Академический Документы

Профессиональный Документы

Культура Документы

Nichols Tillage Tools Product Catalog

Загружено:

black bettyАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Nichols Tillage Tools Product Catalog

Загружено:

black bettyАвторское право:

Доступные форматы

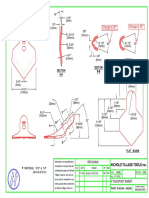

cover

M ISSION

Quick Change System

We are the North American innovator of new for mounting sweeps

and points

concepts in tillage tools. We work to design tools

that help farmers do a better job of cultivating

and raising food. We are constantly creating new

Ultrawing®

ideas for all forms of cultivation. Our ideas have a patented design

been so successful, that they have often been

adopted as standard features in cultivation tools.

Some of the advances we have made are:

• Quick Change System Heel Sweep and Point

• Ultrawing®

• Heel Sweep and Point

• Soil Slitter

• Deep Tillage Shovel Soil Slitter

direct seeding point

Deep Tillage Shovel

for rippers

N ICHOLS T ILLAGE T OOLS , I NC .

2

CONTENTS

C ONTENTS

MISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Peanut Sweeps . . . . . . . . . . . . . . . . 53

Row Crop Sweeps . . . . . . . . . . . . . 54

OVERVIEW Hiniker Blades . . . . . . . . . . . . . . . 55

About Nichols . . . . . . . . . . . . . . . . . . . . . 4 Hiniker Points . . . . . . . . . . . . . . . . 55

Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Sukup Points . . . . . . . . . . . . . . . . . 55

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . 5 Hiniker 1000 Series Sweeps . . . . . 55

Quick Change Chisel Plow Sweeps 57

PRODUCT LINES Soil Slitter Sweeps . . . . . . . . . . . . 58

Chisels & Spikes . . . . . . . . . . . . . . . . . . . . . . . 6

Discs .............................. 11 SPECIALTY PRODUCT LINES

Coulters . . . . . . . . . . . . . . . . . . . . . . . 11 QC Brackets . . . . . . . . . . . . . . . . . . . . . 59

Openers . . . . . . . . . . . . . . . . . . . . . 18 Stalk Cutter Blades . . . . . . . . . . . . . . . . 64

Discs . . . . . . . . . . . . . . . . . . . . . . 19 Do All Spring Assembly . . . . . . . . . . . . 64

Knives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Drag Board . . . . . . . . . . . . . . . . . . . . . . . 64

Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31 Spike Harrow Teeth . . . . . . . . . . . . . . . . 64

Sweeps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37 Drill Shoes . . . . . . . . . . . . . . . . . . . . . . . . 65

About Ultrawing Sweeps . . . . . . . . . 37 Furrowers . . . . . . . . . . . . . . . . . . . . . . . 66

Ultrawing Sweeps . . . . . . . . . . . . . . . 39 Harrow Springs . . . . . . . . . . . . . . . . . . . 67

Conventional Bolt-On Hoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Field Cultivator Sweeps . . . . . . . . . . 40 Hydraulic Hose Holder . . . . . . . . . . . . . 71

Curved Back Alabama Sweeps . . . . 41 Plastic Shank Protectors . . . . . . . . . . . . 71

Square Back Alabama Sweeps . . . . . 41 S Tines . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Beet Sweeps . . . . . . . . . . . . . . . . . . . . 41 Tiller Blades . . . . . . . . . . . . . . . . . . . . . . 72

Beaver Tail Corn Sweeps . . . . . . . . . 41 Cotton Point . . . . . . . . . . . . . . . . . . . . . . 72

Klipped Wing Bolt On Sweeps . . . 42 Bolts for Seed Disc Openers . . . . . . . . . 72

Chisel Plow . . . . . . . . . . . . . . . . . 43

Conventional/Klipped Wing . . . . . 44 SPECIAL ITEMS/FEATURES

V Sweeps . . . . . . . . . . . . . . . . . . . 46 Quick Change System . . . . . . . . . . . . . 73

26” Sweeps . . . . . . . . . . . . . . . . . . . 46 Application Chart for

Nichols Field Cultivator Sweeps . . . . . 75

Chisel Plow Ultrawing Sweeps . . ®

47

Large Pattern Ultrawing® Sweeps 48 Application Chart for Nichols

Field Cultivator Ultrawing Sweeps . . . 77

Heel Sweeps . . . . . . . . . . . . . . . . . . . 49

Hole Patterns for Coulters . . . . . . . . . . 78

Danish Sweeps . . . . . . . . . . . . . . . 50

Part Number Scheme for

Field Cultivator Sweeps . . . . . . . . . . 51 Subsoiler Rippers . . . . . . . . . . . . . . . . . 79

Joyce Pattern Cotton Sweeps . . . . . 52 Metric to English Conversion Chart . . 81

Smith Fin Sweeps . . . . . . . . . . . . . 52

Mini Till/Low Till Sweeps . . . . . . . 53 INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Narrow Wing/

Low Disturbance Sweeps . . . . . . . 53

N ICHOLS T ILLAGE T OOLS , I NC .

3

A BOUT N ICHOLS

Nichols Tillage Tools, Inc. has four sales offices and warehouses to provide service to each of our resellers.

OVERVIEW

We choose store-front businesses to represent our products; you can get the best products and services

through those businesses. Local firms are your best source of products.

We have wholesale distributors in areas where we do not have sales offices. Montana, North Dakota, South

Dakota, and states in the Northwest are serviced by stocking wholesalers and equipment manufacturers.

Nichols representatives and stocking distributors are present in Australia, Canada, the Middle East, and in Europe.

We are also represented on the internet at nicholstillagetools.com.

Please contact us at the head office so that we can point you toward these representatives of

Nichols Tillage Tools, Inc.

Nichols Tillage Tools, Inc.

312 Hereford Avenue

Sterling, CO 80751

Phone: 877.519.2770 • Fax: 970.522.9756

N ICHOLS T ILLAGE T OOLS , I NC .

4

T ERMS

WARRANTY

OVERVIEW

Nichols Tillage Tools, Inc. guarantees its products to be free from defects in materials and workmanship

until one half of one inch of original material is worn from the leading edge or point of ground-engaging tools,

or one year from date of purchase by the user, whichever occurs first.

Liability under warranty shall extend only to replacement or correction of products found to be defective

upon examination by Nichols Tillage Tools, Inc. All products to be considered under this warranty must be

returned to the factory or warehouse for inspection, freight prepaid.

This warranty does not extend to any products subject to misuse or damage by accident or negligence.

Hard surfaced products or products which have castings attached are not guaranteed for use in rocky, stony, or

frozen ground. This warranty is made in lieu of all other warranties, express or implied, including, but not limited

to, warranties of merchantability or suitability for any purpose.

No claims for consequential or incidental damages will be recognized, and no person, firm, or corporation is

authorized to assume for Nichols Tillage Tools, Inc. any other obligation in connection with the sales of its products.

OTHER POLICIES

All freight will be shipped FOB Nichols’ warehouse, and shipments will be made at Nichols’ own convenience

and courier choice. There will be a 15% restocking charge for returned merchandise, and the customer will have the

responsibility of prepaying the return freight charges. Written authorization to return merchandise must be made

before returns will be accepted. There will be no credit allowed, and there will be no return privilege or freight

allowance for special run or special setup parts. We reserve the right to change prices at any time. Past due accounts

are subject to a 1-1/2% per month charge (18% per year). Nichols reserves the right to discontinue any part listed in

this catalog. Nichols Tillage Tools, Inc. is not liable for failure to deliver by expected dates.

Nichols Tillage Tools, Inc. assumes no warranty or guarantee for the products manufactured by other firms

that we resell. No claim of consequential or incidental damages will be recognized by Nichols Tillage Tools, Inc.

DISCS AND COULTERS

No credit will be allowed for a disc blade or a coulter if it has been abused or used in an incorrect manner.

No credit will be allowed for worn or buckled edges which result from the disc or coulter wearing thin, irregular

breaks or tear type fractures that result from use in severe conditions such as rocks, or for broken centers resulting

from implement design error, loose gang bolts, frozen or rocky ground, abnormal flexing of the disc, or from

abnormally severe working conditions.

No credit will be allowed for modified or hardfaced discs or coulters. No warranty will be allowed for discs

that have been rerolled or resharpened.

Breaking at bolt hole pattern is not covered by warranty.

Nichols Tillage Tools, Inc. values your business and appreciates your orders. We take pride in the quality of the products that

we manufacture and distribute. We are here to provide you with the products and services which are necessary to make your

business successful and profitable. We want to merit your business in the future. Remember Nichols.

N ICHOLS T ILLAGE T OOLS , I NC .

5

QUICK CHANGE SPIKES

Stock Code Description Weight

QC2K Spike End 2.5

QC2C Diamond End 2.3

QC383C QC Twisted Point 3.2

QC383MBL 1/4” QC twisted mouldboard left hand 3.2

QC383MBR 1/4” QC twisted mouldboard right hand 3.2

QC383MTL 3/8” material QC twisted mouldboard left hand 3.5

QC383MTR 3/8” material QC twisted mouldboard right hand 3.5

QC384C 3/8” x 4 x 12 QC twisted point

QC2C

hols

CHISELS & SPIKES

the Nic

part of

HANGE

QUICK C m

syste

see pages 73-77

for details.

QC2K

QC383C

N ICHOLS T ILLAGE T OOLS , I NC .

6

CHISELS & REVERSIBLES

Nichols chisels are for when you want the best. Their thoughtful and imaginative design,

and their precision assembly give you an excellent wear life and a correct fit-up. Nichols’

choice of material, including the high-chrome alloy cast wear caps and the special hardening

processes that we use, enhance the strength and wear qualities found in Nichols products.

We have one of the largest selections of chisels offered. Our warehouses are carefully

located to speed delivery to our dealers.

Ask for Nichols when you need repair points.

H23-5

HEAVY FORGED CHISELS

requires hex head bolts

Stock Code Hole Size Hole Spacing Dimensions Ends Weight

H23-5 1/2” 2-1/4” 1-1/4” x 2-1/4” x 18” bulk 13.0

H22-5 1/2” 2-1/4” 1” x 2-1/8” x 18” bulk 8.0 HC2C8

CHISELS & SPIKES

CHISELS & SPIKES

Swedged chisels remain sharp for penetration throughout their life.

Stock Code Hole Size Hole Spacing Dimensions Width Ends Weight

1759D

HC2C8 1/2” 2-1/4” 5/8” x 2” x 16” 2” diamond 5.5

HC2C8 S 1/2” 2-1/2” 5/8” x 2” x 16” 2” diamond 5.5

HC2C8-7 7/16” 2-1/4” 5/8” x 2” x 16” 2” diamond 5.5

HC2 7/16” 2-1/4” 1/2” x 2” x 16” 2” swedged 4.4

1759D 7/16” 2-1/4” 5/8” x 2” x 15-1/2” 2” diamond 6.5

S1215 7/16” slotted 1/2” x 2” x 13-1/2” 1-1/2” diamond 4.3

#28 1/2” 2-1/4” 5/8” x 2” x 16” 2” swedged 4.9

H342D 1/2” 2-1/4” 3/4” x 2” x 16” 2” diamond 6.7

#28

3H 1/2” 2-1/4” 3/8” x 3” x 15” 3” swedged 4.4

HC4-2 1/2” 2-1/4” 3/8” x 4” x 15” 4” diamond 5.3

RA4 1/2” 2-1/4” 1/4” x 4” x 16” 5” flared 4.2

RA4-S slotted 1/2” holes: 2-1/4” - 2-1/2” centers 5” flared 4.2

RA5 1/2” 2-1/4” 5/16” x 4” x 16” 5” flared 5.7

RA5-S slotted 1/2” holes: 2-1/4” - 2-1/2” centers, 5/16” x 4” x 16” flared 5.7

RA6 1/2” 2-1/4” 3/8” x 4” x 16” 5 flared 5.7

The RA5 chisels are superior buys. They are made from 5/16” material, and their unique shape HC4-2

has proven itself for making clods and drying the land.

N ICHOLS T ILLAGE T OOLS , I NC .

