspection EngineerОценок пока нет

- NBIC Pressure Relief Device Inspection Guide 1-19-10 PDFДокумент4 страницыNBIC Pressure Relief Device Inspection Guide 1-19-10 PDFAbdelrahmanAwadОценок пока нет

- Metal Dusting PDFДокумент13 страницMetal Dusting PDFInspection EngineerОценок пока нет

- CP0191 FullДокумент8 страницCP0191 FullDan DumbravescuОценок пока нет

- Distillation Inspecting Towers Part 1Документ10 страницDistillation Inspecting Towers Part 1Ricardo BecОценок пока нет

- API 650 - Welded Steel Tanks For Oil Storage - Law - GovДокумент77 страницAPI 650 - Welded Steel Tanks For Oil Storage - Law - Govosman acarОценок пока нет

- Pressure Equipment IMДокумент43 страницыPressure Equipment IMInspection EngineerОценок пока нет

- API 650 - Welded Steel Tanks For Oil Storage - Law - GovДокумент77 страницAPI 650 - Welded Steel Tanks For Oil Storage - Law - Govosman acarОценок пока нет

- Guide-Control-Valve BookДокумент120 страницGuide-Control-Valve BookInspection EngineerОценок пока нет

- Hydrotest Water PDFДокумент5 страницHydrotest Water PDFSonali SharmaОценок пока нет

- 300 SS Bolting FailureДокумент3 страницы300 SS Bolting FailureInspection EngineerОценок пока нет

- ML040150682 PDFДокумент406 страницML040150682 PDFjimmy_bikerОценок пока нет

- Fatigue Fracture MechanicsДокумент12 страницFatigue Fracture MechanicsInspection Engineer0% (1)

- Relief Valves: Gases and Gas EquipmentДокумент22 страницыRelief Valves: Gases and Gas EquipmentInspection EngineerОценок пока нет

- Pressure Relief DevicesДокумент5 страницPressure Relief DevicesInspection EngineerОценок пока нет

- High Temperature Hydrogen AttackДокумент31 страницаHigh Temperature Hydrogen Attackaecf_13Оценок пока нет

- Rick FairclothДокумент53 страницыRick Fairclothmetasoniko2014Оценок пока нет

- Pressure Relief DevicesДокумент5 страницPressure Relief DevicesInspection EngineerОценок пока нет

- Shell Guidelines For TMLs PDFДокумент17 страницShell Guidelines For TMLs PDFInspection EngineerОценок пока нет

- Shepherd, Fabrication Process For Large Diameter Thin Wall VesselsДокумент35 страницShepherd, Fabrication Process For Large Diameter Thin Wall Vesselschuckhsu1248Оценок пока нет

- Lva1 App6892Документ13 страницLva1 App6892Inspection EngineerОценок пока нет

- Fatigue Fracture MechanicsДокумент12 страницFatigue Fracture MechanicsInspection Engineer0% (1)

- BP Code GS146-1Документ33 страницыBP Code GS146-1khorzooОценок пока нет

- Reducing The Risk of High Temperature Hydrogen Attack (HTHA) FailuresДокумент5 страницReducing The Risk of High Temperature Hydrogen Attack (HTHA) FailuresAgustin Fabian HaddadОценок пока нет

- Simplify Materials Selection: Your Guide To Making Choices That Reduce The Impact of CorrosionДокумент37 страницSimplify Materials Selection: Your Guide To Making Choices That Reduce The Impact of CorrosionInspection EngineerОценок пока нет

- Trg-b1003 Piping Study Column PipingДокумент53 страницыTrg-b1003 Piping Study Column Pipingfronjose100% (3)

- The Application of Risk Based Inspection To Pressure Vessels & AST PDFДокумент7 страницThe Application of Risk Based Inspection To Pressure Vessels & AST PDFعزت عبد المنعمОценок пока нет

- Catalog DF2.5Документ30 страницCatalog DF2.5adyhansolo2100% (1)

- CAT C4.4 Stop Solenoid For Marine GeneratorsДокумент4 страницыCAT C4.4 Stop Solenoid For Marine Generatorsharikrishnanpd3327Оценок пока нет

- Product List Additives For Liquid Coatings MARCH 2013Документ12 страницProduct List Additives For Liquid Coatings MARCH 2013Pongthip PesachpinankulОценок пока нет

- Mechanical Engineering HW 1Документ5 страницMechanical Engineering HW 1DanialОценок пока нет

