Академический Документы

Профессиональный Документы

Культура Документы

WPS 01

Загружено:

SUBHOMOY0 оценок0% нашли этот документ полезным (0 голосов)

42 просмотров3 страницыprocedure qualification record

Оригинальное название

WPS-01

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документprocedure qualification record

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

42 просмотров3 страницыWPS 01

Загружено:

SUBHOMOYprocedure qualification record

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 3

FORMAT NO: VSPLIRILMPCLIENL

‘VISHAL STRUCTURALS PVT. LTD.

SEY conposie tanhage vrs or "at a Ca Pt or MR

PCL Rey Maa Mobi

PROCEDURE QUALIFICATION RECORD (PQR)

J>RoceDURE QUALIFICATION RECORD NO. SPLIEIHPCLIPQR-8 REV. 00 DATE: 20Feb19

[SUPPORTING WPS Ne VSPLIRILMPCLIWPS.08 —REV.: 00 DATE: 2086-19

‘TYPES (MANUAL, AUTOMATIC, SEML-AUTO) MANUAL,

[BASE METALS (QW-403):

[MATERIAL SPECIFICATION [ASTM A106 Geb we ASTM A106 GB

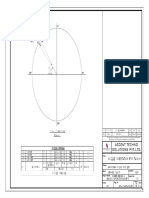

;ROOVE DESIGN [TYPE OF GRADE. [ASTM A106 Gr. to ASTM A106 Gr

[pwo. PNee1 wPNoLGA

Mom

[ach Pine

Na

annem eee

POSITION OF GROOVE 6G

WELDING PROGRESSION co

lore a

PREHEAT (QW-406):

JoReEAT TEMPERATURE |1s% atin, ion 2 4m thine.

I2E OF FILLER [24 mm locrenrass TEMPERATURE as0"e Max

ha PosTHEATING NA

OSTWELD HEAT TREATMENT (QW-407): GAS (Qw-408):

PERATURE RANGE NA [ssnet pose cas.

TIME RANGE (NA fraxcract comPostion

HOLDING TIME INA lrLow Rare s

wa Jans BACKING: INa

NA [RAILING SHIELDING Gas cose. bwin

fecaiQcr aw

anor wexve Rn

20-Fe9

Page 1 of

ORMAT NO: YSPL/EILIIPCLIENLN2

PROCEDURE QUALIFICATION RECORD (PQR)

"ROCEDURE QUALIFICATION RECORD NO.

VSPLIEILHPCLIPQR0S —REV.: 00 DATE:

ea

SUPPORTING WPS No: VsruivncLiwrson niv./00 DATE. 204ebi9

WELDING SEQUENCE & PROCEDURE

varcrnone | | as | vrs [ES] anu

mens | 2 | ssn | moar | onsemaa

maa [24 | ow | aa | earns

TENSILE TEST

Taare TOTAL | uADATE OTA,

sreonaNo rawreroral | uumane rota | gore oF FABURE & CATION

7 Ta = Trt Fn ro

= [wo [sa |e) ae = Ck Fon Pl

‘GbIDED BEND TESTS

Tare AND TREN aT THRE AND MOURENO maT

‘aay stay

ROOT BEND (RBIRB2) | (yp rencear ack) FACE BEND OBIFB2) Wo Evidence of eack)

TOUGHNESS TESTS

OAT VATS

TATA EE

sveciuswno | norontocarion |SOtCH) Test Joe)

we me | was

HADRNESS SURVEY (HV)

Smee | Peornmareaty [waza | wen | txzctin Pe

BoTTOM 8 ae im 5

OF THETEST > RADIOGRARI ACCEPTABLE REFORT Na” RT7 WOT THT 142307

ANALYSE = NA

re ™

ST CONDUCTED BY Mis. METERIAL INSPECTION LABORATORY. - MUMBAL

«TORY TEST REPORT No. TCCNo:F4591 DATED 1942-2019

LDER'S NAME: Mr jay Kumar (VTW-1S8) _CLOCKNo: NA

smo =)

