Академический Документы

Профессиональный Документы

Культура Документы

Corepins

Загружено:

hbhaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Corepins

Загружено:

hbhaАвторское право:

Доступные форматы

CORE PIN MATERIAL

CPM

DIECAST CAVITY PARTS

Feature

Custom made CORE PIN

We have over 30 -year- history to produce custom-made core pins. Always we pick up

customers offer and keep world standard. We take safe, cost value, and delivery every time.

Custom limit

● φ300×L1000mm at maximum core pin length

Water hole: φ1, φ1.8, φ2, φ2.5, φ3, φ3.5 ~

● For

(Basically, L600mm at the longest. Please contact us.)

DYNAMO, INC. Kyouei-douri 7-107 Seto-City Aichi-Ken Japan 489-0809

www . dynamo . co . jp Tel +81-561-88-1076 Fax +81-561-88-1077 E-mail : info@dynamo.co.jp

1409200W

Tel : 847-691-0076 Fax : 630-497-8023

USA

CORE PIN MATERIALS

List of steel classes

Trade name Designation Recommended HRC Features Stock

SKD61(DAC) A 42 ~ 50 General material for die-casting die. ◎

SKD61 H45 43 ~ 47 ◎

2 types of SKD61. Each with different hardness.

SKD61 H48 46 ~ 50 ◎

DAC-MAGIC D-Magic 46 ~ 50 High temperature strength, toughness. ◎

DAC-S D-S 46 ~ 50 ESR Version for H13. Higher heat check resistance. ○

High-toughness, High temperature strength

DIEVAR DIEVAR 42 ~ 50 ○

High heat resistance.

DHA-THERMO THERMO 42 ~ 50 High thermal conductivity. High degree of hardness. ○

DHA-WORLD WORLD 42 ~ 50 SKD61 ○

FDAC FDAC 38 ~ 42 Prehardened, Free-cutting Steel for holders etc. ◎

Prehardened, improved SUS420J2,

HPM38 HPM38 50 ~ 53 ○

Corrosion resistant.

HPM7 HPM7 29 ~ 33 Plastic type steed for prehardening & SCM base. ◎

S45C S45C 20 ~ 25 Standard material for die-casting die machinism Parts. ◎

※Other materials available on request.

SKH51

(YXM1) SKH51 55 ~ 60 For High speed tool steel, general cutting tool. ◎

YXR33 YXR33 52 ~ 58 High-toughness. High erosion resistance. ◎

Very strong steel, Very high-toughness. Can be

YAG YAG 45 ~ 53 ○

hardened by aging treatment. (480 ~ 520℃)

SKD11

(SLD) SKD11 58 ~ 62 For cold working tool steel or press type tool. ○

※DAC、DAC-MAGIC、DAC-S、FDAC、HPM38、HPM7、YXM1、YXR33、YAG、SLD Presented by Hitachi.

※Anvilloy, D2M, Be Cu and other materials available on request.

Copper CU ― Thermal conductivity:389.773(W/ m・K) ◎

Copper 25 BeCU25 ― Thermal conductivity:108.968 ~ 129.924(W/ m・K) △

Copper 50 BeCU50 ― Thermal conductivity:209.556 ~ 238.894(W/ m・K) △

Brass

(BSBM2) CB3604D ― Thermal conductivity:121.542(W/ m・K) ○

SUS303 SUS303 ― Thermal conductivity:16.345(W/ m・K) ○

SUS304 SUS304 ― Thermal conductivity:16.345(W/ m・K) ○

ANVILOY ANVILOY ― Sintering cemented alloy・Excellent erosion resistance. ○

◎:Fully equipped ○:Partly equipped △: Back-order

Вам также может понравиться

- Motorcycle Troubleshooting ManualДокумент15 страницMotorcycle Troubleshooting ManualJan Warmerdam100% (1)

- Nema MG10 PDFДокумент27 страницNema MG10 PDFManuel Antonio Santos VargasОценок пока нет

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantОт EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Charles Haanel - The Master Key System Cd2 Id1919810777 Size878Документ214 страницCharles Haanel - The Master Key System Cd2 Id1919810777 Size878Hmt Nmsl100% (2)

- Handbook For ASHA On Home Based Care For Young Child-EnglishДокумент116 страницHandbook For ASHA On Home Based Care For Young Child-EnglishDr. Vanitha BОценок пока нет

