Академический Документы

Профессиональный Документы

Культура Документы

Why Is GFRG Superior To Conventional Construction?

Загружено:

Krishna ChaitanyaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Why Is GFRG Superior To Conventional Construction?

Загружено:

Krishna ChaitanyaАвторское право:

Доступные форматы

GFRG stands for Glass Fiber Reinforced Gypsum panels.

The panels are

manufactured in sizes of 12 m long,3m height and 124 mm (5 inch) thick thus

providing more carpet area. The hollow cavities inside the panel are filled with

concrete to provide more strength to the panel. GFRG panel costs 999 per sq.m.

Below is an image showing GFRG panel and its internal structure.

Why is GFRG superior to conventional

construction?

Gypsum which is a waste product of fertilizer industry is used to make the panels

economical and Eco-friendly. Glass fiber is used as reinforcing agent which

enhances the strength of the panels. Eventually the usage of cement is reduced.

One-cement industry alone accounts for 5% increase in CO2 emission. By using

GFRG panels cement usage is reduced and thereby reducing environmental

pollution.

In site they are just erected using cranes. Those hollow cavities inside the panels

are filled with concrete and steel. Concrete is poured in every third cavity of the

panel and other cavities can be filled with waste materials like quarry dust hence

its becomes more economical than conventional construction methods.

GFRG is an eco-friendly material:

GFRG iss a GEP (Green Environmental Protection) material has no odor and its

Radioactive Nuclide Limit is accord with A-style decoration material standard of

GB6566-2001, which can be used for recycling.

Factories manufacturing this GFRG panels:

FRBL-FACT RCF Cochin,Kerala

RCF Mumbai

These panels are precast in factories, transported to construction site and

erected with the help of crane.

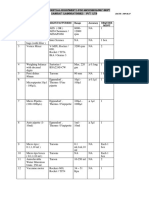

Comparison of GFRG over

conventional building:

Test Results of GFRG:

Cons:

More space needed for crane movement

Complicated design will make it less economical

Skilled labours needed

GFRG panels should be handled with care while transportation and erection

Need specific machinery for cutting GFRG panels at site

Erection and placing of GFRG panels are a bit difficult.

Uses of GFRG:

As light weight load bearing wall

As partition wall

As compound wall

Cladding in industrial structures

Pitched roofing

Horizontal roofs/slabs

Вам также может понравиться

- Conversion Gate01Документ6 страницConversion Gate01Sohan MeharwadeОценок пока нет

- GFRG (Glass Fiber Reinforced Gypsum) : An Eco-Friendly Alternative Construction Technology byДокумент19 страницGFRG (Glass Fiber Reinforced Gypsum) : An Eco-Friendly Alternative Construction Technology byabuzarОценок пока нет

- Glass Fibre Reinforced GypsumДокумент8 страницGlass Fibre Reinforced GypsumVickyОценок пока нет

- Ashok Technical Seminar REPORTДокумент16 страницAshok Technical Seminar REPORTSudeep NayakОценок пока нет

- Cara Tiles GFRCДокумент3 страницыCara Tiles GFRCHussain BagasrawalaОценок пока нет

- NRG Greenboard Spec Booklet V7 2013 - 0Документ36 страницNRG Greenboard Spec Booklet V7 2013 - 0charlie20377240Оценок пока нет

- GFRG Panel ConstructionДокумент2 страницыGFRG Panel Constructiontej23479Оценок пока нет

- Affordable Rapid Mass Housing Using GFRG PanelsДокумент14 страницAffordable Rapid Mass Housing Using GFRG Panelsವಿನಯ್ ಎಮ್. ಆರ್Оценок пока нет

- 1.1 General BackgroundДокумент28 страниц1.1 General Backgroundproject townplanОценок пока нет

- GFRG PanelsДокумент13 страницGFRG PanelsAjay PGI/15/CV/006Оценок пока нет

- Low Cost Houses Using GFRG Panels: Presented By: M.Vikas Naik 17011A0148Документ24 страницыLow Cost Houses Using GFRG Panels: Presented By: M.Vikas Naik 17011A0148Vikas NaikОценок пока нет

