Академический Документы

Профессиональный Документы

Культура Документы

Mass Transfer in Fermentation Process

Загружено:

Simone Bassan Zuicker ElizeuИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mass Transfer in Fermentation Process

Загружено:

Simone Bassan Zuicker ElizeuАвторское право:

Доступные форматы

Процеси, обладнання, автоматизація / Processes, equipment, automation

UDC 663.1; 663.5

MASS TRANSFER IN FERMENTATION PROCESSES

A. Shevchenko, Doctor of Technical Sciences, Professor, Vice-Rector*, E-mail: tmipt@ukr.net

A. Sokolenko, Doctor of Technical Sciences, Professor**, E-mail: mif63@i.ua

O. Stepanets, Candidate of Technical Sciences, Associate Professor**, E-mail: oleguard@meta.ua

O. Bilyk, Candidate of Technical Sciences, Associate Professor***, E-mail: bilyklena@gmail.com

*Department of Processes and Apparatuses for Food Production

**Department of Mechatronics and Packaging Technology

***Department of Bakery and Confectionary Goods Technology

National University of Food Technologies, 68 Volodymyrska str., Kyiv, Ukraine, 01601

Abstract. The peculiarities of anaerobic fermentation processes with the accumulation of dissolved ethyl alcohol and car-

bon dioxide in the culture media are considered in the article.

The solubility of CO2 is limited by the state of saturation in accordance with Henry’s law. This, with all else being equal,

limits the mass transfer on the interface surface of yeast cells and the liquid phase of the medium. A phenomenological model

of the media restoration technologies based on the unsaturation index on СО 2 is developed. It is shown that this restoration in

the existing technologies of fermentation of sugar-rich media occurs, to a limited extent, in self-organized flow circuits, with

variable values of temperatures and hydrostatic pressures, due to the creation of unsaturated local zones.

It is shown that increasing the height of the media in isovolumetric apparatuses leads to an increase in the levels of flow

circuits organization and to the improvement of the desaturation and saturation modes of the liquid phase and intensification of

mass transfer processes. Among the deterministic principles of restoring the saturation possibilities of the media, there are

forced variables of pressures with time pauses on their lower and upper levels. In such cases, the possibilities of short-term

intensive desaturations in full media volumes, the restoration of their saturation perception of CO2, and the activation of fer-

mentation processes are achieved. This direction is technically feasible for active industrial equipment.

The cumulative effect of the action of variable pressures and temperatures corresponds to the superposition principle, but at

the final stages of fermentation, the pressure and temperature values are leveled, so the restoration of the unsaturation state

slows down to the level of the bacteriostatic effect. The possibility of eliminating the disadvantages of the final stage of fer-

mentation by means of programmable variable pressures is shown.

Key words: mass transfer, fermentation, hydrodynamics, pressure, temperature, solubility, gas phase.

МАСООБМІН В ПРОЦЕСАХ БРОДІННЯ

О.Ю. Шевченко, доктор технічних наук, професор, проректор*, E-mail: tmipt@ukr.net

А.І. Соколенко, доктор технічних наук, професор**, E-mail: mif63@i.ua

О.І. Степанець, кандидат технічних наук, доцент**, E-mail: oleguard@meyta.ua

О.А. Білик, кандидат технічних наук, доцент***, E-mail: bilyklena@gmail.com

*Кафедра процесів і апаратів харчових виробництв

**Кафедра мехатроніки та пакувальної техніки

***Кафедра технології хлібопекарських і кондитерських виробів

Національний університет харчових технологій, вул. Володимирська, 68, м. Київ, Україна 00160

Анотація. Розглянуто особливості перебігу процесів анаеробного бродіння з накопиченням в культуральних

середовищах розчинених етилового спирту і діоксиду вуглецю. Показано, що збільшення висоти середовищ в

ізооб’ємних апаратах приводить до обмеження рівня невпорядкованості циркуляційних контурів, що вказує на

перспективи організованої детермінованої циркуляції. Цей напрямок можливо вважати першим кроком в

удосконаленні апаратів і технологій бродіння, тоді як наступний етап має стосуватися регульованих впливів у формі

використання змінних тисків у сполученні зі змінними температурами для гарантованого обмеження станів насичення

зброджуваних середовищ на СО2 з відповідними технологічними і економічними наслідками. Це позбавляє недоліків

завершальної стадії бродіння, на якій нівелюються показники інтенсивності циркуляційних контурів і потреби в

динаміці охолодження середовищ. Досягнення такого стану припиняє процеси їх локальних переходів до ненасичених

станів. Зростаючі осмотичні тиски в сукупності з насиченістю середовищ діоксидом вуглецю на фізичному рівні

приводять до біостатичних ефектів.

Ключові слова: масообмін, бродіння, гідродинаміка, тиск, температура, розчинність, газова фаза.

