Академический Документы

Профессиональный Документы

Культура Документы

Medium-Weight, Junior and Light-Weight Channels To IS 808: 1989 (Reaffirmed 1999) Edition 4.1 (1992-07)

Загружено:

CIVILОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Medium-Weight, Junior and Light-Weight Channels To IS 808: 1989 (Reaffirmed 1999) Edition 4.1 (1992-07)

Загружено:

CIVILАвторское право:

Доступные форматы

User Registration No: Unregistered Copy

RSC

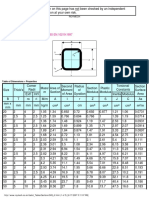

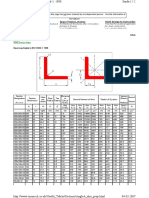

Diagram Medium-weight, Junior and Light-weight Channels to IS 808: 1989 (Reaffirmed 1999) Edition 4.1 (1992-07)

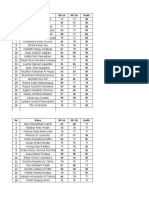

Mass Depth Width Thickness Radius Flange Depth Shear centre Second Moment Radius Elastic Elastic Plastic Plastic Buckling Torsional Warping Torsional Area

Section per of of of of Taper between Position from of Area of Gyration Modulus Neutral Modulus Neutral Parameter Index Constant Constant of

Designation Metre Section section Web Flange Root Toe in fillets web cg Axis x-x Axis y-y Axis x-x Axis y-y Axis x-x Axis y-y Axis Axis x-x Axis y-y Axis Inertia Section

M h b s t r1 r2 a d eo Cs Ix Iy rx ry Zx Zy Cy Sx Sy Ceq u x H J A

Home kg/m mm mm mm mm mm mm degrees mm cm cm cm4 cm4 cm cm cm3 cm3 cm cm3 cm3 cm dm6 cm4 cm2

1 ISMC 75 ###### 75 40 4.8 7.5 8.5 2.4 6 41 1.58 2.66 78.5 12.8 2.94 1.18 20.9 4.77 1.32 25.1 9.02 0.879 0.913 8.26 0.000117 1.57 9.1

2 ISMC 100 ###### 100 50 5 7.7 9 2.4 6 63.7 1.96 3.26 192 26.4 3.98 1.47 38.5 7.64 1.54 45.4 14.8 0.928 0.91 11.1 0.000461 2.23 12.2

3 ISMC 125 ###### 125 65 5.3 8.1 9.5 2.4 6 85.4 2.59 4.26 422 59.8 5.04 1.9 67.5 13.1 1.94 78.4 25.9 1.16 0.903 13.3 0.00173 3.47 16.6

4 ISMC 125* ###### 125 66 6 8.1 9.5 2.4 6 85.4 2.56 4.18 435 63.8 4.98 1.91 69.6 13.6 1.92 81.4 27.1 1.04 0.895 12.9 0.00184 3.87 17.5

5 ISMC 150 ###### 150 75 5.7 9 10 2.4 6 106.7 2.99 4.91 788 102 6.08 2.19 105 19.3 2.2 122 38.3 1.3 0.904 14.6 0.00432 5.41 21.3

6 ISMC 150* ###### 150 76 6.5 9 10 2.4 6 106.7 2.95 4.8 813 109 6 2.19 108 20 2.17 126 40 1.14 0.896 14.2 0.00459 6.02 22.6

7 ISMC 175 ###### 175 75 6 10.2 10.5 3.2 6 128.4 2.94 4.83 1237 121 7.05 2.2 141 22.7 2.19 164 44.7 1.19 0.912 15.6 0.00681 7.44 24.9

8 ISMC 175* ###### 175 77 7.5 10.2 10.5 3.2 6 128.4 2.87 4.63 1311 135 6.89 2.21 150 24.3 2.14 176 48 0.93 0.897 14.8 0.00761 9.05 27.6