- Rsumners PDFДокумент12 страницRsumners PDFSaloni guptaОценок пока нет

- Capstone Project - Batch Vi (Aldep Class of 2019) Affordable Housing - Design, Cost & Time Optimization Using Rapid Wall Panels & PodsДокумент11 страницCapstone Project - Batch Vi (Aldep Class of 2019) Affordable Housing - Design, Cost & Time Optimization Using Rapid Wall Panels & PodszuberОценок пока нет

- Glass Fibre Reinforced ConcreteДокумент10 страницGlass Fibre Reinforced ConcreteHimanshu Sekhar PandaОценок пока нет

- GFRGДокумент19 страницGFRGaishwarya biradarОценок пока нет

- Contemporary Building MaterialsДокумент22 страницыContemporary Building MaterialsShif renОценок пока нет

- Emerging Lecture (Walling)Документ46 страницEmerging Lecture (Walling)izim izimОценок пока нет

- GFRG 124Документ22 страницыGFRG 124Ganesh AitharajuОценок пока нет

- Nps BFДокумент1 страницаNps BFanudattОценок пока нет

- Concrete: From Grey To GreenДокумент12 страницConcrete: From Grey To GreenOmar Marghani SalmaОценок пока нет

- Advance Construction MaterialsДокумент4 страницыAdvance Construction MaterialsVivek MakhechaОценок пока нет

- Glass Fibre Reinforced ConcreteДокумент14 страницGlass Fibre Reinforced ConcreteShif renОценок пока нет

- Critical Review of Use of Glass Fiber Reinforced G PDFДокумент4 страницыCritical Review of Use of Glass Fiber Reinforced G PDFDharmendra PawarОценок пока нет

- GRC Report - Group 4Документ2 страницыGRC Report - Group 4Viraj RaneОценок пока нет

- GFRGarticle PublishedДокумент15 страницGFRGarticle Publishedvamshi krishnaОценок пока нет

- GlasGrid CatalogueДокумент25 страницGlasGrid CatalogueYuda OktoramdaniОценок пока нет

- Welcome To Grcuk One of EuropeДокумент8 страницWelcome To Grcuk One of EuropeIqbal F AwaluddinОценок пока нет

- GRC in Action Design of Glass Fiber Reinforced ConcreteДокумент24 страницыGRC in Action Design of Glass Fiber Reinforced Concreteümit özkan100% (1)

- Journal - Precast WallsДокумент5 страницJournal - Precast WallsshailacОценок пока нет

- Asokan2009 PDFДокумент9 страницAsokan2009 PDFMoiz HashmiОценок пока нет

- Modern Consruction of Building (2) - 1Документ27 страницModern Consruction of Building (2) - 1Devendra SharmaОценок пока нет

- Glass Fiber Reinforced Gypsum Panel Use in Building ConstructionДокумент5 страницGlass Fiber Reinforced Gypsum Panel Use in Building ConstructionGRD JournalsОценок пока нет

- Contemporary Building MaterialsДокумент23 страницыContemporary Building MaterialsShif renОценок пока нет

- GypДокумент4 страницыGypshanky22Оценок пока нет

- Glass Fibre Reinforced Plastic and Its Architectural ApplicationsДокумент27 страницGlass Fibre Reinforced Plastic and Its Architectural ApplicationsVipul UttamchandaniОценок пока нет

- GRP Stands For Glass Reinforced Plastic or Glass Reinforced PolymerДокумент13 страницGRP Stands For Glass Reinforced Plastic or Glass Reinforced PolymerChoice NwikaОценок пока нет

- Fibre Reinforced Gypsum RiyaДокумент4 страницыFibre Reinforced Gypsum Riyariya mittalОценок пока нет

- PDS Glasroc-F-FIRECASE ENGL 1 PDFДокумент3 страницыPDS Glasroc-F-FIRECASE ENGL 1 PDFVlad TirzianОценок пока нет

- Green ConcreteДокумент14 страницGreen ConcreteChitransh RajatОценок пока нет

- Final Project ReportДокумент15 страницFinal Project ReportRishi Mehta100% (1)

- Using Gypsum BoardДокумент138 страницUsing Gypsum BoardkeitОценок пока нет

- BMCT GYPSUM FinalДокумент17 страницBMCT GYPSUM FinaltheinteriorlaneОценок пока нет