DOI: http://dx.doi.org/10.15673/fst.v12i1.846

Introduction. Formulation of the problem sition to a liquid medium. It is important that alcohol dis-

solves in water in random proportions unlike carbon di-

The process of anaerobic fermentation is accompa- oxide because its solubility is restricted by Henry’s law

nied by endogenous synthesis of carbon dioxide and eth- by which the saturation constant cs is proportional to the

anol that enter the fermented medium through biological partial pressure P of the gas phase:

membranes. Without going into the peculiarity of the сs kP . (1)

intracellular transportation of these substances at the mo-

lecular level, let’s dwell on the peculiarities of their tran- Since the situation relates not to a mixture of gases,

Харчова наука і технологія / 104 Volume 12 Issue 1/ 2018

Food science and technology

Процеси, обладнання, автоматизація / Processes, equipment, automation

but only to CO2, then it is believed that the specified par- Analysis of recent research and publications

tial pressure is the general pressure at each point of the

fermented medium. The Henry constant k in condition (1) An overview of literary sources leads to the conclu-

reflects the physical properties of the liquid and gas phas- sion about the availability of information about character-

es and the influence of the thermodynamic parameter of istics of anaerobic and aerobic processes of fermentation,

the temperature. In this connection, in the graphic repre- physical-chemical properties of gas-liquid media, features

sentations of the condition (1), the values of cs are given of osmotic pressure, etc.

by isotherms (Fig. 1), and in this case: So in the study [1], the stages of alcohol fermentation

under the conditions of primary fermentation of wine

t1 t 2 t 3 t 4 . (2)

materials are considered. The composition of the input

cs material streams of grape must has certain characteristics,

t1 t2 but the classical principles of alcohol fermentation, in-

cs2 А cluding that in the presence of saprophytic microflora, are

t3 preserved.

Дсs

The paper [2] presents the results of analytical studies

cs1 В t4 concerning the colligative properties of fermentable sug-

ar-containing media. The dynamics of osmotic pressure

changes, and the transformation of organic substances are

registered.

P

The publication [3] is devoted to a general technical

0 Р1 P2 and thermodynamic approach to the intensification of

Fig. 1. Graphic representa- heat and mass exchange processes in food technologies. It

tion of Henry's law in the presents modern technologies based on the use of closed

form of equation (1) energy circuits and discrete impulse influences.

The interconnections between transformations of or-

The fact that the fermentation machines are of consid- ganic substances and osmotic media pressures are inves-

erable dimensions, its hydrostatic component significant- tigated in [4, 5], with the corresponding mathematical

ly influences the overall pressure index. Therefore, in formalizations obtained.

each coordinate h we have: In the publication [6], the peculiarities of transfor-

P P0 gh , (3) mations in fermentable media are analyzed, accompanied

where P0 is the pressure of the gas phase over the me- by thermodynamic transformations at the level of entropy

dium; с is the specific mass of the liquid phase; h – alti- estimates.

tude coordinate in terms of the liquid phase. Modern ideas in the technology and physiology of

We note that the indices of pressures P0 and hydro- wort fermentation [7] are supplemented by including the

description of methods of obtaining non-alcoholic beer.

static pressures gh are often proportional, so they Publications [8, 9] are devoted to the physical and

should be considered collectively. physical-chemical principles of the existence of the bio-

From the moment the liquid phase is saturated with logical world, and the work [10] refers to the peculiarities

carbon dioxide, dynamic equilibrium is violated, and the of the synthesis of bioenergetic potentials of ethanol in

dispersed gas phase is formed, with the continuity of the the agro-sector.

medium ruptured from the zone with the smallest to the The research [11] is devoted to the features of indus-

zone with the greatest hydrostatic pressure. Under the trial fermentation processes. The publication [12] pro-

action of the Archimedean forces, the dispersed phase vides information about the intensification of anaerobic

passes with the formation of flow circuits of unstable fermentation technology.

structure and energy potentials. With gas forming at However, there are no attempts to evaluate the pos-

greater and greater depths, the gas-retaining capacity of sibilities for the intensification of mass transfer pro-

the medium increases with increasing energy potentials in cesses due to the interaction of the alternating pressures

the flow circuits. and the levels of solubility of the gas phase.

The formation of a dispersed gas phase means that the The aim of the study. In the form of a local conclu-

saturation state is reached in the liquid phase, which re- sion, let’s point out the practicability of limiting the peri-

stricts, and under certain conditions stops the mass trans- ods of media’s saturated states. Obviously, this is how the

fer of CO2 between the yeast cells and the medium. Liter- processes of fermentation are completed, and therefore

ary sources [1–5] point out the negative effects of elevat- the purpose of this study is to look for the ways of creat-

ed concentrations of dissolved carbon dioxide on fermen- ing technologies to restore media according to the param-

tation dynamics. So, at the СО2 pressure 0.1 МPa, the eter of the unsaturated state.

reduction of yeast growth is recorded, and at the pressure The research task is connected with the creation of

of 0.8 MPa and the temperature 15°C, fermentation stops. phenomenological (theoretical) justification of the possi-

Although these data do not give a complete picture of the bilities of regenerating the culture media of anaerobic

physical state of the medium, they confirm the significant fermentation to renew the modes of the active mass trans-

effects of dissolved CO2. fer with yeast cells and renew their activity.

Харчова наука і технологія / 105 Volume 12 Issue 1/ 2018

Food science and technology

Процеси, обладнання, автоматизація / Processes, equipment, automation

Research materials and methods thermal process and in the linear relationship between the

value cs and P, only a range of pressure changes in the

The basis for our research is the gas solubility law form of P2 – P1 matters, and not the absolute pressure

and, related to it, Pascal’s law about hydrostatic pres- values.

sures, and regularities concerning the conditions of conti- A fast pressure increase in the over-liquid gas phase

nuity of media. by the difference: P P2 P1 (6)

The well-known provisions concerning the hydrody- leads to a positive disturbance of the equilibrium at

namics of gas-liquid media and the effects of flow cir- the phase interface, because the condition (4) is fulfilled

cuits on the mass transfer processes are used. Some con- and the liquid phase of the medium becomes unsaturated.

clusions were formulated basing on the phenomenologi- In this case, the initial driving factor of the mass transfer

cal generalizations. process is determined by the condition:

Results of the research and their discussion cs(i) cs 2 cs1(i) , (7)

where index (i) is the index of the initial parameter of

With the state of the medium physically complying

the value.

with the condition (1), we turn to the search of transition

It is obvious that the flowing concentration of dis-

processes modes, by which the flowing concentration of

solved CO2 is variable in the form of the time function.

carbon dioxide c will be less than this indicator in the

saturation state with the representation of the condition: The same holds true for the driving factor cs cs t .