9 ISMC 200 ###### 200 75 6.2 11.4 11 3.2 6 150.2 2.90 4.77 1830 139 8.02 2.21 183 26.2 2.18 213 51.1 1.12 0.918 16.4 0.0101 9.83 28.5

10 ISMC 200* ###### 200 76 7.5 11.4 11 3.2 6 150.2 2.81 4.54 1910 150 7.85 2.2 191 27.3 2.11 225 53.3 0.864 0.905 15.9 0.0108 11.4 31

11 ISMC 225 ###### 225 80 6.5 12.4 12 3.2 6 170.9 3.09 5.07 2711 186 9.02 2.36 241 32.7 2.31 280 63.7 1.15 0.92 17.2 0.0171 13.3 33.3

12 ISMC 225* ###### 225 83 9 12.4 12 3.2 6 170.8 2.96 4.73 2962 218 8.71 2.36 263 35.9 2.22 313 69.7 0.868 0.897 16.1 0.02 17.7 39

13 ISMC 250 ###### 250 80 7.2 14.1 12 3.2 6 192.5 3.03 4.96 3838 218 9.92 2.37 307 38.3 2.29 359 73.9 1.04 0.922 17.1 0.0242 18.8 39

14 ISMC 250* ###### 250 82 9 14.1 12 3.2 6 192.5 2.93 4.71 4080 243 9.68 2.36 326 40.7 2.23 388 78.3 0.871 0.906 16.5 0.0269 22.7 43.5

15 ISMC 250* ###### 250 84 11 14.1 12 3.2 6 192.5 2.82 4.47 4340 267 9.46 2.35 347 43.1 2.19 419 82.7 0.971 0.891 15.5 0.0296 28.6 48.5

16 ISMC 300 ###### 300 90 7.8 13.6 13 3.2 6 240.7 3.27 5.23 6418 311 11.8 2.59 428 46.9 2.35 502 91.2 0.771 0.904 21.4 0.0521 21.7 46.3

17 ISMC 300* ###### 300 92 10 13.6 13 3.2 6 240.8 3.10 4.86 6902 344 11.4 2.55 460 49.6 2.26 551 96.1 0.881 0.885 20.2 0.0579 28 52.8

18 ISMC 300* ###### 300 94 12 13.6 13 3.2 6 240.8 2.98 4.6 7352 375 11.2 2.52 490 52.2 2.22 596 101 0.981 0.871 18.8 0.0633 36.1 58.8

19 ISMC 350 ###### 350 100 8.3 13.5 14 4.8 6 288.2 3.52 5.55 10090 430 13.6 2.81 577 56.9 2.44 679 111 0.777 0.89 25.3 0.102 25.9 54.4

20 ISMC 400 ###### 400 100 8.8 15.3 15 4.8 6 332.8 3.45 5.43 15207 505 15.4 2.81 760 66.6 2.42 900 129 0.797 0.892 26.3 0.154 35.9 63.8

1 ISJC 100 ###### 100 45 3 5.1 6 2 1.5 77 1.79 3.04 124 14.6 4.09 1.41 24.8 4.73 1.4 28.4 8.76 0.803 0.933 17.7 0.000249 0.517 7.41

2 ISJC 125 ###### 125 50 3 6.6 6 2.4 1.5 98.9 2.05 3.53 270 25.2 5.18 1.58 43.2 7.48 1.64 49.1 13.6 1.1 0.951 17.8 0.000663 1.07 10.1

3 ISJC 150 ###### 150 55 3.6 6.9 7 2.4 1.5 121.2 2.16 3.64 472 37.4 6.1 1.72 62.9 9.75 1.67 72.1 18.1 0.852 0.94 20.5 0.00143 1.47 12.7

4 ISJC 175 ###### 175 60 3.6 6.9 7 3 1.5 146.1 2.33 3.9 720 49.6 7.11 1.87 82.3 11.7 1.75 94.2 21.8 0.778 0.937 24.4 0.00262 1.63 14.2

