Академический Документы

Профессиональный Документы

Культура Документы

M.M.A. Welding Electrode

Загружено:

cwiksjОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

M.M.A. Welding Electrode

Загружено:

cwiksjАвторское право:

Доступные форматы

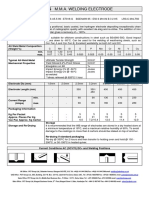

WB2418E M.M.A.

WELDING ELECTRODE

Classifications AWS A5.5 : E10018-M

Approvals ABS : 4YQ500

All positional, basic coated, low hydrogen electrode depositing exceptionally clean

Product Description metal of radiographic quality. The addition of iron powder gives a recovery of ∼ 120%.

Excellent impact values at sub-zero temperatures. Excellent de-slag and welder

appeal.

Applications Widely used for the welding of steels with a tensile strength of 700/800 N/mm², such

as RQT600, HY80 and NAXTRA 70

All-Weld Metal Composition

(Weight %) C Mn Si S P Mo Cr Ni V

min. 0.02 0.75 0.20 - - 0.20 - 1.40 -

max. 0.06 1.70 0.50 0.020 0.025 0.50 0.05 2.10 0.05

Typical All-Weld Metal Ultimate Tensile Strength N/mm² 730

Mechanical Properties Yield Stress/0.2% Proof Stress N/mm² 650

Elongation on 5D % 22

Impact Energy CV @ -51°C Joules 60

As-welded

Electrode Dia (mm) 1.6mm 2.0mm 2.5mm 3.2mm 4.0mm 5.0mm 6.0mm

Electrode Length (mm) - - 350 450 450 450 450

min. - - 60 105 140 160 220

Current Range

(Amps) max. - - 90 140 180 210 280

Packaging Information

Kg Per Vac-Pac Packet - - 2 2 2 2 2

Approx. Pieces Per Kg - - 44 21 15 10 7

Kg Carton - - 20 20 20 20 20

Storage

Storage and Re-Drying It is recommended that the WB range of electrodes are stored in a dry heated store at

a minimum temperature of 18°C, and a maximum relative humidity of 60%. To avoid

damage to the coatings no more than 6 cartons should be staked on top of another.

Re-drying if standard packaging

Re-dry @ 350°C for 2 hours and then transfer to holding oven and hold @ 100 -

200°C, or 50-100°C in heated quiver.

Current Conditions AC OCV70 DC +/- and Welding Positions

Вам также может понравиться

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesОт EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesРейтинг: 4.5 из 5 звезд4.5/5 (7)

- 3050 Using This Manual: Chevron Corporation 3050-1 August 1999Документ8 страниц3050 Using This Manual: Chevron Corporation 3050-1 August 1999milecsa100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Superduplex Welding Procedure Specification (WPSДокумент4 страницыSuperduplex Welding Procedure Specification (WPSClaudia Mms100% (3)

- Distillation Column ReportДокумент81 страницаDistillation Column ReportJaspreet Singh67% (9)

- Technip FMC Matl Selection Philosophy - Pages From B224-125-86-41-TA-01 - 0 - A-1Документ26 страницTechnip FMC Matl Selection Philosophy - Pages From B224-125-86-41-TA-01 - 0 - A-1Swath M MuraliОценок пока нет

- Eil Spec Bo16-000-80-44-Ol-S001 Rev AДокумент2 страницыEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganОценок пока нет

- Analysis of Vitamin C in Food by HPLCДокумент4 страницыAnalysis of Vitamin C in Food by HPLCanon_123827560% (1)

- Aisi 304Документ2 страницыAisi 304Rohit100% (1)

- Wb2318e E9018-MДокумент1 страницаWb2318e E9018-McwiksjОценок пока нет

- M.M.A. Welding ElectrodeДокумент1 страницаM.M.A. Welding ElectrodecwiksjОценок пока нет

- WB56S M.M.A. Welding Electrode for Offshore FabricationsДокумент1 страницаWB56S M.M.A. Welding Electrode for Offshore FabricationscwiksjОценок пока нет

- M.M.A. Welding Electrode: Classifications & ApprovalsДокумент1 страницаM.M.A. Welding Electrode: Classifications & ApprovalscwiksjОценок пока нет

- M.M.A. welding electrode for Martensitic stainless steelsДокумент1 страницаM.M.A. welding electrode for Martensitic stainless steelscwiksjОценок пока нет

- Wb1700e Enicu-BДокумент1 страницаWb1700e Enicu-BcwiksjОценок пока нет

- All-position stainless steel electrode for difficult weldsДокумент1 страницаAll-position stainless steel electrode for difficult weldscwiksjОценок пока нет

