Академический Документы

Профессиональный Документы

Культура Документы

Minhaj Report

Загружено:

Noushz channelОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Minhaj Report

Загружено:

Noushz channelАвторское право:

Доступные форматы

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

Abstract

To meet the never ending fuel demand of the vehicle, Hybrid Vehicle was introduced in

the research. Generally a hybrid vehicle is the combination of an internal combustion engine

(ICE) and electrical drive system. The performance of the vehicle is largely dependent on the

accuracy and efficiency of the electrical system of the vehicle powertrain. This paper analyzed

an electrical system for the powertrain of Hybrid Electric vehicle which is powered by Fuel

cell, Battery and PV panel. A Simulink model is prepared and simulated successfully.

Permanent magnet synchronous motor drive system is used in the Simulink model. The

simulation results like rotor speed, electromagnetic torque, current, DC-DC converter current,

voltage, state of charging, grid charger performance, photovoltaic panel performance and

mechanical torque are discussed and compared with the state of the art methods. Including this

the research also compared the performance of energy storage system with the reference which

is frequently used in the electrical system of the HEV.

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 1

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

Chapter 1

INTRODUCTION

According to the centre of solar energy and hydrogen research a total number of 550,000 new

hybrid electric vehicle registered till 2015. Based on the use of energy storage system electric

vehicle can be classified into battery electric vehicle, hybrid electric vehicle and plug-in hybrid

electric vehicle. The key factor behind the revolution of Hybrid Electric Vehicle is the

improved performance of power electronics and performance oriented motor drives. The

performance of the powertrain of HEV is solely dependent on the performance of motor drives.

The demand of hybrid electric vehicle are increasing day by day due to immense Fuel cell

technology specifically proton exchange membrane fuel cell (PEMC) used vastly to utilize

hydrogen as major fuel source of the vehicle. As an environmentally safe and efficient fuel

hydrogen is the vital choice for the manufacturer in case electric vehicle.

The main advantage of hybrid electric vehicle beside the improved fuel economy, is the

reduction of carbon-di-oxide emission. The carbon dioxide emission rate on May 2016 was

near 407.70 ppm and it is simultaneously increasing. Hybrid electric vehicle uses many state

of the art environment friendly technologies like regenerative braking system, fuel cell etc.

which will greatly reduce the emission of harmful elements whose are responsible for

environment pollution. Along with this green technologies use of efficient power electronics

and lighting system will greatly improve the overall performance of hybrid electric vehicles

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 2

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

1. 1 WHAT IS HYBRID

Any vehicle is a hybrid when it combines two or more sources of power.

Hybrid vehicles are all around us. most of the locomotive we see pulling trains are

diesel-electric hybrids. We have diesel-electric trains-these can draw electric power

from overhead wires or run on diesel when they are away from the wires.

The gasoline-electric hybrid car is just that -a cross between a gasoline-powered

car and an electric car

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 3

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

Chapter2

DESIGN

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 4

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

2.1 Permanent Magnet Synchronous Machine

A PMSM is the first choice for the HEV system, because a PMSM has the advantages of high

torque density and efficiency. The high energy permanent magnets, such as rare earth or

samarium cobalt, used for exciting the magnetic field of a PMSM, enable the PMSM to be

significantly smaller than the IM and SRM in size and weight. The PMSM also has better

efficiency because of the absence of a rotor winding and the small size of the rotor.

Additionally, since the PMSM is efficient at low speed, the HEV using a PMSM is attractive

in the city mode in which the vehicle is required to frequently start and stop.

However, the PMSM has some drawbacks caused by its permanent magnets. For operation

above its base speed, the permanent magnets produce a significant back electromotive force

(emf) that must be reduced for its field weakening capability; a direct axis demagnetization

current produces magnetic flux to oppose the flux from the permanent magnets, and then

reduces the flux linked through the stator wires. For this field weakening operation, the fixed

huge magnetic flux from the highly energized permanent magnets prevents the direct axis

current coming to the stator wires and limits the constant power speed region

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 5

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

A salient pole permanent magnet synchronous machine is used in the Simulink model where

back emf waveform will be Sinusoidal. According to the above Figure when the simulation

is done electromagnetic torque of the permanent magnet synchronous motor is varied from -

100 Nm to 300 Nm at t=16 sec. Rotor speed is simultaneously increasing and increase till the

speed goes to 7000 rpm and tends to follow the expected. The mechanical power is varied

according to the reference within the range 0 W to 15*104 W. There are some distortion found

in case of electro-magnetic torque and mechanical power with the reference output. However

this performance fluctuation is for a small period of time and can be neglected as overall rotor

speed is continuously increasing. The stable output of rotor speed ensures that this two slightly

fluctuated value has a very low impact on the overall stability of the entire system.