5 ISJC 200 ###### 200 70 4.1 7.1 8 3.2 1.5 168.5 2.67 4.43 1161 82.9 8.08 2.16 116 16.5 1.97 133 30.8 0.712 0.929 26.7 0.00581 2.23 17.8

1 ISLC 75 ###### 75 40 3.7 6 6 2 1.5 50.4 1.61 2.78 66.1 11.3 3.02 1.25 17.6 4.26 1.35 20.6 7.74 0.924 0.929 10.7 0.000101 0.725 7.26

2 ISLC 100 ###### 100 50 4 6.4 6 2 1.5 74.3 1.99 3.42 165 24.4 4.05 1.56 32.9 7.24 1.62 38.1 13.3 1.02 0.931 13.7 0.0004 1.11 10

3 ISLC 125 ###### 125 65 4.4 6.6 7 2.4 1.5 96.6 2.60 4.42 357 56.3 5.11 2.03 57.1 12.6 2.05 65.5 23.4 1.22 0.924 16.6 0.00149 1.68 13.7

4 ISLC (P) 125 ###### 125 65 4.6 7 7 2.4 6 92 2.60 4.24 371 50.6 5.08 1.88 59.3 10.9 1.87 68.4 22 1.1 0.897 15.7 0.00153 2.27 14.4

5 ISLC 150 ###### 150 75 4.8 7.8 8 2.4 1.5 117 3.02 5.17 699 102 6.16 2.35 93.1 19.9 2.39 106 36.7 1.49 0.931 17.2 0.00388 3.04 18.4

6 ISPC (P) 150 ###### 150 75 5 8.7 8 2.4 6 110.8 3.05 5.05 752 96.2 6.15 2.2 100 18.3 2.24 115 36.3 1.44 0.91 15.5 0.00411 4.54 19.9

7 ISLC 175 ###### 175 75 5.1 9.5 8 3.2 1.5 138.6 3.01 5.15 1150 124 7.16 2.36 131 24.4 2.4 151 44.8 1.5 0.942 17 0.00636 5.07 22.4

8 ISLC 200 ###### 200 75 5.5 10.8 8.5 3.2 1.5 160 2.96 5.04 1730 145 8.12 2.35 173 28.2 2.36 199 51.9 1.34 0.945 17.5 0.00959 7.3 26.3

9 ISLC (P) 200 ###### 200 75 5.7 11.4 8.5 3.2 6 154.6 2.96 4.91 1795 137 8.09 2.23 180 25.9 2.23 207 50.5 1.27 0.925 16.7 0.00987 9.12 27.4

10 ISLC 225 ###### 225 90 5.8 10.2 11 3.2 6 175.9 3.53 5.71 2555 208 9.14 2.6 227 31.8 2.47 261 64.1 1.23 0.905 20.5 0.0207 9.25 30.6

11 ISLC 250 ###### 250 100 6.1 10.7 11 3.2 6 198.9 3.93 6.33 3697 296 10.2 2.88 296 40.6 2.71 339 82.5 1.33 0.902 21.8 0.037 12 35.7

12 ISLC 300 ###### 300 100 6.7 11.6 12 3.2 6 245.4 3.75 5.98 6066 345 12 2.86 404 46.3 2.56 468 93.1 0.891 0.898 24.9 0.0615 15.6 42.2

13 ISLC (P) 300 ###### 300 90 7 12.5 12 3.2 6 244.7 3.30 5.28 5927 283 11.9 2.59 395 42.4 2.33 461 83.3 0.719 0.903 23.5 0.0484 16.8 42.2

14 ISLC 350 ###### 350 100 7.4 12.5 13 4.8 6 291.9 3.58 5.63 9330 392 13.7 2.81 533 51.7 2.42 624 102 0.708 0.889 27.6 0.0952 20.2 49.5

15 ISLC 400 ###### 400 100 8 14 14 4.8 6 337.1 3.47 5.44 14021 458 15.5 2.8 701 60.1 2.37 827 117 0.729 0.888 29 0.143 27.8 58.3

* The heavier section in each size are intended for use in the wagon industry.

