Академический Документы

Профессиональный Документы

Культура Документы

Chiller Maintenance List

Загружено:

adnan100%(7)100% нашли этот документ полезным (7 голосов)

4K просмотров1 страницаChiller maintenace file

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документChiller maintenace file

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

100%(7)100% нашли этот документ полезным (7 голосов)

4K просмотров1 страницаChiller Maintenance List

Загружено:

adnanChiller maintenace file

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

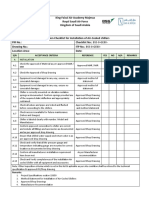

Chiller Maintenance Checklist #4

Maintenance

Description Comment Frequency

Daily Weekly Month Annua

l

Overall Visual Complete overall visual inspection to be sure

Inspection all equipment is operating and that safety X

systems are in place.

Leak testing Conduct leak testing on all compressor

fittings, oil pump joints and fitting, and relief X

valves

Check set points Check all set point for proper setting and

function. X

Evaporator and Assess evaporator and condenser coil fouling

condenser coil as required. X

fouling

Compressor motor Check temperature as per manufacturer’s

temperature specifications. X

Chiller use and Turn off or sequence unnecessary chillers.

sequencing X

Check all Check insulation for condition and

insulation appropriateness. X

Control operation Verify proper control function including:

X

Hot gas bypass

Liquid injection

Check vane Check settings as per manufacturer’s

control setting specification. X

Verify motor load Check setting as per manufacture’s

limit control specification. X

Verify motor Check setting as per manufacture’s

balance operation specification. X

Check chilled Check setting as per manufacture’s

water reset specification. X

settings and

function

Check chiller Check setting as per manufacture’s

locknut set point specification. X

Clean condenser Clean tubes at least annually as part of

tubes shutdown procedures. X

Вам также может понравиться

- Chiller Maintenance ChecklistДокумент2 страницыChiller Maintenance ChecklistAssem Elhajj100% (17)

- Cooling Tower ChecklistДокумент2 страницыCooling Tower ChecklistLaiq100% (4)

- Fans Checklist: Project Name: Project Ref. No.: Owner: Department: GroupДокумент1 страницаFans Checklist: Project Name: Project Ref. No.: Owner: Department: GroupAlvin BadzОценок пока нет

- Boiler Maintenance ChecklistДокумент2 страницыBoiler Maintenance ChecklistRidwanAlwi50% (4)

- Chiller ChecklistДокумент3 страницыChiller ChecklistMohammed SayeeduddinОценок пока нет

- Centrifugal Chiller Maintenance ChecklistДокумент1 страницаCentrifugal Chiller Maintenance Checklistosama alabsiОценок пока нет

- Chillers Daily Preventive MaintenanceДокумент2 страницыChillers Daily Preventive MaintenanceEhteshem Mazhari0% (1)

- Present Chiller 2 Log Sheet.....Документ1 страницаPresent Chiller 2 Log Sheet.....Madan Tiwari100% (1)

- Chiller Maintenance Procedure PDFДокумент4 страницыChiller Maintenance Procedure PDFMd. Yusuf100% (1)

- Chiller Maintenance ChecklistДокумент2 страницыChiller Maintenance ChecklistMd Rizwan Khan100% (3)

- Water Cooled Chiller - SOPДокумент13 страницWater Cooled Chiller - SOParunceedee100% (4)

- Air Cooled Package Units Roof Top Unit - AnnuallyДокумент2 страницыAir Cooled Package Units Roof Top Unit - AnnuallyDreamlinerОценок пока нет

- Chiller ChecklistДокумент18 страницChiller Checklistavinash rathod100% (1)

- FCU ChecklistДокумент11 страницFCU Checklistsiva ramakrishnanОценок пока нет

- Standard Operating Procedure For Ahu Start & StopДокумент2 страницыStandard Operating Procedure For Ahu Start & Stopdeekshitkumar77100% (1)

- Cooling Tower Construction ChecklistДокумент6 страницCooling Tower Construction ChecklistGopinath GopiОценок пока нет

- Coldroom Installation ChecklistДокумент3 страницыColdroom Installation ChecklistBedan KivuvaОценок пока нет

- Chiller Troubleshooting CheckListДокумент2 страницыChiller Troubleshooting CheckListMac Gerrard93% (15)

- Chiller Testing Procedure Rev 3Документ11 страницChiller Testing Procedure Rev 3Ali AimranОценок пока нет

- Air-Cooled Chillers Maintenance & Inspection ChecklistДокумент3 страницыAir-Cooled Chillers Maintenance & Inspection ChecklistdjukalОценок пока нет

- Hvac PM Service Checklist ContractorДокумент1 страницаHvac PM Service Checklist Contractorudupiganesh3069100% (1)

- Operations and Maintenance Preventive Maintenance Checklists PDFДокумент35 страницOperations and Maintenance Preventive Maintenance Checklists PDFAdewale BamgbadeОценок пока нет

- SOP For Air Handling UnitДокумент10 страницSOP For Air Handling UnitFaisal Ahmed100% (1)