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 6

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

2.2 Grid Charger

A grid charger is an electronic device that can charge the battery pack of hybrid electric vehicle

at a very low current. In near future vehicle to grid charge concept can be seen where electric

vehicles can be charged directly from the gird .Its name implying that it will use AC power for

charging. During parking electric vehicle can be recharged and by vehicle to grid technology

a vehicle can recharge its battery pack anywhere. This will be a great improvement as battery

electric vehicles are struggling with their battery packs. Widespread implementation of vehicle

to grid technology will remove the driving range limitations of electric vehicle.

Batteries have a finite number of charging cycles, as well as a shelf-life, therefore using

vehicles as grid storage can impact battery longevity. Studies that cycle batteries two or more

times per day have shown large decreases in capacity and greatly shortened life. However,

battery capacity is a complex function of factors such as battery chemistry, charging and

discharging rate, temperature, state of charge and age. Most studies with slower discharge rates

show only a few percent of additional degradation while one study has suggested that using

vehicles for grid storage could improve longevity.

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 7

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

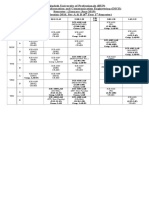

Parameter Value

Peak amplitude 312 V

Frequency 50 Hz

Phase 0˚

Transformer Primary 312 V

Transformer Secondary 280 V

Diode Parameters

Snubber resistance 500 ohm

Forward voltage 0.8 V

Resistance Ron .001 ohm

According to the below Figure the output voltage of the grid charger varies within the 255 V

to 280 V at t=16 sec which meets the desired system requirement of 280 V.

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 8

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

2.3 Photovoltaic Panel

Commercial photovoltaic panels cannot provide equal performance due to average thermal

conductivity of substrate material. Here eighteen photovoltaic cells are used to complete the

model of photovoltaic panel.

It is mentioned earlier that photovoltaic panel will support the auxiliary battery of the vehicle

which is typically contains the rating of 12 V. From the simulation result it is seen that initially

the panel generating 11.929 V however the generation is slightly reduced in course of time

which remains till 15.95s. In 16th second and onwards a constant supply of 11.928 V is achieved

which is very close to recharge a 12 V battery. That means photovoltaic panel successfully

meets the system requirements.

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 9

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 10

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

2.4 Fuel Cell

Fuel cell is an integral part of the proposed hybrid electric vehicle power system. The use of

fuel cell was initiated by NASA as supporting power source to meet the power demand of their

space shuttle. Overall performance of the vehicle specifically the fuel economy of the vehicle

depends on the vehicle energy management system where the power distribution between the

fuel cell and battery is done panel so power produced from the fuel cell will be used completely

for the propulsion of the vehicle. The relation between stack voltage vs. current and stack power

vs. stack current reflects the accurate power production from fuel cell.

That means to improve the fuel economy of the vehicle it is equally important to improve

energy management system. To measure the performance of the fuel cell system generally the

initial state of charging and final state of charging are considered.

Total number of fuel cell stack used in this Simulink model is 400 where stack efficiency is

57%. Operating temperature plays important role in case of fuel cell. In this system the system

temperature kept 95˚C. Vehicle fuel cell system can be classified into four sub-system and the

air flow sub-system plays important role with having greater impact on fuel cell overall

performance. Air flow system is generally consists of cooler, compressor, valve and pipes etc.

To maintain the stable and reliable performance air flow control is an impressive method for

fuel cell system. Here nominal air flow rate is 1698 Ipm.

Parameter Value

Number of cell 400

Stack efficiency 57%

Operating 95˚

temperature

Nominal air flow rate 1698 Ipm

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 11

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 12

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

2.5 Battery

In any energy management system (EMS), energy storage system as well as battery play the

key role. Lithium-ion battery is used in this Simulink model. Detail specification of the battery

used in the Simulink model are visualized below

Parameter Value

Battery type Lithium-ion

Nominal voltage 288 V

Rated capacity 13.9 Ah

Initial state of charge 40.32%

Fully charged voltage 335.2283 V

Battery response time 30 sec

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 13

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

2.6 OVERALL PERFORMANCE MEASUREMENT

Above Figure represents an overall electrical measurement of the HEV power system. Here

