Академический Документы

Профессиональный Документы

Культура Документы

Bahrain International Airport: Remote Aircraft Aprons

Загружено:

RaymanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bahrain International Airport: Remote Aircraft Aprons

Загружено:

RaymanАвторское право:

Доступные форматы

Bahrain International Airport

Terminal Building Expansion Phase 5

Remote Aircraft Aprons

As part of the expansion of Bahrain International

Airport the aircraft aprons needed to be

expanded to suit future demand.

In view of the mixed loose silty/ sandy deposits of the

existing ground the main contractor Haji Hassan Group

has nominated Keller Grundbau GmbH as specialized

subcontractor for the ground improvement works.

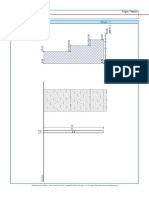

In order to limit the settlement and to achieve the

Stone Column Installation Process required bearing capacity of up to 150kPa for the new

airport aprons, soil improvement by means of Vibro-

Replacement (Stone Columns) was employed to improve

the ground down to max. 7.00 m depth or refusal of the

vibrator whichever occurred first.

Client:

Kingdom of Bahrain, Ministry of Works As the works were to be carried out next to the fully

Consultant:

operational airport runways Keller has employed it’s dry

Jacobs-GIBB LTD bottom feed system for stone column installation. This

system does not require flushing water and minimizes

Main Contractor:

Haji Hassan Group B.S.C. dust and mud hazards during the operation. The dry

12-24Ei

method utilizes a depth vibrator with an attached stone

Work carried out: feeder tube to penetrate into the ground and build a

96,017 lin. m stone columns (19,318 Nos)

2 Field Trials column from the bottom up. The vibrator assembly is

13 Plate Load Tests supported by Keller/s custom built “Vibrocat”, a special

8 Zone Load Test crawler mounted rig which can exert a pull down force

Construction Period: on the vibrator string, thus further improving the

Phase 1: 5/2008 -12/2008 performance.

Phase 2: 8/2009 – 1/2010

The ground conditions were varying significantly over the

site. In some areas soft silt/sand-deposits were

encountered up to the design depth of 7m. However, in

other parts only sand of various density was encountered

up to 2m depth, followed by hard caprock.

The ground improvement works were carried out in two

phases.

During most of the construction period Keller was

working in double shift. In some areas only limited access

was available due to the ongoing airport operations.

Henceforth, a close coordination with the main

contractor and the authorities was required.

The stone column spacing was varying over the site and

had to be adjusted locally to avoid obstructions such as

service and utility lines. Generally, a 3m safe working

distance from the existing services had to be maintained.

When working close to service lines vibration monitoring

was carried out as preventive measure by a third party

agency.

Vibration Monitoring on service lines The Vibrocat carrier unit is equipped with a number of

sensors which produce a direct read out from Keller’s

M4 quality control computer. All relevant parameters

such as time, depth, power consumption, probe number

etc are recorded and printed in real time on the unit

itself.

Further, as part of the Quality Control Procedure two

field trials were carried out prior to the main works.

During the duration of the project additionally 8 Zone

Load Tests on a 2.5m x 2.5m cast-in-situ dummy footing

Keller Grundbau GmbH and 13 plate load tests on a 76cm diameter plate were

International Geotechnical Contractor

performed to verify the required bearing capacity and

www.Keller Grun dbau.com uniformity of the ground improvement works.

Bahrain

Flat 205, Bldg.63

P.O.Box 5452

Manama, Bahrain

Tel. +973 17741677

Fax +973 17741688

E-mail Keller@batelco.com.bh

Вам также может понравиться

- Presentation by Chemical GroutingДокумент10 страницPresentation by Chemical GroutingK.SivanathanОценок пока нет

- Practical Applications of Ground ImprovementДокумент12 страницPractical Applications of Ground ImprovementprashantlingayatОценок пока нет

- 16 - Roadbase - Pavement WorksДокумент4 страницы16 - Roadbase - Pavement Worksasr.engineering2023Оценок пока нет