7

SINGLE ENDED CHISELS

The H342CP and HS13CP single end chisel points with an extended wear high-chrome

alloy cast wear cap will outperform regular chisels. The HS13CP is designed to go with the

Nichols Heel Sweep and it works very successfully in regular chiseling operations.

Stock Code Hole Size Hole Spacing Dimensions Ends Weight

H342CP 1/2” 2-1/4” 3/4” x 2” x 13” capped 5.2

HS13CP 1/2” 2-1/4” 1” x 2” x 13” capped 7.5

H342CP

REVERSIBLES FOR FIELD CULTIVATORS

Stock Code Hole Size Hole Spacing Dimensions Ends Weight

CC37 7/16” 1-3/4” 3/8” x 2” x 11” swedged 2.0

CC33 3/8” 1-3/4” 3/8” x 2” x 11” swedged 2.0 HS13CP

CHISELS & SPIKES

AC72 7/16” 2” 3/8” x 2” x 11” swedged 2.0

CC134-7 7/16” 1-3/4” 1/4” x 1-3/4” x 11” swedged 1.0

CC134-7 7/16” 1-3/4” 1/4” x 1-3/4” x 11” cut 1.0

CS2 7/16” 2” 1/4” x 2” x 11” swedged .75

CS3 slot 7/16” 1/4” x 2” x 11” swedged .75

CS4 slot 3/8” 1/4” x 2” x 11” swedged .75

CC2B2 1/2” 1-3/4” 5/8” x 2” x 14” diamond 2.5

with flat back for Bourgault CS 2

For Crustbuster

CB1 3/8” 2” 1/4” x 2” x 11” flared 1.4

CB2 3/8” 2” 3/8” x 2” x 11” swedged 2.0

AB7 3/8” 2” 7” sweep for Crustbuster & early Deere 1.7

flat stem angle of 36 degrees swedged

For Lilliston

LIL 13 7/16” 2” a forged shape for Lilliston 3.8

CC 37

CB 1

N ICHOLS T ILLAGE T OOLS , I NC .

8

TWISTED CHISELS

Stock Code Hole Size Hole Spacing Dimensions Ends Weight

3” Twisted

383R-2 1/2” 2-1/4” 3/8” x 3” x 23” RH diamond 6.2

383L-2 1/2” 2-1/4” 3/8” x 3” x 23” LH diamond 6.2

383R-2 HF 1/2” 2-1/4” hardfaced RH diamond 6.6

383L-2 HF 1/2” 2-1/4” hardfaced LH diamond 6.6

483R-2 1/2” 2-1/4” 1/2” x 3” x 23” RH diamond 8.1

483L-2 1/2” 2-1/4” 1/2” x 3” x 23” LH diamond 8.1 483R-2

483R-2 HF 1/2” 2-1/4” hardfaced RH diamond 8.5

483L-2 HF 1/2” 2-1/4” hardfaced LH diamond 8.5 4” Twisted Chisel

583R-2 1/2” 2-1/4” 1/2” x 4” x 23” RH diamond 10.4

583L-2 1/2” 2-1/4” 1/2” x 4” x 23” LH diamond 10.4

583R-2 HF 1/2” 2-1/4” hardfaced RH diamond 10.8

583L-2 HF 1/2” 2-1/4” hardfaced LH diamond 10.8

498C-L 1/2” 2-1/4 1/2” x 3” x 26” cupface 10.8

583R-2

498C-R 1/2” 2-1/4 1/2” x 3” x 26” cupface 10.8

CHISELS & SPIKES

598C-L 1/2” 2-1/4 1/2” x 4” x 26” cupface 10.8

598C-R 1/2” 2-1/4 1/2” x 4” x 26” cupface 10.8 Slashed Point

SLASHED POINT TWISTED CHISELS

Stock Code Hole Size Hole Spacing Dimensions Ends Weight

SL123R 1/2” 2-1/4” 1/2” x 3” x 23” RH slashed 9.6

SL124R

SL123L 1/2” 2-1/4” 1/2” x 3” x 23” LH slashed 9.6

SL123R HF 1/2” 2-1/4” hardfaced RH slashed 10.

SL123L HF 1/2” 2-1/4” hardfaced LH slashed 10. Cupface

SL124R 1/2” 2-1/4” 1/2” x 4” x 23” RH slashed 12.6

SL124L 1/2” 2-1/4” 1/2” x 4” x 23” LH slashed 12.6

SL124R HF 1/2” 2-1/4” hardfaced RH slashed 13.0

SL124L HF 1/2” 2-1/4” hardfaced LH slashed 13.0

498CL

N ICHOLS T ILLAGE T OOLS , I NC .

9

DISC-CHISEL PARTS

Stock Code Hole Size Hole Spacing Dimensions Weight

MOULDBOARDS 3/8” material

SSM24R 1/2” 2-1/4” 3/8” x 4” 8.0

SSM24L 1/2” 2-1/4” 3/8” x 4” 8.0

SSM24R HF 1/2” 2-1/4” 3/8” x 4” HARDFACED 8.5

SSM24L HF 1/2” 2-1/4” 3/8” x 4” HARDFACED 8.5

REPLACEMENT POINTS

SSP22R 1/2” 1/2” x 4” 3.1

SSP22L 1/2” 1/2” x 4” 3.1

SSP22R HF 1/2” 1/2” x 4” HARDFACED 3.5

SSP22L HF 1/2” 1/2” x 4” HARDFACED 3.5

FROG MOUNTING PLATES

SSF20R 1/2” 2-1/4” 4.8

SSF20R 1/2” 2-1/4” 4.8

Fits: all standard chisel plows or disc chisel machines with 1/2” holes on 2-1/4” hole centers

CHISELS & SPIKES

Two part chisel parts will fit the following disc chisel machines:

• Bush Hog • Ford • Massey

• Brillion • Glencoe • Steiger

• Case • Hiniker • White

• Deere • IHC

• Ferguson • Landoll

Frog Mounting Plate

SSP22R Plain

SSP22R HF Hardfaced

N ICHOLS T ILLAGE T OOLS , I NC .

10

COULTERS

Cut through that field with Nichols 12 and 13 wave coulters!

These coulters have presharpened edges, are made from superior metals to be true running coulters, and are made

to factory standard hardness.

True 1” twelve wave coulters may throw more dirt than standard width wavy coulters. Depth control may be a problem

because the heavy springs on the openers will force them too far into the slot. Stick with standard width wavy coulters. Ours

have standard OEM cutting widths.

12 WAVE COULTERS

Stock Code Wave Size Diameter Ga. Center Hole Holes Bolt Circle Diameter Weight

Fits: YETTER, GREAT PLAINS, WHITE, NEW KINZE, KRAUSE

W154001 WFE 1/2” 15” 8 4” four 17/32” 5-1/4” 8

W164001 WFE 5/8” 16” 8 4” four 17/32” 5-1/4” 9

W174001 WFE 3/4” 17” 8 4” four 17/32” 5-1/4” 10

W184001 WFE 7/8” 18” 8 4” four 17/32” 5-1/4” 11

Fits: D.M.I., TYE, WIL-RICH, MELROE, MARLISS, CRUSTBUSTER, KMC, BLU-JET, SUNFLOWER, NEW UFT

DISCS/COULTERS

W174001 DMI 3/4” 17” 8 3-11/16” four 17/32” 5” 10

W184001 DMI 7/8” 18” 8 3-11/16” four 17/32” 5” 11

Fits: DEERE - 6 holes

W164001 JDNU 5/8” 16” 8 2” six 13/32” 3-1/2” 9

W174001 JDNU 3/4” 17” 8 2” six 13/32” 3-1/2” 10

W184001 JDNU 7/8” 18” 8 2” six 13/32” 3-1/2” 11

Fits: DEERE - Metric - 5 holes

W164001 JDM 5/8” 16” 8 2-1/8” five 17/32” 4-3/4” 9

Fits: RAWSON, UNVERFERTH

W175001 RWS 3/4” 17” 6 3-3/4” six 13/32” 5” 12.5

W185001TT 7/8” 18” 6 3-3/4” six 13/32” 5” 13.8

Fits: NEW IDEA, old style KINZE

W164001 KNZ 5/8” 16” 8 2” six 13/32” 3-3/8” 9

Fits: AC

W174001 AC 3/4” 17” 8 1-13/16” six 13/32” 3-1/4” 10

Fits: UFT

W184001 UFT 7/8” 18” 8 2-1/2” four 17/32” 4” 11

8 WAVE COULTERS

Stock Code Wave Size Diameter Ga. Center Hole Holes Bolt Circle Diameter Weight

Fits: RAWSON, UNVERFERTH

W175002 RWS 2” 17” 6 3-3/4” six 13/32” 5” 12.5

W185002 TT 8 2” 18” 6 3-3/4” six 13/32” 5”

Fits: A C

W174002 AC 8 2” 17” 8 1-13/16” six 13/32” 3-1/4” 10

Fits: KMC Rip Strip

W184002 DMI 2” 18” 8 3-11/16” four 17/32” 5” 11

W204002 DMI 2” 20” 8 3-11/16” four 17/32” 5” 11

N ICHOLS T ILLAGE T OOLS , I NC .

11

13 WAVE COULTERS

Stock Code Wave Width Diameter Ga. Center Hole Holes Bolt Circle Diameter Weight

Fits: A C

W174131 AC 3/4” 17” 8 1-13/16” six 13/32” 3-1/4” 10

Fits: YETTER, GREAT PLAINS, WHITE, NEW KINZE, KRAUSE, MARLISS

W154131 WFE 1/2” 15” 8 4” four 17/32” 5-1/4” 8

W164131 WFE 5/8” 16” 8 4” four 17/32” 5-1/4” 9

W174131 WFE 3/4” 17” 8 4” four 17/32” 5-1/4” 10

Fits: DMI, TYE, WIL-RICH, MELROE, CRUSTBUSTER, KMC, BLU-JET, SUNFLOWER, (new) UFT

W174131 DMI 3/4” 17” 8 3-11/16” four 17/32” 5” 10

W184131 DMI 7/8” 18” 8 3-11/16” four 17/32” 5” 11

Fits: DEERE - 6 holes

W164131 JDNU 5/8” 16” 8 2” six 13/32” 3-1/2” 9

W174131 JDNU 3/4” 17” 8 2” six 13/32” 3-1/2” 10

Fits: DEERE - METRIC

W164131 JDM 5/8” 16” 8 2-1/8” five 17/32” 4-3/4” 9

DISCS/COULTERS

Fits: NEW IDEA, old style KINZE

W164131 KNZ 5/8” 16” 8 2” six 13/32” 3-3/8” 9

Fits: UNVERFERTH, RAWSON, CASE

W184131 Case 7/8” 18” 8 3-3/4” six 13/32” 5” 11

W204131 Case 7/8” 20” 8 3-3/4” six 13/32” 5” 12

For Disc Harrows

W20450118DS 1” 20” 7 1-1/8 to 1-1/4” square holes dual square 12

The wave size on Nichols coulters is the same as OEM standards.

BUBBLE COULTERS

Stock Code

Fits: YETTER, WFE, GREAT PLAINS, CASE, FORD

B17400 WFE

Fits: DEERE

B17400 JDNU

Wavy

Bubble

N ICHOLS T ILLAGE T OOLS , I NC .