- Testing & Commissioning of Fan Coil Units FCU'sДокумент3 страницыTesting & Commissioning of Fan Coil Units FCU'svin ssОценок пока нет

- Mannai Corporation: Mannai Trading Co. WLLДокумент18 страницMannai Corporation: Mannai Trading Co. WLLAyu Oktaviani100% (2)

- Sop of Maintenance of Air Conditioning UnitsДокумент9 страницSop of Maintenance of Air Conditioning Unitsruhy690Оценок пока нет

- Maintenance & Troubleshoot AHUДокумент11 страницMaintenance & Troubleshoot AHUEva Sulistiany100% (2)

- 04 Inspection Checklist - Installation of Air-Cooled ChillersДокумент2 страницы04 Inspection Checklist - Installation of Air-Cooled ChillersBabar Shehzad100% (3)

- Chiller Plant CommissioningДокумент38 страницChiller Plant Commissioningavbsky100% (1)

- Sequence of Operation ChillerДокумент2 страницыSequence of Operation ChillerOoi Tze Hoong60% (5)

- Method Statement For Installation of Pre Fabricated HVAC DuctsДокумент3 страницыMethod Statement For Installation of Pre Fabricated HVAC Ductsamg007Оценок пока нет

- 4 Commissioning Report of VRF CassetteДокумент4 страницы4 Commissioning Report of VRF CassetteMohammed IqbalОценок пока нет

- Standard Operating Procedure - HVAC - V01 - 29082010Документ10 страницStandard Operating Procedure - HVAC - V01 - 29082010Karthik MandyaОценок пока нет

- Air Handling Unit QC Checklist: AHU InformationДокумент5 страницAir Handling Unit QC Checklist: AHU InformationRaheel AhmedОценок пока нет

- VRF Test MethodДокумент6 страницVRF Test Methodprado01Оценок пока нет

- VRF Execution Check ListДокумент2 страницыVRF Execution Check ListSkill IndiaОценок пока нет

- Method Statement For Installation of Chillers Rev 1 - AFUДокумент12 страницMethod Statement For Installation of Chillers Rev 1 - AFUAzwan SunlineОценок пока нет

- Yaep York CatalogueДокумент36 страницYaep York Cataloguecysauts58% (12)

- Chiller Testing Procedure Rev 3 PDFДокумент11 страницChiller Testing Procedure Rev 3 PDFOanh NguyenОценок пока нет

- ACU PM Checklist AДокумент1 страницаACU PM Checklist Aamdesilva125100% (1)

- Method Statement For Air Leak Test For HVAC Duct System Light TestДокумент18 страницMethod Statement For Air Leak Test For HVAC Duct System Light TestAhmed Omar100% (2)

- Weekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekДокумент8 страницWeekly Maintenance Checks: Ensure Daily Checklist Has Been Completed and Signed Off For This WeekfcfernandoОценок пока нет

- Method Statement For Testing & Commissioning of AHUДокумент4 страницыMethod Statement For Testing & Commissioning of AHUsamsul maarif100% (1)

- Checklist For Installation of Pressurization UnitДокумент1 страницаChecklist For Installation of Pressurization Unitvictor100% (3)

- CHILLER - Service SOPДокумент6 страницCHILLER - Service SOPsambasivamme100% (1)

- cOMMISSIONING 1 - WorksheetДокумент60 страницcOMMISSIONING 1 - WorksheetPramod Dhir100% (1)

- Method Statement of Chiller Preventive MaintenanceДокумент5 страницMethod Statement of Chiller Preventive MaintenanceBalajiОценок пока нет

- Air Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationДокумент6 страницAir Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationGopinath GopiОценок пока нет

- Cleaning and Flushing of The Chilled Water Piping SystemДокумент2 страницыCleaning and Flushing of The Chilled Water Piping Systemsujan198086% (14)

- Condenser Water Piping Construction Checklist: Project: Date: Building: LocationДокумент4 страницыCondenser Water Piping Construction Checklist: Project: Date: Building: LocationGopinath GopiОценок пока нет

- PPM - Chilled Water PumpДокумент1 страницаPPM - Chilled Water PumpMohammed Sayeeduddin100% (2)

- Johnson Controls YK Chiller Operation and Maintenance ManualДокумент38 страницJohnson Controls YK Chiller Operation and Maintenance ManualYuche ChangОценок пока нет

- Testing & Commissioning of Chilled Water PumpsДокумент3 страницыTesting & Commissioning of Chilled Water Pumpsamg00733% (3)

- Boiler ChecklistДокумент3 страницыBoiler ChecklistSegamaha Palm Oil Mill33% (3)

- Checklist For Cooling System MaintenanceДокумент1 страницаChecklist For Cooling System MaintenanceK.Sivanathan33% (3)

- 160 54-MR1Документ3 страницы160 54-MR1Areeb FizaОценок пока нет

- Maintenanace Proposal NAF Officers Mess & Suites AC PDFДокумент9 страницMaintenanace Proposal NAF Officers Mess & Suites AC PDFM.Y AbdulrahimОценок пока нет