- Earth WorkДокумент15 страницEarth WorkArifian NugrohoОценок пока нет

- Foundation Packages - COMBISLAB - AshfordДокумент2 страницыFoundation Packages - COMBISLAB - AshfordFaraz HussainОценок пока нет

- Gen App Windfarm TengfcДокумент5 страницGen App Windfarm TengfcvillarpolancoОценок пока нет

- Piling Rigs Overturning On Construction Sites: A Guide To Loss PreventionДокумент4 страницыPiling Rigs Overturning On Construction Sites: A Guide To Loss Preventionmohd addinОценок пока нет

- Hyc GW Oct 18 March 19Документ34 страницыHyc GW Oct 18 March 19Ashish KumarОценок пока нет

- MS - 33 Rev 0 - Reinstatement of KNO.06 Lateral Line AsphaltДокумент6 страницMS - 33 Rev 0 - Reinstatement of KNO.06 Lateral Line AsphaltSyed Umair HashmiОценок пока нет

- Tech - Paper - Assessing RDC Effectiveness - DFI EventДокумент10 страницTech - Paper - Assessing RDC Effectiveness - DFI Event_seeОценок пока нет

- AFRD - PresentationДокумент15 страницAFRD - PresentationDarshan KhedkarОценок пока нет

- AddtiX Airport PDF (1) - 1 PDFДокумент7 страницAddtiX Airport PDF (1) - 1 PDFSyahrul PasaribuОценок пока нет

- SPDC Standard Drilling Procedures Manual Site: CHA Pter 07Документ39 страницSPDC Standard Drilling Procedures Manual Site: CHA Pter 07Agaba Idu100% (1)

- W Brochure Cold-Recyclers-Soil-Stabilizers 0316 EN PDFДокумент44 страницыW Brochure Cold-Recyclers-Soil-Stabilizers 0316 EN PDFDao Phuc Lam100% (1)

- Lot 1 - Expansion Civil WorksДокумент6 страницLot 1 - Expansion Civil WorksJethro AbanadorОценок пока нет

- BWWA EFC Pavements - 2015 PDFДокумент9 страницBWWA EFC Pavements - 2015 PDFKan BunsamranjitОценок пока нет

- Aprroved Do-1 LCA June 2022Документ227 страницAprroved Do-1 LCA June 2022arunОценок пока нет

- PR174 Hong Kong International AirportДокумент2 страницыPR174 Hong Kong International AirportWang MaxОценок пока нет

- An Innovative Approch For Jet Grouting in Soft Clays: November 2020Документ11 страницAn Innovative Approch For Jet Grouting in Soft Clays: November 2020rigaz6366Оценок пока нет

- Expandable SolutionsДокумент2 страницыExpandable SolutionsHunterОценок пока нет

- 3) Work Method Statement Ground Floor SlabДокумент3 страницы3) Work Method Statement Ground Floor Slabhks1209Оценок пока нет

- VFPE Geomembrane Installation For Landfill Capping Applications EngineeringДокумент3 страницыVFPE Geomembrane Installation For Landfill Capping Applications EngineeringDAVE MARK EMBODOОценок пока нет

- Bahrain - Shaikh Khalifa Bin Salman CausewayДокумент2 страницыBahrain - Shaikh Khalifa Bin Salman CausewayMonirul IslamОценок пока нет

- Methodology For Laying of Kerb Concrete: - 1 - VKLR - QmeДокумент5 страницMethodology For Laying of Kerb Concrete: - 1 - VKLR - QmevaideehОценок пока нет

- Final TechAbutment - MIAL Casestudy 17112014Документ2 страницыFinal TechAbutment - MIAL Casestudy 17112014Ankit GuptaОценок пока нет

- Wheatstone Project Execution Overview 3Q12Документ15 страницWheatstone Project Execution Overview 3Q12tipu001Оценок пока нет

- Single Shell Lining For Road TunnelsДокумент2 страницыSingle Shell Lining For Road TunnelsDebasis BarmanОценок пока нет

- Hayward Baker Vibro Systems BrochureДокумент16 страницHayward Baker Vibro Systems Brochuresamudra.gs83Оценок пока нет