5 CONDRCTD AY. MR et Mh SPL Pra ML

1E CERTIFY THAT THE STATEMENTS IN THIS RECORD ARE CORRECT AND THAT THE TEST COUPON WAS PREPARED, WELDED AND

STED IN ACCORDANCE WITH THE REQUIREMENTS OF SECTION IX OF ASME CODE,

SiR PE LTD. TNGINTERS INDIA LIMITED PCL

; =

io ) Races Qe .od 2S

Le saree

D.

wees | WOE 1D ech

ee eemtiro- ne NBR

aa ypatt PRONE

{mexx| | MATERIAL INSPECTION LABORATORY

I I ‘Accredited by NABL under ISO / IEC 17025 for Chemical & Mechanical Testing

‘Approved by Govt. Organisations & Third Party Inspection Agencies.

= Unit No, 2, Regal Industrial Estate, Ground Floor, A. 0. Marg, Next to Thakre Udyan,

00 015, + Tel.: 022-66553785 - 86 *

Sewree (W), Mumbai -

Test Report Page 1 of 1

uur -¥¢670819000002875F

Report No. Faso Date: 19-02-2019

Datiy'sName & Add. M/s. Engineers India Limited

HPCLTankages Projects, 8..Patl Marg, Mahl,

Mumbai - 400078

Ponty Ret. Cia 7/QNLA0/3809 ff. Doe: 14-02-2019

Letter No. VSPL/Calc Ste/265 std 14.02.2019

Ghent hs vishal Sruturals Private td

mingpectionlab@yahoo.com + Web: www.minspectiontab.com fin sr)

Material C.Welded Coupon Pipe

Specification [ASME SEC IK 2017 / ASTM A 106 Grade 8.2035 / Procedure Qualification

Sample Stamped By —_L/802

‘Material Dimension 2"x8, Pen

welder No. vrw-158

Welding Process /Electrode GTAW/ER 7052

PaR No \VSPL/EIL/POR-08 =

Tensile Test Report “Test Method : ASME SEC DX2017

Equipment -UTE-40 Sr.No. 06/2012-4965 Cal. Ot: 23-ul-2018 Que Ot: 221-2019 |

Hy (2 Read

idl (ny 1s 3

hk mm) 862 3.62

‘area (rom") 163.78 163.78

Ukimate Load (kN) 77.02 80.36

usr (Ma) 470 aan 415 mia

Fracture in Pom. inp.

Remark z Satisfactory Satisfactory

‘Guided Bend Test Report Test Method : ASME SEC I:2011

Fquipment :UTE-40 Sr.No, 06/2012-4965 Cal. Dt 23-Jul-2018 Ove Dt. 22-Jul-2039

Result

Re Fon Rez Faz

Specimen size smn asmm 85mm 85mm

Mandrel Size = t= 3ammg 34mmo 3ammp 30mm

Angle of Bend 180" a0" 180" 260"

Remark Setisfactory Satisfactory Satisfactory _ Satisfactory

“Hardness “Test Method : ASTM E92: 2017 _ es

Result

HREW ov

wewo 2,84,83 156,162,159

HAZ (Left) 73,72,73 132, 130,132

HAZ (Right) 72,72,73 130, 130, 132

Poaivelt) 76,75,74 139,137, 135

(right) 74, 75,74 135,137,135

‘Remarks The material conforms to ASME SEC IX:2017 / ASTM A 106 Grade B:2015 / Procedure Qualification with

respect to test/s carried out.