- Technology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemДокумент8 страницTechnology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemQ8123Оценок пока нет

- Anchor Boards-1Документ12 страницAnchor Boards-1Tabish MahfuzОценок пока нет

- Lining Systems: Geomembranes For Protecting Structures and The EnvironmentДокумент24 страницыLining Systems: Geomembranes For Protecting Structures and The Environmentcolic822Оценок пока нет

- Cem-FIL GRC Technical DataДокумент91 страницаCem-FIL GRC Technical Datacbler100% (1)

- Glass Fibre Reinforced ConcreteДокумент13 страницGlass Fibre Reinforced ConcretehanumОценок пока нет

- BMCT GYPSUMДокумент17 страницBMCT GYPSUMtheinteriorlaneОценок пока нет

- Glass Fiber Reinforced Concrete Made With Fly AshДокумент8 страницGlass Fiber Reinforced Concrete Made With Fly AshDharma banothuОценок пока нет

- 2 Gyproc Plasterboard Range: Main MenuДокумент23 страницы2 Gyproc Plasterboard Range: Main Menurealdaross100% (1)

- Gypsum PDFДокумент32 страницыGypsum PDFRUPESHKSОценок пока нет

- 3 Is GRC A Green Building MaterialДокумент7 страниц3 Is GRC A Green Building MaterialJuliano. PQMОценок пока нет

- Gypsum Plaster Boards - Specification: Indian StandardДокумент7 страницGypsum Plaster Boards - Specification: Indian StandardGopal SudhirОценок пока нет

- Practical Design Guide For Glass Reinforced ConcreteДокумент98 страницPractical Design Guide For Glass Reinforced ConcreteThompson LaiОценок пока нет

- Green ConcreteДокумент14 страницGreen ConcretePankajKumar100% (1)

- Revolutionary Graphene Applications For ConstructionДокумент5 страницRevolutionary Graphene Applications For ConstructionChandrakant VermaОценок пока нет

- DEVIДокумент10 страницDEVIDibyaranjan DasОценок пока нет

- TAH Climatic Altitude Chamber 1mДокумент1 страницаTAH Climatic Altitude Chamber 1mKrishna ChaitanyaОценок пока нет

- Solar Simulation Test Chamber FDL-02400 - R3Документ2 страницыSolar Simulation Test Chamber FDL-02400 - R3Krishna ChaitanyaОценок пока нет

- SAMSACT TVac Write Up & SpecДокумент6 страницSAMSACT TVac Write Up & SpecKrishna ChaitanyaОценок пока нет

- New P-300 Programmer/Controller: Get Improved Performance, Energy Savings, Plus USB or Ethernet AccessДокумент2 страницыNew P-300 Programmer/Controller: Get Improved Performance, Energy Savings, Plus USB or Ethernet AccessKrishna ChaitanyaОценок пока нет

- Temperature: Heat Transfer and Air Flow Analysis Environmental Chambers and Air ServosДокумент12 страницTemperature: Heat Transfer and Air Flow Analysis Environmental Chambers and Air ServosKrishna ChaitanyaОценок пока нет

- Outline of Environmental Condition and Testing Standards For Electrical and Electronic Equipment in Road Vehicles and Description of Related ProductsДокумент6 страницOutline of Environmental Condition and Testing Standards For Electrical and Electronic Equipment in Road Vehicles and Description of Related ProductsKrishna ChaitanyaОценок пока нет

- Microbiology Available Equipments Data As Per NABL FormatДокумент8 страницMicrobiology Available Equipments Data As Per NABL FormatKrishna ChaitanyaОценок пока нет

- S.No Equipments Description Manufacturers Range Accuracy REQUIRE MentДокумент3 страницыS.No Equipments Description Manufacturers Range Accuracy REQUIRE MentKrishna ChaitanyaОценок пока нет

- Micro Equipments Power Consumption DetailsДокумент6 страницMicro Equipments Power Consumption DetailsKrishna ChaitanyaОценок пока нет

- Method of MeasurementsДокумент41 страницаMethod of MeasurementsKrishna ChaitanyaОценок пока нет

- Columns TheoryДокумент112 страницColumns TheoryJosé Gualavisí100% (1)