- WHOC09-526 Paper PDFДокумент5 страницWHOC09-526 Paper PDFEngelbert MorenoОценок пока нет

- L1 Intro Well CompletionДокумент27 страницL1 Intro Well CompletionVG100% (1)

- DHL Concrete SocietyДокумент2 страницыDHL Concrete SocietyTaraknath PalОценок пока нет

- AFRD - PresentationДокумент15 страницAFRD - PresentationDarshan KhedkarОценок пока нет

- Daily Site Report 4-19-2022 (AutoRecovered)Документ3 страницыDaily Site Report 4-19-2022 (AutoRecovered)oye.mathewОценок пока нет

- Method Statement For Road OBJECTIVE: Preparation of Sub-Grade, Laying of Sub-Base, Water Bound MacadamДокумент8 страницMethod Statement For Road OBJECTIVE: Preparation of Sub-Grade, Laying of Sub-Base, Water Bound MacadamRanjit SinghОценок пока нет

- "Group Housing Project": Half Yearly ComplianceДокумент27 страниц"Group Housing Project": Half Yearly ComplianceRohit SharmaОценок пока нет

- A Case History of Ground Improvement Work For Kuala LumpurДокумент8 страницA Case History of Ground Improvement Work For Kuala Lumpurhassan sethОценок пока нет

- Fibra PlasticaДокумент14 страницFibra PlasticaEmiliano QuispeОценок пока нет

- Design of Durbale Prestressed Concrete For Dabhol TrestleДокумент10 страницDesign of Durbale Prestressed Concrete For Dabhol TrestleKalipada SenОценок пока нет

- Final Soil Investigation Report For Hammar DGS - Phase 1: Eni - Iraq Zubair Oil Field Development ProjectДокумент203 страницыFinal Soil Investigation Report For Hammar DGS - Phase 1: Eni - Iraq Zubair Oil Field Development ProjectMohammed HijaziОценок пока нет

- Stabilized Mobile Paste Backfill North Longo April2015Документ2 страницыStabilized Mobile Paste Backfill North Longo April2015Anil SinghОценок пока нет

- Vibro Ground BrochureДокумент12 страницVibro Ground Brochurealphaboi100% (1)

- BG MiskarДокумент2 страницыBG MiskarHASHMI MAHMOODОценок пока нет

- Roesyanto 2018 IOP Conf. Ser. Mater. Sci. Eng. 309 012024Документ9 страницRoesyanto 2018 IOP Conf. Ser. Mater. Sci. Eng. 309 012024Desti Santi PratiwiОценок пока нет

- Guwahati Metropolitan Development Authority (GMDA) : Section 7 (Price Bid)Документ10 страницGuwahati Metropolitan Development Authority (GMDA) : Section 7 (Price Bid)Jwngsar DaimaryОценок пока нет

- Ground Force Foundation LLC and Their Method of StatementsДокумент36 страницGround Force Foundation LLC and Their Method of StatementsTan C H100% (1)

- Application of Artificial Ground Freezing Method For Tunnel Construction in Hong Kong - A Construction Case in Harbour Area Treatment Scheme Stage 2AДокумент12 страницApplication of Artificial Ground Freezing Method For Tunnel Construction in Hong Kong - A Construction Case in Harbour Area Treatment Scheme Stage 2ADangol RupeshОценок пока нет

- Successful Sub-ERD Well in Offshore MahakamДокумент20 страницSuccessful Sub-ERD Well in Offshore MahakamanasriredjekiОценок пока нет

- Method Statement For RoofДокумент22 страницыMethod Statement For Roofahmed samirОценок пока нет

- BettergroundДокумент13 страницBettergroundLmes ErnultОценок пока нет

- Using FBC and Stoker Ashes As Roadfill - A Case Study - Deschamps. 1998Документ8 страницUsing FBC and Stoker Ashes As Roadfill - A Case Study - Deschamps. 1998Mahesh JalluОценок пока нет

- OTC 18839 - Reverse-Circulation Cementing To Seal A Tight Liner Lap PDFДокумент10 страницOTC 18839 - Reverse-Circulation Cementing To Seal A Tight Liner Lap PDFAndresОценок пока нет