- Bomber JacketДокумент3 страницыBomber JacketLaura Carrascosa FusterОценок пока нет

- Akshaya Vanam: Indian SandalwoodДокумент52 страницыAkshaya Vanam: Indian Sandalwoodprasadgss100% (4)

- Inverse Curve Trip Time Calculation: Enter Values in White CellДокумент3 страницыInverse Curve Trip Time Calculation: Enter Values in White CellVijay FxОценок пока нет

- LINEAR INDUCTION MOTOR 6981660.ppsxДокумент56 страницLINEAR INDUCTION MOTOR 6981660.ppsxFalley FasterОценок пока нет

- WaterfordДокумент12 страницWaterfordCamilo MorenoОценок пока нет

- South Valley University Faculty of Science Geology Department Dr. Mohamed Youssef AliДокумент29 страницSouth Valley University Faculty of Science Geology Department Dr. Mohamed Youssef AliHari Dante Cry100% (1)

- Marxism and The Oppression of Women Lise VogelДокумент259 страницMarxism and The Oppression of Women Lise VogelMoises SaavedraОценок пока нет

- List MaterialДокумент1 страницаList Materialhoahongdo1998.2907Оценок пока нет

- Tech Uddeholm-Orvar-Supreme enДокумент12 страницTech Uddeholm-Orvar-Supreme enSteve OoiОценок пока нет

- Dievar D20140715Документ16 страницDievar D20140715Keattikhun ChaichanaОценок пока нет

- PB Orvar Supreme EnglishДокумент12 страницPB Orvar Supreme EnglishTrexa GyreueОценок пока нет

- DIN GS-42CrMo4 Datasheet, GS-42CrMo4 Chemical Composition, GS-42CrMo4 Mechanical PropertiesДокумент2 страницыDIN GS-42CrMo4 Datasheet, GS-42CrMo4 Chemical Composition, GS-42CrMo4 Mechanical PropertiesRiset GerlinkОценок пока нет

- Sikadur 42LE Epoxy Grout DatasheetДокумент5 страницSikadur 42LE Epoxy Grout DatasheetJoshua HobsonОценок пока нет

- Sikadur 42 LeДокумент5 страницSikadur 42 LekhudhayerОценок пока нет

- Panasonic-Matsushita Thermal Cutoff 139-C PDFДокумент8 страницPanasonic-Matsushita Thermal Cutoff 139-C PDFDanGibbsОценок пока нет

- High Hardness & Toughness New General-Purpose Cold Die SteelДокумент2 страницыHigh Hardness & Toughness New General-Purpose Cold Die SteelSinan YıldızОценок пока нет

- Why HARDOX in Tipping TrailersДокумент8 страницWhy HARDOX in Tipping TrailersHugo RodriguezОценок пока нет

- Types of YSS Cold Work Tool Steels: Sld-Magic SLDДокумент6 страницTypes of YSS Cold Work Tool Steels: Sld-Magic SLDtaknevОценок пока нет

- Sikadur - 42 MP NormalДокумент5 страницSikadur - 42 MP NormalMochamad TaufikОценок пока нет

- ListДокумент1 страницаListAbyan FarrasОценок пока нет

- (JIS SKD61) : FeaturesДокумент6 страниц(JIS SKD61) : FeaturestaknevОценок пока нет

- Tech Uddeholm Orvar Superior ENДокумент12 страницTech Uddeholm Orvar Superior EN1almurilОценок пока нет

- Sleipner UddeholmДокумент12 страницSleipner UddeholmKalipse FerreiraОценок пока нет

- Welcome To Honingcraft: Total Support in Hydraulic Cylinder ManufacturingДокумент34 страницыWelcome To Honingcraft: Total Support in Hydraulic Cylinder ManufacturingSHANEОценок пока нет

- Aço Uddeholm CalmaxДокумент12 страницAço Uddeholm CalmaxDanilo SilvaОценок пока нет

- CDP 4923Документ2 страницыCDP 4923Juan LondonoОценок пока нет

- D2 Data Sheet 09032013Документ9 страницD2 Data Sheet 09032013السيد ابراهيم عبدالعزيز عبداللهОценок пока нет