12

CONSERVATION TILL BLADES AND BLADES FOR RIDGE TILL CULTIVATOR

Stock Code Diameter Ga. Center Hole Holes Bolt Circle Diameter Weight

CURVED COULTER Fits: BUFFALO

14X778R 14” 8 2-15/16” four 27/64” 4” 6.3

14X8BNC narrow cavity 14” 8 2-15/16” four 27/64” 4” 6.3

18X8C double punched 18” 8 2-1/4” six 15/32” 3-3/4” 10.0

holes for depth ring: four 15/32” 9-7/8”

18X8C2 no depth ring holes 18” 8 2-1/4” six 15/32” 3-3/4” 10.0

20X8C 20” 8 2-1/4” six 13/32” 3-3/4” 10.0

Fits: B&H, JM, HINIKER, ORTHMAN, PROGRESSIVE, REMLINGER, UFT, WETHERELL

14X8CH flat coulter 14" 8 1” flat coulter 6.3

14X8H curved 14” 8 2-1/2” four 17/32” 4” 6.3

16X8CH flat coulter 16” 8 2-1/2” four 17/32” 4” 8.0

18X8CH flat coulter 18” 9 2-1/2” four 17/32” 4” 10.0

20X7CH flat coulter 20” 7 2-1/2” four 17/32” 4” 11.0

22X8CH flat coulter 22” 8 2-1/2” four 17/32” 4” 11.0

DISCS/COULTERS

24X8CH flat coulter 24” 8 2-1/2” four 17/32” 4” 11.0

Fits: BUFFALO, HINIKER, ORTHMAN

14X7OR 1-1/4” concavity 14” 7 none six 5/16” 2-1/8” 6.3

18X8CO flat coulter 18” 8 2-3/4” four 13/32” 4-1/4” 10.0

2045POR 20” 7 2-3/4” four 13/32” 4” 14.3

2245POR flat coulter 22” 7 2-3/4” four 13/32” 4” 14.3

Fits: KMC, WFE, YETTER

2045P WFE 20” 7 4” four 17/32” 5-1/4” 14.3

All flat coulters listed on this page have double bevels.

N ICHOLS T ILLAGE T OOLS , I NC .

13

RIPPLE ROLLING COULTERS

Stock Code Diameter Ga. Center Hole Holes Bolt Circle Diameter Weight

Fits: AC

20450AC 20” 7 1-13/16” six 13/32” 3-1/4” 14.3

Fits: BLUE JET, DMI, TYE, WIL-RICH, MELROE

20450BJ 20” 7 3 -11/16” four 17/32” 5” 14.3

Straight Edge. The ripple begins 3/4" from the edge.

Fits: CASE (prior to White), RAWSON, BRENT, TILL TECH, UNVERFERTH

20450 CASE 20” 7 3-3/4” six 13/32” 5” 14.3

Fits: DEERE - 6 holes

17400 JDNU 17” 8 2” six 13/32” 3-1/2” 8.9

20450 JDNU 20” 7 2” six 13/32” 3-1/2” 14.3

2045P JD flat 20” 5mm 3-11/16” four 13/32” 4-3/8” 14.0

Fits: DEERE - Metric - 5 holes

20450 JDM 20” 7 2-1/8” five 17/32” 4-3/4” 14.3

2045P JDM flat 20” 5mm 2-1/8” five 17/32” 4-3/4” 14.3

DISCS/COULTERS

Fits: D.M.I., TYE, WIL-RICH, MELROE, PROGRESSIVE, THURSTON, SUNFLOWER.

NEW UFT, BLUE JET, KMC, RIP-STRIP, FLEXI COIL, LANDOLL, BINGHAM

17400 DMI 17” 8 3-11/16” four 17/32” 5” 8.9

20450 DMI 20” 7 3-11/16” four 17/32” 5” 14.3

20450 DMI-B with holes for scraper 20” 7 3-11/16” four 17/32” 5” 14.3

FLAT COULTERS

24500 DMI flat coulter 24” 6 3-11/16” four 17/32” 5” 23.8

2045P DMI flat coulter 20” 7 3-11/16” four 17/32” 5” 14.3

20500 DMI flat coulter 20” 6 3-11/16” four 17/32” 5” 15.9

2245P DMI flat coulter 22” 7 3-11/16” four 17/32” 5” 20.3

22500P DMI 22” 6 3-11/16” four 17/32” 5” 20.3

Fits: WFE, DMI double hole punch

20450 WFDM 20” 7 4” four 17/32” 5-1/4” & 5” 14.3

punched for both WFE & DMI holes

Fits: I.H.C.

20450 IHC 20” 7 rectangle six 11/32” 3-1/4” 14.3

Fits: MASSEY FERGUSON

20450 MF 20” 7 3-1/4” four 15/32” 4-3/4” 14.3

Fits:YETTER, GREAT PLAINS, WHITE, (new) KINZE, KRAUSE, FORD, NEW HOLLAND, KBH, MARLISS,ADAMS,AUSHERM

16400 WFE 16” 8 4” four 17/32” 5-1/4” 8.0

17400 WFE 17” 8 4” four 17/32” 5-1/4” 8.9

20450 WFE 20” 7 4” four 17/32” 5-1/4” 14.3

20450 WFES straight edge 20” 7 4” four 17/32” 5-1/4” 14.3

Straight edge. The ripple begins 3/4” from the edge

20450 WFE-A has extra holes 20” 7 4” four 17/32” 5-1/4” 14.3

2045P WFE flat 20” 7 4” four 17/32” 5-1/4” 14.3

N ICHOLS T ILLAGE T OOLS , I NC .

14

RIPPLE ROLLING COULTERS

Stock Code Diameter Ga. Center Hole Holes Bolt Circle Diameter Weight

Fits: KELLY

20450 KEL rippled to the edge 20” 4.5 mm 2-1/2” four 13/32” 3-5/8” 14.3

2045P KEL flat coulter no ripple 20” 4.5 mm 2-1/2” four 13/32” 3-5/8” 14.3

17400 KEL rippled to the edge 17” 4.5 mm 2-1/2” four 13/32” 3-5/8” 8.9

Fits: ORTHMAN

20450 OR ripple 20” 4.5 mm 2-1/2” four 13/32” 4” 14.3

Breakage around the bolt pattern is not covered by warranty.

FLAT COULTERS

Stock Code Description Weight

DISCS/COULTERS

for NOBLE, QUINTAR

22X14 QN 22” x 1/4” 4” center hole, five 1/2” holes on 5-1/4” BCD

24X14 QN 24” x 1/4” 4” center hole, five 1/2” holes on 5-1/4” BCD

SPECIALIZED VEGETABLE FLAT COULTERS

12FC451RD 12” X 4.5 mm flat coulter 1” round hole 12

14FC451RD 14” X 4.5 mm flat coulter 1” round hole 14

16FC451RD 16” X 4.5 mm flat coulter 1” round hole 16

18FC451RD 18” X 4.5 mm flat coulter 1” round hole 18

20FC451RD 20” X 4.5 mm flat coulter 1” round hole 20

N14N3P 14” X 3 mm notched flat coulter 1” pilot hole 14

N18N6P 16” X 6 mm notched flat coulter 1” pilot hole 18

N20N6P 20” X 6 mm notched flat coulter 1” pilot hole 20

HILLER DISC

N12DW 12” X 4.5 mm, center hole, five planetary holes 12

N ICHOLS T ILLAGE T OOLS , I NC .

15

COULTERS, TWISTED CHISELS, AND REPAIR POINTS

FOR DISC-CHISEL MACHINES

Nichols tools are hot forged and heat treated for precision fit and long wear. Nichols hardfaced coulters chisels, and

points are coated with the best wear-resisting alloys. Flat and rippled coulter blades for disc-chisel machines are made with

engineered steel and are true running.

Our 20” and 22” diameter coulter blades are available in 6 gauge, 7 gauge, and 1/4” steel.

Use Nichols heel sweeps in place of twisted chisels for a smooth finish to your fields. The HS13CP or H342CP chisels

are inserted with a high chrome alloy wear resisting edge. They run below the sweep wing line to break up the soil. The heel

sweep acts in a sweep fashion to move soil less aggressively than a twisted chisel. Set them deep for more action. Try a set!

Choose Nichols for your disc-chisel machine.

COULTER BLADES FOR DISC-CHISEL MACHINES

Stock Code Hole Size & Shapes Weight

20” Diameter Double Bevel

DISCS/COULTERS

SSD26 7 gauge, 1-1/2” round hole, flat coulter 14.3

SSD26B 7 gauge, 1-1/2” square hole, flat coulter 14.3

SSD26 R 7 gauge, 1-1/2” round hole, RIPPLED coulter 14.3

SSD26-1412SR 1/4” mtrl., 1-1/2” square X 1-3/4” round hole, flat coulter 19.8

SSD26-1414SR 1/4” mtrl., 1-1/4” square X 1-1/2” round hole, flat coulter 19.8

SSD26-6 6 gauge, 1-1/2” round hole flat coulter 17.5

SSD26-612SR 6 gauge, 1-1/2” square X 1-3/4” round hole, flat coulter 17.5

SSD26-6DS 6 gauge, 1-1/8” X 1-1/4” dual square, flat coulter 17.5

SSD26DS 7 gauge, 1-1/8” X 1-1/4” dual square, flat coulter 14.3

22” Diameter Double Bevel

SSD28 6 gauge, 1-1/2” round hole, flat coulter 20.3

SSD28-N 6 gauge, 1-1/2” round hole, NOTCHED flat coulter 18.6

SSD28B 6 gauge, 1-1/2” square hole, flat coulter 20.3

SSD28SR 6 gauge, 1-1/4” square X 1-1/2” round hole, flat coulter 20.3

N ICHOLS T ILLAGE T OOLS , I NC .

16

SINGLE BEVEL COULTERS

Stock Code Description Weight

for DEERE 750

18X5JD750 18” x 5 mm blade only. 3-1/16” center hole, four 13/32” holes

on a 4-3/8” bolt circle diameter. No bolt included. 13.0

20X45PLD 20” x 5 mm plain edge coulter, 3-1/2” center hole,

four 7/32” holes on a 4-1/4” bolt circle diameter 17.0

13X125JD Flat blade with slotted hole

for CRUSTBUSTER #3400 requires two 204RY2 bearings

16X4PCB 16” x 4 mm blade only. No bolt included. 8.6

for CRUSTBUSTER #3400 a Flat Notched Coulter requires two 204RY2 bearings

16X4NCB 16” x 4 mm blade only. No bolt included. 3.4

COVERING DISC ASSEMBLY

DISCS/COULTERS

Stock Code Description Weight

Fits: DEERE & KINZE

8JDCD 8” assembly w/ bearing. No bolt included. 2.0

8JDCDOS 8” assembly w/ bearing – bolt included (original style). 2.0

Fits: I H

8IHCD 8” assembly w/ bearing. No bolt included. 2.0

N ICHOLS T ILLAGE T OOLS , I NC .

17

DOUBLE DISC OPENERS, SEED OPENERS/GRAIN DRILLS

Nichols Openers for planters, seeders, and drills are factory assembled with Nichols retainers.

We use gothic arch bearings.

Stock Code Description Weight

Fits: AC385, LANDOLL No bolt included

164AC 16” x 4mm blade. Bevel faces outside. Uses pop in cap. 9.7

Fits: DEERE, KINZE, WHITE 6100 No bolt included. Uses a pop in cap.

150JD 15” diameter blade 7.4

150FJD 15” diameter blade w/205 bearing 3.0 mm thickness 7.4

15035JD 15” diameter blade w/205 bearing 3.5 mm thickness 7.4

15035FJD 15” diameter blade w/205 bearing 3.5 mm thickness 7.4

Fits: DEERE plus 7000 PLANTERS #8300, #9300. These are fertilizer blades for the DEERE #8300 & #9300.

135JD HD

150KZ HD

Fits: GREAT PLAINS; AC50, 71, & 72 fertilizer only; No bolt included. Some CRUSTBUSTERS

DISCS/COULTERS

135GP 13-1/2” diameter blade Uses a hole through cap. 5.5

135GPA 13-1/2” diameter blade Uses a hole through cap. w/ depth band holes. 5.5

135FGP 13-1/2” diameter blade Uses a hole through cap. Includes 205 bearing. 5.5

Fits: GREAT PLAINS/205 Bearing

150GP 15” diameter blade 5/8 hole. Uses a hole through cap. 7.4

150GP34 15” diameter blade 3/4 hole.

Fits: IH PLANTERS #800 & #900. No bolt included. Uses a pop in cap. Bevels to the right and left.

140IHR RIGHT 14” diameter blade. No bolt included. Uses a pop in dust cap. 6.2

140IHL LEFT 14” diameter blade. No bolt included. Uses a pop in dust cap. 6.2

Fits: IH #510, #5100, #620, #6200 grain drills, & some old models of planters

140IHL LEFT 14” diameter blade. No bolt included. Uses a pop in dust cap. 6.2

Fits: KRAUSE Retainer is on back side. Uses a hole through cap.

