Академический Документы

Профессиональный Документы

Культура Документы

EEEPL - JSA EARTH FLAT LAYING New 123

Загружено:

nishanth0 оценок0% нашли этот документ полезным (0 голосов)

152 просмотров7 страницОригинальное название

EEEPL - JSA EARTH FLAT LAYING new 123.doc

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

152 просмотров7 страницEEEPL - JSA EARTH FLAT LAYING New 123

Загружено:

nishanthАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 7

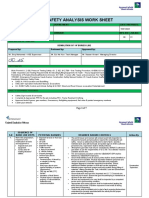

Ref.

No: EEEPL - 04

Revision No. 01

Date 19/04/19

JOB SAFETY &

ENVIRONMENT ANALYSIS

Job Title: Grid Earth Flat laying Date of Job Analysis:

Projects: BSH HOUSE HOLD APPLIANCES Reference No:

Analyst/ Reviewer: PTK / BSH

Description of Job:

GI Earth flat for ESD Earthing.

Sequence of job steps Risks identified Precautions advised Responsible persons

Vehicle (Unloading) Enters Vehicle accident The following documents to be

enclosed before permit the vehicle;

via Gate 3, reach the store

Vehicle documents(Registration

yard area. and Insurance) Site Engineer & Safety

Driver License with valid date officer

Speed limit is 15kmph at inside

the campus.

Ensure Safety and traffic

marshals been informed about

the vehicle entry.

Ensure logistic plan explained to

the driver by banks man.

Safety marshal and bangs man

will walk with truck from

entrance to unloading.

Stop the other tenant vehicle

movement by BSH security

while entering and reversing the

vehicle.

Provide barricade(cone with

chain) at around the vehicle

while unloading

Basic PPE’S (Safety Helmets,

Reflective jacket, , Hand gloves,

Safety shoe,)

Deploy sufficient persons to

unload material

Weight limit for male<25kgs Site Engineer &

Labor should be ensure proper Safety officer

Ergonomic Hazards induction and job specific

Unloading of Earth flats Cut & crush injury training

Manually by workers Slip and trip Hazard

Using Proper Manual handling

Access should be free from

unwanted materials and debris

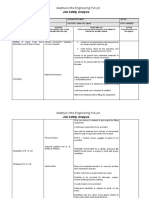

Ref. No: EEEPL - 04

Revision No. 01

Date 19/04/19

JOB SAFETY &

ENVIRONMENT ANALYSIS

Basic PPE’S (Safety Helmets,

Reflective jacket, shoulder pad,

Hand gloves, Safety shoe,)

Obstructions in access ways to

be cleared.

Adequate illumination to be Site Engineer & Safety

provided @ 150lux as per site officer

requirement.

TPC shall be submitted for the

Slip, Trip and Fall hydraulic trolley.

Hit to personnel Both the end of earth flat must

Shifting of Earth flat to work be protected by using soft

place through using materials.

hydraulic trolley / Manually. Basic PPE’s ( Safety helmet,

( All GI earth flats shall be Safety shoes, Reflective jackets,

folded to 3m length while hand gloves)

unloading and shifting)

All obstructions shall be

removed off from access areas.

Warning signage shall be

Slip & Trip displayed.

Cut and Crush injury Both the edges shall be protected

Shifting of Earth flats in the Sprain & strain using cloth or any sort of soft Site Engineer & Safety

floors to the work area materials. officer

manually Ensure the area is isolated using

( Max Weight of per flat is barricades.

15kgs) Adequate illumination shall be

provided @ 150 lux in work

area.

Full time supervision shall be

avail for the activity.

Basic PPE’s ( Safety helmet,

Safety shoes, Reflective jackets,

hand gloves, Shoulder pads)

Area shall be isolated using

Sprain ,strain and crush barricading.

injury Hand tools like hammer shall be

inspected prior to use

Damage and defective tools Site Engineer & Safety

Straightening the earth flat officer

shall not be used.

using hammer manually @

Full time supervisor is

work area.

mandatory for the activity.

Both sharp ends of the earth flat

shall be protected using soft

materials.