- Ramax Hh-Eng P 1604 E6Документ8 страницRamax Hh-Eng P 1604 E6venkithankamОценок пока нет

- Sanweld Electrodes Catalog Vol 4Документ24 страницыSanweld Electrodes Catalog Vol 4prashant mishra100% (4)

- Wegusta Caststeel CastironДокумент3 страницыWegusta Caststeel CastironPandurang KadamОценок пока нет

- Knock OUT: IntroducingДокумент10 страницKnock OUT: IntroducingMuhammad QusyairiОценок пока нет

- D2 1.2379 SKD11 Flat BarДокумент4 страницыD2 1.2379 SKD11 Flat BarMANJEET KUMARОценок пока нет

- Dac BДокумент15 страницDac BArief BudimanОценок пока нет

- CDP 4666Документ2 страницыCDP 4666sareddytejaaeОценок пока нет

- Sikadur®-42 MP Slow - PDS - GCC - AE - (07-2016) - 1 - 1Документ5 страницSikadur®-42 MP Slow - PDS - GCC - AE - (07-2016) - 1 - 1邢焕震Оценок пока нет

- Tech Uddeholm-Sverker-21 enДокумент10 страницTech Uddeholm-Sverker-21 enJose AldanaОценок пока нет

- Sumihard 400 (ASM 400)Документ2 страницыSumihard 400 (ASM 400)jose wanderleyОценок пока нет

- YE-DD15 Dream Drill NEW PDFДокумент52 страницыYE-DD15 Dream Drill NEW PDFdrazaanОценок пока нет

- Tech Uddeholm Ramax HH ENДокумент8 страницTech Uddeholm Ramax HH ENwrh9rqr22vОценок пока нет

- En Akraplast Brochure AkrathermДокумент2 страницыEn Akraplast Brochure AkrathermPrabartak DasОценок пока нет

- Assab - XW 42 150216Документ8 страницAssab - XW 42 150216Rachmadi NorcahyoОценок пока нет

- Kobel Forge SSДокумент1 страницаKobel Forge SSBHARAT KОценок пока нет

- Vanadis-23 UddeholmДокумент16 страницVanadis-23 UddeholmKalipse FerreiraОценок пока нет

- High Speed Steel Round BarДокумент4 страницыHigh Speed Steel Round BarMANJEET KUMARОценок пока нет

- Welding WireДокумент20 страницWelding WirefoxmancementОценок пока нет

- 9Cr - 1mo Modified With V, NB, and N.: OdificationДокумент1 страница9Cr - 1mo Modified With V, NB, and N.: OdificationAshok RajОценок пока нет

- PB Uddeholm Stavax Esr EnglishДокумент12 страницPB Uddeholm Stavax Esr EnglishDanu MamlukatОценок пока нет

- Rogers Corp Product Selector GuideДокумент3 страницыRogers Corp Product Selector GuideGeorgios SarrisОценок пока нет

- Sikadur®-31 CF Slow: Product Data SheetДокумент4 страницыSikadur®-31 CF Slow: Product Data SheetMichael MazoОценок пока нет

- Worm Gear Sets enДокумент29 страницWorm Gear Sets enmohammad khoraminiaОценок пока нет

- Catalogue Worm Gear Sets and Customised Worm Gear SetsДокумент30 страницCatalogue Worm Gear Sets and Customised Worm Gear Setsfog900Оценок пока нет

- Concrete RebarsДокумент3 страницыConcrete RebarsLuca FelappiОценок пока нет

- Q&Q 16 Pages - Uk LDДокумент16 страницQ&Q 16 Pages - Uk LDMichel ClaytonОценок пока нет

- D2 Tool Steel: Shipping PolicyДокумент2 страницыD2 Tool Steel: Shipping Policyالسيد ابراهيم عبدالعزيز عبداللهОценок пока нет

- CK45 (1.1191)Документ3 страницыCK45 (1.1191)alextentwentyОценок пока нет

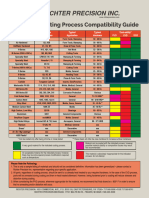

- Material Coating Process Compatibility Guide 2021Документ2 страницыMaterial Coating Process Compatibility Guide 2021max8086Оценок пока нет

- OCR12VMДокумент4 страницыOCR12VMcvgfgОценок пока нет

- PB Uddeholm Sleipner EnglishДокумент12 страницPB Uddeholm Sleipner EnglishAlfya ChinikamwalaОценок пока нет