13535KRA 13-1/2” diameter blade x 3.5 mm. Bevel faces inside. No bolt included. 7.0

Fits: TRANSPLANTER

135JD34 13-1/2” diameter blade. 3/4” hole. No bolt included. Uses pop in dust cap. 5.5

Fits: MONOSEM

150MON 15” diameter blade. 3/4” hole. Uses a pop in dust cap. 7.4

Fits: MARLISS & M&W

130MRLS 13” diameter blade. 3/4” bore. No bolt included. 5.2

Uses a hole through metal dust cap with 3/4” hole.

Fits: SUNFLOWER

150SF 15” diameter blade. 3/4” hole. Uses a metal dust cap with 3/4” hole. 7.4

Fits: SUNFLOWER #9430 AND # 9431 drill. Spacer is needed.

150FSF 15” diameter with 205 bearing

Fits: UFT; TYE; CRUSTBUSTER 3800

(UFT, TYE, & CBR do require left hand and right hand bolts. Bolts are supplied separately.)

Uses a metal cap that the bolt goes through. No bolt included.

135TUF 13-1/2” diameter blade 5.5

135CB 13-1/2” diameter blade. Bolt not included. Uses a pop in cap.

Fits: WHITE #5100 PLANTER, AC 74, 77, 78 (fertilizer uses only)

135WFE 13-1/2” diameter blade. No bolt included. Uses a pop in cap. 5.5

Fits: KINZE, WHITE & COLE

1535KNWF 15” DIAMETER BLADE. 3.5mm blade

130CPL 13” diameter, 3.0 thickness, 5/8” bearing – no bolt included

N ICHOLS T ILLAGE T OOLS , I NC .

18

SMOOTH PLAIN EDGE SPHERICAL DISCS

SQ= SQUARE DS= DUAL SQUARE RD= ROUND SR= SQUARE & ROUND

Stock Code Diameter Ga. Metric Hole Size Weight

16X111DS 16” 11 3.0 mm 1” x 1-1/8” DS 7.0

16X1112R 16” 11 3.0 mm 1-1/2” RD 7.0

16X918S 16” 9 3.5 mm 1-1/8” SQ 8.2

16S31116SQ 16” 3.0 mm 1 1/16” SQ 7.0

16S451RD 16” 4.5 mm PILOT 7.0

16S4COM 16” 4.0 mm COMMON 7.0

18X91DS 18” 9 3.5 mm 1” x 1-1/8” DS 10.3

18X918DS 18” 9 3.5 mm 1-1/8” x 1-1/4” DS 10.3

18X918R 18” 9 3.5 mm 1-1/8” RD 10.3

18X918S 18” 9 3.5 mm 1-1/8” SQ 10.3

18X912R 18” 9 3.5 mm 1-1/2” RD 10.3

18X912S 18” 9 3.5 mm 1-1/2” SQ 10.3

DISCS/COULTERS

18S4COM 18” 4.0 mm COMMON 10.3

18S6P 18” 6.0 mm PILOT 10.3

18X81DS 18” 8 4.0 mm 1” x 1-1/8” DS 11.7

18X818DS 18” 8 4.0 mm 1-1/8” x 1-1/4” DS 11.7

18X818R 18” 8 4.0 mm 1-1/8” RD 11.7

18X812R 18” 8 4.0 mm 1-1/2” RD 11.7

18X812S 18” 8 4.0 mm 1-1/2” SQ 11.7

18X812SR 18” 8 4.0 mm 1-1/2” SQ x 1-3/4” RD 11.7

18X718S 18” 7 4.5 mm 1-1/8” SQ 13.0

18X712R 18” 7 4.5 mm 1-1/2” RD 13.0

20X71DS 20” 7 4.5 mm 1” x 1-1/8” DS 15.6

20X718DS 20” 7 4.5 mm 1-1/8” x 1-1/4” DS 15.6

20X712S 20” 7 4.5 mm 1-1/2” SQ 15.6

20X712R 20” 7 4.5 mm 1-1/2” RD 15.6

20X718S 20” 7 4.5 mm 1-1/8” SQ 15.6

20X714DS 20” 7 4.5 mm 1-1/4” x 1-1/2” DS 15.6

20X61DS 20” 6 5.0 mm 1” x 1-1/8” DS 18.0

20X618DS 20” 6 5.0 mm 1-1/8” x 1-1/4” DS 18.0

20X612R 20” 6 5.0 mm 1-1/2” RD 18.0

20X612S 20” 6 5.0 mm 1-1/2” SQ 18.0

20X612SR 20” 6 5.0 mm 1-1/2” SQ x 1-3/4” RD 18.0

20S4CO 20” 4.0 mm COMMON 18.0

20S6P 20” 6.0 mm PILOT 18.0

20X14DMI 20” 1/4” 6.0 mm 5 holes DMI pattern 21.0

20X1412SR 20” 1/4” 6.0 mm 1-1/2” SQ x 1-3/4” RD 21.0

20X1418DS 20” 1/4” 6.0 mm 1-1/8” x 1-1/4” DS 21.0

20X1418S 20” 1/4” 6.0 mm 1-1/8” SQ 21.0

N ICHOLS T ILLAGE T OOLS , I NC .

19

SMOOTH EDGE SPHERICAL DISC BLADES

Stock Code Diameter Ga. Metric Hole Size Weight

22X71DS 22” 7 4.5 mm 1” x 1-1/8” DS 19.0

22X718DS 22” 7 4.5 mm 1-1/8” x 1-1/4” DS 19.0

22X712R 22” 7 4.5 mm 1-1/2” RD 19.0

22X712S 22” 7 4.5 mm 1-1/2” SQ 19.0

22X712SR 22” 7 4.5 mm 1-1/2” SQ x 1-3/4” RD 19.0

22X734R 22” 7 4.5 mm 1-3/4” RD 19.0

22X718S 22” 7 4.5 mm 1-1/8” SQ 19.0

22S451316SQ 22” 4.5 mm 1 3/16” SQ 19.0

22S45P 22” 4.5 mm PILOT 19.0

22X618S 22” 6 5.0 mm 1-1/8” SQ 21.8

22X618DS 22” 6 5.0 mm 1-1/8” x 1-1/4” DS 21.8

22X612R 22” 6 5.0 mm 1-1/2” RD 21.8

22X612S 22” 6 5.0 mm 1-1/2” SQ 21.8

22X612SR 22” 6 5.0 mm 1-1/2” SQ x 1-3/4” RD 21.8

DISCS/COULTERS

22X14DMI 22” 1/4” 6.0 mm 5 holes DMI pattern 27.4

22X141DS 22” 1/4” 6.0 mm 1” x 1-1/8” DS 27.4

22X1418DS 22” 1/4” 6.0 mm 1-1/8” x 1-1/4” DS 27.4

22X1414SR 22” 1/4” 6.0 mm 1-1/4” SQ x 1-1/2” RD 27.4

22X1412S 22” 1/4” 6.0 mm 1-1/2” SQ 27.4

22X1412SR 22” 1/4” 6.0 mm 1-1/2” SQ x 1-3/4” RD 27.4

22X1418S 22” 1/4” 6.0 mm 1-1/8” SQ 27.4

22X1434R 22” 1/4” 6.0 mm 1 3/4” RD 27.4

22X51612R 22” 5/16” 6.5 mm 1-1/2” RD 36.5

22X51634R 22” 5/16” 6.5 mm 1-3/4” RD 36.5

24X1412S 24” 1/4” 6.0 mm 1-1/2” SQ 31.4

24X1414SR 24” 1/4” 6.0 mm 1-1/4” SQ x 1-1/2” RD 31.4

24X1412SR 24” 1/4” 6.0 mm 1-1/2” SQ x 1-3/4” RD 31.4

24X1412DS 24” 1/4” 6.0 mm 1-1/4” x 1-1/2” DS 31.4

24X1434R 24” 1/4” 6.0 mm 1-3/4” RD 31.4

24X142R 24” 1/4” 6.0 mm 2” RD 31.4

24S45P 24” 4.5 mm PILOT 31.4

24S61516SQ 24” 6.0 mm 1-5/16” SQ 31.4

24S6P 24” 6.0 mm PILOT 31.4

26X1412S 26” 1/4” 6.0 mm 1-1/2” SQ 37.0

26X1412SR 26” 1/4” 6.0 mm 1-1/2” SQ x 1-3/4” RD 37.0

26X14158S 26” 1/4” 6.0 mm 1-5/8” SQ 37.0

26S45P 26” 4.5 mm PILOT 37.0

26S611316SQ 26” 6.0 mm 1-13/16” SQ 37.0

26S61916SQ 26” 6.0 mm 1-9/16” SQ 37.0

28S61916SQ 28” 6.0 mm 1-9/16” SQ 37.0

28S6P 28” 6.0 mm PILOT 37.0

28S811316SQ 28” 8.0 mm 1-13/16” SQ 37.0

28S81916SQ 28” 8.0 mm 1-9/16” SQ 37.0

28S8P 28” 8.0 mm PILOT 37.0

28S8P 28” 8.0 mm PILOT 37.0

N ICHOLS T ILLAGE T OOLS , I NC .

20

NOTCHED SPHERICAL DISC BLADES

Stock Code Diameter Ga. Metric Hole Size Weight

16X9N18S 16” 9 3.5 mm 1-1/8” SQ 11.0

18X14N18S 18” 1/4” 6.0 mm 1-1/8” SQ 11.7

18X7N78SR 18” 7 4.5 mm 7/8” SQ x 1” RD 12.0

18X7N18S 18” 7 4.5 mm 1-1/8” SQ 12.0

18X9N18DS 18” 9 3.5 mm 1-1/8” x 1-1/4” DS 9.9

18X9N18S 18” 9 3.5 mm 1-1/8” SQ 9.9

20X7N18DS 20” 7 4.5 mm 1-1/8” x 1-1/4” DS 15.0

20X9N18S 20” 9 3.5 mm 1-1/8” SQ 11.7

20X14N18S 20” 1/4” 6.0 mm 1-1/8” SQ 20

22X7N18DS 22” 7 4.5 mm 1-1/8” x 1-1/4” DS 17.5

22X7N12S 22” 7 4.5 mm 1-1/2” SQ 17.5

22X7N18S 22” 7 4.5 mm 1-1/8” SQ 17.5

22X14N18DS 22” 1/4" 6.0 mm 1-1/8” x 1-1/4” DS 24.8

22X14N12S 22” 1/4 6.0 mm 1-1/2” SQ 29.4

DISCS/COULTERS

22X14N14SR 22” 1/4 6.0 mm 1-1/4” SQ x 1-1/2” RD 29.4

22X14N12SR 22” 1/4 6.0 mm 1-1/2” SQ x 1-3/4” RD 29.4

22N451316SQ 22” 4.5mm 1-3/16” SQ 29.4

22N45P 22” 4.5 mm PILOT 29.4

24X14N12SR 24” 1/4” 6.0 mm 1-1/2” SQ x 1-3/4” RD 29.4

24X14N34R 24” 1/4” 6.0 mm 1-3/4” RD 29.4

24X14N12S 24” 1/4” 6.0 mm 1-1/2” SQ 24.8

24X14N12R 24” 1/4” 6.0 mm 1-1/2” RD 24.8

24X14N18DS 24” 1/4” 6.0 mm 1-1/8” x 1-1/4” DS 24.8

24N45P 24” 4.5 mm PILOT 24.8

24N61516SQ 24” 6.0 mm 1-5/16” SQ 24.8

24N61916SQ 24” 6.0 mm 1-9/16” SQ 24.8

24N6P 24” 6.0 mm PILOT 24.8

24SD 24” FITS SUNDANCE 24.8

26X14N12S 26” 1/4” 1-1/2" SQ 35

26X14N134R 26” 1/4” 1-3/4" RD 35

26N45P 26” 4.5 mm PILOT 35

26N611316SQ 26” 6.0 mm 1-13/16” SQ 35

26N61916SQ 26” 6.0 mm 1-9/16” SQ 35

26N6P 26” 6.0 mm PILOT 35

N ICHOLS T ILLAGE T OOLS , I NC .