(P) stands for provisional section.

SteelIS20070710 Note: Value Colours: Blue=Basic dimensions; Black=Calculated values Compiled & calculated by Techno Consultants Ltd, April 2007

File: SteelIS20070710.xls Tab: ISRSCISRSC Page 1/1 Date Printed 07-05-2019

Вам также может понравиться

- Pipe Dimensions Chart Rev Jan 2012Документ1 страницаPipe Dimensions Chart Rev Jan 2012snake13Оценок пока нет

- Rectangular Hollow Sections - Hot FormedДокумент5 страницRectangular Hollow Sections - Hot FormedAristotle MedinaОценок пока нет

- C Purlin Data SheetДокумент6 страницC Purlin Data SheetAkhil VNОценок пока нет

- Popular Music Analysis and MusicologyДокумент15 страницPopular Music Analysis and MusicologyAlexMartínVidal100% (3)

- Jake Atlas Extract 2Документ25 страницJake Atlas Extract 2Walker BooksОценок пока нет

- Water - Hammer - Calculation - of Gravitational - AdductionДокумент36 страницWater - Hammer - Calculation - of Gravitational - AdductionAnonymous cuOIjrLIОценок пока нет

- Pipe Dimensions Chart Rev Jan 2012Документ1 страницаPipe Dimensions Chart Rev Jan 2012eljammalОценок пока нет

- Isolated Flyback Switching Regulator W - 9V OutputДокумент16 страницIsolated Flyback Switching Regulator W - 9V OutputCasey DialОценок пока нет

- Square Hollow Sections - Hot FormedДокумент5 страницSquare Hollow Sections - Hot FormedAristotle MedinaОценок пока нет

- Pipe & FlangeДокумент8 страницPipe & FlangeAbhiyan Anala ArvindОценок пока нет

- Square Hollow Sections - Cold FormedДокумент5 страницSquare Hollow Sections - Cold FormedAristotle MedinaОценок пока нет

- Hdpe Pe80 Din 8074 / Iso 4427Документ79 страницHdpe Pe80 Din 8074 / Iso 4427Steve WanОценок пока нет

- Key Performance IndicatorsДокумент15 страницKey Performance IndicatorsAbdul HafeezОценок пока нет

- EIS Summary NotsДокумент62 страницыEIS Summary NotsKESHAV DroliaОценок пока нет

- Wall Thickness (MM) Nominal Pipe Size Stainless Steel Carbon Steel DN NPS Outside Diameter (MM)Документ1 страницаWall Thickness (MM) Nominal Pipe Size Stainless Steel Carbon Steel DN NPS Outside Diameter (MM)Murali Fabtool100% (1)

- Discussion #3: The Concept of Culture Learning ObjectivesДокумент4 страницыDiscussion #3: The Concept of Culture Learning ObjectivesJohn Lery SurellОценок пока нет

- Saisc Structural Steel Section PropertiesДокумент12 страницSaisc Structural Steel Section PropertiesNathan PattersonОценок пока нет

- Stainless Steel Pipes Dimension (Schedule, Wall Tickness & Weight)Документ1 страницаStainless Steel Pipes Dimension (Schedule, Wall Tickness & Weight)Senthil KumarОценок пока нет

- THE LAW OF - John Searl Solution PDFДокумент50 страницTHE LAW OF - John Searl Solution PDFerehov1100% (1)

- Flange Weight ChartДокумент1 страницаFlange Weight Chartabhishek198327Оценок пока нет

- Toward A Design Theory of Problem SolvingДокумент24 страницыToward A Design Theory of Problem SolvingThiago GonzagaОценок пока нет