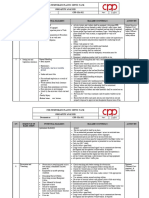

Ref. No: EEEPL - 04

Revision No. 01

Date 19/04/19

JOB SAFETY &

ENVIRONMENT ANALYSIS

All obstructions shall be

Electrocution removed off from access areas.

Hammering area must be

isolated from unauthorized

8mm Hole making in GI entry.

Earth Flat for joints using Adequate training shall be given Site Engineer &

Bench drilling machine at to respective workers

floors. Basic PPE’s safety helmet, Safety officer

safety shoes, reflective jacket,

Goggles, hand gloves and ear

plugs shall be worn.

Provide ELCB (30mA tripping

capacity) and inspect on daily

basis.

Electrical machineries should be

checked by ‘B’ license holder

prior to use.

Display the tag on machine.

Cable should be over headed

above 7feet.

Provide IP44/48 rated sockets

and ensure no wire joints

Hit by drilling particles Provide Emergency stopper.

Cut & crush injury Ensure the platform and the

Exposure to heat vertical stand is supported.

Slip, trip , fall hazard Sign boards shall be displayed.

Wastages shall be collected in

waste bins.

Enclosure for the drilling check

shall be provided to avoid using

the hands close to the machine.

Basic PPE’s ( Safety helmet,

Safety shoes, Reflective jackets,

hand gloves, face shield, safety

goggles)

Provide table for whole making

Electrocution. in earth flat.

Water shall be dipped upon the

drilling area while drilling to

avoid heat exposure.

Drip tray or area to be secured

by sand bund temporarily to

Cutting of earth flats by avoid water scattering.

using cutting machine. Area to be barricaded to

unauthorized entry. Site Engineer & Safety

officer

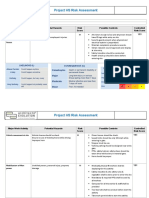

Ref. No: EEEPL - 04

Revision No. 01

Date 19/04/19

JOB SAFETY &

ENVIRONMENT ANALYSIS

Basic PPE’s ( Safety helmet,

Safety shoes, safety goggles,

Reflective jackets, hand gloves )

Provide ELCB (30mA tripping

capacity) and inspect on daily basis.

All rotating parts in the potable

machineries must have guard.

Secondary guard is must for cutting

machine

Electrical machineries should be

checked by ‘B’ license holder prior

to use.

Display the tag on machine.

Eye Injury.

Cable should be over headed above

Penetrating hazards

( While Cleaning Cut 7feet.

Provide Emergency stopper.

pieces) Ensure the platform and the vertical

stand is supported.

Sign boards shall be displayed.

Wastages shall be collected in waste

bins.

Enclosure for the wheel deck shall

be provided to avoid using the hands

close to the machine.

Provide IP44/48 rated sockets and

ensure no wire joints.

Basic PPE’s ( Safety helmet, Safety

shoes, Reflective jackets, hand

gloves, face shield,

Hitting of Sparks while Table must be provided for

cutting Earth Flats using cutting activity.

Cutting machine Basic PPE’s (safety helmet,

safety shoes, hand glove, safety

goggles, nose mask, ear plug,

face shield).

Unauthorized entry shall be

prohibited inside the cutting

zone.

Waste pieces should be collected

in box.

Floor shall be covered with

plastic cover to avoid earth flat

cut piece particles scattered on

the floor.

The collected dust particles shall

be stored in a box.

Ref. No: EEEPL - 04

Revision No. 01

Date 19/04/19

JOB SAFETY &

ENVIRONMENT ANALYSIS

Collapse of scaffold Proper platform to be provided

Provide CO2 fire extinguisher.

Three side screening using Fire

Installation of Earth flats in blankets shall be provided.

trays using 8mm bold and Fire blanket MTC shall be

Nets manually. provided.

Secondary guard is must for

cutting machine.

Obtain HOT work permit from

BSH / PTK.

Fire watcher must be present

during works.

Avoid multiple connections and

cable joints for electrical tools.

Provide IP rated panel boards

Fall of person /material along with IP44/48 sockets.

on scaffold. Basic PPE’s (Safety helmet,

Safety shoes, Reflective jackets,

hand gloves, face shields.)

Obtain height work permit from

BSH / PTK..