- 160 54-MR1 PDFДокумент1 страница160 54-MR1 PDFghilesОценок пока нет

- Maintenance Schedule - MOL - WH64 Manual - Rev. 01 PDFДокумент2 страницыMaintenance Schedule - MOL - WH64 Manual - Rev. 01 PDFJaadi 786100% (1)

- Preventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceДокумент1 страницаPreventative Maintenance Tasks Sheet: Item Weekly Service Monthly ServiceMohammad Anwar0% (1)

- User S Manual AURORA 1.2K - 2.2KДокумент288 страницUser S Manual AURORA 1.2K - 2.2KEprom ServisОценок пока нет

- Android Developer PDFДокумент2 страницыAndroid Developer PDFDarshan ChakrasaliОценок пока нет

- The Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderДокумент7 страницThe Use of Air Cooled Heat Exchangers in Mechanical Seal Piping Plans - SnyderJaime Ocampo SalgadoОценок пока нет

- Gods Omnipresence in The World On Possible MeaninДокумент20 страницGods Omnipresence in The World On Possible MeaninJoan Amanci Casas MuñozОценок пока нет

- Damodaram Sanjivayya National Law University Visakhapatnam, A.P., IndiaДокумент25 страницDamodaram Sanjivayya National Law University Visakhapatnam, A.P., IndiaSumanth RoxtaОценок пока нет

- B122 - Tma03Документ7 страницB122 - Tma03Martin SantambrogioОценок пока нет

- Human EpigenomicsДокумент234 страницыHuman EpigenomicsHeron HilárioОценок пока нет

- SimovertДокумент41 страницаSimovertRamez YassaОценок пока нет

- Linguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowДокумент2 страницыLinguistics Is Descriptive, Not Prescriptive.: Prescriptive Grammar. Prescriptive Rules Tell You HowMonette Rivera Villanueva100% (1)

- Leigh Shawntel J. Nitro Bsmt-1A Biostatistics Quiz No. 3Документ6 страницLeigh Shawntel J. Nitro Bsmt-1A Biostatistics Quiz No. 3Lue SolesОценок пока нет

- Read While Being Blind.. Braille's Alphabet: Be Aware and Active !Документ3 страницыRead While Being Blind.. Braille's Alphabet: Be Aware and Active !bitermanОценок пока нет

- Companyprofil E: Erfanconstructionsolut IonДокумент14 страницCompanyprofil E: Erfanconstructionsolut IonNurin AleesyaОценок пока нет

- Arnold Ventures Letter To Congressional Social Determinants of Health CaucusДокумент7 страницArnold Ventures Letter To Congressional Social Determinants of Health CaucusArnold VenturesОценок пока нет

- 18 June 2020 12:03: New Section 1 Page 1Документ4 страницы18 June 2020 12:03: New Section 1 Page 1KarthikNayakaОценок пока нет

- Gemini Dollar WhitepaperДокумент7 страницGemini Dollar WhitepaperdazeeeОценок пока нет

- Task 3 - LPДокумент21 страницаTask 3 - LPTan S YeeОценок пока нет

- Analizador de Combustion Kigaz 310 Manual EngДокумент60 страницAnalizador de Combustion Kigaz 310 Manual EngJully Milagros Rodriguez LaicheОценок пока нет

- Science7 - q1 - Mod3 - Distinguishing Mixtures From Substances - v5Документ25 страницScience7 - q1 - Mod3 - Distinguishing Mixtures From Substances - v5Bella BalendresОценок пока нет

- Iec TR 61010-3-020-1999Документ76 страницIec TR 61010-3-020-1999Vasko MandilОценок пока нет

- Dtu Placement BrouchureДокумент25 страницDtu Placement BrouchureAbhishek KumarОценок пока нет

- User Manual For Speed Control of BLDC Motor Using DspicДокумент12 страницUser Manual For Speed Control of BLDC Motor Using DspicTrung TrựcОценок пока нет

- B. Geoinformatics PDFДокумент77 страницB. Geoinformatics PDFmchakra720% (1)

- Azimuth Steueung - EngДокумент13 страницAzimuth Steueung - EnglacothОценок пока нет

- FMC Derive Price Action GuideДокумент50 страницFMC Derive Price Action GuideTafara MichaelОценок пока нет

- Agco Serie 800 PDFДокумент24 страницыAgco Serie 800 PDFJohnny VargasОценок пока нет

- Problem Set-02Документ2 страницыProblem Set-02linn.pa.pa.khaing.2020.2021.fbОценок пока нет

- E MudhraDownload HardДокумент17 страницE MudhraDownload HardVivek RajanОценок пока нет

- Crown WF-3000 1.2Документ5 страницCrown WF-3000 1.2Qirat KhanОценок пока нет

- Chemistry: Crash Course For JEE Main 2020Документ18 страницChemistry: Crash Course For JEE Main 2020Sanjeeb KumarОценок пока нет

- Week 7 Sex Limited InfluencedДокумент19 страницWeek 7 Sex Limited InfluencedLorelyn VillamorОценок пока нет