- Pump. Slurry Selection Typical Warman-1Документ51 страницаPump. Slurry Selection Typical Warman-1Christopher LloydОценок пока нет

- Calcined Clays For Sustainable Concrete Karen Scrivener, AurÇlie Favier, 2015Документ552 страницыCalcined Clays For Sustainable Concrete Karen Scrivener, AurÇlie Favier, 2015Débora BretasОценок пока нет

- BhattacharyaДокумент10 страницBhattacharyavoraciousvОценок пока нет

- Dimensions and Weights of SS Pipe PDFДокумент1 страницаDimensions and Weights of SS Pipe PDFAyhan AkyüzОценок пока нет

- ISPFCДокумент1 страницаISPFCCIVILОценок пока нет

- Indian Standard Heavy I SectionДокумент1 страницаIndian Standard Heavy I SectionCIVILОценок пока нет

- Indian Standard I SectionДокумент1 страницаIndian Standard I SectionCIVILОценок пока нет

- Iplex PVC U Pressure Series 1 Pipe DimensionsДокумент1 страницаIplex PVC U Pressure Series 1 Pipe Dimensions许爱文Оценок пока нет

- 10 Design of Gantry GirderДокумент10 страниц10 Design of Gantry GirderutsavОценок пока нет

- Hdpe Pe80 Din 8074 / Iso 4427Документ11 страницHdpe Pe80 Din 8074 / Iso 4427juan_saavedra_10Оценок пока нет

- SANS Section Properties Steel Profiles Rev2Документ10 страницSANS Section Properties Steel Profiles Rev2JakesОценок пока нет

- BSPT Thread ChartДокумент1 страницаBSPT Thread ChartsaaraanОценок пока нет

- Circular Hollow Sections - Cold Formed: D T M A L I W WДокумент5 страницCircular Hollow Sections - Cold Formed: D T M A L I W WVasilis LappasОценок пока нет

- Pipe Series: Wall Thickness and MassДокумент24 страницыPipe Series: Wall Thickness and MassTammam HassanОценок пока нет

- PE Pipe Wallthickness Mass Table DIN8074 PDFДокумент3 страницыPE Pipe Wallthickness Mass Table DIN8074 PDFzoveisiОценок пока нет

- Sizing Steel Sections For BeamsДокумент25 страницSizing Steel Sections For BeamsAnonymous ujfx6mОценок пока нет

- Equal Leg Angles EN 10056-1 - 1998Документ1 страницаEqual Leg Angles EN 10056-1 - 1998Axiv The GreatОценок пока нет

- Channels DimensionsДокумент2 страницыChannels DimensionsAristotle MedinaОценок пока нет

- MK19 v1 FullДокумент1 страницаMK19 v1 FullMaratОценок пока нет

- Gradation DataДокумент1 страницаGradation DataRobeam SolomonОценок пока нет

- Aluminium Conductor Steel Reinforced (Acsr) : Characteristics of A1/S1 B Conductors As Per IEC 1089/91 TYPE A1/S1 BДокумент12 страницAluminium Conductor Steel Reinforced (Acsr) : Characteristics of A1/S1 B Conductors As Per IEC 1089/91 TYPE A1/S1 Briddler_007Оценок пока нет

- Channe IДокумент1 страницаChanne IRahul B. WaghaleОценок пока нет

- Pipe Dimensions Chart Rev Jan 2012Документ1 страницаPipe Dimensions Chart Rev Jan 2012Thomas CalvinОценок пока нет

- Structural PDFДокумент5 страницStructural PDFrouhoОценок пока нет

- Section Properties Steel Profiles 25-05-12Документ17 страницSection Properties Steel Profiles 25-05-12Nhlakanipho NkwanyanaОценок пока нет

- Section - Properties - Steel - Profiles Rev 2 4Документ10 страницSection - Properties - Steel - Profiles Rev 2 4Francisco Javier Alvarez GarzaОценок пока нет