- 2016 Industrial Controls Catalog Nov 2015 PDFДокумент1 568 страниц2016 Industrial Controls Catalog Nov 2015 PDFsandesh sawateОценок пока нет

- Vlsi & SDLДокумент8 страницVlsi & SDLmycatalystsОценок пока нет

- Construction of FacadesДокумент5 страницConstruction of FacadesGunjan UttamchandaniОценок пока нет

- York Close Control Air Cooled Twin Circuit RangeДокумент15 страницYork Close Control Air Cooled Twin Circuit Rangemuqtar4uОценок пока нет

- Fse100 FinalДокумент37 страницFse100 Finalapi-456985970100% (1)

- TorsionДокумент36 страницTorsiondixn__Оценок пока нет

- Agriculture Pesticide Sprayer: Chapter-IДокумент70 страницAgriculture Pesticide Sprayer: Chapter-IAvinash GummadiОценок пока нет

- Cement and Steel Rates For The Month of June-2015Документ2 страницыCement and Steel Rates For The Month of June-2015NagabhushanamОценок пока нет

- 2013 DTH Hammer Catalog PDFДокумент61 страница2013 DTH Hammer Catalog PDFNelson de la RosaОценок пока нет

- Handheld Digital Doppler Flowmeter Model HFM Operation ManualДокумент10 страницHandheld Digital Doppler Flowmeter Model HFM Operation ManualyutОценок пока нет

- KGN BIO TECH EIA Report PDFДокумент275 страницKGN BIO TECH EIA Report PDFjyothi0% (1)

- Mack WIRING DIAGRAM TYPE OM W-CNGДокумент98 страницMack WIRING DIAGRAM TYPE OM W-CNGAlex Renne Chambi67% (3)

- Table - C 1 Standard Design For Axial Loaded Short Square Columns STEEL Fe 415 Concrete: M15, M20, M25Документ14 страницTable - C 1 Standard Design For Axial Loaded Short Square Columns STEEL Fe 415 Concrete: M15, M20, M25VMRAJAN0% (1)

- BIM Titles Job DescriptionsДокумент17 страницBIM Titles Job DescriptionskuraimundОценок пока нет

- Motores A Gas CatДокумент3 страницыMotores A Gas CatLuisОценок пока нет

- Rengshausen2014 PDFДокумент10 страницRengshausen2014 PDFSérgio BernardesОценок пока нет

- Compressor ManualДокумент276 страницCompressor Manualoth369100% (1)

- Installation and Servicing Instructions For Highflow 400 BF Manufactured After 1997Документ48 страницInstallation and Servicing Instructions For Highflow 400 BF Manufactured After 1997Tom GuthrieОценок пока нет

- Doors and WindowsДокумент12 страницDoors and WindowsVishal NaikОценок пока нет

- WTP PresentationДокумент23 страницыWTP Presentationdeepak2628Оценок пока нет

- Argumentative EssayДокумент4 страницыArgumentative Essayvictorbernal7749Оценок пока нет

- City of Houston IdmДокумент272 страницыCity of Houston IdmKevin MillsОценок пока нет

- Peugeot 207 Caravan PDFДокумент255 страницPeugeot 207 Caravan PDFsiile100% (1)

- Rotary Spoa7-9 Spo9 400 Series Install PDFДокумент16 страницRotary Spoa7-9 Spo9 400 Series Install PDFFranck RoyerОценок пока нет

- Flowserve General Product Guide PDFДокумент84 страницыFlowserve General Product Guide PDFSIMON S. FLORES G.Оценок пока нет

- The Laws of Thermodynamics: A Very Short IntroductionОт EverandThe Laws of Thermodynamics: A Very Short IntroductionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Shorting the Grid: The Hidden Fragility of Our Electric GridОт EverandShorting the Grid: The Hidden Fragility of Our Electric GridРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseОт EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (51)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesОт EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionОт EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideОт Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideРейтинг: 3.5 из 5 звезд3.5/5 (7)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsОт EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОт EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОценок пока нет

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceОт EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceОценок пока нет

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CОт EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CОценок пока нет

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsОт EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsОценок пока нет

- Introduction to Power System ProtectionОт EverandIntroduction to Power System ProtectionРейтинг: 5 из 5 звезд5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchОт EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchРейтинг: 4 из 5 звезд4/5 (10)

- A Pathway to Decarbonise the Shipping Sector by 2050От EverandA Pathway to Decarbonise the Shipping Sector by 2050Оценок пока нет

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsОт EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsОценок пока нет

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)