Phy. Test Wi

‘By Mr. K.prabhu for EIL & Mi, Rajan Bera for M/s. Vishal Structurals Pvt. Utd

For Material sagpettion Laboratory

jadhiat—_/K.C, Shrivastav / Kiran Khot

7

7 A

| Fe i

ewe |

1. The above tst epost lates ony tthe sample submited. # Not covered und

2. The above samlos are not drawn by the laboratory

Fee cece tain no wey be responsible fr any franca abit duo fo any ato omisslon or err made

TR eee Tat Report sal be reproduced without he writen permission of tis laboratory.

“

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Load Data of TanksДокумент3 страницыLoad Data of TanksSUBHOMOYОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ6 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- Quality Assurance Plan For Is 2062 E250 GR BRДокумент2 страницыQuality Assurance Plan For Is 2062 E250 GR BRSUBHOMOYОценок пока нет

- Design Analysis and Optimization of Double Wall Vacuum Vessel-A Review PaperДокумент3 страницыDesign Analysis and Optimization of Double Wall Vacuum Vessel-A Review PaperSUBHOMOYОценок пока нет

- Draft Piping LayoutДокумент1 страницаDraft Piping LayoutSUBHOMOYОценок пока нет

- Bangladesh National Building Code-2015 Vol - 3 - 3 (Draft) PDFДокумент518 страницBangladesh National Building Code-2015 Vol - 3 - 3 (Draft) PDFQuetaste ArtisatОценок пока нет

- Deadstock Volume Tankwise 24.12.15 in DetailДокумент2 страницыDeadstock Volume Tankwise 24.12.15 in DetailSUBHOMOYОценок пока нет

- Nozzle Orientation DrawingДокумент1 страницаNozzle Orientation DrawingSUBHOMOYОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ6 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- Technical Specifications for Furnace Oil Transfer PumpДокумент1 страницаTechnical Specifications for Furnace Oil Transfer PumpSUBHOMOYОценок пока нет

- Intergard 966: Product DescriptionДокумент4 страницыIntergard 966: Product DescriptionSUBHOMOYОценок пока нет

- PMS A1aДокумент1 страницаPMS A1aSUBHOMOYОценок пока нет

- PDS Intergard 906Документ4 страницыPDS Intergard 906SUBHOMOYОценок пока нет

- Interseal 547 PDFДокумент4 страницыInterseal 547 PDFSUBHOMOYОценок пока нет

- WPS 01Документ8 страницWPS 01SUBHOMOYОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ14 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- Lab Test ReportДокумент3 страницыLab Test ReportSUBHOMOYОценок пока нет

- SeatringДокумент4 страницыSeatringSUBHOMOYОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ6 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- 110012130-81 3 Nos. LotДокумент16 страниц110012130-81 3 Nos. LotSUBHOMOYОценок пока нет

- Final Energy Balance-Vizag DT 9-6-18Документ6 страницFinal Energy Balance-Vizag DT 9-6-18SUBHOMOYОценок пока нет

- AFB HIN MN MEC 001 (T 06 07 08 09) ModelДокумент1 страницаAFB HIN MN MEC 001 (T 06 07 08 09) ModelSUBHOMOYОценок пока нет

- MTC For Rawmaterial of ValvesДокумент17 страницMTC For Rawmaterial of ValvesSUBHOMOYОценок пока нет

- MTC For ValvesДокумент18 страницMTC For ValvesSUBHOMOYОценок пока нет

- M K Roy - HPCL Kota Terminal - Tank Foundation Drawing R2Документ1 страницаM K Roy - HPCL Kota Terminal - Tank Foundation Drawing R2SUBHOMOYОценок пока нет

- External Floating RoofДокумент14 страницExternal Floating RoofAjeetKumarОценок пока нет

- P Peaking BandingДокумент4 страницыP Peaking BandingSUBHOMOYОценок пока нет

- Revised Foundation Drawing 22.05.2010-ModelДокумент1 страницаRevised Foundation Drawing 22.05.2010-ModelSUBHOMOYОценок пока нет

- Soil Bearing CapacityДокумент1 страницаSoil Bearing CapacitySUBHOMOYОценок пока нет