Академический Документы

Профессиональный Документы

Культура Документы

Impact Bed Techdata Rsa

Загружено:

Enter ExitАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Impact Bed Techdata Rsa

Загружено:

Enter ExitАвторское право:

Доступные форматы

TECHNICAL DATA SHEET

Martin® Impact Bed

1207

Installed under the belt conveyor loading zone, Martin® Impact Bed absorb the force of falling material to prevent CONVEYOR BELT

damage to the belt and structure and to help eliminate spillage.

IDLER

250

FEATURES & BENEFITS 16 x Ø18

• Steel reinforcement for impact bars; each impact

76 TYP

bar is reinforced with a bed of steel angles.

200 343 2 200

SEE APPLICATION NOTE 5 SEE APPLICATION NOTE 4 SEE APPLICATION NOTE 5

• Allows compensation for wear; eccentrics in wing

1029 2

SECTION F-F

supports allow outer bars five degrees of wear

adjustment.

• Durable impact bars; rugged bars are composed of

a top layer of low friction UHMW and a lower layer

of energy-absorbing urethane.

• Simple bar replacement; impact bars are each

secured with four bolts.

• Rugged structure stands up to abuse; sturdy cradle

base is formed channels.

FRONT AND SIDE VIEW

DIM "E"

CONVEYOR BELT mm

50

TO

SH

F LU

F

SEE APPLICATION

NOTE 2

DIM

"A"

DIM "D"

F

124 TYP

CONVEYOR

STRINGER

DIM "B" (BACKMARK)

DIM "C"

FRONT VIEW

1207

CONVEYOR BELT

IDLER

250

16 x Ø18

76 TYP

200 343 2 200

SEE APPLICATION NOTE 5 SEE APPLICATION NOTE 4 SEE APPLICATION NOTE 5

1029 2

SECTION F-F

Form No. L000-ZA-05/16

© Martin Engineering Company 2014

TECHNICAL DATA SHEET 16 x Ø18

76 TYP

DIMENSIONS

200 343 2

SEE APPLICATION NOTE 5 SEE APPLICATION NOTE 4 SEE APP

* INDICATES REPLACEMENT PARTS

THROUGH ITEM 4 * ITEM 5 * 1029 2

BELT WIDTH ANGLE ITEM 1 * ITEM 2 ITEM 3 IMPACT BAR T-BOLT DIM DIM DIM DIM

SUPPORT ARM INCLINE BAR INCLINE BAR SLEEVE PART No. PART No. "B" "C" "D" "E"

DIM "A" 3161/7 3177/5

SECTION F-F

(mm) (DEG) PART No. QTY PART No. QTY PART No. QTY QTY QTY (mm) (mm) (mm) (mm)