Mobile scaffold shall be erected

by trained person and training

must to attend before deploy.

Scaffolding checklist to be done

and display the tag system.

Do not stack the material at

platform.

Ladder/ stair case to be provided

Slip & Trip for access to reach platform.

Complete platform to be

provided at above & below

level.

Basic PPE’s ( Safety helmet,

Safety shoes, Reflective jackets,

hand gloves, safety harness)

Ensured free from gap on

working platform.

Handrail, mid rails and toe board

must to provide.

Height work Permit to be taken

prior to start the work.

Do not drop the material from

Fall from height height.

Ensure the erected pipes

Ref. No: EEEPL - 04

Revision No. 01

Date 19/04/19

JOB SAFETY &

ENVIRONMENT ANALYSIS

Provide barricading cone with

signage.

Basic PPE’s ( Safety helmet,

Safety shoes, Reflective jackets,

hand gloves, Safety harness)

All obstructions shall be

removed off from access areas.

Adequate signage shall be

provided.

Use appropriate hand tools

All hand tools to be inspected

prior to start activity.

Ensure the area is isolated using

barricades.

Adequate illumination shall be

provided @ 150 lux in work

area.

Basic PPE’s (Safety helmet,

Safety shoes, Reflective jackets,

hand gloves)

Slip & Trip

Fall of materials Scaffolding shall be erected /

dismantle by competent person

and inspected by competent

person.

Area to be isolated to avoid

unauthorized entry.

Only two persons are permitted

to work at a time in working

platform.

Scaffolding tag shall be

Electrocution. displayed.

Adequate sign / caution boards

to be displayed.

SWL of 225kgs shall be

displayed in mobile scaffoldings.

Mobile scaffolding must not be

pulled or dragged when persons

are above.

Inspection shall be carried out

on weekly basis and recorded in

inspection checklists daily.

Basic PPE’s ( Safety helmet,

Safety shoes, Reflective jackets,

hand gloves, Safety harness)

Ref. No: EEEPL - 04

Revision No. 01

Date 19/04/19

JOB SAFETY &

ENVIRONMENT ANALYSIS

No loose materials permitted to

kept on the platform.

Warning signage shall be

displayed.

Ensure the area is isolated using

barricades.

Adequate illumination shall be

provided @ 150 lux in work

area.

Full time supervision shall be

avail for the activity.

Basic PPE’s ( Safety helmet,

Safety shoes, Reflective jackets,

hand gloves)

Ensure no return supply or

electrical leakage in the builder

earth flat by using multi meter

prior to start tapping each point.

Basic PPE’s(Safety helmet,

Safety shoes, Reflective jackets,

hand gloves)

Suggested safe system of work:

Suggested Review date: (if required)

Suggested further job safety instructions: (if required)

Suggested training programs: (Tool Box Talks)

Signed By: Approved By:

Вам также может понравиться

- Job Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyДокумент9 страницJob Hazard Analysis (JHA) Worksheet: Jerp # 3, Aromatics Unit CompanyTeodoro Esquillo100% (1)

- JSA For Hydro Jetting, Removal and Cleaning of SludgeДокумент18 страницJSA For Hydro Jetting, Removal and Cleaning of Sludgesk sajidОценок пока нет

- JSA Installation of Equipment For Electrical and InstrumentДокумент3 страницыJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham75% (4)

- Hydro Power GenerationДокумент112 страницHydro Power Generationnaveed1986sirfОценок пока нет

- Project HS Risk Assessment for Sandvik Pvt LtdДокумент6 страницProject HS Risk Assessment for Sandvik Pvt LtdParas100% (1)

- JSA For Pipe Line DemolitionДокумент7 страницJSA For Pipe Line DemolitionSiraj Mohamed Ikbal75% (4)

- AIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610От EverandAIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610Оценок пока нет

- JSA For Road BarrierДокумент3 страницыJSA For Road BarrierMohammed MinhajОценок пока нет

- EEEPL - JSA Unloading MaterialsДокумент3 страницыEEEPL - JSA Unloading MaterialsnishanthОценок пока нет

- EEEPL - JSA Unloading MaterialsДокумент3 страницыEEEPL - JSA Unloading MaterialsnishanthОценок пока нет