- 905 026 2 BAUER-Soil-ImprovementДокумент24 страницы905 026 2 BAUER-Soil-ImprovementMasood Hassan100% (1)

- HHHI-IC-0104 Rev. 0 - 2017Документ3 страницыHHHI-IC-0104 Rev. 0 - 2017Shabbar Abbas MalikОценок пока нет

- Goodwyn A Steel Jacket Offshore PlatformДокумент1 страницаGoodwyn A Steel Jacket Offshore PlatformvinnuzОценок пока нет

- BOG Clif ProtectionДокумент7 страницBOG Clif Protectionbaginda zulkifli siregarОценок пока нет

- Jet Grouting: Single SystemДокумент2 страницыJet Grouting: Single SystemhamefОценок пока нет

- Case History For Fortrac MP Basal Reinforced Piled EmbankmentДокумент2 страницыCase History For Fortrac MP Basal Reinforced Piled EmbankmentsandycastleОценок пока нет

- Faridpur - BOQ - ID. No.721334Документ17 страницFaridpur - BOQ - ID. No.721334masumnetrokona26Оценок пока нет

- Ground Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsОт EverandGround Improvement Case Histories: Embankments with Special Reference to Consolidation and Other Physical MethodsОценок пока нет

- Burland RankineLecture PDFДокумент51 страницаBurland RankineLecture PDFRaymanОценок пока нет

- If Anyone Needs Research Paper or Books Please Search The Following WebsitesДокумент3 страницыIf Anyone Needs Research Paper or Books Please Search The Following WebsitesBADIRUN basirОценок пока нет

- Comparison of Cement Standards PDFДокумент1 страницаComparison of Cement Standards PDFRaymanОценок пока нет

- EScholarship UC Item 0375f55mДокумент70 страницEScholarship UC Item 0375f55mRaymanОценок пока нет

- Thrust Block Calculator - 201708230926201609Документ1 страницаThrust Block Calculator - 201708230926201609Ramachandra SahuОценок пока нет

- Name: Stage: 1: Faray Tugas TekponДокумент1 страницаName: Stage: 1: Faray Tugas TekponRaymanОценок пока нет

- On The Physical and Chemical Stability of ShalesДокумент24 страницыOn The Physical and Chemical Stability of ShalesRaymanОценок пока нет

- Ch8 Strength PDFДокумент38 страницCh8 Strength PDFSaid HaddiouiОценок пока нет

- Port of Igoumenitsa Offshore Stone Columns: Typical M4 PrintoutДокумент1 страницаPort of Igoumenitsa Offshore Stone Columns: Typical M4 PrintoutRaymanОценок пока нет

- Chapter 5 LimestonesДокумент32 страницыChapter 5 LimestonesMatsurika Nee Chan100% (2)

- CookiesДокумент1 страницаCookiesRaymanОценок пока нет

- Load Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbДокумент8 страницLoad Calculation Spreadsheets: Quick Answers Without Relying On Rules of ThumbGithu OommenОценок пока нет

- Basic Concepts of Strength of MaterialsДокумент50 страницBasic Concepts of Strength of Materialsmegharajamds93% (29)

- Vibro Compaction & Vibro Replacement For Oiltanking Phase 10 at Jurong Island, SingaporeДокумент1 страницаVibro Compaction & Vibro Replacement For Oiltanking Phase 10 at Jurong Island, SingaporeRaymanОценок пока нет

- Concrete BasicsДокумент56 страницConcrete Basicsengcecbepc100% (6)

- Vibro Compaction For Extension of Port of Tanjung Pelepas (Phase II) in Johor, MalaysiaДокумент1 страницаVibro Compaction For Extension of Port of Tanjung Pelepas (Phase II) in Johor, MalaysiaRaymanОценок пока нет

- Warm-Up Exercise Quadriceps:: Lower-Body 1 Set of 15 Repetitions On EachДокумент8 страницWarm-Up Exercise Quadriceps:: Lower-Body 1 Set of 15 Repetitions On EachRaymanОценок пока нет