21

NOTCHED SPHERICAL DISC BLADES

Stock Code Diameter Ga. Metric Hole Size Weight

28N61916SQ 28” 6.0 mm 1-9/16” SQ 35

28N6P 28” 6.0 mm PILOT 35

28N811316SQ 28” 8.0 mm 1-3/16” SQ 35

28N81916SQ 28” 8.0 mm 1-9/16” SQ 35

28N8P 28” 8.0 mm PILOT 35

SPHERICAL CONE DISC BLADES FOR JOHN DEERE

Stock Code Diameter Ga. Metric Hole Size Weight

20X7C18DS 20” 7 4.5 mm 1-1/8” X 1-1/4” DS 17.0

22X6C18DS 22” 6 5.0 mm 1-1/8” X 1-1/4” DS 21.8

22X14C14S 22” 1/4” 6.0 mm 1-1/4” SQ 24.7

22X14C12S 22” 1/4” 6.0 mm 1-1/2” SQ 24.7

22X14C18DS 22” 1/4” 6.0 mm 1-1/8” X 1-1/4” DS 24.7

DISCS/COULTERS

24X14C18DS 24” 1/4” 6.0 mm 1-1/8” X 1-1/4” DS 32.6

24X14C14S 24” 1/4” 6.0 mm 1-1/4” SQ 32.6

NOTCHED CONE DISC BLADES FOR JOHN DEERE

Stock Code Diameter Ga. Metric Hole Size Weight

22X14CN14S 22” 1/4” 1-1/4” SQ 24.7

24X14CN14S 24” 1/4” 1-1/4” SQ 32.6

22X14CN18DS 22” 1/4” 1-1/8 x 1-1/4” DS 24.6

22X14CN18S 22” 1/4” 1-1/8” SQ 24.6

FLAT CENTER DISC BLADES FOR CASE IH

Stock Code Diameter Ga. Metric Hole Size Weight

18X8FC18S 18” 8 4.0 mm 1-1/8” SQ 11.7

18X7FC18S 18” 7 4.5 mm 1-1/8” SQ 11.7

18X7FC451RD 18” 4.5 mm 1” RD 11.7

20X7FC12R 20” 7 4.5 mm 1-1/2” RD 15.6

20X9FC18S 20” 9 3.5 mm 1-1/8” SQ 12.2

20X7FC18S 20” 7 4.5 mm 1-1/8” SQ 15.6

20X6FC18S 20” 6 5.0 mm 1-1/8” SQ 18.0

20X14FC12S 20” 1/4” 6.0 mm 1-1/2” SQ 21.0

20X14FC451RD 20” 1/4” 4.5 mm 1” RD, pilot 21.0

22X6FC18S 22” 6 5.0 mm 1-1/8” SQ 21.8

22X7FC12R 22” 7 4.5 mm 1-1/2” RD 19.0

22X6FC12R 22” 6 5.0 mm 1-1/2” RD 21.8

22X7FC18S 22” 7 4.5 mm 1-1/8” SQ 19.0

22X14FC18S 22” 1/4” 6.0 mm 1-1/8” SQ 27.4

24X6FC18S 24” 6 5.0 mm 1-1/8” SQ 26.2

24X14FC12S 24” 1/4” 6.0 mm 1-1/2” SQ 31.4

26X14FC12S 26” 1/4” 6.0 mm 1-1/2” SQ 38.2

26S6P FC 26” 6.0 mm PILOT 38.2

28S61916SQFC 28” 6 mm 5.0 mm 1-9/16” SQ 42

28S81916SQFC 28” 8 mm 4.0 mm 1-9/16” SQ 42

N ICHOLS T ILLAGE T OOLS , I NC .

22

NOTCHED FLAT CENTER DISC BLADES

Stock Code Diameter Ga. Hole Size Weight

18N61916SQFC 18” 6 ga 1-9/16” SQ 18

20N6P 20” 6 ga PILOT 18

26N6P 20” 6 ga PILOT 18

28N6P 28” 6 mm PILOT 32

28N61916SQFC 28” 6 mm 1-9/16” SQ 32

28N811316SQFC 28” 8 mm 1-13/16” SQ 32

28N81916SQFC 28” 8 mm 1-9/16” SQ 32

18X8FCN18S 18” 8 1-1/8” SQ NOTCHED FLAT CENTER 18

20X316FCN18S 18” 3/16” 1-1/8” SQ NOTCHED FLAT CENTER 18

NOTCHED FLAT CENTER DISC BLADES FOR CASE

DISCS/COULTERS

Stock Code Size Weight

18X7FCN18S 18” x 7 ga x 1-1/8” Sq. 11.70

20X7FCN18S 20” x 7 ga x 1-1/8” Sq. 15.60

22X7FCN18S 22” x 7 ga x 1-1/8” Sq. 19.00

20X9FCN18S 20” x 9 ga x 1-1/8” Sq. 12.40

22X14FCN12R 22” x 1/4” x 1-1/2” Rd. 24.80

22X6FCN12R 22” x 6 ga x 1-1/2” Rd. 21.80

22X6FCN18S 22” x 6 ga x 1-1/8” Sq. 21.80

24X6FCN18S 24” x 6 ga x 1-1/8” Sq. 24.80

MILLER DISCS

Stock Code Description Weight

24X1434R MF 24” x 1/4”, 2-5/8” concavity for front rank 29.4

24X1434R MR 24” x 1/4”, 3-3/4” concavity for rear rank 29.4

26X51634R MF 26” x 5/16”, 3” concavity for front rank 46.0

26X51634R MR 26” x 5/16”, 4” concavity for rear rank 46.0

DEERE BLADES

Stock Code Size Length HF PL

DE51622 22” 4.30 lb 13.89 7.31

DE51624 24” 4.50 lb 14.48 7.62

To order hardfaced, specify “HF” after part number.

N ICHOLS T ILLAGE T OOLS , I NC .

23

SHALLOW CONCAVITY DISC BLADES

Stock Code Diameter Ga. Hole Diameter Concavity Metric Weight

18X9SH12R 18” 9 mm 1-1/2” RD 1.06” concavity 40 mm 13.5

20X7SH12R 20” 7 ga 1-1/2” RD 1.31” concavity 40 mm 15.6

20X6SH12R 20” 6 ga 1-1/2” RD 1.31” concavity 40 mm 18.0

20X6SH34R 20” 6 ga 1-3/4” RD 1.31” concavity 40 mm 18.0

20X14SH34R 20” 1/4” 1-3/4” RD 1.31” concavity 40 mm 21.0

22X6SH34R 22” 6 ga 1-3/4” RD 1.69” concavity 43 mm 23.0

24X6SH34R 24” 6 ga 1-3/4” RD 1.69” concavity 43 mm 25.0

The following machines require specific disc sizes:

• Landoll 7 ga

• Krause 6 ga

• Sunflower 6 ga and 1/4”

• Kent 7 ga

ORTHMAN BLADES

DISCS/COULTERS

Stock Code Size Length Weight

OR264RH HF hardfaced right hand 26” 21-3/4 4.2

OR265LH HF hardfaced left hand 26” 21-3/4 4.2

OR284RH HF hardfaced right hand 28” 28-1/4 7.1

OR285LH HF hardfaced left hand 28” 28-1/4 7.1

DISC BEARINGS,

see Quality Replacement Parts Catalog or contact your Nichols representative.

N ICHOLS T ILLAGE T OOLS , I NC .

24

BEAN KNIVES

These bean knives fit Deere, Heath, Speedy & Orthman bean pullers.

The material is 3/8” x 4” carbon steel with a bevel. The stocking code number for the hardfaced knives is designated by

adding HF to the plain part number. When you order, specify whether the hardfacing is to be on the top or on the bottom.

Add HF to part number to indicate hardfacing.

Stock Code Size Weight

for HEATH (fits DEERE)

HETH48L 48” long left hand 14

HETH48R 48” long right hand 14

HETH54L 54” long left hand 16

HETH54R 54” long right hand 16

for SPEEDY

SPDY48L 48” long left hand 14

SPDY48R 48” long right hand 14

SPDY54L 54” long left hand 16

SPDY54R 54” long right hand 16

for ORTHMAN

ORTH58L 58” long left hand 18

KNIVES

ORTH58R 58” long right hand 18

HEATH

SPEEDY

N ICHOLS T ILLAGE T OOLS , I NC .

25

PARABOLIC FRONT SWEPT KNIFE

Nichols Parabolic Front Swept Knives provide better gas and solutions placement … and seal better, too.

They are crafted with abrasion-resistant, high-chrome alloy, cast points and pipe protectors. Designed to fit side mount

or plate mount shanks, they are available with or without a sealer.

Our N40TP (“Regular”) Series has the standard pipe protector which shields the pipe on its sides. Our Regular series

are rigged with a 1/8” standard wall pipe, or, if you prefer, a 1/4” standard wall steel pipe. (Please specify when ordering.)

Our N40LTP (“L”) Series includes a unique U-shaped pipe protector which shelters a 1/8” plastic pipe all around to

help assure the life of the plastic pipe. Use this arrangement to connect the plastic pipe directly to the manifold without

using connectors or adapters. (Applications tip: Cut off the end of the pipe to remove a plug-up.) The plastic pipe resists

corrosion and can be used in acid applications. Our “L” series can also be easily rigged for dual applications where acid is

pumped in the plastic, and ammonia is pumped in the steel pipe. “L” series are equipped with 1/8” flexible plastic pipe.

Our Long N40 Knives are 1/2” x 2-1/2” with 1/2” holes on 1-1/2” to 3” centers.

Stock Code Description Weight

Regular Series

N40TP8 with pipe protector and 1/8” pipe 6.65

N40TP8 20” 20” long N40

N40TP4 with 1/4” pipe & pipe protector 6.65

N40TPSR8 with 1/8” pipe, pipe protector, and sealer 7.35

N40TPSR8 20” 20” with sealer

KNIVES

N40TPSR4 with 1/4” pipe, pipe protector, and sealer 7.35

N40TPSR8

N40TPSRSR4 tube protector & two sealers, 1/4” pipe 8.50

N40TPSR DUO8 rigged with two 1/8” pipes and sealer 8.0

N40TP DUO8 dual 1/8” pipes with tube protectors 8.20

N40TPSR DUO4 rigged with two 1/4” pipes and sealer 8.0

Plastic Pipe LTP Series

N40LTP with plastic pipe and wrap 7.00

around pipe protector

N40LTPSR with plastic pipe, pipe protector & sealer 7.75

N40LTPDUO8 with two 1/8” pipes, pipe protector 8.0

LONG N40 KNIFE 20” long knife N40TP8 20”

N40TP8 20” with a 1/8” pipe, pipe protector, 20” long 8.5

M1 WINGED ANHYDROUS KNIFE

Nichols winged anhydrous knives enable easy ripping-in of gases and

solutions in both standard and strip till applications. The sharp nose pulls

easier, plus the wings are inclined to accept all soils and moisture situations

for successful penetration and sealing.

Stock Code Size N40TP8

M1TP8 with pipe protector and 1/8” pipe

M1TP4 with 1/4” pipe & pipe protector

M1TPSR8 with 1/8” pipe, pipe protector, and sealer

M1TPSR4 with 1/4” standard wall pipe and sealer

M1TPDUO8 with two1/8” pipes,pipe protector

M1TPDUO4 with two 1/4” pipes, pipe protector

M1

N ICHOLS T ILLAGE T OOLS , I NC .

26

ECONOMY KNIVES

The FL30 has an attack angle for good penetration. Its heavy cast alloy point provides an enhanced service life.

A high alloy pipe protector is installed on all FL30 knives. The FL30 has a superior design, and is a well

assembled injector knife for good service in basic applications.

FL30 knives are punched with 1/2" holes for standard vertical plate mounting to shanks with 1-1/2” to 3” hole centers.

Stock Code Description Weight

These are all made with 1/2" x 2" hardened material.