- JSA Hot Work and ModificationДокумент19 страницJSA Hot Work and ModificationBrings MotoVlogОценок пока нет

- All Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicableДокумент6 страницAll Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicablecrnkarlosОценок пока нет

- 02-Job Safety Analysis - Excavation WorkДокумент2 страницы02-Job Safety Analysis - Excavation Workkhaja asifuddinОценок пока нет

- Install water supply system risk assessmentДокумент2 страницыInstall water supply system risk assessmentمقاول تكييف كهرباء وصحيОценок пока нет

- Job Safety Analysis (Jsa) - Water Proofing WorkДокумент6 страницJob Safety Analysis (Jsa) - Water Proofing Worknitish tiwariОценок пока нет

- Job Safety Analysis Report for Using A Type LadderДокумент1 страницаJob Safety Analysis Report for Using A Type LaddernishanthОценок пока нет

- Job Safety Analysis: Rohan Builders (I) PVT LTDДокумент3 страницыJob Safety Analysis: Rohan Builders (I) PVT LTDTigor GurningОценок пока нет

- 20-RAS-Transformer InstallationДокумент2 страницы20-RAS-Transformer InstallationWalid MarhabaОценок пока нет

- SS JSP - 063 Testing and Pre-Commissioning WorksДокумент9 страницSS JSP - 063 Testing and Pre-Commissioning WorksBarkat UllahОценок пока нет

- O MM 8060 Series Iveco MotorsДокумент79 страницO MM 8060 Series Iveco Motorsfishhunter18100% (3)

- Case Study of Urea Reactor Explosion in Lake Charles USAДокумент50 страницCase Study of Urea Reactor Explosion in Lake Charles USAGhulam AhmadОценок пока нет

- JSA For Erection and Repair Work of TanksДокумент19 страницJSA For Erection and Repair Work of TanksMohamed Farouk100% (2)

- 01 Job Safety Analysis HousekeepingДокумент1 страница01 Job Safety Analysis Housekeepingkhaja asifuddin100% (1)

- Wet Scrubbers 022002 PDFДокумент8 страницWet Scrubbers 022002 PDFbaharuonlyhumanОценок пока нет

- JSA Installation-Fire-Alarm-SystemДокумент12 страницJSA Installation-Fire-Alarm-Systemuz9143895Оценок пока нет

- Jsa For Pilling WorkДокумент12 страницJsa For Pilling WorkLakhan kumar100% (1)

- Job Safety Analysis for Rohan Builders Construction ProjectsДокумент9 страницJob Safety Analysis for Rohan Builders Construction Projectsradeep100% (1)

- JSP For Electrical and HV TestingДокумент4 страницыJSP For Electrical and HV TestingmohammedОценок пока нет

- Revised Job Safety AnalysisДокумент11 страницRevised Job Safety AnalysisTigor GurningОценок пока нет

- Job Safety & Environment Analysis: Revision NoДокумент3 страницыJob Safety & Environment Analysis: Revision NonishanthОценок пока нет

- Investigation Report Mongstad Naphta - 102417Документ24 страницыInvestigation Report Mongstad Naphta - 102417Cepi Sindang KamulanОценок пока нет

- Jsa For Lifting Crane 016Документ6 страницJsa For Lifting Crane 016kiran kumar100% (1)

- Fabrication Work Risk AssessmentДокумент11 страницFabrication Work Risk Assessmentstansilous100% (1)

- JHA - To Carry Out Reinstate of Interlock StonesДокумент7 страницJHA - To Carry Out Reinstate of Interlock Stoneslinga201450% (2)

- Jsa D. G. INSTALLATIONДокумент5 страницJsa D. G. INSTALLATIONRavi thokalОценок пока нет

- Penn Students Design Propane to Acrylic Acid ProcessДокумент231 страницаPenn Students Design Propane to Acrylic Acid ProcessCluisantony Jayco DizeОценок пока нет

- JSA Cable LayingДокумент2 страницыJSA Cable Layingnishanth100% (2)

- Job Safety & Environment Analysis: Revision NoДокумент3 страницыJob Safety & Environment Analysis: Revision NonishanthОценок пока нет