с cs . (4) The final value of the second stage corresponds to:

Achieving this proportion means a decrease in the cs ( f ) cs 2 . (8)

medium’s resistance to the mass transfer on the boundary The existence of the second stage means the possibil-

where the phases are separated, and the renewal of the ity of renewal of active mass transfer of СО2 at the inter-

latter. When a dispersed phase appears in the liquid phase face of phase separation.

of a fermented medium, it is an indication that the bound- This phenomenological representation of the physics

ary state in the form c = cs is reached and cannot be ex- of mass transfer processes between the liquid phase and

ceeded. However, a move towards a decrease of the satu- yeast is a certain approximation to the real processes,

ration constant is possible due to the decrease in the pres- since it relates to a static point of view on the medium, in

sure P0 in the gas over-liquid phase, which will be imme- which the influence of geometric parameters, the pres-

diately reflected in the full volume of the gas-liquid me- ence of flow circuits with the peculiarities of their kine-

dium. In Fig. 1, this process is represented by the line matic characteristics etc. are not taken into account.

segment AB on the isotherm t2 with a decrease of the However, an important conclusion from this is that over-

saturation constant by the Δcs value: coming barriers of saturation in fermentable media re-

cs cs 2 cs1 . (5) quires processes in which self-sustaining or organized

The system’s double response to the pressure reduc- pressure changes are achieved. The self-sustainability of

tion will be the growth of gas-retaining capacity, firstly, the latter is connected with the presence of vertical flow

due to the formation of an additional dispersed gas phase circuits and the manifestation of a gravitational field in

at the level Δcs and, secondly, due to the expansion of the the form of hydrostatic pressures and Archimedes forces.

existing gas phase. However, at the level of the condition The passing of the dispersed gas phase is accompa-

(4), the situation does not improve, since the liquid phase nied by the appearance of ascending gas-liquid streams

remains in the saturation state. The fulfilment of the con- and, at the same time, the descending streams with un-

dition (5) means reducing the amount of dissolved CO2 in steady parameters as for their structure and kinematics.

the medium in accordance with the final pressure P1 at Although the level of instability of such characteristics is

this stage. It is important that, during the transition of important, however, in general assessment of the hydro-

pressure from P2 to P1, the medium is in the saturation dynamics of media, the presence of flow circuits is posi-

state. tive for a number of aspects, including the creation of

Thus, the pressure reduction does not improve the sit- variable pressures in the volumetric zones of the ascend-

uation of mass transfer at the interface of phase separa- ing and descending parts of the flow circuits. It is obvious

tion, but reducing the concentration of dissolved gas leads that these are hydrostatic pressures that decrease in the

to a decrease in osmotic pressure for this component. medium’s ascending streams with the formation of an

This feature is practically the only technical opportunity additional dispersed gas phase. In the descending parts,

to organize oscillations of osmotic pressures at the ex- the increase in hydrostatic pressures increases the solubil-

pense of physical influences. Obviously, as for the fer- ity of CO2. In this case, the hydrodynamics of the medi-

mentation dynamics, this result can be considered posi- um with the parameters of gas-holding capacity and the

tive. reduced rate of the gas phase are secondary phenomena

The outgassing process lags somewhat behind the associated with the life of microorganisms and with CO2

pressure drop dynamics due to the inertial properties of synthesis. The intensity of fermentation and the volume

the media. But the limited time pause after reaching the of the culture medium determine the velocity and volume

given P1 leads to the case of cs1, which is the completion of the generated gas phase. Thus, this regulates how the

of the first stage. Its important feature is that, in the iso- geometry of the medium influences (by means of the

technological apparatus’s geometry) the medium’s gas-

Харчова наука і технологія / 106 Volume 12 Issue 1/ 2018

Food science and technology

Процеси, обладнання, автоматизація / Processes, equipment, automation

holding capacity and energy potentials, the power of flow the final pressure is P2. That is why, in the isothermal

circuits and the possibilities of restoring the liquid phase process at tA = t3, the increase in solubility would be equal

properties in the saturation and desaturation modes. to Δcss, and at the medium’s temperature tB = t1, the in-

The processes of fermentation in given cycles are un- crease in solubility becomes Δcsts.