FL30TP8 with pipe protector & 1/8” pipe 6.75

FL30TPSR8 with pipe protector, sealer, & 1/8” pipe 6.88

FL30TPSR4 with pipe protector, sealer, and 1/4” pipe 6.88

FL30TP4 with pipe protector and 1/4” pipe 6.88

FL30TPSRDUO8 with pipe protector, sealer, 1/8” pipe 8.00

FL30TPSRDUO4 with pipe protector, sealer, 1/4” pipe 8.00

FL30TPDUAL4 with pipe protector, two 1/4” pipes 8.00

FL30TP8

KNIVES

NARROW PROFILE KNIVES

The FL20 is a narrow profile/low tillage knife that can be used both in minimum till, or where

narrow (3/8”) knives are required for lower soil disturbance. A high alloy pipe protector is installed

on all FL20 knives. They are punched with 1/2” holes on 1-1/2” to 3” centers and Stam notches.

Stock Code Description Weight

FL20TP8 with pipe protector & 1/8” pipe 6.30

FL20TPSR8 with pipe protector, sealer, & 1/8” pipe 6.50

FL20TPSRDUO8 with pipe protector, sealer, and two 1/8” pipes 7.75

FL20TPSRDUO4 with pipe protector, sealer, and two 1/4” pipes 7.75

FL20TP4 with pipe protector, 1/4” pipe 6.30

FL20TPSR4 with pipe protector, sealer, 1/4” pipe 6.50 FL20TP8

KNIVES FOR COULTER KNIFE COMBINATION

Stock Code Description Weight

1/4” pipe fits a 1/2” hose; 1/2” pipe fits a 3/8” hose.

N5P8 Plain knife w/ 1/8” pipe 4.0

N5HF8 Hardfaced knife w/ 1/8” pipe 4.0

N5P4 Plain knife w/ 1/4” pipe 4.0

N5HF4 Hardfaced knife w/ 1/4” pipe 4.0

N5P8S Plain knife w/ 1/8” stainless pipe 4.0

N5HF8S Hardfaced knife w/ 1/8” stainless pipe 4.0

N5P4S Plain knife w/ 1/4” stainless pipe 4.0

N5HF4S Hardfaced knife w/ 1/4” stainless pipe 4.0 N5HF8

Frontswept 3/8” x 2” forged knife for use in combination with the coulters on page 11.

N ICHOLS T ILLAGE T OOLS , I NC .

27

CURVED BACKSWEPT KNIVES

N13CPTP8 and N17CPTP8 knives are inserted with a wear resisting alloy casting at the leading edge and an optional

pipe protector made from the same material.

N13HF8 and N17HF8 are conventionally and correctly hardfaced on one side, assuring they remain sharp longer.

The backswept knives are used for sidedressing vegetables and to apply fertilizer during seeding. They are punched with

1/2” holes on 1-1/2” to 3” centers and can be used on MaxiMerge equipment for fertilizing while planting.

Stock Code Description Weight

All knives are rigged with 1/8” standard wall pipe unless otherwise special ordered.

3/8" x 13" knives:

N13B blank with no pipe and no hardfacing 3.50

N13B8 blank with 1/8” pipe but no hardfacing 3.50

N13CP8 cast alloy edge and 1/8” pipe 3.70

N13CPTP8 cast alloy edge, pipe protector, & 1/8” pipe 3.80

N13HF8 hardfaced & 1/8” pipe 3.80

3/8" x 17" knives:

N17B heattreated 17” blank 3.50

N17B8 blank with 1/8” pipe and no hardfacing 4.20

N17CP8 cast alloy edge and 1/8” pipe 4.20 N17B8

KNIVES

N17CPTP8 cast alloy edge, pipe protector, & 1/8” pipe 4.30

N17HF8 hardfaced & 1/8” pipe 4.30

FRONTSWEPT STANDARD HARDFACED

Stock Code Description Weight

N15 B heattreated blank no pipe 4.50

N15 B 8 with 1/8” pipe attached 4.60

N15 HF8 hardfaced with 1/8” pipe 5.50

N15 HF4 hardfaced with 1/4” pipe 5.50

N15HFSR8 with sealer and 1/8” pipe 5.55 N13B8

BACKSWEPT KNIFE FOR DRY FERTILIZER DELIVERY

Stock Code Description Weight

N13HF-112 3/8” x 2” curved backswept knife 3.8

w/an attached 1-1/2” tube

N ICHOLS T ILLAGE T OOLS , I NC .

28

N19 STRAIGHT BACKSWEPT KNIVES

N19HF8 comes either as hardfaced or as a knife inserted with an abrasion resisting alloy wear edge. These are the

knives you need on your rigs. There is nothing like them elsewhere!

We apply the hardfacing by hand with acetylene so that it is smooth and the craftmanship is excellent. So are the results.

The edge stays sharp for good cutting action.

The inserted N19CPTP8 knife is assembled carefully with chrome alloy cast wear edges and pipe protectors. The pipe is

positioned carefully and the discharge ports are arranged to your liking. The 1/2” holes are punched on 1-1/2” to 3" centers.

Stock Code Description Weight

Hardfaced series 1/2” material

N19B Heat treated blank 4.40

N19B4 Heat treated blank with 1/4” pipe 4.50

N19B8 Heat treated blank with 1/8” pipe 4.50

N19HF8 Hardfaced knife with 1/8” pipe 4.75

N19HF28 Hardfaced on both sides with 1/8” pipe 4.80

Wear resisting alloy inserted series. 1/2” material

N19CP8 Heat treated blank with pipe protector and 1/8” pipe 5.30

N19CPTP8 Both the wear edge & pipe protector are wear 5.30

resisting alloy. With a 1/8” standard wall pipe.

N19CP8

KNIVES

N19HF8-212 2-1/2” wide, hardfaced with 1/8” pipe 6.00

LONG SHANK KNIVES

The #N30 applicator shank is used on tool bar holders and is used in fumigation or fertilizer applications in vegetables

and other leafy crops. It has a special tongue that accepts replacement cast points that are held in place with a screw and nut

or a roll pin. It is punched with a 1/4” or a 5/16” screw or roll pin.

Stock Code Description Hole Size Weight

N30-5 1/2” X 2” X 32” shank with tongue for the fixture

of a cast wear point and with a 5/16” hole in the tongue 11

215 1601 CR High chrome alloy casting for long wear with a 5/16” hole.

Fits N30-5 1.8

N30-4 1/2” X 2” X 32” shank with tongue for the fixture

of a cast wear point and with a 1/4” hole in the tongue 11

2604 High chrome alloy casting for long wear. Fits N30-4 1.8

N30-4 HF A hardfaced N30 with a 1/4” hole in the tongue 11

N30-5 HF The same as above but also hardfaced. 5/16” hole in the tongue 11

N30-5

N ICHOLS T ILLAGE T OOLS , I NC .

29

FERTILIZER KNIVES FOR CHISEL PLOWS

The 43N20 is a hardfaced special forged product which has been built for rugged work in a chisel plow application.

The 43N60, designed for use on chisel plows, is an assembly with the leading point welded in place. The shank is 2” wide.

The alloy cast point is made from solid hardfacing and is assembled with a forged blank for long wear. The 43N60 is not

recommended for deep ripping activity. They require plow bolts for mounting.

The 33N20HF8 is a hardfaced knife that has been especially designed for field cultivators. The shank is 1-3/4” wide

and it has two 7/16” holes on 1-3/4” centers and the forging is made for strength.

All these knives require plow bolts for mounting.

Stock Code Description Weight

For chisel plows: 1/2” holes are on 2-1/4” centers

43N20HF8 hardfaced knife with a 1/8” pipe 5.4

43N60TP8 w/alloy point & pipe protector for the 1/8” pipe 5.5

For field cultivators

33N20HF8 hardfaced knife, 1/8” pipe, 7/16” holes are on 1-3/4” centers 2.2

33ICS9 3/8” x 2” x 9” single end point for field cultivators. 3.2

Two 7/16” holes on 1-3/4” centers. The customer welds his

pipe to the back of the 33ICS9 to place the fertilizer.

43N20HF8

KNIVES

CREASER POINTS

Stock Code Description Weight

Number 1 5/16” material square hole 2.6

Number 1 HF 5/16” material square hole, hardfaced on inside of the curve 2.6

Number 3 5/16” material, round nose, square hole 2.6

Number 3 HF 5/16” material, round nose, hardfaced on inside of the curve, square hole

33N20HF8

ROD POINTS FOR ROD WEEDERS

Stock Code Fits Weight

21 MILLER, under the rod 2.2

22 MILLER, over the rod 2.2

23 CALKINS 2.2

24 QUINSTAR 2.2

25 QUINSTAR 2.2

#22 #21 #24

N ICHOLS T ILLAGE T OOLS , I NC .

30

NICHOLS RIPPER POINTS

Nichols designed a better ripper point for deep soil shattering. It is made to withstand heavy wear, resist

breakage, and penetrate in tough conditions. They are made with a high chrome-carbide, wear resistant casting which

is attached to the point. The leading edges are hardfaced with the best alloys and made from the heaviest of materials.

The shovel is assembled to Nichols high standards. The Nichols shovel will fit many different makes of equipment.

The hardfacing is applied with computer controlled devices, and the point is deep hardened through the width

of the whole point.

The unique saddle construction, where the wings are welded tightly onto the hot forged back bone of the ripper

POINTS

point, strengthens and secures the Nichols ripper point.

Brackets are heavy duty 3/16" or 1/4" material.

Choose Nichols Ripper Points for durability and longer wear life.

C o m p a r e t h e W e a r™ !

Capped Ripper Points

FOR PART NUMBER SCHEME FOR SUBSOIL RIPPERS,

see page 79.

N ICHOLS T ILLAGE T OOLS , I NC .

31

RIPPER POINTS

Stock Code Type of End Description Weight

fits: BIG OX

OXCAP high alloy cap 4.5

OX HF hardfaced 2.4

OX P plain 2.4

800207 solid cast point requires roll pin 8.5

fits: BLU JET points: RPBRL20

N801300 spring point, high chrome alloy cast 9.9

N801400 fall point, high chrome alloy cast 14.9

shin guard:

N801600 high chrome cast shin guard 9.0

fits: BUSH HOG boot width 1-1/8”

RPBH20 plain 2” x 12” 6.55

RPBH20CP flat alloy wear cap 2” x 12” 7.4

fits: BRENT, CPC boot width 1-3/8” RPBRL22N

RPBR25 plain 2-1/2” x 12” 8.25

RPBR25CP flat alloy wear cap 2-1/2” x 12” 9.25

RPBR22NCP raised center high alloy cast w/ shank guard notch 11.6

POINTS

RPBR22NHF raised center hardfaced w/ shank guard notch 11.2

RPBR22UCP wings and raised center high alloy cast w/ shank guard notch 13.6

RPBR22UHF wings and hardfaced raised center w/ shank guard notch 13.2

RPBR25HF hardfaced 2-1/2” x 12” 9.25

RPBR27 ripple faced 11.0

RPBR27HF hardfaced, ripple faced 11.5

RPBR27GHF hardfaced, with 1/2” x 11” fin, ripple faced

fits: BRILLION boot width 1-3/8"

RPBRLX19 13/16” wide shank

RPBRLX19GHF 13/16” wide shank

RPBRLX19HF 13/16” wide shank

RPBRL20 plain 1-1/8” boot width 2” x 12” 6.74

RPBRL20CP flat alloy wear cap 1-1/8" boot width 2” x 12” 7.73

RPBRL25B bolt on double end, 5/8” holes on 2-1/4” ctrs 1” x 2-1/2” 10.50

RPBRL25 Brillion 1” x 2” x 10-1/4”

RPBRL22N raised center fits Land Commander w/ shank guard notch 11.2

RPBRL22NHF hardfaced raised fits Land Commander w/ shank guard notch 11.2

RPBRL22NCP raised center high alloy cast

fits Land Commander w/ shank guard notch 11.6

RPBRL22UCP wings and raised center high alloy cast w/ shank guard notch 11.2

RPBRL22UHF wings and hardfaced raised center w/ shank guard notch 13.6

RPBRL235CP 1-5/8” x 2” x 11” with alloy cap, 5” wide 18

RPBRL237CP 1-5/8” x 2” x 11” with alloy cap, 7” wide 18.5

RPBRL2310CP 1-5/8” x 2” x 11” with alloy cap, 10” wide 19

Older Brillion have 1-1/8” shank. Newer ripper points have 1-3/8” and requires a shank

guard notch in the point.

N ICHOLS T ILLAGE T OOLS , I NC .