- WB35S welding electrodeДокумент1 страницаWB35S welding electrodelathasri78Оценок пока нет

- WB56S M.M.A. welding electrode specificationsДокумент1 страницаWB56S M.M.A. welding electrode specificationslathasri78Оценок пока нет

- WB88SHR M.M.A. welding electrode propertiesДокумент1 страницаWB88SHR M.M.A. welding electrode propertieslathasri78Оценок пока нет

- WB5525E MMA Welding Electrode Spec SheetДокумент1 страницаWB5525E MMA Welding Electrode Spec SheetcwiksjОценок пока нет

- WB4303EДокумент1 страницаWB4303EcwiksjОценок пока нет

- All-Purpose Welding ElectrodeДокумент1 страницаAll-Purpose Welding ElectrodecwiksjОценок пока нет

- Wb76S M.M.A. Welding Electrode: Classifications & ApprovalsДокумент1 страницаWb76S M.M.A. Welding Electrode: Classifications & Approvalslathasri78Оценок пока нет

- Wb2092e E7024Документ1 страницаWb2092e E7024cwiksjОценок пока нет

- Wb1500e Eni CiДокумент1 страницаWb1500e Eni CicwiksjОценок пока нет

- Wb1700e Enicu-BДокумент1 страницаWb1700e Enicu-BcwiksjОценок пока нет

- 90 MN CR V8Документ1 страница90 MN CR V8arunajay724Оценок пока нет

- WB9009E M.M.A. Welding Electrode Product InformationДокумент1 страницаWB9009E M.M.A. Welding Electrode Product Informationlathasri78Оценок пока нет

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesДокумент6 страниц2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobОценок пока нет

- 1564 Fox Ev 85 ElettrodoДокумент1 страница1564 Fox Ev 85 ElettrodoAminОценок пока нет

- ASM Material Data Sheet PDFДокумент2 страницыASM Material Data Sheet PDFtiele_barcelosОценок пока нет

- X17CrNi16 2Документ2 страницыX17CrNi16 2madodandembeОценок пока нет

- LFBCW510L TN enДокумент4 страницыLFBCW510L TN endrgilleОценок пока нет

- TT - Electronics 898 3 R100K Datasheet PDFДокумент4 страницыTT - Electronics 898 3 R100K Datasheet PDFelnegritoheberОценок пока нет

- Electrode Booklet F Web 21Документ1 страницаElectrode Booklet F Web 21satnamОценок пока нет

- Supabase-X-Plus AdorДокумент1 страницаSupabase-X-Plus AdorJagan TnОценок пока нет

- X Bond: Welding Electrode For Structural Welding ApplicationДокумент1 страницаX Bond: Welding Electrode For Structural Welding ApplicationAmit ChapagainОценок пока нет

- Railrod: Data SheetДокумент1 страницаRailrod: Data Sheetmohamed AdelОценок пока нет

- Section 2 - Nikko Welding ConsumablesДокумент9 страницSection 2 - Nikko Welding Consumablesangga franugrahaОценок пока нет

- Typical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationДокумент1 страницаTypical Tensile Properties: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationKukuh YuonoОценок пока нет

- en GB FactSheet Main 01Документ1 страницаen GB FactSheet Main 01Chandra YudistiraОценок пока нет

- ASM Material Data Sheet 304Документ2 страницыASM Material Data Sheet 304.xОценок пока нет

- CZLLCW511L TN enДокумент4 страницыCZLLCW511L TN endrgilleОценок пока нет

- Tenalloy Z PlusДокумент1 страницаTenalloy Z Plushemal ChauhanОценок пока нет

- 12a DPST Miniature Power RelayДокумент2 страницы12a DPST Miniature Power RelaykarkeraОценок пока нет

- Low alloy electrodes for welding high-strength steels with OK 75.75Документ1 страницаLow alloy electrodes for welding high-strength steels with OK 75.75corsini999Оценок пока нет

- CLC4003 HardnessДокумент5 страницCLC4003 Hardnessarif.haddieОценок пока нет

- Copper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. WebДокумент7 страницCopper-Nickel Cu-Ni 90/10 Alloy (UNS C70600) : Heanjia Super-Metals Co., LTD, Call-12068907337. Webboydoc inspectionОценок пока нет

- YAWATA 7018: Classification Applications Characteristics ApprovalsДокумент1 страницаYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusОценок пока нет

- Wire Wound Resistors GuideДокумент7 страницWire Wound Resistors GuideteoilcaОценок пока нет