- Stainlesssteel Sheets As Per Astm&Weight-Kg.: Thickness Sizes MM 1219mm X 2438mm 1524mm X 3048mmДокумент3 страницыStainlesssteel Sheets As Per Astm&Weight-Kg.: Thickness Sizes MM 1219mm X 2438mm 1524mm X 3048mmuaarОценок пока нет

- Tools TipsExtensionsДокумент4 страницыTools TipsExtensionsSolina AlunorteОценок пока нет

- ISO 4422-2.pdf 2Документ3 страницыISO 4422-2.pdf 2Ashraf MansourОценок пока нет

- DN Pipe PDFДокумент6 страницDN Pipe PDFnassimОценок пока нет

- Dim Bridas PDFДокумент2 страницыDim Bridas PDFSiles LimberdsОценок пока нет

- Mild Steel Flat SectionsДокумент2 страницыMild Steel Flat SectionsmaheshОценок пока нет

- Pipe Sch. - Dimensions - ChartДокумент1 страницаPipe Sch. - Dimensions - ChartwwcengОценок пока нет

- I SectionsДокумент2 страницыI SectionsThanawatОценок пока нет

- Long Radius Elbow 20.4.2020Документ2 страницыLong Radius Elbow 20.4.2020Sunil GurubaxaniОценок пока нет

- Astm A252Документ1 страницаAstm A252Mohammad Faqih MaulanaОценок пока нет

- No Depth (FT) GR LLD MSFL Nphi Rhob DTДокумент3 страницыNo Depth (FT) GR LLD MSFL Nphi Rhob DTAriya SetiyakiОценок пока нет

- Lonne Marine Motors - Lowres Rev1 2015Документ12 страницLonne Marine Motors - Lowres Rev1 2015이정재Оценок пока нет

- ASME ANSI B16.25 Butt Welding EndsДокумент4 страницыASME ANSI B16.25 Butt Welding EndsFernandoОценок пока нет

- Stainless Steel Pipe: "Annealed" Welded and Seamless Comparison of Wall ThicknessesДокумент1 страницаStainless Steel Pipe: "Annealed" Welded and Seamless Comparison of Wall ThicknessesArief RachmanОценок пока нет

- Standard Sectional Reference Dimension (MM.) Geometrical Moment Sectional Area (CM) of Inertia (CM) L LДокумент2 страницыStandard Sectional Reference Dimension (MM.) Geometrical Moment Sectional Area (CM) of Inertia (CM) L LnoppadolОценок пока нет

- Dimensions Setional Properties Designation Mass (M) D B t T Sectional Area (a) Flange Slope (α) R R C I I rДокумент4 страницыDimensions Setional Properties Designation Mass (M) D B t T Sectional Area (a) Flange Slope (α) R R C I I rRahul SolankiОценок пока нет

- AngleA Dim PropДокумент2 страницыAngleA Dim PropserkanОценок пока нет

- Unequal Leg Angles EN 10056-1 - 1998Документ2 страницыUnequal Leg Angles EN 10056-1 - 1998Axiv The GreatОценок пока нет

- Black & Galvanized Steel Pipe BS 1387-1985 Size68 - 7kДокумент1 страницаBlack & Galvanized Steel Pipe BS 1387-1985 Size68 - 7kวิทวัส นิเทียนОценок пока нет

- Airborne Molecular Contamination ControlДокумент1 страницаAirborne Molecular Contamination ControlCIVILОценок пока нет

- Isolation Rooms and Isolation Anterooms With Appropriate Ventilation-Pressure Relationships AreДокумент1 страницаIsolation Rooms and Isolation Anterooms With Appropriate Ventilation-Pressure Relationships AreCIVILОценок пока нет

- Clean Rooms - Semiconductor ManufacturingДокумент1 страницаClean Rooms - Semiconductor ManufacturingCIVILОценок пока нет