- Ea295 PDFДокумент3 страницыEa295 PDFjhiilОценок пока нет

- Six Sigma Green Belt Training Statistical Self Assessment ToolДокумент5 страницSix Sigma Green Belt Training Statistical Self Assessment Toolashutoshsingh2302Оценок пока нет

- Aluminium Composite PanelsДокумент46 страницAluminium Composite PanelsSashwat GhaiОценок пока нет

- Intro To Computing SyllabusДокумент7 страницIntro To Computing SyllabusAireen Rose Rabino ManguiranОценок пока нет

- Orbital Rendezvous Using An Augmented Lambert Guidance SchemeДокумент0 страницOrbital Rendezvous Using An Augmented Lambert Guidance Schemegirithik14Оценок пока нет

- The Running and Maintenance ofДокумент459 страницThe Running and Maintenance ofantonigor100% (1)

- Conceptual ModelingДокумент24 страницыConceptual ModelinggellymelyОценок пока нет

- MemoДокумент12 страницMemoGaurav GoelОценок пока нет

- Jeppesen PowerplantДокумент255 страницJeppesen PowerplantWilliam Palma100% (1)

- Math Lesson Plan-Topic 8.4 - Tens and OnesДокумент4 страницыMath Lesson Plan-Topic 8.4 - Tens and Onesapi-352123670Оценок пока нет

- Tuirum Adhaar Update Tur ListДокумент4 страницыTuirum Adhaar Update Tur ListLalthlamuana MuanaОценок пока нет

- Fiber-Optic Sensing A Historical PerspectiveДокумент15 страницFiber-Optic Sensing A Historical PerspectiveAnonymous Shv3RwsWnrОценок пока нет

- India International Centre India International Centre QuarterlyДокумент15 страницIndia International Centre India International Centre QuarterlySruti UОценок пока нет

- CSC712 - Questions On Chapter 10 - Project ManagementДокумент3 страницыCSC712 - Questions On Chapter 10 - Project ManagementKhairiBudayawanОценок пока нет

- Week 03 Network Concepts and Network Media PDFДокумент63 страницыWeek 03 Network Concepts and Network Media PDFikonОценок пока нет

- Types and Construction of Biogas PlantДокумент36 страницTypes and Construction of Biogas Plantadeel_jamel100% (3)

- Caledonian: BS 6346 PVC Insulated, Armored Power and Control CablesДокумент28 страницCaledonian: BS 6346 PVC Insulated, Armored Power and Control CablessurenediyaОценок пока нет

- RefrigerationДокумент44 страницыRefrigerationY20me135 V.LokeshОценок пока нет

- Ethics Approval Process 20150223Документ8 страницEthics Approval Process 20150223MPTScribidОценок пока нет

- 17 - Defining Service Level Agreement (SLA) For E-Gov ProjectsДокумент9 страниц17 - Defining Service Level Agreement (SLA) For E-Gov ProjectsdevОценок пока нет

- Technics Su-7200 SMДокумент21 страницаTechnics Su-7200 SMF_E_TermanОценок пока нет

- Drainage Service GuidelinesДокумент15 страницDrainage Service GuidelinesMarllon LobatoОценок пока нет

- Pet CRD CRPDN Adc MBBL MДокумент125 страницPet CRD CRPDN Adc MBBL MpmellaОценок пока нет

- Chapter Eighteen: Creating Competitive AdvantageДокумент34 страницыChapter Eighteen: Creating Competitive AdvantageSana MehmoodОценок пока нет

- Trafo Manual ABBДокумент104 страницыTrafo Manual ABBMarcos SebastianОценок пока нет

- Sec 1038Документ4 страницыSec 1038Lauren BowenОценок пока нет

- HR AuditДокумент5 страницHR AuditshanumanuranuОценок пока нет

- sw8 chp06Документ22 страницыsw8 chp06api-115560904Оценок пока нет

- Versidrain 30: Green RoofДокумент2 страницыVersidrain 30: Green RoofMichael Tiu TorresОценок пока нет

- McQuay PFS C Installation Manual EngДокумент17 страницMcQuay PFS C Installation Manual EngAnbarasan Nagarajan100% (1)