interrupted. This leads to an increase in total pressures in

the over-liquid volume of the apparatus, followed by the

operation of the safety valves and the removal of excess

CO2 outside. This process is accompanied by a partial

desaturation in full volume, but the flowing concentration

still corresponds to the state of saturation with new pres- Waste

sure indicators. The subsequent gradual increase in the cooling agent

pressure in the over-liquid volume only occurs at the ex-

pense of the further desaturation of the medium with the

fulfillment of the condition с сs . The transition to a

relation с сs is only possible with the forced increase of

pressure in the over-liquid volume as well as in the vol-

ume of the gas-liquid medium. In this case, the use of

carbon dioxide for such an increase is undesirable due to

the increased saturation on the phase interface. However,

a rapid pressure increase in the system provides transition

to the desired condition с сs . This positive effect on the

Cooling agent

medium is combined with the effects of the presence of

flow circuits in accordance with the superposition princi-

ple. Fig. 2. Circulation circuits in the

The presence of cooling systems in the fermentation fermentation apparatus

apparatuses is due to the need to stabilize the temperature сн t1

D

of the fermented medium at the nominal level by divert-

t2

ing biological heat in accordance with the Gay-Lussac

Дснtp

equation: снB В

C6 H12O6 2C2 H5OH 2CO 2 169 kJ . (9) t3

Дснp

Дснt

When we know the fermentation dynamics, the power бt 1 C

of the diverted heat is estimated. The intensity of heat loss A t4

снA E

is influenced by the coefficients of heat exchange, heat бt3 P

transmission, heat transfer surface, and temperature dif-

0 Р1 P2

ference. The heat transfer coefficients on the heat ex-

change surfaces are determined by the hydrodynamic Fig. 3. Graphic dependences for

states of the liquid phases and depend on the intensity of determining the reducing poten-

the flow circuits created, among other things, by cooling tial of solubility СО2

the medium. All else being equal, the influence of temperatures on

With the shirt cooling system (Fig. 2), in the peripher- the solubility of CO2 is shown by the tangents of the an-

al zones, the downstream flows of the liquid phase are gles of the isotherm to the horizontal axis:

formed. Their temperature, without clearly defined c c

tg t1 sB ; tg t 3 sA , (10)

boundaries, is 5–7°С lower than the corresponding pa- P1 P1

rameter in the central part of the medium. where t1 and t 3 are angles of inclination corre-

The presence of a temperature gradient in the cross-

sections of the medium, in conjunction with the flow sponding to isotherms 1 and 3.

circuits, further increases the solubility level of carbon On the basis of the condition (10), the saturation con-

dioxide. The effects of local cooling zones and variable stant of the medium, when the values of temperature t1

hydrostatic pressures are represented by the dependences and pressure P2 are known at the point D, is determined:

in Fig. 3. csD P2 tg t1 (11)

The saturation parameters csA at the input of the and the overall result of the recovery potential of the

downstream part of the flow circuit at a temperature tA=t3 solubility of CO2:

and at the pressure P1 correspond to point A on the graph. csВ

Let us assume that, along with the continuous down- cstp csD csА Р 2 tg t1 P1tg t 3 P2 сsА .(12)

Р1

stream motion of the local zone, the temperature in it will Approbation of the research results. Approbation

decrease to the value tB = t1 under the condition of an of theoretical studies was carried out on fermentation

isobar process with the value csB = t1 reached at P1 = machines of “Brewery on Podil”. It showed a decrease in

const. However, in the case of circulation, the hydrostatic the fermentation time by 15–17 %.

pressure P ≠ const, and in the lower part of the apparatus,

Харчова наука і технологія / 107 Volume 12 Issue 1/ 2018

Food science and technology

Процеси, обладнання, автоматизація / Processes, equipment, automation

Conclusions and technologies of fermentation. The next step should

1. Thus, it can be called a fact that the existence of deal with regulated influences. They are exerted through

zones for the restoration of solubility is associated with using alternating pressures in combination with variable

such components as flow circuits of gas-liquid media, temperatures to ensure limiting the saturation states of

cooling systems and hydrostatic pressures. It is important digestible media on СО2 with the corresponding techno-

that the factors mentioned depend on the geometrical logical and economic consequences.

parameters of the technological devices, which is con- 3. Due to such conditions it is possible to get rid of the

firmed in modern sizes and ratios of cylindrical conical disadvantages of the final stage of fermentation, at which

devices (CCD) for the fermentation of media in the brew- the indicators of the intensity of flow circuits and the need

ing industry. for the dynamics of cooling of the media are leveled.

2. The increase in the height of the media in the iso- Achieving such state discontinues the processes of their

volume apparatuses leads to limiting the irregularity level local transitions to unsaturated states. Increasing osmotic

of the flow circuits, which shows the prospects of orga- pressures in combination with the saturation of media

nized deterministic circulation. This direction can be con- with carbon dioxide on the physical level leads to biostat-

sidered the first step in the improvement of apparatuses ic effects.

List of references

1. Спиртовое брожение. Биохимические этапы спиртового брожения // Виноград и вина Процессы, происходящие при изготовлении вина

Спиртовое брожение http://vinograd-vino.ru/protsessy-proiskhodyashchie-pri-izgotovlenii-vina/173-spirtovoe-brozhenie.html/ (дата звернення

01.02.2018).

2. Колігативні властивості культуральних середовищ / Шевченко О.Ю. та ін. // Наукові праці НУХТ. 2016. Т. 62, № 2. С. 131-139.

3. Інтенсифікація тепло- масообмінних процесів в харчових технологіях / Соколенко А. І. та ін. Київ: Фенікс, 2011, 536 с.

4. Osmotic pressure in the fermentation media technologies / Sokolenko A. et al. // Ukrainian Food Journal. 2017. V. 6, №1. P. 134-140.

5. Stefan Hohmann Osmotic adaptation in yeast-control of the yeast osmolyte system // International Review of Cytology, 2002, №215. Р. 149-187.