the voltage through DC-DC converter varies within 0 V to 400 V. From output response it is

seen that the converter output failed to follow the reference waveform accurately though

conversion in different time period are done successfully. If the focus can be given on the

battery and fuel cell voltage, some distortion in the battery performance can be found though

fluctuation for a very small period of time so this fluctuation can be neglected. Though

optimum voltage for the propulsion is 288V but the voltage production from fuel cell varies

within the range of 300-450 V which is quite satisfactory for the smooth operation of the

system. Current production of fuel cell is varies within the range 0 A to 400 A which is within

the desired range of the system. According to the figure the state of charge (SOC) lies between

the range 39.8% to 40.8% where system requirement is 40.32% so the output response of state

of charge (SOC) clearly satisfies the demand.

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 14

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

Chapter 3

3.1 ADVANTAGES

Environmentally Friendly:

1. One of the biggest advantage of hybrid car over gasoline powered car is that it runs

cleaner and has better gas mileage which makes it environmentally friendly. A hybrid

vehicle runs on twin powered engine (gasoline engine and electric motor) that cuts fuel

consumption and conserves energy.

2. Financial Benefits:

Hybrid cars are supported by many credits and incentives that help to make them

affordable. Lower annual tax bills and exemption from congestion charges comes in the

form of less amount of money spent on the fuel.

3. Less dependence on Fossil Fuels:

A Hybrid car is much cleaner and requires less fuel to run which means less emissions

and less dependence on fossil fuels. This in turn also helps to reduce the price of

gasoline in domestic market.

4. Regenerative Braking System;

Each time you apply brake while driving a hybrid vehicle helps you to recharge your

battery a little. An internal mechanism kicks in that captures the energy released and

uses it to charge the battery which in turn eliminates the amount of time and need for

stopping to recharge the battery periodically.

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 15

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

5. Built From Light Materials:

Hybrid vehicles are made up of lighter materials which means less energy is required

to run. The engine is also smaller and lighter which also saves much energy.

6. Higher Resale Value:

With continuous increase in price of gasoline, more and more people are turning

towards hybrid cars. The result is that these green vehicles have started commanding

higher than average resale values. So, in case you are not satisfied with your vehicle,

you can always sell it at a premium price to buyers looking for it.

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 16

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

3.1 DISADVANTAGES

1.Less Power:

Hybrid cars are twin powered engine. The gasoline engine which is primary source of

power is much smaller as compared to what you get in single engine powered car and

electric motor is low power. The combined power of both is often less than that of gas

powered engine. It is therefore suited for city driving and not for speed and acceleration.

2. Can be Expensive:

The biggest drawback of having a hybrid car is that it can burn a hole in your pocket.

Hybrid cars are comparatively expensive than a regular petrol car and can cost $5000

to $10000 more than a standard version. However, that extra amount can be offset with

lower running cost and tax exemptions.

3.Poorer Handling:

A hybrid car houses an gasoline powered engine, a lighter electric engine and a pack

of powerful batteries. This adds weight and eats up the extra space in the car. Extra

weight results in fuel inefficiency and manufacturers cut down weight which has

resulted in motor and battery downsizing and less support in the suspension and body.

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 17

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

4. Higher Maintenance Costs:

The presence of dual engine, continuous improvement in technology, and higher

maintenance cost can make it difficult for mechanics to repair the car. It is also difficult

to find a mechanic with such an expertise.

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 18

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

CONCLUSION

In this paper mainly discussed modelling and simulation of HEV power system. More

specifically performance of various electrical components of HEV power system are closely

observed and analyzed. Comparison of the performance of various components of HEV power

system with the state of the art methods are done. The growth of market potential of hybrid

electric vehicle can be kept up by keeping the uninterrupted supply of power. That means the

long lasting success of HEV is largely dependent on the sustainability and flexibility of its

power system. Automotive market is currently struggling with the high price of the fuel and

the most convenient way to face this is to rely on hybrid electric vehicle. Beside this a major

advantage of hybrid electric vehicle is the lower emission of CO2 which ensures the safety of

environment. This paper represented a complete Simulink model of hybrid electric vehicle

power system which is powered by PEM fuel cell, Lithium-ion battery and photovoltaic panel.

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 19

Modelling and simulation of power system of battery, solar 2019

and fuel cell powered Hybrid Electric Vehicle

REFERENCE

[1] Number of electric car worldwide can be acccessed at:

https://evannex.com/blogs/news/77801925-number-of-electric-carsworldwide-climbs-

to-1-3-million-tesla-model-s-takes-top-spot-amongnew-ev-registrations [August

21,2016].