20 30665060020SA 306690600SA 306750600SA 332 770

600 35 30665060035SA 306690600SA 306750600SA 6 18 838 914 386 675

45 30665060045SA 306690600SA 306750600SA 413 598

20 30665060020SA 306690600SA 306750750SA 332 814

750 35 30665060035SA 306690600SA 306750750SA 6 18 990 1066 386 719

45 30665060045SA 306690600SA 306750750SA 413 642

20 30665090020SA 306690900SA 306750900SA 340 886

900 35 30665090035SA 306690900SA 306750900SA 7 21 1144 1220 392 787

45 30665090045SA 306690900SA 306750900SA 419 708

20 30665105020SA 306691200SA 306751050SA 382 1163

1050 35 30665105035SA 306691200SA 306751050SA 9 27 1296 1372 463 1035

45 30665105045SA 306691200SA 306751050SA 507 928

20 30665120020SA 306691200SA 306751200SA 382 1227

1200 35 30665120035SA 306691200SA 306751200SA 10 30 1448 1524 463 1099

45 30665120045SA 306691200SA 306751200SA 507 992

20 30665120020SA 306691200SA 306751350SA 382 1272

1350 35 30665120035SA 306691200SA 306751350SA 10 30 1600 1676 463 1144

45 30665120045SA 306691200SA 306751350SA 507 1037

20 30665150020SA 306691500SA 306751500SA 421 1578

1500 35 30665150035SA 16 306691500SA 8 306751500SA 8 13 39 1752 1828 531 1421

45 30665150045SA 306691500SA 306751500SA 592 1287

20 30665150020SA 306691500SA 306751650SA 421 1616

1650 35 30665150035SA 306691500SA 306751650SA 13 39 1904 1980 531 1459

45 30665150045SA 306691500SA 306751650SA 592 1325

20 30665150020SA 306691800SA 306751800SA 421 1666

1800 35 30665150035SA 306691800SA 306751800SA 13 39 2058 2134 531 1509

45 30665150045SA 306691800SA 306751800SA 592 1375

20 30665210020SA 306692100SA 306752000SA 470 1995

2000 35 30665210035SA 306692100SA 306752000SA 16 48 2260 2336 608 1805

45 30665210045SA 306692100SA 306752000SA 685 1641

20 30665210020SA 306692100SA 306752100SA 470 2025

2100 35 30665210035SA 306692100SA 306752100SA 16 48 2362 2438 608 1835

45 30665210045SA 306692100SA 306752100SA 685 1671

20 30665220020SA 306692200SA 306752200SA 516 2307

2200 35 30665220035SA 306692200SA 306752200SA 19 57 2464 2540 683 2085

45 30665220045SA 306692200SA 306752200SA 776 1892

20 30665220020SA 306692200SA 306752400SA 516 2365

2400 35 30665220035SA 306692200SA 306752400SA 19 57 2668 2744 683 2143

45 30665220045SA 306692200SA 306752400SA 776 1950

APPLICATION NOTES:

1) ALL DIMENSIONS CONFORM TO SABS STANDARD NO. 1313-1 CONVEYOR BELT IDLERS.

2) A MINIMUM CLEARANCE OF 19mm BETWEEN BELT AND IMPACT BED ® IMPACT BARS

MUST BE MAINTAINED FOR PROPER OPERATION OF SYSTEM. PREMATURE WEAR OF

THE TOP LAYER ON THE IMPACT BAR COULD RESULT.

3) SUPPORT SYSTEM MAY BE BOLTED OR WELDED IN PLACE. MARTIN ENGINEERING

RECOMMENDS BOLTING TO STRUCTURE WHEN APPLICABLE FOR

EASY ACCESSIBILITY AND MAINTENANCE.

4) 343mm DIMENSION MUST BE MAINTAINED TO ALLOW PROPER SLIDING ACTION OF

BAR WELDMENTS, AND INSURE EASY INSTALLATION AND SERVICING.

5) MARTIN RECOMMENDS THAT IDLERS BE POSITIONED 200mm (FROM CENTER)

BEFORE AND 200mm AFTER THE IMPACT SYSTEM.

6) MOTOR H.P. REQUIRMENTS SHOULD BE REVIEWED PRIOR TO INSTALLATION

OF THE IMPACT BED ® IMPACT SYSTEM.

7) CONSULT MARTIN ENGINEERING OPERATOR'S MANUAL PRIOR TO INSTALLATION OF

IMPACT SYSTEM FOR APPLICATION AND SELECTION GUIDES.

8) MARTIN RECOMMENDS TRAC-MOUNT SKIRTBOARD AND TRAC-MOUNT IDLER

SYSTEMS TO COMPLIMENT IMPACT BED ® IMPACT SYSTEM. CONTACT

MARTIN ENGINEERING COMPANY FOR FURTHER DETAILS.

9) THE IMPACT BED ® IS DESIGNED FOR 3-ROLL CONVEYOR CONFIGURATIONS ONLY.

Martin Engineering RSA

Subject to change without prior notice.

Cnr Antwerpen str & Arnhemsingel

Quality Management System Certified by DNV -

Die Heuwel, Witbank, Emalahleni ISO 9001

Tel +27 13 656 5135

Fax +27 13 656 5129

www.martin-eng.co.za

Form No. L000-ZA-05/16

© Martin Engineering Company 2014

Вам также может понравиться

- Blast Design PDFДокумент16 страницBlast Design PDFJohndejohnОценок пока нет

- Pull-Safe PS-P (Polybutylene Terephthalate (PBT) .Polycarbonate (PC) )Документ2 страницыPull-Safe PS-P (Polybutylene Terephthalate (PBT) .Polycarbonate (PC) )mathan_aeОценок пока нет

- Section H Battery Slab DetailsДокумент1 страницаSection H Battery Slab DetailsMoses MussОценок пока нет

- Type F9 by Lindapter 983Документ1 страницаType F9 by Lindapter 983Dan Dela PeñaОценок пока нет

- EXpulsion Fuse Cut OutДокумент8 страницEXpulsion Fuse Cut OutAsanka KumaraОценок пока нет