6. Особливості трансформацій матеріальних і енергетичних потоків у бродильних середовищах / Шевченко О. Ю. та ін. // Наукові праці

НУХТ. 2017. Т. 23. № 3. С. 107-115.

7. Кунце В. Технология солода и пива: Пер. с нем. Санкт-петербург: "Издательство", 2003. 912 с.

8. Tippens Paul E. Physics. 7th ed, McGraw–Hill, 2007. 413 р.

9. Monk Paul. Physical Chemistry: Understanding our Chemical World: Wiley, 2004. 618 р.

10. Fernando Santos, Alunzio Borйm and Celso Caldas. Sugarcane. Agricultural Production, Bioenergy and Ethanol: Academic Press, 2015. 492 р.

11. Anderson T.M. Industrial Fermentation Processes, Encyclopedia of Microbiology: Third Edition, 2009, Р. 349-361.

12. Інтенсифікація зброджування цукровмістких середовищ / Чагайда А.О. та ін. // Наукові праці НУХТ. 2014. № 51. С.77-83.

References

1. Spyrtovoe brozhenye. Byokhymycheskye эtapы spyrtovoho brozhenyia [Internet] – Rezhym dostupu: http://vinograd-vino.ru/protsessy-

proiskhodyashchie-pri-izgotovlenii-vina/173-spirtovoe-brozhenie.html/ (data zvertannia 01.02.2018).

2. Shevchenko OIu, Sokolenko AI, Vasylkivskyi KV, Vinnichenko IM. Kolihatyvni vlastyvosti kulturalnykh seredovyshch. Naukovi pratsi NUKhT.

2017. Ber 2; 3(2):131-139.

3. Sokolenko AI, Mazaraki AA, Shevchenko OYu. ta in. Intensyfikatsiia teplo- masoobminnykh protsesiv v kharchovykh tekhnolohiiakh. Kyiv:

Feniks: 2011.

4. Sokolenko A. Shevchenko O, Makcymenko I, Vinnichenko I, Кostyuk V. Osmotic pressure in the fermentation media technologies. Ukrainian

Food Journal. 2017. Ber 30; 6(1):134-140.

5. Stefan Hohmann Osmotic adaptation in yeast-control of the yeast osmolyte system. International Review of Cytology. 2002ж 215: 149-187.

6. Shevchenko OYu, Vinnichenko IO, Stepanets OI., Boiko OO. Osoblyvosti transformatsii materialnykh i enerhetychnykh potokiv u brodylnykh

seredovyshchakh/ Naukovi pratsi NUKhT. 2017 Kvi. 27;23(3);107-115.

7. Kuntse V. Tekhnolohyia soloda y pyva: Per. s nem. Sankt-Peterburg: "Yzdatelstvo";2003.

8. Tippens Paul E. Physics. 7th ed, McGraw–Hill, 2007.

9. Monk Paul. Physical Chemistry: Understanding our Chemical World: Wiley 2004.

10. Fernando Santos, Alunzio Borйm and Celso Caldas. Sugarcane. Agricultural Production, Bioenergy and Ethanol, Academic Press. 2015.492 р.

11. Anderson TM. Industrial Fermentation Processes, Encyclopedia of Microbiology. Third Edition. 2009; 349-361.

12. Chahaida AO, Piddubnyi VA, Maksymenko IF, Boiko OO. Intensyfikatsiia zbrodzhuvannia tsukrovmistkykh seredovyshch. Naukovi pratsi

NUKhT. 2014; 51: 77-83.

Отримано в редакцію 05.02.2018 Received 05.02.2018

Прийнято до друку 06.03.2018 Approved 06.03.2018

Цитування згідно ДСТУ 8302:2015

Mass transfer in fermentation processes / Shevchenko A. et al. // Food science and technology. 2018. Vol. 12, Issue 2. P. 104-108. DOI:

http://dx.doi.org/10.15673/fst.v12i1.846

Cite as Vancuver ctyle citation

Shevchenko A et al. Mass transfer in fermentation processes. Food science and technology. 2018; 12(1): 104-108. DOI:

http://dx.doi.org/10.15673/fst.v12i1.846

Харчова наука і технологія / 108 Volume 12 Issue 1/ 2018

Food science and technology

Вам также может понравиться

- Ieee C57.98-2011Документ92 страницыIeee C57.98-2011CLAUDIO ALONSO MADRIDОценок пока нет

- 108590202A GU Basic Laboratory Skills A4 en LRДокумент92 страницы108590202A GU Basic Laboratory Skills A4 en LRΔΑΝΑΗ ΓΙΑΝΝΑΡΗОценок пока нет

- Fermentation Technology, Bioprocessing and Scaleup - ChistiДокумент39 страницFermentation Technology, Bioprocessing and Scaleup - Chistirobertoagonzalezc0% (1)

- IKI 30 V11 EngДокумент2 страницыIKI 30 V11 EngAydın PERÇEMОценок пока нет

- Information/Data Required For Wax Modelling: A) B) C) D) E)Документ6 страницInformation/Data Required For Wax Modelling: A) B) C) D) E)AYAUWU LOVEDAY100% (1)

- Engineering Properties in Food Processing SimulationДокумент6 страницEngineering Properties in Food Processing SimulationcsandrasОценок пока нет

- The Thermophilic Anaerobic Digestion ProcessДокумент15 страницThe Thermophilic Anaerobic Digestion ProcessoccbuziОценок пока нет