[2] M. Anderman, “Status and trends in the HEV/PHEC/EV battery industry,” Rocky

Mountain Institute, 2008.

[3] Subotic, Ivan, and Emil Levi. "A review of single-phase on-board integrated battery

charging topologies for electric vehicles." Electrical Machines Design, Control and

Diagnosis (WEMDCD), 2015 IEEE Workshop on. IEEE, 2015

DEPT OF EEE, P A COLLEGE OF ENGINEERING Page 20

Вам также может понравиться

- Hume 100 ReviewerДокумент7 страницHume 100 ReviewerShai GaviñoОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Learning Plans in The Context of The 21 ST CenturyДокумент29 страницLearning Plans in The Context of The 21 ST CenturyHaidee F. PatalinghugОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Cimo Guide 2014 en I 3Документ36 страницCimo Guide 2014 en I 3lakisОценок пока нет

- CE-23113-SP-902-R01-00 Asset SpecificationДокумент14 страницCE-23113-SP-902-R01-00 Asset SpecificationСветлана ФайберОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- 20235UGSEM2206Документ2 страницы20235UGSEM2206Lovepreet KaurОценок пока нет

- CUIT 201 Assignment3 March2023Документ2 страницыCUIT 201 Assignment3 March2023crybert zinyamaОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- IU IIDC Time Management and Organizational SkillsДокумент40 страницIU IIDC Time Management and Organizational SkillsAsger HamzaОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- E Voucher Hotel en 1241564309Документ2 страницыE Voucher Hotel en 1241564309taufksОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Chapter Two: General Design ConsiderationsДокумент27 страницChapter Two: General Design ConsiderationsTeddy Ekubay GОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Chemical Engineering & Processing: Process Intensi Fication: ArticleinfoДокумент9 страницChemical Engineering & Processing: Process Intensi Fication: Articleinfomiza adlinОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Data Driven AuditДокумент34 страницыThe Data Driven AuditMon compte Mon compteОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Concept of Lokmitra Kendra in Himachal PradeshДокумент2 страницыConcept of Lokmitra Kendra in Himachal PradeshSureshSharmaОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- UntitledДокумент5 страницUntitledapril montejoОценок пока нет

- MidsemДокумент6 страницMidsemAravind SomasundaramОценок пока нет

- Noth PicturesДокумент17 страницNoth PicturesJana AssaОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- CTRLX Automation BrochureДокумент60 страницCTRLX Automation BrochureNinja do SofáОценок пока нет

- Class Routine Final 13.12.18Документ7 страницClass Routine Final 13.12.18RakibОценок пока нет

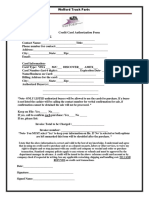

- Credit Card Authorization Form WoffordДокумент1 страницаCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- I.A.-1 Question Bank EM-3 (Answers)Документ11 страницI.A.-1 Question Bank EM-3 (Answers)UmmОценок пока нет

- SIMPLE PlaybookДокумент12 страницSIMPLE PlaybookMatt LylesОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Fanii 2Документ55 страницFanii 2Remixer INDONESIAОценок пока нет

- Measures of Indicator 1Документ2 страницыMeasures of Indicator 1ROMMEL BALAN CELSOОценок пока нет

- Bombas KMPДокумент42 страницыBombas KMPReagrinca Ventas80% (5)

- Solar-range-brochure-all-in-one-Gen 2Документ8 страницSolar-range-brochure-all-in-one-Gen 2sibasish patelОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Kunst 1600 Case AnalysisДокумент3 страницыKunst 1600 Case AnalysisrakeshОценок пока нет

- Myers Briggs Type Indicator-2Документ1 страницаMyers Briggs Type Indicator-2api-261818438Оценок пока нет

- Progressive Muscle Relaxation ExerciseДокумент2 страницыProgressive Muscle Relaxation Exerciseraghu2362704100% (1)

- GATE Chemical Engineering 2015Документ18 страницGATE Chemical Engineering 2015Sabareesh Chandra ShekarОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Why We Need A Flying Amphibious Car 1. CarsДокумент20 страницWhy We Need A Flying Amphibious Car 1. CarsAsim AhmedОценок пока нет

- Group 4 - When Technology and Humanity CrossДокумент32 страницыGroup 4 - When Technology and Humanity CrossJaen NajarОценок пока нет