- SD10-01 System DrawingДокумент1 страницаSD10-01 System DrawingnankinОценок пока нет

- Alumaxi: Concealed Bracket With and Without HolesДокумент10 страницAlumaxi: Concealed Bracket With and Without HolesAlex ZecevicОценок пока нет

- Type AF by Lindapter 1226Документ3 страницыType AF by Lindapter 1226Venkatesh PrasathОценок пока нет

- Lindapter Type f3 DatasheetДокумент1 страницаLindapter Type f3 DatasheetTarun SharmaОценок пока нет

- Страницы из Allway UK 2018 parking joint RFP su pavad 30 & 50 - kopijaДокумент1 страницаСтраницы из Allway UK 2018 parking joint RFP su pavad 30 & 50 - kopijaScenic777Оценок пока нет

- E McqaДокумент19 страницE McqaTháiSơnTrầnОценок пока нет

- "T" Shaped Post Base: InvisibleДокумент6 страниц"T" Shaped Post Base: Invisiblemilivoj ilibasicОценок пока нет

- SD-208 - Rev 2Документ1 страницаSD-208 - Rev 2sathishОценок пока нет

- Lock T Evo - en - 02-20 PDFДокумент10 страницLock T Evo - en - 02-20 PDFmilivoj ilibasicОценок пока нет

- Keystone 222 Datasheet - UnlockedДокумент8 страницKeystone 222 Datasheet - UnlockedviksursОценок пока нет

- M81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationДокумент1 страницаM81935/7 Self-Lubricated Rod End Bearings: Specifications and Ordering InformationFlavio Abreu100% (1)

- De Va: Series 58Документ8 страницDe Va: Series 58Prathamesh Pradeep MashilkarОценок пока нет

- Elevator Shaft 1 Fire Exit Stairs Elevator Shaft 2: 500X500 MM Ceramic TilesДокумент1 страницаElevator Shaft 1 Fire Exit Stairs Elevator Shaft 2: 500X500 MM Ceramic TilesDarwin Lasala DesembranaОценок пока нет

- Flexible Rubber Joint: Design Connection Face To Face Marking Tests Corrosion ProtectionДокумент4 страницыFlexible Rubber Joint: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatОценок пока нет

- Diffuser AirmasterДокумент8 страницDiffuser AirmasterdesignОценок пока нет

- 2Документ5 страниц2enes özОценок пока нет

- Alumidi: Concealed Bracket With and Without HolesДокумент12 страницAlumidi: Concealed Bracket With and Without HolesAlex ZecevicОценок пока нет

- 3 Mget SP MKT Get and Buckets Surface Mining EnglishДокумент15 страниц3 Mget SP MKT Get and Buckets Surface Mining EnglishMarcoОценок пока нет

- Chapter 6 3part-4Документ1 страницаChapter 6 3part-4Enak CenirОценок пока нет

- Embelton Datasheets AДокумент3 страницыEmbelton Datasheets AaswarОценок пока нет

- BRIDGESTONE VREP-quarryДокумент2 страницыBRIDGESTONE VREP-quarryMORTEMОценок пока нет

- Timken Ball Bearings CatalogДокумент126 страницTimken Ball Bearings Catalogmohananc67Оценок пока нет

- Lifting365 SW-W ALPHA Wall-MountedДокумент1 страницаLifting365 SW-W ALPHA Wall-MountedPatrick MurphyОценок пока нет

- FBN IiДокумент6 страницFBN IiZuberahmed ShaikhОценок пока нет

- Iron Giant: Series Jaw CrushersДокумент8 страницIron Giant: Series Jaw CrushersBearingman100% (1)

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFДокумент1 страница4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFKrish KumarОценок пока нет

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFДокумент1 страница4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFMumum100% (1)

- Bulk Water Meter Installation in Chamber DrawingДокумент1 страницаBulk Water Meter Installation in Chamber DrawingSijo JoyОценок пока нет

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFДокумент1 страница4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFRonald ValenciaОценок пока нет

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFДокумент1 страница4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFabdullah amanullah0% (1)

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFДокумент1 страница4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFbaban patilОценок пока нет

- 4a Bulk Water Meter Installation in Chamber Drawing - PEWSTDAMI004Документ1 страница4a Bulk Water Meter Installation in Chamber Drawing - PEWSTDAMI004Abey Vettoor100% (2)