- Job Safety & Environment Analysis: Revision NoДокумент3 страницыJob Safety & Environment Analysis: Revision NonishanthОценок пока нет

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectДокумент5 страницJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyОценок пока нет

- Risk Assessment For PVC ConduitsДокумент2 страницыRisk Assessment For PVC Conduitsمقاول تكييف كهرباء وصحي100% (1)

- JSA-RHI-ARZ-0-006 ASU - Confined Space Rev00 - ArzewДокумент3 страницыJSA-RHI-ARZ-0-006 ASU - Confined Space Rev00 - ArzewUmit KaymakОценок пока нет

- JSA Mobile CranesДокумент2 страницыJSA Mobile CranesAmanya DickallansОценок пока нет

- ChillerДокумент79 страницChillerSameera LakmalОценок пока нет

- JSA Cable Tray Erection On Pipe RackДокумент7 страницJSA Cable Tray Erection On Pipe RacknishanthОценок пока нет

- CV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)Документ5 страницCV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)toalok4723Оценок пока нет

- ECCS Report No 039Документ34 страницыECCS Report No 039Cpm102Оценок пока нет

- Exterior Wall TestingДокумент32 страницыExterior Wall Testingtkm20040% (1)

- EEEPL - JSA Light Fitting ErectionДокумент6 страницEEEPL - JSA Light Fitting ErectionnishanthОценок пока нет

- Vehicle Accident E M Site Engg: The Materials (Blocks, Cement Bags, Sand Will Be Delivered in TATA TruckДокумент2 страницыVehicle Accident E M Site Engg: The Materials (Blocks, Cement Bags, Sand Will Be Delivered in TATA Trucksasi kumarОценок пока нет

- JSA Mobile Crane Pipe Installation Tandem LiftДокумент3 страницыJSA Mobile Crane Pipe Installation Tandem LiftSyed HarisОценок пока нет

- 29 HIRA Annexure HДокумент328 страниц29 HIRA Annexure HpradeepyellurОценок пока нет

- Loading Stones in Dumper Tractor - Transportation Near Pit JSA HSE ProfessionalsДокумент1 страницаLoading Stones in Dumper Tractor - Transportation Near Pit JSA HSE ProfessionalsSamadov 13Оценок пока нет

- JCB -Breaking WorksДокумент2 страницыJCB -Breaking WorksKoneti JanardhanaraoОценок пока нет

- GOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchДокумент6 страницGOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchShahid BhattiОценок пока нет

- JSA - Area Hard BarricationДокумент1 страницаJSA - Area Hard BarricationNFRN0% (1)

- Reactor-Confined Space Entry & Internal WorkДокумент7 страницReactor-Confined Space Entry & Internal WorkAkash VermaОценок пока нет

- Job Safety AnalysisДокумент3 страницыJob Safety AnalysisMuhammad KaleemОценок пока нет

- Jsa for Drilling WellДокумент5 страницJsa for Drilling WellAnna JisabaОценок пока нет

- Mobile Stone Crushing JSA HSE ProfessionalsДокумент1 страницаMobile Stone Crushing JSA HSE ProfessionalsLebohang ChakaОценок пока нет

- Hazard Analysis-FEATURE: Mobilization: Driving To JobsiteДокумент3 страницыHazard Analysis-FEATURE: Mobilization: Driving To Jobsiteavaldez1972Оценок пока нет

- JHSA for Temporary Plastic Septic TankДокумент4 страницыJHSA for Temporary Plastic Septic TankAnna JisabaОценок пока нет

- Erection of Movable Scaffold - Work On It JSA HSE ProfessionalsДокумент2 страницыErection of Movable Scaffold - Work On It JSA HSE ProfessionalsSamadov 13Оценок пока нет

- Gunitting Operation JSA HSE ProfessionalsДокумент1 страницаGunitting Operation JSA HSE ProfessionalsSamadov 13Оценок пока нет

- Majeestech JSP for Scaffolding and Working at HeightДокумент3 страницыMajeestech JSP for Scaffolding and Working at HeightkrishnakumarОценок пока нет