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenДокумент2 страницыProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87Оценок пока нет

- T90 A230xsmdДокумент2 страницыT90 A230xsmdhgfgffgfggffgОценок пока нет

- 21CrMoV5 7Документ2 страницы21CrMoV5 7zamporpsОценок пока нет

- F For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationДокумент1 страницаF For .: Approvals Are Based On Factory Location. Please Contact ESAB For More InformationTolga UZUNERОценок пока нет

- Sandvik 3re60 Tube and Pipe, Seamless: DatasheetДокумент10 страницSandvik 3re60 Tube and Pipe, Seamless: DatasheetVinay TrivediОценок пока нет

- Relé RY SchrackДокумент4 страницыRelé RY SchrackRogério PereiraОценок пока нет

- American - Zettler AZ732 053 52 DatasheetДокумент2 страницыAmerican - Zettler AZ732 053 52 DatasheetZoro DОценок пока нет

- Martensitic Stainless Steel EN 1.4057, QT 800Документ2 страницыMartensitic Stainless Steel EN 1.4057, QT 800LebasОценок пока нет

- En 1 4057 - 1408 Valbruna Nordic EnglishДокумент2 страницыEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67Оценок пока нет

- Resistor ArrayДокумент5 страницResistor ArrayJuampa ChruscielОценок пока нет

- Bohler Fox N CM 2 KBДокумент1 страницаBohler Fox N CM 2 KBkamals55Оценок пока нет

- AW60Документ1 страницаAW60Fitra VertikalОценок пока нет

- CM-9CB TG-S9Cb US-9CbДокумент3 страницыCM-9CB TG-S9Cb US-9Cbamit singhОценок пока нет

- Ok 68.55Документ1 страницаOk 68.55Sadashiva sahooОценок пока нет

- Daikoflux 940 ESW cladding flux data sheetДокумент1 страницаDaikoflux 940 ESW cladding flux data sheetcwiksjОценок пока нет

- Specifications: Product TypeДокумент1 страницаSpecifications: Product TypecwiksjОценок пока нет

- N004 - Daiko Strip 625Документ1 страницаN004 - Daiko Strip 625cwiksjОценок пока нет

- Hardfacing Wood Chipper KnivesДокумент1 страницаHardfacing Wood Chipper KnivescwiksjОценок пока нет

- Carboklad Cr36 Data SheetДокумент1 страницаCarboklad Cr36 Data SheetcwiksjОценок пока нет

- Robo TiPTiG Data Sheet FinalДокумент2 страницыRobo TiPTiG Data Sheet FinalcwiksjОценок пока нет

- Specifications: Product TypeДокумент1 страницаSpecifications: Product TypecwiksjОценок пока нет

- NiCrFe alloy welding electrodeДокумент1 страницаNiCrFe alloy welding electrodeRoberto_PrrОценок пока нет

- Wb1700e Enicu-BДокумент1 страницаWb1700e Enicu-BcwiksjОценок пока нет

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsДокумент3 страницыRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjОценок пока нет

- A Max WearplateДокумент1 страницаA Max WearplatecwiksjОценок пока нет

- Wb1700e Enicu-BДокумент1 страницаWb1700e Enicu-BcwiksjОценок пока нет

- Red To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorsДокумент3 страницыRed To (-) Negative and Yellow To (+) Positive When Connecting Wires To ConnectorscwiksjОценок пока нет

- Meeting Minutes Roberts RulesДокумент1 страницаMeeting Minutes Roberts RulessaeedОценок пока нет

- IN150 ProHeat 35 WaterCooled Induction System EnglishДокумент4 страницыIN150 ProHeat 35 WaterCooled Induction System EnglishCARLOSОценок пока нет

- All-position stainless steel electrode for difficult weldsДокумент1 страницаAll-position stainless steel electrode for difficult weldscwiksjОценок пока нет

- Wb2092e E7024Документ1 страницаWb2092e E7024cwiksjОценок пока нет

- WB4303EДокумент1 страницаWB4303EcwiksjОценок пока нет

- WB5525E MMA Welding Electrode Spec SheetДокумент1 страницаWB5525E MMA Welding Electrode Spec SheetcwiksjОценок пока нет

- All-Purpose Welding ElectrodeДокумент1 страницаAll-Purpose Welding ElectrodecwiksjОценок пока нет