- 4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFДокумент1 страница4a Bulk Water Meter Installation in Chamber DrawingPEWSTDAMI004 PDFshawonscribdОценок пока нет

- C1-F1 Detail Plan View: 0.4x0.5 20mm 0.3x0.4 20mm 3 2 4 4 3 2 4 4 3 2 4 4Документ1 страницаC1-F1 Detail Plan View: 0.4x0.5 20mm 0.3x0.4 20mm 3 2 4 4 3 2 4 4 3 2 4 4Lyka AnchetaОценок пока нет

- Type F9 by Lindapter 1124Документ1 страницаType F9 by Lindapter 1124Suzaikumar R SanglikarОценок пока нет

- Nozzles Data-SheetДокумент9 страницNozzles Data-SheetMawada RashedОценок пока нет

- 4N Tapping Band NewДокумент2 страницы4N Tapping Band NewAkshat JainОценок пока нет

- PARTITIONДокумент1 страницаPARTITIONKanak YadavОценок пока нет

- Mez Standard System 40Документ1 страницаMez Standard System 40Antonio Carlos AtaideОценок пока нет

- Under Reamed Piles - 1-10-09Документ20 страницUnder Reamed Piles - 1-10-09f100% (1)

- Schletter-Product Sheets-Roof Systems-Beaver Tail Roof HooksДокумент6 страницSchletter-Product Sheets-Roof Systems-Beaver Tail Roof Hooksf789sgacanonОценок пока нет

- Installation Instructions EL-G-E500 Encore Dispenser: Shear Valve Arrangement in PlanДокумент4 страницыInstallation Instructions EL-G-E500 Encore Dispenser: Shear Valve Arrangement in PlanCamilo CorreaОценок пока нет

- PERIMETER FENCE-Layout2Документ1 страницаPERIMETER FENCE-Layout2Stefen SalvadorОценок пока нет

- Submittal Sheet Kennedy Guardian k81d K81a and K81am 89dfbd8f PDFДокумент18 страницSubmittal Sheet Kennedy Guardian k81d K81a and K81am 89dfbd8f PDFvicvic34Оценок пока нет

- KennedyДокумент18 страницKennedyHimat KhimaniОценок пока нет

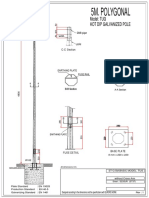

- 5M. Polygonal: Hot Dip Galvanized Pole Model: TUGДокумент1 страница5M. Polygonal: Hot Dip Galvanized Pole Model: TUGDumitrache IulianОценок пока нет

- BreezecatalogДокумент29 страницBreezecatalogVo ManhОценок пока нет

- Lock T - en - 02-20 PDFДокумент14 страницLock T - en - 02-20 PDFmilivoj ilibasicОценок пока нет

- VFlo - Mascot Ball Vale VnotchДокумент8 страницVFlo - Mascot Ball Vale VnotchEnerprec SASОценок пока нет

- RC Square Pile Brochure 2022Документ8 страницRC Square Pile Brochure 2022k33_hon87Оценок пока нет

- WH Brady Electric Hoist PDFДокумент4 страницыWH Brady Electric Hoist PDFSuresh NathОценок пока нет

- Hollow Core Floors: Bearing DetailsДокумент4 страницыHollow Core Floors: Bearing DetailsAhmadОценок пока нет

- Wa 700Документ16 страницWa 700Enter ExitОценок пока нет

- SPCL ConvДокумент2 страницыSPCL ConvEnter ExitОценок пока нет

- AIR SUPPORTED BELT ConvДокумент48 страницAIR SUPPORTED BELT ConvEnter ExitОценок пока нет

- Truck Tippler Control RoomДокумент1 страницаTruck Tippler Control RoomEnter ExitОценок пока нет

- Elevation View QДокумент1 страницаElevation View QEnter ExitОценок пока нет

- Fever Clinic in DISTRICTS: SL No District Block/ Municipality Location of Fever ClinicДокумент44 страницыFever Clinic in DISTRICTS: SL No District Block/ Municipality Location of Fever ClinicEnter ExitОценок пока нет

- C45 Medium Carbon Steel - Hillfoot Multi Metals PDFДокумент1 страницаC45 Medium Carbon Steel - Hillfoot Multi Metals PDFEnter ExitОценок пока нет