- Chemie Ingenieur Technik Volume 73 Issue 6 2001 (Doi 10.1002/1522-2640 (200106) 73:6-696::aid-Cite6962222-3.0.Co;2-t) Th. Rieckmann; S. VГ¶Lker - Product Quality of Recycled Food GradeДокумент1 страницаChemie Ingenieur Technik Volume 73 Issue 6 2001 (Doi 10.1002/1522-2640 (200106) 73:6-696::aid-Cite6962222-3.0.Co;2-t) Th. Rieckmann; S. VГ¶Lker - Product Quality of Recycled Food GradeJunaid AhmadОценок пока нет

- Note 1492436712 PDFДокумент15 страницNote 1492436712 PDFRamyaОценок пока нет

- Bimetanizacion de Residuos Solidos UrbanosДокумент8 страницBimetanizacion de Residuos Solidos UrbanosricardoОценок пока нет

- Determination and Calculation of Solubility of Bisphenol A in Supercritical Carbon DioxideДокумент7 страницDetermination and Calculation of Solubility of Bisphenol A in Supercritical Carbon DioxideAndrés F. CáceresОценок пока нет

- Freezing TempДокумент4 страницыFreezing TempЕвгенийОценок пока нет

- Characterisation and Modelling of Fouling in Membrane BioreactorsДокумент7 страницCharacterisation and Modelling of Fouling in Membrane BioreactorskiasamОценок пока нет

- Biochemical Engineering JournalДокумент5 страницBiochemical Engineering JournalJenniferОценок пока нет

- Kinetics Study of Propylene Oxide and WaterДокумент8 страницKinetics Study of Propylene Oxide and WaterRisma RegiyantiОценок пока нет

- Microkinetic Analysis of Acetone Hydrogenation Over Pt-SiO2Документ16 страницMicrokinetic Analysis of Acetone Hydrogenation Over Pt-SiO2李国俊Оценок пока нет

- Combination of Physico-Chemical Treatment and Nanofiltration To Reuse Wastewater of A Printing, Dyeing and Finishing Textile IndustryДокумент8 страницCombination of Physico-Chemical Treatment and Nanofiltration To Reuse Wastewater of A Printing, Dyeing and Finishing Textile IndustryChittaranjan SahooОценок пока нет

- Thermal Properties of Biological Agricultural Materials: Milena Jiřičková, Zbyšek Pavlík, Robert ČernýДокумент4 страницыThermal Properties of Biological Agricultural Materials: Milena Jiřičková, Zbyšek Pavlík, Robert ČernýPedro Casanova TretoОценок пока нет

- Evaluation of A Biocide Effect Upon MIC of Mild SteelДокумент6 страницEvaluation of A Biocide Effect Upon MIC of Mild Steelmaria angelica moreno montañoОценок пока нет

- Bioresource Technology: Jianguo Jiang, Xuejuan Du, Siio NG, Chang ZhangДокумент7 страницBioresource Technology: Jianguo Jiang, Xuejuan Du, Siio NG, Chang Zhang233701Оценок пока нет

- Chemical Kinetics of Biomass Pyrolysis: Energy & Fuels January 2009Документ11 страницChemical Kinetics of Biomass Pyrolysis: Energy & Fuels January 2009Claudia MendozaОценок пока нет

- Non-Catalytic Liquefaction of Microalgae in Sub and Supercritical AcetoneДокумент28 страницNon-Catalytic Liquefaction of Microalgae in Sub and Supercritical Acetonejosè CarhuapomaОценок пока нет

- Modelling and Simulation of CO Absorption in Alkaline Buffer Solutions in gPROMSДокумент6 страницModelling and Simulation of CO Absorption in Alkaline Buffer Solutions in gPROMSalinoriОценок пока нет

- JP CCR 36 2 OriginalДокумент53 страницыJP CCR 36 2 Originalvergin12345Оценок пока нет

- Characterization of Bioreactors Processes Aerobic Escherichia Coli CulturesДокумент12 страницCharacterization of Bioreactors Processes Aerobic Escherichia Coli CulturesWilliam Mejia GalarzaОценок пока нет

- Ipa Acetone KineticsДокумент6 страницIpa Acetone Kineticsbobcruise2k2Оценок пока нет

- Template Technical ReportДокумент6 страницTemplate Technical ReportZarith IhsanОценок пока нет

- Chemical Engineering JournalДокумент11 страницChemical Engineering Journalpk011Оценок пока нет

- Lesson 1 AbwtpДокумент25 страницLesson 1 AbwtpZakaria HaiderОценок пока нет

- Project Catalogue 2023 4 SemesterДокумент10 страницProject Catalogue 2023 4 Semestereman hussainОценок пока нет

- Temperature-And Pressure-Dependent Stopped-Flow Kinetic Studies of Jack Bean Urease. Implications For The Catalytic MechanismДокумент13 страницTemperature-And Pressure-Dependent Stopped-Flow Kinetic Studies of Jack Bean Urease. Implications For The Catalytic MechanismRodrigo LimaОценок пока нет

- Hydrothermal Treatment of Palm Oil Mill Effluent PДокумент9 страницHydrothermal Treatment of Palm Oil Mill Effluent PsahrierОценок пока нет

- 1 s2.0 S0141022913000513 MainДокумент5 страниц1 s2.0 S0141022913000513 MainJaviera Moraga TorresОценок пока нет

- De Pra - 2012Документ7 страницDe Pra - 2012Doulalas GiorgosОценок пока нет

- (2019-11p) IOP MSE - Subcritical Water...Документ7 страниц(2019-11p) IOP MSE - Subcritical Water...ClearyОценок пока нет