- Mastercut Tool Corp - Rotary Cutting Tools Fractional PDFДокумент60 страницMastercut Tool Corp - Rotary Cutting Tools Fractional PDFJennifer SmallОценок пока нет

- Yss Tool Steels BДокумент77 страницYss Tool Steels BneramjanОценок пока нет

- Moldmax Hh-Eng P 1609 E6Документ8 страницMoldmax Hh-Eng P 1609 E6gurtekinkubra8Оценок пока нет

- Dievar PropertiesДокумент12 страницDievar PropertiesSyed NawazОценок пока нет

- Tank Power PDFДокумент22 страницыTank Power PDFstctoolОценок пока нет

- A2 Tool Steel PDFДокумент7 страницA2 Tool Steel PDFOscar SaldivarОценок пока нет

- ESM-4810A1 Energy Storage Module User ManualДокумент31 страницаESM-4810A1 Energy Storage Module User ManualOscar SosaОценок пока нет

- North Central Mindanao College: Maranding, Lala, Lanao Del NorteДокумент8 страницNorth Central Mindanao College: Maranding, Lala, Lanao Del NorteAnalyn FielОценок пока нет

- Massage Techniques in SpaДокумент1 страницаMassage Techniques in SpaALISA SAITAОценок пока нет

- Ield Methods: A Typical Field Mapping Camp in The 1950sДокумент4 страницыIeld Methods: A Typical Field Mapping Camp in The 1950sshivam soniОценок пока нет

- Introduction To Cement Chemistry and Classification BY Dr.K.RainaДокумент89 страницIntroduction To Cement Chemistry and Classification BY Dr.K.Rainakishana ramОценок пока нет

- Topik 3 - Hazard Di Air Selangor, Penilaian Risiko Langkah Kawalan Rev1 2020 090320Документ59 страницTopik 3 - Hazard Di Air Selangor, Penilaian Risiko Langkah Kawalan Rev1 2020 090320Nuratiqah SmailОценок пока нет

- SFT PresentationДокумент16 страницSFT Presentationapna indiaОценок пока нет

- Introduction To The New 8-Bit PIC MCU Hardware Peripherals (CLC, Nco, Cog)Документ161 страницаIntroduction To The New 8-Bit PIC MCU Hardware Peripherals (CLC, Nco, Cog)Andres Bruno SaraviaОценок пока нет

- Joseph Conrad - Heart of DarknessДокумент86 страницJoseph Conrad - Heart of DarknessCaztor SscОценок пока нет

- Unit 3 InfiltrationДокумент5 страницUnit 3 InfiltrationHRIDYA MGОценок пока нет

- Module 02 Connect Hardware Peripherals EndaleДокумент49 страницModule 02 Connect Hardware Peripherals EndaleSoli Mondo100% (1)

- Wiring of The Distribution Board With RCD (Residual Current Devices) - Single Phase Home SupplyДокумент14 страницWiring of The Distribution Board With RCD (Residual Current Devices) - Single Phase Home SupplyKadhir BoseОценок пока нет

- Onitsuka Tiger PDFДокумент67 страницOnitsuka Tiger PDFAhmad Bilal MawardiОценок пока нет

- Assignment 1 - Statistics ProbabilityДокумент3 страницыAssignment 1 - Statistics ProbabilityAzel Fume100% (1)

- BMS of Dubai International AirportДокумент4 страницыBMS of Dubai International AirportJomari Carl Rafal MansuetoОценок пока нет

- Pertanyaan TK PDBДокумент4 страницыPertanyaan TK PDBHardenОценок пока нет

- O Solitude! If I Must With Thee Dwell by John Keats: SonnetДокумент6 страницO Solitude! If I Must With Thee Dwell by John Keats: SonnetshettyОценок пока нет

- Sikagrout®-214 Ae: Product Data SheetДокумент3 страницыSikagrout®-214 Ae: Product Data Sheetmohammed rinshinОценок пока нет

- Geology of Johannesburg ReadingДокумент2 страницыGeology of Johannesburg ReadingKavish DayaОценок пока нет

- Boyle's Law 2023Документ6 страницBoyle's Law 2023Justin HuynhОценок пока нет