- C45 Medium Carbon Steel - Hillfoot Multi MetalsДокумент1 страницаC45 Medium Carbon Steel - Hillfoot Multi MetalsEnter ExitОценок пока нет

- EXERCISE 1-Passive FormДокумент5 страницEXERCISE 1-Passive FormMichele LangОценок пока нет

- New Rich Text DocumentДокумент12 страницNew Rich Text Documentsonam dorjiОценок пока нет

- Price and Output Determination Under OligopolyДокумент26 страницPrice and Output Determination Under OligopolySangitha Nadar100% (1)

- Ra 9293 Amending Ra 7836Документ2 страницыRa 9293 Amending Ra 7836vonoblesseОценок пока нет

- HLX 150Документ44 страницыHLX 150menendez2050100% (1)

- My Personal Brand and Career GoalsДокумент3 страницыMy Personal Brand and Career GoalsPhúc ĐàoОценок пока нет

- Accounting For Financial Institutions Week 1Документ4 страницыAccounting For Financial Institutions Week 1emadhamdy2002Оценок пока нет

- Legal Framework On Sexual Violence in Sri Lanka - Policy BriefДокумент4 страницыLegal Framework On Sexual Violence in Sri Lanka - Policy BriefwmcsrilankaОценок пока нет

- SPE 166182 Radio Frequency Identification (RFID) Leads The Way in The Quest For Intervention Free Upper Completion InstallationДокумент9 страницSPE 166182 Radio Frequency Identification (RFID) Leads The Way in The Quest For Intervention Free Upper Completion InstallationjangolovaОценок пока нет

- BoSY CRLA Grade 1 MT Administration GuideДокумент13 страницBoSY CRLA Grade 1 MT Administration GuideJOCELYN SANANO100% (1)

- Answers & Solutions: For For For For For JEE (MAIN) - 2019 (Online) Phase-2Документ22 страницыAnswers & Solutions: For For For For For JEE (MAIN) - 2019 (Online) Phase-2Manila NandaОценок пока нет

- TaxationДокумент26 страницTaxationReynamae Garcia AbalesОценок пока нет

- SSP 861603 - EN - Tire Pressure Monitoring SystemsДокумент42 страницыSSP 861603 - EN - Tire Pressure Monitoring Systemsa.diedrichsОценок пока нет

- Hitachi Zx330 3 Series Hydraulic ExcavatorДокумент15 страницHitachi Zx330 3 Series Hydraulic ExcavatorAgung ArdhanaОценок пока нет

- Founders' ShareДокумент2 страницыFounders' ShareHenry BerlangaОценок пока нет

- MAPEH Q4 ScriptДокумент4 страницыMAPEH Q4 Scriptcharice maanoОценок пока нет

- Once Upon A Timein AmericaДокумент335 страницOnce Upon A Timein Americaqwerty-keysОценок пока нет

- Robot Structural Analysis 2017 Help - Push Over Analysis ParametersДокумент3 страницыRobot Structural Analysis 2017 Help - Push Over Analysis ParametersJustin MusopoleОценок пока нет

- Oral ComДокумент2 страницыOral ComChristian OwlzОценок пока нет

- Curriculum in MalaysiaДокумент37 страницCurriculum in MalaysiaEmily Ling100% (1)

- RLB Procuring For Value 18 July PDFДокумент56 страницRLB Procuring For Value 18 July PDFDaniel LixandruОценок пока нет

- RagragsakanДокумент6 страницRagragsakanRazel Hijastro86% (7)

- Govt Considers Putting ShahbazДокумент27 страницGovt Considers Putting ShahbazWanderer123Оценок пока нет

- QAS M001 SLPS Quality Assurance ManualДокумент49 страницQAS M001 SLPS Quality Assurance ManualMHDОценок пока нет

- Reich 0001 PDFДокумент87 страницReich 0001 PDFYordys Domínguez RodríguezОценок пока нет

- Bcos 186Документ3 страницыBcos 186Shiv KumarОценок пока нет

- STAS 111 - Information AgeДокумент20 страницSTAS 111 - Information AgeMayeee GayosoОценок пока нет

- Denso HP4Документ87 страницDenso HP4Abraham Janco Janco100% (2)

- Alberico Da BarbianoДокумент3 страницыAlberico Da BarbianoNupur PalОценок пока нет

- Uplifting Hauora Maori RealДокумент32 страницыUplifting Hauora Maori RealFano AsiataОценок пока нет