- Septic Clean Rooms For Pharmaceutical and Bio-Manufacturing: Parameters Influencing Levels of ProtectionДокумент1 страницаSeptic Clean Rooms For Pharmaceutical and Bio-Manufacturing: Parameters Influencing Levels of ProtectionCIVILОценок пока нет

- Clean Room-52Документ1 страницаClean Room-52CIVILОценок пока нет

- Clean Room-46Документ1 страницаClean Room-46CIVILОценок пока нет

- Clean Room-49Документ1 страницаClean Room-49CIVILОценок пока нет

- As A Rule of Thumb Every 1" WG Static Pressure Shall Result in 1.1 F Rise in Temperature of AirДокумент1 страницаAs A Rule of Thumb Every 1" WG Static Pressure Shall Result in 1.1 F Rise in Temperature of AirCIVILОценок пока нет

- Factors That Contribute To Quality Products:: Case Examples (Bioclean & Semiconductor Rooms)Документ1 страницаFactors That Contribute To Quality Products:: Case Examples (Bioclean & Semiconductor Rooms)CIVILОценок пока нет

- Clean Rooms - Non-Aseptic Pharma Manufacturing/Health Care: o o o o o oДокумент1 страницаClean Rooms - Non-Aseptic Pharma Manufacturing/Health Care: o o o o o oCIVILОценок пока нет

- Clean Room-47Документ1 страницаClean Room-47CIVILОценок пока нет

- Lean Room Rrangement: Typical Arrangement & Energy ConservationДокумент1 страницаLean Room Rrangement: Typical Arrangement & Energy ConservationCIVILОценок пока нет

- Humidity Control:: 2) Noise CriteriaДокумент1 страницаHumidity Control:: 2) Noise CriteriaCIVILОценок пока нет

- Clean Room-31Документ1 страницаClean Room-31CIVILОценок пока нет

- Clean Room-40Документ1 страницаClean Room-40CIVILОценок пока нет

- Nergy Onservation: Figure # 3 (Документ1 страницаNergy Onservation: Figure # 3 (CIVILОценок пока нет

- MAH (Make Up Air Handler) : Figure #2Документ1 страницаMAH (Make Up Air Handler) : Figure #2CIVILОценок пока нет

- Conceptual Scheme: Parameters Class 10 Class 1000 Class 10000Документ1 страницаConceptual Scheme: Parameters Class 10 Class 1000 Class 10000CIVILОценок пока нет

- PDH Course M143: Minimum Wall Surf AceДокумент1 страницаPDH Course M143: Minimum Wall Surf AceCIVILОценок пока нет

- Ertification Requirments: System Design ExampleДокумент1 страницаErtification Requirments: System Design ExampleCIVILОценок пока нет

- PDH Course M143: Clean Room Design Criteria (Mechanical Practices)Документ1 страницаPDH Course M143: Clean Room Design Criteria (Mechanical Practices)CIVILОценок пока нет

- 5) Vacuum Systems (House Keeping)Документ1 страница5) Vacuum Systems (House Keeping)CIVILОценок пока нет

- Lectrical Considerations: 1) GeneralДокумент1 страницаLectrical Considerations: 1) GeneralCIVILОценок пока нет

- Unidirectional Flow System DesignsДокумент1 страницаUnidirectional Flow System DesignsCIVILОценок пока нет

- Points To Note For AttenuationДокумент1 страницаPoints To Note For AttenuationCIVILОценок пока нет

- 3) Raised Access FloorsДокумент1 страница3) Raised Access FloorsCIVILОценок пока нет

- 7) Minimize Contamination From Clean-Room Personnel: Echcanical ConsiderationsДокумент1 страница7) Minimize Contamination From Clean-Room Personnel: Echcanical ConsiderationsCIVILОценок пока нет