- Bearing Capacity of Pile Foundation & Construction) - TinSoeДокумент78 страницBearing Capacity of Pile Foundation & Construction) - TinSoeBluebelgianОценок пока нет

- Partial Fixity BaseДокумент24 страницыPartial Fixity Basekhemindra narain100% (1)

- Assignment 4 Model Answer PDFДокумент8 страницAssignment 4 Model Answer PDFRyan HuangОценок пока нет

- Long ColumnДокумент10 страницLong ColumnSheenaMarieM.SalvadorОценок пока нет

- Structure Magazine 02 Feb 2019 PDFДокумент52 страницыStructure Magazine 02 Feb 2019 PDFmoizoro100% (1)

- CE530 Exercises 2021Документ3 страницыCE530 Exercises 2021jonathan katongoОценок пока нет

- Schedule of Structural MembersДокумент2 страницыSchedule of Structural MembersEljoy C. AgsamosamОценок пока нет

- Design of Purlin & Runner-Ro-Final-Rev-0Документ8 страницDesign of Purlin & Runner-Ro-Final-Rev-0Sabrina ImloulОценок пока нет

- Earthquake Resistant Design and Detailing of Steel BuildingsДокумент7 страницEarthquake Resistant Design and Detailing of Steel BuildingsYalamanchali KishoreОценок пока нет

- Rilem ProДокумент298 страницRilem ProEdwin MirandaОценок пока нет

- Tank AGC ModifДокумент63 страницыTank AGC ModifRedouane TebbouneОценок пока нет

- Calculation Sheet of Residential Building (Pile Caps Type)Документ143 страницыCalculation Sheet of Residential Building (Pile Caps Type)Anonymous ciKyr0t100% (1)

- Ce 113 - Concrete Pavement Behavior and CharacteristicsДокумент12 страницCe 113 - Concrete Pavement Behavior and CharacteristicsJacob John100% (3)

- How Do I Calculate Steel Reinforcement and Its Quantity in Slab, Beams, Columns and Footing For Given Dimensions - QuoraДокумент6 страницHow Do I Calculate Steel Reinforcement and Its Quantity in Slab, Beams, Columns and Footing For Given Dimensions - QuoraSheikh Nouman Mohsin Ramzi50% (2)

- Floor Slab Design "DDM"Документ142 страницыFloor Slab Design "DDM"batistathegameОценок пока нет

- Connection Design SheetДокумент47 страницConnection Design SheetStephen James100% (1)

- Beam CalculationДокумент93 страницыBeam CalculationFairus FizzОценок пока нет

- Thumb Rules FormulaДокумент13 страницThumb Rules FormulaRamesh MehraОценок пока нет

- Isolated Foundation Calculation Sheet: Greater Mekong Power Network Develvopment ProjectДокумент7 страницIsolated Foundation Calculation Sheet: Greater Mekong Power Network Develvopment ProjectSereyponleu Khun100% (1)

- Behaviour of Skew BridgeДокумент7 страницBehaviour of Skew BridgeSohan GeorgeОценок пока нет

- Design of Bending MembersДокумент21 страницаDesign of Bending MembersChico AlvesОценок пока нет

- Repair and Rehabiliation PDFДокумент210 страницRepair and Rehabiliation PDFSivaramakrishnaNalluri100% (1)

- C3 Fresh and Hardened Concrete TestДокумент11 страницC3 Fresh and Hardened Concrete TestSyukri Abd KadirОценок пока нет

- FM Global 1-55 Weak Construction and DesignДокумент18 страницFM Global 1-55 Weak Construction and DesignhungОценок пока нет

- Wang, Chu-Kia - Reinforced Concrete Design-Oxford University Press, USA (2017 - 2018)Документ993 страницыWang, Chu-Kia - Reinforced Concrete Design-Oxford University Press, USA (2017 - 2018)PROSPEROUS LUCKILY100% (1)

- MR JustinreestimatedagreementДокумент5 страницMR Justinreestimatedagreementshiva kumarОценок пока нет

- OutputДокумент78 страницOutputSAI ASSOCIATE100% (1)

- Rectangle BeamДокумент5 страницRectangle BeamAlok SarkarОценок пока нет

- Chapter 1 5 FinalДокумент41 страницаChapter 1 5 FinalLorenaОценок пока нет