32

RIPPER POINTS

Stock Code Type of End Description Weight

fits: DEERE boot width 1-3/8”

RPD20B plain bolt on 1/2” holes on 3” cntrs 2” x 12” 5.60

RPD20BCP flat alloy cast bolt on 1/2” holes on

3” cntrs 2” x 12” 6.60

RPD22UHF wings and hardfaced raised center 13.2

RPD22UCP wings and raised center high alloy cap 13.6 RPDM20CP

RPD25 plain (also fits New Glencoe & Krause) 2-1/2” x 12” 8.45

RPD25FCP flat alloy cap and a fin 2-1/2” x 12” 9.73

RPD25CPCP double capped with flat alloy cap 2-1/2” x 12” 9.95

RPD25HF hardfaced 2-1/2” x 12” 8.85

RPD25B plain bolt on 5/8” holes on 3” cntrs 2-1/2” x 12” 7.10

RPD25BCP flat alloy cap bolt on 5/8” holes on 3” cntrs 2-1/2” x 12” 9.38

fits: DMI, CNH, DEERE

RPDM13CPW bolt on, 7” wide, alloywear cap, C shank 1-1/4” boot width 8.2 RPDM237CP

RPDM20CP 1” x 2” x 11” alloy wear cap 1-1/4” boot width 10.1

RPDM235CP 1-5/8” x 2” x 11” alloy wear cap, 5” wide 1-1/4” boot width 16.2

RPDM237CP 1-5/8” x 2” x 11” alloy wear cap, 7” wide 1-1/4” boot width 17.4

POINTS

RPDM2310CP alloy wear cap, 10” wide 1-1/4” boot width 19.3

RPDM2410CP 1-5/8” x 2-1/4” x 11” alloy wear cap 10” wide 1-1/2” boot width 29.8

RPDM2410HF 1-5/8” x 2-1/4” x 11” hardfaced 1-1/2” boot width 29.8

RPDM25CP 1” x 2-1/2” x 11” alloy wear cap 1-1/2” boot width 16.8

RPDM247CP alloy wear cap, 7” wide 1-1/2” boot width 17.4

RPDM27

RPDM27 1-1/2” x 2-3/8” x 13” forged ripple

RPDM27HF 1-1/2” x 2-3/8” x 13” forged ripple hardfaced

RPDM27GHF 1-1/2” x 2-3/8” x 13” forged ripple hardfaced with fin

COVER BOARDS FOR DMI - CNH

CE4 4” wide 5/16” material 4.13

CE6 6” wide 5/16” material 4.43

CE8 8” wide 5/16” material 5.65

RPDM2410CP

N ICHOLS T ILLAGE T OOLS , I NC .

33

RIPPER POINTS

Stock Code Type of End Description Weight

fits: NEW FORREST CITY 1-1/8” boot width

RPFC20 plain 1” x 2” 8.5

RPFC20CP alloy wear cap 1” x 2” 8.5 fits:

HAMBY 1” boot width for HINIKER, SUKUP, KMC

RPHB20 plain 5/8” x 2” 2.5

RPHB20CP flat alloy cap 5/8” x 2” 3.4 RPKE114

fits: I H 1-3/8” boot width

RPIH25 plain 2-1/2” x 12” 8.45

RPIH25CP flat alloy cap 2-1/2” x 12” 9.45

fits: KELLEY (KMC)

fin is 1/2” thick material NEW vertical dorsal fin or rooster comb on popular sizes

RPKE114 plain, Rip-Strip Halifax 13/16” boot width 6.26

RPKE114CP flat alloy cap Rip-Strip Halifax 13/16” boot width 7.04

RPKE114FCP flat alloy cap with a vertical fine 13/16” boot width

RPKE119F

RPKE114G large vertical fin 13/16” boot width

RPKE20G large vertical fin 2” x 12" 1-1/8” boot width

RPKE20 plain, for bedder 2” x 12" 1-1/8” boot width 6.10

POINTS

RPKE20CP flat alloy cap, for bedder 2” x 12" 1-1/8” boot width 7.06

RPKE20FCP finned with flat alloy cap 2” x 12" 1-1/8” boot width 7.06

RPKE20X plain, Rip-Strip wide Halifax 13/16” boot width 6.40

RPKE20XCP flat alloy cap, Rip Strip wide Halifax 13/16” boot width 6.5

RPKE20XFCP finned with flat alloy cap 13/16” boot width 7.9

RPKE19

RPKE25B plain bolt on 5/8” holes

on 3” centers 2-1/2” x 12” 7.10

RPKE25BCP flat cap bolt on 5/8” holes

on 3" centers 2-1/2” x 12” 8.17

RPOFIN304 FIN for Kelly ripper points 2.3

RPKE19 plain, Ripple Face solid 1” shank 3.75

RPKE19G plain, Ripple Face solid

with long 1/2” fin 1” shank 6.8

RPKEX19 plain, Ripple Face solid 3/4” shank 8.0

RPKEX19G plain, Ripple Face solid

with 1/2” fin 3/4” shank 10.75

RPKE22UHF winged hardfaced raised center

fits: KRAUSE Disc Ripper and NEW GLENCOE

RPD25 plain 2-1/2” x 12” 8.45

RPD25CP alloy cap 2-1/2” x 12” 8.5

RPD25HF hardfaced 2-1/2” x 12” 8.5

RPD20CP 1” x 2” x 11” alloy wear cap 1-1/4” boot width 10.1

RPDM235CP 1-5/8” x 2” x 11” alloy wear cap 5” wide 1-1/4” boot width 16.2

RPDM237CP 1-5/8” x 2” x 11” alloy wear cap 7” wide 1-1/4” boot width 17.4

RPDM2310CP alloy wear cap 1-1/4” boot width 19.3

N ICHOLS T ILLAGE T OOLS , I NC .

34

RIPPER POINTS

Stock Code Type of End Description Weight

fits: LANDOLL 1-1/8” shank

RPLA20 plain 2” x 12” 8.0

RPLA20CP flat alloy cap 2” x 12” 8.6

RPLA20B plain bolt on 1/2” holes on 3” centers 2” x 12” 6.0

RPLA20BCP flat alloy cap bolt on 1/2” holes on 3” centers 2” x 12” 6.6

RPLA22N raised center w/ shank guard notch 11.2 RPBR27

RPLA22NCP raised center alloy cap w/ shank guard notch 11.6

RPLA22NHF hardfaced raised center alloy w/ shank guard notch 11.6

RPLA22UCP wings and raised center alloy cap w/ shank guard notch 13.6

RPLA22UHF wings and hardfaced raised center w/ shank guard notch 13.2

RPLA27 1-1/2” x 2-3/8” x 13” forged ripple w/ shank guard notch

RPLA27HF 1-1/2” x 2-3/8” x 13” forged ripple hardfaced w/ shank guard notch

RPLA27GHF 1-1/2” x 2-3/8” x 13” forged ripple hardfaced with fin w/ shank guard notch

RPBRL25B double end bolt on 5/8” holes on 2-1/4” centers 1” x 2-1/2” 10.5

fits: LILLISTON

RPLI25B plain bolt on 1/2” holes on 2-1/4” centers 7.13

POINTS

RPLI25BCP flat alloy cap bolt on 1/2” holes on 2-1/4” centers 7.13

fits: M & W, SUNFLOWER, IH#14

RPRM12 plain 6.0

RPRM12HF hardfaced 6.0

77MW PIN knurled pin for RM12 .20

88MW PIN oversized knurled pin for RM12 .20

fits: ORTHMAN

CPR800102 fits 1” shank cast

CPR800104 wide point for Orthman

DNC8001 cast

N ICHOLS T ILLAGE T OOLS , I NC .

35

RIPPER POINTS

Stock Code Type of End Description Weight

fits: PARATIL 1-1/2" boot width Tye, Bigham

RPPT25CP flat alloy cast 9” x 2-1/2” 8.3

DNC559T high alloy casting 9” x 2-1/2” 4.3

fits: PAULK 1-1/8" boot width

RPPA20 plain 6.25

RPPA20CP flat alloy cast 7.25

fits: RAWSON 13/16 boot width

RPRW20 plain 2” x 10-1/2” 6.0

RPRW20HF hardfaced 2” x 10-1/2” 6.4

RPRW20CP flat alloy cast 2” x 10-1/2” 6.6

fits: SUNFLOWER, M & W, BLU JET

RPSU22UCP raised center alloy cap 13.6

RPSU22UHF raised center hardfaced 13.2

RPSU25 plain 2-1/2” x 12” 8.25

RPSU25CP flat alloy cast cap 2-1/2” x 12” 9.15

RPSU25HF hardfaced 2-1/2” x 12” 8.85

POINTS

RPSU25FCP flat alloy cast cap with a vertical fin 2-1/2” x 12” 8.85

RPSU27 1-1/2” x 2-3/8” x 13” forged ripple

RPSU27HF 1-1/2” x 2-3/8” x 13” forged ripple hardfaced

RPSU27GHF 1-1/2” x 2-3/8” x 13” forged ripple hardfaced with fin

fits: TEBBEN

RPWA20N plain 6.89

RPWA20NCP flat alloy cast 7.82

RPBRL25B plain double end bolt on 5/8” hole on 2-1/4” center 10.50

fits: UNVERFERTH, KELLEY

RPUV20 plain (same as RPKE20X) 6.5

RPKE20XCP flat alloy cap 6.5

fits: NEW W & A 1-1/8” boot width

RPWA20N plain 6.5

RPWA20NCP flat alloy cap 6.5

REPLACEMENT HIGH CHROME WEAR CAPS

Stock Code Description Weight

NCC178 1-7/8” x 3” high alloy chrome wear cap 1.5

NCC214 2-1/4” x 3” high alloy chrome wear cap 1.5

NCC238 2-3/8” x 3” high alloy chrome wear cap 1.5

NCC278 2-7/8” x 3” high alloy chrome wear cap 1.5

NCC2784 2-7/8” x 4” high alloy chrome wear cap 1.5

WEAR BARS-SHIN PROTECTORS

Stock Code Description Weight

Fits: Kelley

BPW039K KMC ripper wide wear pad 4.21

BPW039K CR KMC ripper and no till wide wear pad 3.26

DNC038 high chrome alloy cast wear pad 6.2

TF108 chrome alloy shin guard 7.1

N ICHOLS T ILLAGE T OOLS , I NC .

36

ULTRAWING® SWEEP

The Ultrawing® sweep, designed and made by Nichols, is a state-of-the-art

sweep. Its unique design advances it beyond conventional sweeps in performance,

features, durability, and quality.

Optimal Crown Configuration: Many conventional sweeps have a rounded

crown, the area in front of the shank, and in one instance, there is an elevated ridge

along the central portion of the crown. See figure #1 on page 38.

There is a tendency for the nose to demonstrate a rounded effect during wear which

decreases the penetrating effect of the sweep, because the rounded nose presents a blunt

frontal edge. In the case of the elevated ridge, there is the appearance of a sharper nose

on the sweep when viewed from above. However, observation from the side reveals that

the nose is actually above the wing edges and provides little penetrating ability. There

have been instances in which this elevated ridge has also worn in such a way as to leave

a “double nose” which acts as a catcher of residue and causes a “ball-up” of trash.

SWEEPS

The wings of the Ultrawing® sweep converge at the crown at an optimum angle.

This effect elevates the crown so that it is at the proper position for the most efficient

wear and helps maintain the nose of the sweep during wear.

In addition, near the neck of the Ultrawing® sweep the material is crimped at an

angle that provides extra strength to the area where the stem and wings intersect.

This crimped area helps separate the soil away from the bolt heads. Ultrawing® retains its width

and nose during wear.

Curved Wings: The curved wings of the Ultrawing® sweep provide extra weed

killing ability over conventional straight wings. Acting like an old-fashioned scythe,

the curvature prevents weeds from sliding off the end of the sweep with incomplete severing of the roots.

The length of the cutting edge is approximately 10% less than the length of the cutting edge of a conventional

sweep. While no formal studies have been conducted to determine if this provides less resistance to passage through

the soil, and consequently less draft, there is a growing belief that this might be the case.