- Wet Air Oxidation - A Review of Process Technologies and Aspects in Reactor Design PDFДокумент18 страницWet Air Oxidation - A Review of Process Technologies and Aspects in Reactor Design PDFAnonymous 1XHScfCIОценок пока нет

- Wet Air Oxidation - A Review of Process Technologies and Reactor Design - S.T. Kolaczkowski - 1999Документ18 страницWet Air Oxidation - A Review of Process Technologies and Reactor Design - S.T. Kolaczkowski - 1999Jose M. Gomez RuedaОценок пока нет

- Experimental and Theoretical Investigation GAS PUTITYДокумент167 страницExperimental and Theoretical Investigation GAS PUTITYJesús Javier Antuña CouceiroОценок пока нет

- Conferinte Sectiunea V - cnc2018Документ8 страницConferinte Sectiunea V - cnc2018Cristina IoanaОценок пока нет

- Processes: in Situ Bio-Methanation Modelling of A Randomly Packed Gas Stirred Tank Reactor (GSTR)Документ13 страницProcesses: in Situ Bio-Methanation Modelling of A Randomly Packed Gas Stirred Tank Reactor (GSTR)Giorgio VilardiОценок пока нет

- Rajagopal Luis Augusto Prosciba 2010Документ7 страницRajagopal Luis Augusto Prosciba 2010rajabrasilОценок пока нет

- An Analysis of The Economic Production and Use ofДокумент9 страницAn Analysis of The Economic Production and Use ofMr PolashОценок пока нет

- CEJ 434 134732-Efficient Degradation of Tetracycline by Persulfate Activation With Fe, Co and O Co Doped G C3N4Документ17 страницCEJ 434 134732-Efficient Degradation of Tetracycline by Persulfate Activation With Fe, Co and O Co Doped G C3N4silambarasan kОценок пока нет

- Chemical Engineering Journal: Xiuqin Dong, Zhongdong Gan, Xianlin Lu, Wenzhu Jin, Yingzhe Yu, Minhua ZhangДокумент10 страницChemical Engineering Journal: Xiuqin Dong, Zhongdong Gan, Xianlin Lu, Wenzhu Jin, Yingzhe Yu, Minhua ZhangNeeraj Kumar KanaujiaОценок пока нет

- Advanced Control of A Complex Chemical PДокумент14 страницAdvanced Control of A Complex Chemical PTrương Tấn DươngОценок пока нет

- Types of A Erator S Used in Waste Water Treatment PlantsДокумент7 страницTypes of A Erator S Used in Waste Water Treatment Plantssandipkulkarni27Оценок пока нет

- Energy Conversion and ManagementДокумент9 страницEnergy Conversion and ManagementNurkholis Bin AbdulОценок пока нет

- 1 s2.0 S002196142100224X MainДокумент9 страниц1 s2.0 S002196142100224X MainPara DiseОценок пока нет

- Direct Synthesis of Hydrogen Peroxide in Batch Reactors: Understanding The Kinetics and MechanismsДокумент2 страницыDirect Synthesis of Hydrogen Peroxide in Batch Reactors: Understanding The Kinetics and MechanismsSanaОценок пока нет

- Organic promoters effect on refrigerant gas hydrate thermodynamicsДокумент16 страницOrganic promoters effect on refrigerant gas hydrate thermodynamicsShurooq TaibОценок пока нет

- OzonoДокумент8 страницOzonoDaniella CelisОценок пока нет

- Modelling of Nutrient Removal Processes in An Intermittently Aerated BioreactorДокумент8 страницModelling of Nutrient Removal Processes in An Intermittently Aerated BioreactorSalsa_Picante_BabyОценок пока нет

- Physical Processes in Bioreactors: Bioprocess TechnologyДокумент31 страницаPhysical Processes in Bioreactors: Bioprocess TechnologyRachel HechanovaОценок пока нет

- Anaerobic Digestion of The Vinasses From The Fermentation of Agave Tequilana Weber To Tequila - The Effect of PH, Temperature and Hydraulic Retention Time On The Production of Hydrogen and MethaneДокумент7 страницAnaerobic Digestion of The Vinasses From The Fermentation of Agave Tequilana Weber To Tequila - The Effect of PH, Temperature and Hydraulic Retention Time On The Production of Hydrogen and MethaneprofjohnalencarОценок пока нет

- Investigation of Osmotic Distillation TeДокумент6 страницInvestigation of Osmotic Distillation TeMarina ButuceaОценок пока нет

- Thermal Effects of Biomass PyrolysisДокумент29 страницThermal Effects of Biomass PyrolysisyascheОценок пока нет

- Accepted Manuscript: Thermochimica ActaДокумент22 страницыAccepted Manuscript: Thermochimica ActaAngelica Taipe ZevallosОценок пока нет

- Dokumen - Tips Penyediaan Air PanasДокумент30 страницDokumen - Tips Penyediaan Air PanasMuh FarhanОценок пока нет

- Application of UNIQUAC Model in Modeling VLE ofДокумент46 страницApplication of UNIQUAC Model in Modeling VLE ofAhmed AliОценок пока нет

- Plasma-Assisted Catalysis For Volatile Organic Compounds AbatementДокумент9 страницPlasma-Assisted Catalysis For Volatile Organic Compounds AbatementcligcodiОценок пока нет