- Wb2092e E7024Документ1 страницаWb2092e E7024cwiksjОценок пока нет

- Wb1700e Enicu-BДокумент1 страницаWb1700e Enicu-BcwiksjОценок пока нет

- Wb1500e Eni CiДокумент1 страницаWb1500e Eni CicwiksjОценок пока нет

- Wb1500e Eni CiДокумент1 страницаWb1500e Eni CicwiksjОценок пока нет

- Wb2092e E7024Документ1 страницаWb2092e E7024cwiksjОценок пока нет

- CHE 507 1st Lectures PresentationДокумент34 страницыCHE 507 1st Lectures PresentationTahiru SakaОценок пока нет

- Oreas 402Документ2 страницыOreas 402flysch_ukОценок пока нет

- Introduction To Materials ScienceДокумент13 страницIntroduction To Materials ScienceEmmanuel OlalekanОценок пока нет

- MMAW and SAW Refresher Course - ANBДокумент55 страницMMAW and SAW Refresher Course - ANBdayalram0% (1)

- Biodegradation of Low Density Polyethylene LDPE by Mesophilic Fungus Penicillium Citrinum Isolated From Soils of Plastic WasteДокумент16 страницBiodegradation of Low Density Polyethylene LDPE by Mesophilic Fungus Penicillium Citrinum Isolated From Soils of Plastic WasteKewin HernandezОценок пока нет

- The Preparation of Acetic Acid For Use in Otic Drops and Its Effect On Endocochlear Potential and PH in Inner Ear FluidДокумент4 страницыThe Preparation of Acetic Acid For Use in Otic Drops and Its Effect On Endocochlear Potential and PH in Inner Ear Fluidronahaniifah11Оценок пока нет

- Acids 1Документ22 страницыAcids 1Pratima JainОценок пока нет

- Halogenated Hydrocarbons WorksheetДокумент3 страницыHalogenated Hydrocarbons Worksheetjiya jainОценок пока нет

- Avoiding Penetration Defects ThroughДокумент3 страницыAvoiding Penetration Defects ThroughOscar SotomayorОценок пока нет

- Gas ConcentrationsДокумент10 страницGas ConcentrationsHadrien FaryalaОценок пока нет

- SolutionsДокумент9 страницSolutionsKota Venkata SukumarОценок пока нет

- Odic Table Periodicity NeetДокумент59 страницOdic Table Periodicity NeetAnubhav KohliОценок пока нет

- AspirinДокумент15 страницAspirinBryanОценок пока нет

- Electrochemistry: 0 8 0 79 0 34 2 37 Ag / Ag - HG / HG - Cu / Cu - MG / MGДокумент11 страницElectrochemistry: 0 8 0 79 0 34 2 37 Ag / Ag - HG / HG - Cu / Cu - MG / MGAnikin Skywalker100% (1)

- Ceridust 5551 - For Lively Colors.: Exactly Your ChemistryДокумент2 страницыCeridust 5551 - For Lively Colors.: Exactly Your ChemistryMaximiliano MackeviciusОценок пока нет

- Chemistry Data BookletДокумент22 страницыChemistry Data BookletIsaline GurneОценок пока нет

- INTRODUCTION ProjectДокумент11 страницINTRODUCTION Projectalive computerОценок пока нет

- MULTIPLAZ 3500 Operating ManualДокумент48 страницMULTIPLAZ 3500 Operating ManualarmindaОценок пока нет

- 24 Acid-Base TitrationДокумент5 страниц24 Acid-Base Titrationgardarr11Оценок пока нет

- Coco Gly PDFДокумент8 страницCoco Gly PDFАнна МарчукОценок пока нет

- Acronal 7808: Polymer Dispersions For ConstructionДокумент2 страницыAcronal 7808: Polymer Dispersions For ConstructionLong An ĐỗОценок пока нет

- Nominal Size 20mm (/ In) : Flange TablesДокумент1 страницаNominal Size 20mm (/ In) : Flange TablesReşat DEMİRОценок пока нет

- Marshall's Reagent: Origins, Modifications, and New ApplicationsДокумент2 страницыMarshall's Reagent: Origins, Modifications, and New Applicationso_l_0Оценок пока нет

- Percent API Content Per TabletДокумент3 страницыPercent API Content Per TabletRey BrondaОценок пока нет

- Catalysis and Catalytic Reactors: 10.1 CatalystsДокумент13 страницCatalysis and Catalytic Reactors: 10.1 CatalystsKubra Ėdris100% (1)

- Utilization of Distillery Slops and Gelatin to Produce Slow-Release FertilizerДокумент38 страницUtilization of Distillery Slops and Gelatin to Produce Slow-Release FertilizerDizОценок пока нет