- Rchitectural Issues: Arcitectural, Electrical & Noise IssuesДокумент1 страницаRchitectural Issues: Arcitectural, Electrical & Noise IssuesCIVILОценок пока нет

- CSEC Eng A Summary ExerciseДокумент1 страницаCSEC Eng A Summary ExerciseArisha NicholsОценок пока нет

- Survey Results Central Zone First LinkДокумент807 страницSurvey Results Central Zone First LinkCrystal Nicca ArellanoОценок пока нет

- 2,3,5 Aqidah Dan QHДокумент5 страниц2,3,5 Aqidah Dan QHBang PaingОценок пока нет

- Average Waves in Unprotected Waters by Anne Tyler - Summary PDFДокумент1 страницаAverage Waves in Unprotected Waters by Anne Tyler - Summary PDFRK PADHI0% (1)

- Coronally Advanced Flap With Connective Tissue GraДокумент13 страницCoronally Advanced Flap With Connective Tissue GrasutriОценок пока нет

- Sentence Connectors: 1.contrast 1. A. Direct OppositionДокумент8 страницSentence Connectors: 1.contrast 1. A. Direct OppositionCathy siganОценок пока нет

- Sucesos de Las Islas Filipinas PPT Content - Carlos 1Документ2 страницыSucesos de Las Islas Filipinas PPT Content - Carlos 1A Mi YaОценок пока нет

- Graphic Organizers As A Reading Strategy: Research FindДокумент9 страницGraphic Organizers As A Reading Strategy: Research Findzwn zwnОценок пока нет

- Operations Management (Scheduling) PDFДокумент4 страницыOperations Management (Scheduling) PDFVijay Singh ThakurОценок пока нет

- Roofing Shingles in KeralaДокумент13 страницRoofing Shingles in KeralaCertainteed Roofing tilesОценок пока нет

- India: SupplyДокумент6 страницIndia: SupplyHarish NathanОценок пока нет

- Physics - TRIAL S1, STPM 2022 - CoverДокумент1 страницаPhysics - TRIAL S1, STPM 2022 - CoverbenОценок пока нет

- Supporting References in Release 12 SLA PDFДокумент8 страницSupporting References in Release 12 SLA PDFsoireeОценок пока нет

- General Health Questionnaire-28 GHQ-28Документ3 страницыGeneral Health Questionnaire-28 GHQ-28srajanОценок пока нет

- Acfrogb0i3jalza4d2cm33ab0kjvfqevdmmcia - Kifkmf7zqew8tpk3ef Iav8r9j0ys0ekwrl4a8k7yqd0pqdr9qk1cpmjq Xx5x6kxzc8uq9it Zno Fwdrmyo98jelpvjb-9ahfdekf3cqptДокумент1 страницаAcfrogb0i3jalza4d2cm33ab0kjvfqevdmmcia - Kifkmf7zqew8tpk3ef Iav8r9j0ys0ekwrl4a8k7yqd0pqdr9qk1cpmjq Xx5x6kxzc8uq9it Zno Fwdrmyo98jelpvjb-9ahfdekf3cqptbbОценок пока нет

- Motivational Speech About Our Dreams and AmbitionsДокумент2 страницыMotivational Speech About Our Dreams and AmbitionsÇhärlöttë Çhrístíñë Dë ÇöldëОценок пока нет

- Echnical Ocational Ivelihood: Edia and Nformation IteracyДокумент12 страницEchnical Ocational Ivelihood: Edia and Nformation IteracyKrystelle Marie AnteroОценок пока нет

- LittorinidaeДокумент358 страницLittorinidaeSyarif Prasetyo AdyutaОценок пока нет

- Capacitor Banks in Power System Part FourДокумент4 страницыCapacitor Banks in Power System Part FourTigrillo100% (1)

- Icc Enrichment AcitivityДокумент2 страницыIcc Enrichment AcitivityDan Rey Miras MiñaОценок пока нет