- Miklos2018. Evaluation of Advanced Oxidation Processes For Water and Wastewater PDFДокумент14 страницMiklos2018. Evaluation of Advanced Oxidation Processes For Water and Wastewater PDFmayquer lin delgadillo perezОценок пока нет

- Development of A Method For Calculating A AnaerobiДокумент10 страницDevelopment of A Method For Calculating A AnaerobiNaresh GanisonОценок пока нет

- Use of Inert Gases For The Preservation of Nuclear Blood CellsДокумент7 страницUse of Inert Gases For The Preservation of Nuclear Blood CellsyutefupОценок пока нет

- Principles and Applications of Fermentation TechnologyДокумент2 страницыPrinciples and Applications of Fermentation TechnologySimone Bassan Zuicker ElizeuОценок пока нет

- Femas International Core Standard 2013Документ40 страницFemas International Core Standard 2013Simone Bassan Zuicker ElizeuОценок пока нет

- GFSI Guidance Document Sixth Edition Version 6.3Документ168 страницGFSI Guidance Document Sixth Edition Version 6.3Nuñez EdwardОценок пока нет

- Glass InclusionДокумент10 страницGlass InclusionSimone Bassan Zuicker ElizeuОценок пока нет

- Glass InclusionДокумент10 страницGlass InclusionSimone Bassan Zuicker ElizeuОценок пока нет

- Kinetics of Growth and Sugar Consumption in YeatsДокумент10 страницKinetics of Growth and Sugar Consumption in YeatsSimone Bassan Zuicker ElizeuОценок пока нет

- CT1 Part 9 Image QualityДокумент29 страницCT1 Part 9 Image Qualityrazan abdalrhmanОценок пока нет

- Shock & Vibration Response Spectra Rev DДокумент460 страницShock & Vibration Response Spectra Rev DTom IrvineОценок пока нет

- Printed AntennasДокумент463 страницыPrinted AntennasvasikasОценок пока нет

- Phase Diagrams and Heating-Cooling Curves of H2O and CO2Документ31 страницаPhase Diagrams and Heating-Cooling Curves of H2O and CO2Marielle LabradoresОценок пока нет

- Macedonia1Документ94 страницыMacedonia1Rodney FloresОценок пока нет

- Pressure Sensors: Types and Applications (TITLEДокумент44 страницыPressure Sensors: Types and Applications (TITLEIroshiniОценок пока нет

- Bitumen 50-70 Pen EcДокумент1 страницаBitumen 50-70 Pen Ecaegean227Оценок пока нет

- WinnerДокумент26 страницWinnerNguyễn Tấn PhátОценок пока нет

- Geometrey of The TheodoliteДокумент27 страницGeometrey of The Theodolitecharles_david_sutherlandОценок пока нет

- YEAR PLAN - 10 (2023-2024) Mathematics WMДокумент4 страницыYEAR PLAN - 10 (2023-2024) Mathematics WMMurali KrishnaОценок пока нет

- Theorems of SSLC Maths-7marksДокумент21 страницаTheorems of SSLC Maths-7marksPRAJWAL GОценок пока нет

- What Are Valence Electrons?: Oxidation StateДокумент3 страницыWhat Are Valence Electrons?: Oxidation StateexoisnineОценок пока нет

- Sabik Marine-Datasheet m660 2020Документ2 страницыSabik Marine-Datasheet m660 2020purchasingОценок пока нет

- XCKM115: Product Data SheetДокумент6 страницXCKM115: Product Data SheetVasile DumitruОценок пока нет

- DLP Q1 WK 8 D4 (37) ScienceДокумент7 страницDLP Q1 WK 8 D4 (37) ScienceRed MarquezОценок пока нет

- Fx3U 4AD PTДокумент3 страницыFx3U 4AD PTquân nguyễnОценок пока нет

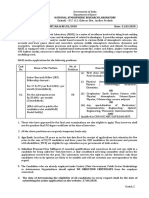

- National Atmospheric Research Laboratory Advertisement No - Narl/Rmt/Ra & Rf/01/2020 Date: 11.03.2020Документ2 страницыNational Atmospheric Research Laboratory Advertisement No - Narl/Rmt/Ra & Rf/01/2020 Date: 11.03.2020Srikanth RollaОценок пока нет

- 4007ES and 4007ES Hybrid Fire Alarm Systems: Installation Manual 579-1102 Rev. EДокумент44 страницы4007ES and 4007ES Hybrid Fire Alarm Systems: Installation Manual 579-1102 Rev. ELuis Walter LeoneОценок пока нет

- Lecture 4-Bec411Документ36 страницLecture 4-Bec411Mohd Nizam ShakimonОценок пока нет

- Microsoft Word - MIOS Universal Meter Reading Common Format V3.0Документ2 страницыMicrosoft Word - MIOS Universal Meter Reading Common Format V3.0rahul singhОценок пока нет

- Check Synchronising Relays: Technical DataДокумент2 страницыCheck Synchronising Relays: Technical DataBruce CoxОценок пока нет

- NuclearДокумент77 страницNuclearKynt Nathaniel L. TAMBUSONОценок пока нет

- Daikin CodesДокумент2 страницыDaikin CodesmosterjoeОценок пока нет

- Tor Qui MetroДокумент68 страницTor Qui MetroVíc Mac IIОценок пока нет

- EWDWEДокумент11 страницEWDWERanjanDsОценок пока нет

- 01 Vajhm23Документ6 страниц01 Vajhm23jigyeshОценок пока нет