- Fixing of Pre-Cast Drain Cover - Chamber Cover JSA HSE ProfessionalsДокумент2 страницыFixing of Pre-Cast Drain Cover - Chamber Cover JSA HSE ProfessionalsViron BaxhiaОценок пока нет

- Temporary Sheds JSA HSE ProfessionalsДокумент1 страницаTemporary Sheds JSA HSE ProfessionalsAli KaziОценок пока нет

- PTP for DB Termination WorkДокумент2 страницыPTP for DB Termination WorkfatimahОценок пока нет

- RA-Containment WorksДокумент17 страницRA-Containment WorkshseОценок пока нет

- JSA For SURGE VESSEL WorkДокумент6 страницJSA For SURGE VESSEL Workathul subashОценок пока нет

- Drain Line Work JSA HSE ProfessionalsДокумент2 страницыDrain Line Work JSA HSE ProfessionalsSamadov 13Оценок пока нет

- Sunmow Jha 001Документ3 страницыSunmow Jha 001Douglas DellyОценок пока нет

- Project HS Risk AssessmentДокумент9 страницProject HS Risk AssessmentParasОценок пока нет

- JHA - Unloading of Sheet PileДокумент3 страницыJHA - Unloading of Sheet PileJensen Sunga100% (1)

- The Handbook of Safety Engineering: Principles and ApplicationsОт EverandThe Handbook of Safety Engineering: Principles and ApplicationsРейтинг: 4 из 5 звезд4/5 (1)

- Mach 3 Brochure enДокумент3 страницыMach 3 Brochure enIsaías AguilarОценок пока нет

- Foreword: Lam Siew WahДокумент68 страницForeword: Lam Siew WahngthienyОценок пока нет

- 1 D 713224192Документ1 страница1 D 713224192Jaganathan KrishnanОценок пока нет

- Acceleration and braking performance factorsДокумент115 страницAcceleration and braking performance factorsSivateja NallamothuОценок пока нет

- BROSURA - SCADA PACiS - 2011 (EN) PDFДокумент12 страницBROSURA - SCADA PACiS - 2011 (EN) PDFCata CatalinОценок пока нет

- Bitzer - 4GE-30-40P X 2comp - (1'C) - r407c - 070917 PDFДокумент7 страницBitzer - 4GE-30-40P X 2comp - (1'C) - r407c - 070917 PDFAgus CahyonoОценок пока нет

- Guidelines For Health Check Report: 1. Cover PageДокумент6 страницGuidelines For Health Check Report: 1. Cover Pageanon_516655412Оценок пока нет

- Hydraulic Hybrid Drive Train For Off-Road VehiclesДокумент5 страницHydraulic Hybrid Drive Train For Off-Road Vehiclesiamvik100% (2)

- Grundfos 28-80Документ6 страницGrundfos 28-80anОценок пока нет

- Annexure Classification of ServicesДокумент20 страницAnnexure Classification of Servicesamitkap00rОценок пока нет

- Designing a 13 kW Pelton Water TurbineДокумент10 страницDesigning a 13 kW Pelton Water TurbineFanie-XОценок пока нет

- Fabrication & Performance Testing1Документ27 страницFabrication & Performance Testing1DIPAK VINAYAK SHIRBHATEОценок пока нет

- Hackingstem Hotwheels InstructionsДокумент19 страницHackingstem Hotwheels Instructionsapi-275968397Оценок пока нет

- 4x-Datasheet BONDiT B-481Документ4 страницы4x-Datasheet BONDiT B-481Marco BrolloОценок пока нет

- NG DS FX19 A8-1130295Документ6 страницNG DS FX19 A8-1130295viernes06Оценок пока нет

- Categorization-Classification Table - 12052017Документ2 страницыCategorization-Classification Table - 12052017Sho Delos AngelesОценок пока нет

- Wall CladdingДокумент24 страницыWall CladdingRemya R. KumarОценок пока нет

- Atomizer Study For Processing PGMДокумент6 страницAtomizer Study For Processing PGMAFLAC ............Оценок пока нет

- 52 Sample ChapterДокумент29 страниц52 Sample ChapterSaroj GaireОценок пока нет

- Operation and Maintenance ManualДокумент37 страницOperation and Maintenance Manualpepenapao1217Оценок пока нет