The unique curved wing of the Ultrawing® sweep also provides extra nose length while retaining a uniform

wing width. The geometry of this effect is illustrated in Figure No. 2 on page 38.

Convex Wing Surfaces: The surfaces of the Ultrawing® sweep are convex. This effect turns the leading

edge downward to provide an increased angle of presentation to the soil. This feature, together with the

extended nose, helps to provide effective soil penetration without a “plowing” or ridging effect. The convex

surface also provides a stiffening effect to the wing. Soil passes smoothly over the convex surface and is not

excessively lifted. See Figure No. 3 on page 38.

Ultrawing® is a copywritten trademark owned by Nichols Tillage Tools, Inc. The ULTRAWING® sweep is patented.

Its US Patent Number is 4,787,462. The Canadian Patent Number is 1,334,352. Its Australian Patent Number is 587,735.

N ICHOLS T ILLAGE T OOLS , I NC .

37

FIGURE 1: CROSS SECTION OF THE CROWN

CONVENTIONAL

RIBBED CENTER

SWEEPS

ULTRAWING®

FIGURE 2:

FIGURE 3:

A

CONSTANT WING WIDTH

LENGTH “A” GREATER THAN “B”

B

N ICHOLS T ILLAGE T OOLS , I NC .

38

ULTRAWING® SWEEPS

Size 3/8” Holes 7/16” Holes 1/2” Holes Weight

1/4” MATERIAL for 47 DEGREE SHANKS

6” 47UW6B3 47UW6B7 2.7

7” 47UW7B3 47UW7B7 2.8

8” 47UW8B3 47UW8B7 2.85

9” 47UW9B3 47UW9B7 3.1

10” 47UW10B3 47UW10B7 47UW10B2 3.4 47UW9B7

11” 47UW11B3 47UW11B7 47UW11B2 3.5

12” 47UW12B3 47UW12B7 47UW12B2 3.7

1/4” MATERIAL for 43 DEGREE SHANKS

7” 43UW7B3 43UW7B7 2.8

9” 43UW9B3 43UW9B7 3.1

10” 43UW10B3 43UW10B7 3.4

11” 43UW11B3 43UW11B7 3.5

1/4” MATERIAL for 52 DEGREE SHANKS - 2” HOLE CENTERS

6” 52UW6B7 2.7

7” 52UW7B7 2.8

SWEEPS

8” 52UW8B7 2.85

9” 52UW9B7 3.1

10” 52UW10B7 3.4

1/4” MATERIAL for 41 DEGREE SHANKS

6” 41UW6B3 41UW6B7 2.7

7” 41UW7B3 41UW7B7 2.8

8” 41UW8B3 41UW8B7 2.85

9” 41UW9B3 41UW9B7 3.1

10” 41UW10B3 41UW10B7 3.4

5/16” MATERIAL for 47 DEGREE SHANKS

9” 47UW9F7 47UW9F2 4.0

10” 47UW10F7 47UW10F2 4.25

11” 47UW11F7 47UW11F2 4.5

12” 47UW12F7 47UW12F2 4.75

These part numbers are for field cultivators with 1-3/4” hole centers. The holes are slightly

slotted for 1-5/8” hole centers.

ULTRAWING® ROW CROP SWEEPS

Ultrawing Sweeps punched for use on row equipment. Two 7/16” holes on 2” centers with one 5/8”

hole in between. Discover all of the advantages of the Nichols Ultrawing sweep in row crop use.

Size Stock Code Weight

6” SUW6B7 2.7

8” SUW8B7 2.8

10” SUW10B7 3.0

12” SUW12B7 3.3

SUW

N ICHOLS T ILLAGE T OOLS , I NC .

39

CONVENTIONAL BOLT-ON FIELD CULTIVATOR SWEEPS

The holes are slightly elongated to accommodate both 1-5/8” and 1-3/4” hole centers.

To order hardfaced, specify “HF” after part number.

CONVENTIONAL SWEEP

Width 3/16” Material 3/16” Material Weight 1/4” Material Weight

3/8” Holes 7/16” Holes 7/16” Holes

4” – CC4A7 1.3 CC4B7 1.8

6” – CC6A7 1.5 CC6B7 2.1

7” – CC7A7 1.6 CC7B7 2.3

8” – CC8A7 1.8 CC8B7 2.4

9” – CC9A7 2.0 CC9B7 2.5

10” – CC10A7 2.2 CC10B7 2.8

11” – CC11A7 2.35 CC11B7 2.9

12” – CC12A7 2.5 CC12B7 3.1

SWEEPS WITH 47 DEGREE SHANKS

SWEEPS

Width 3/16” Material 3/16” Material Weight 1/4” Material 1/4” Material Weight

3/8” Holes 7/16” Holes 3/8” Holes 7/16” Holes

4” – – 1.3 – – –

6” – 47C6A7 1.5 – – –

8” – 47C8A7 1.8 – – –

9” – – – 47C9B7 – 2.5

10” – 47C10A7 2.2 47C10B7 – 2.8

S W E E P S W I T H 4 7 D E G R E E S H A N K S made from 5/16” material

Width 516” Material 5/16” Material Weight

7/16” Holes 1/2” Holes

11” 47C11F7 47C11F2 4.5

11” w/straight shanks 47C11SF7 47C11SF2 4.5

S W E E P S W I T H 5 2 D E G R E E S H A N K S two 7/16” holes on 2” centers

Width Stock Code Weight

6” 52C6B7 2.1

7” 52C7B7 2.3

8” 52C8B7 2.4

9” 52C9B7 2.5

10” 52C10B7 2.8

N ICHOLS T ILLAGE T OOLS , I NC .

40

CURVED BACK ALABAMA SWEEPS

This style of solid sweep is punched with two 7/16” holes on 2-1/4” centers and with a 5/8” square hole in between.

1/4” Material

Width Stock Code Weight

14” AL14B3 3 holes 6.8

16” AL16B3 3 holes 7.9

18” AL18B3 3 holes 8.1

20” AL20B3 3 holes 13.5

22” AL22B3 3 holes 15.5

24” AL24B3 3 holes 15.75

SQUARE BACK ALABAMA SWEEPS

Alabama or Solid Sweeps are used to break middles and ridges. These solid sweeps are durable and long-wearing, and

are made in a variety of shapes, hole arrangements, and materials.

The seven-hole pattern has a 3/4” square hole on a 2-1/4” center with a 5/8” square hole, and there is a 1/2” peg below the

lower hole. Two 7/16” holes for wing extenders or “hungry boards” are in each wing. The holes are punched into a flat surface

which assures the operator that the sweep will not rock on the shank.

SWEEPS

5/16” Material

Width Stock Code Weight

18” AL18F7SB 12.9

20” AL20F7SB 16.5

22” AL22F7SB 18.5

24” AL24F7SB 19.5

26” AL26F7SB 19.75

BEET SWEEPS

Beet Sweeps are narrow wing, long nosed sweeps used in place of danish style sweeps for shallow cultivation. Beet sweeps run

very shallow, and the dirt does not flow near the bolt head. They can be used anywhere that a danish sweep is used. Only Nichols has

the curved wing Beet Sweep, which are particularly effective when used on the shanks in the last row of the danish-tine cultivator.

They also take the place of smith fin sweeps and can be used in most row crop situations. For best results use beet sweeps on S-Tines.

Width Stock Code Weight

6” G6A 1.2

8” G8A 1.3

10” G10A 1.5

12” G12A 1.6

14” G14A 1.8

16” G16A 1.9

BEAVER TAIL CORN SWEEPS

Beaver Tail Point is used in deep tillage applications. It is also called a Corn Shovel. Beaver Tails are punched with two

1/2” holes on 2-1/4” centers.

Stock Code Size/Width at top of Beaver Tail Weight

BT6 6” 2.8

BT5 5” 2.6

BT4 4” 2.4

N ICHOLS T ILLAGE T OOLS , I NC .

41

KLIPPED WING BOLT-ON SWEEPS

The holes are slightly elongated to accommodate both 1-5/8” and 1-3/4” hole centers.

KLIPPED WING SWEEPS WITH 47 DEGREE SHANKS

Width 1/4” Material 1/4” Material Weight 5/16” Material 5/16” Material Weight

7/16” Holes 1/2” Holes 7/16” Holes 1/2” Holes

6” 47C6BK7 – 3.0 – – –

7” 47C7BK7 – 3.45 – – –

8” 47C8BK7 – 3.55 – – –

9” 47C9BK7 – 3.75 – – –

10” 47C10BK7 47C10BK2 3.85 – – –

11” 47C11BK7 47C11BK2 4.0 47C11FK7 47C11FK2 4.5

12” 47C12BK7 47C12BK2 4.25 47C12FK7 47C12FK2 5.0

SPECIAL KLIPPED WING SWEEPS WITH STRAIGHT 47 DEGREE SHANKS

SWEEPS

Width 1/4” Material 1/4” Material Weight 5/16” Material 5/16” Material Weight

7/16” Holes 1/2” Holes 7/16” Holes 1/2” Holes

7” 47C7SBK7 – 3.45 – – –

9” 47C9SBK7 – 3.75 – – –

10” 47C10SBK7 47C10SBK2 3.85 – – –

11” 47C11SBK7 47C11SBK2 4.0 47C11SFK7 47C11SFK2 4.5

12” 47C12SBK7 47C12SBK2 4.5 – – –

KLIPPED WING SWEEPS WITH 52 DEGREE SHANKS

Width 7/16” Holes Weight

10” 52C10BK7 3.85

47C7BK7

N ICHOLS T ILLAGE T OOLS , I NC .

42

CHISEL PLOW SWEEPS

Nichols Conventional and Klipped Wing sweeps are the best designed sweeps

on the market.

The long profile puts plenty of nose out front for wear life and lasting penetration.

The heavy flanged shank and the deep counter-sunk holes provide a strong shank as well

as good bolt head protection. The large web between the wing and the base

HC16BK-2

of the shank add to the strength of the sweep in an important area.

The nose has a wear tab forged in place. Consistent heat treatment gives

these sweeps excellent wear life.

Both Conventional and Klipped Wing sweeps are made in three

crown heights for various applications. They are designated as: HC16B-2

“B” for high crown: The area in front of the shank where it becomes

part of the sweep, the “crown”, is raised and the wings are higher. This shape

SWEEPS

generates high soil activity when plowing and is preferred in heavier soils or during

field preparation before planting. It is also preferred where a corrugation might be

preferred for moisture accumulation over winter.

“A” medium crown: This crown is used in middle weight soils and where less

B5016-2

soil activity is wanted. Loose or sandy soils invite its use.

“AA” flat crown: Sweeps with this crown are used in situations where little soil

disturbance is desired. It is operated just below the surface of the soil. A sweep with this low crown will leave a good

amount of stubble and residue in place on the surface. Often this sweep is used in summer fallow work at the end of the

crop season for weed kill and to prepare the soil for acceptance of moisture.

Smaller sweeps in 6”, 8”, 10”, 12” & 14” sizes are not made in various crowns, because their widths will not allow

the wings to generate the soil activity to be effective. Choice of crown heights is limited to 16”, 18” and 20” widths in

Conventional and Klipped Wing shapes.

Nichols chisel plow sweeps – come in many shapes and with many features for an excellent wear life and good sweeping

action. Special heat treatment of the clean steels that we use make Nichols sweeps durable, tough, and abrasion resistant.

The carbides in these steels resist wear better than any material that would be used in an application like cultivating or plowing.

Nichols chisel plow sweeps have heavy flange shanks for strength, straight edges for even wear, and a variety of

crowns for the right amount of soil turbulence and residue retention.

Nichols chisel plow sweeps are made in three shapes, each of which work for you. Ultrawing®, a patented design,

retains its nose through its wear life to enhance its penetration ability and has curved wings for strength and constant

wing width for better soil action. It shows less footprint which means that less steel is being pulled behind the tractor.

The Klipped Wing sweep has its wings trimmed on the outside edge, so that it will have the same width at the end

of its service life as it did at the beginning.

Choose Nichols chisel plow sweeps – when you want the best!

N ICHOLS T ILLAGE T OOLS , I NC .

43

CHISEL PLOW CONVENTIONAL AND KLIPPED WING SWEEPS