Академический Документы

Профессиональный Документы

Культура Документы

Adsorptive and Chromato Separations of Life Science Molecules II

Загружено:

BabbooАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Adsorptive and Chromato Separations of Life Science Molecules II

Загружено:

BabbooАвторское право:

Доступные форматы

Adsorptive and DOWNSTREAM

PROCESSING

chromatographic

separations of life

science molecules. published by srl

Via Cesare da Sesto, 10

20123 Milano (Italy)

Part II – Process Tel. 0039 02 83241119

Fax 0039 02 8376457

www.b5srl.com

design and scale-up *

T

he exercise of designing a membrane columns (1). The basic idea

chromatographic separation is provision of low pressure system that ARVIND LALI 1

technology essentially involves at the same time affords large number of SANDEEP KALE 1

UMESH INGLE 1

three steps: theoretical plates per unit column height. SILVIA NICOTRA 2

– Selection of media and scouting for Maximum allowable pressure drop PAOLO CAIMI 2

best protocol; determines the limiting linear flow MORENO DAMINATI 2

– Optimizing the protocol for purity and velocity through an adsorbent bed. The MATTEO VILLA 3

productivity; and larger this velocity the better is the 1. Chemical Engineering Division

– Scaling up and design of the process adsorbent from a throughput standpoint. Institute of Chemical Technology

and equipment. Soft gel matrices like those based on Matunga, Mumbai, India 400 019

In Part I of this two paper series we agarose, cellulose or dextran permit low aml@udct.org

discussed some basic aspects pertaining to velocities due to their compressible

2. Resindion Srl

adsorbent media properties and their nature and hence scale-up results in Via Roma, 55

bearing on selection for a given application. large diameter short height columns. 20082 Binasco (MI), Italy

Optimizing an operation at marketing@resindion.com

laboratory or semi- Table I – Maximum permissible linear flow velocity

3. Hydro Air Research SpA

preparatory scale involves for various matrices Strada Provinciale 181, 11

optimizing the operation 26833 Merlino (LO), Italy

with respect to flow rate,

pressure drop,

productivity, and

resolution. A high

inter-phase mass transfer

rate is desirable at the

lowest possible pressure

drop. Unfortunately these

two objectives work

against each other. Solute

mass transfer rate from

mobile to stationary phase

is inversely proportional to

square of particle

diameter, and so is the

bed pressure drop. Hence

any attempt to reduce particle size to Rigid adsorbents on the other hand,

improve mass transfer results in increasing permit high velocity and thus higher

pressure drop and reduction of throughput. throughput. Table I gives the comparison

of maximum permissible linear velocities

Process design approach to overcome on different types of resins used in Part I – Selection

the above mentioned catch has evolved preparative scale chromatography. of adsorbent

several solutions like expanded bed Solute mass transfer rate is reflected

Dynamics of adsorption -

adsorption, monolithic columns, super in HETP, lower HETP signifying faster

Thermodynamics and

porous beaded adsorbents and rates of mass transfer. Low HETP bed will

fluid dynamics

not only give sharp breakthrough profiles

and higher dynamic binding capacity, but Sepabeads® media

* Part I – This journal – 2005, October, also result in sharper peaks and Media selection

p. 52-55 increased resolutions. However, as Summary

DOWNSTREAM PROCESSING NOVEMBER/DECEMBER 2005 37

pointed above, EXPANDED adopts a combination of both approaches

HETP is directly BED since using mere one of the two

related to particle ADSORPTION approaches has been observed to cause

diameter, and also bed instabilities leading to deterioration of

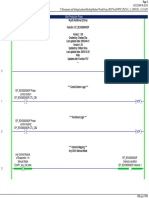

increases with flow Sepabeads® EB bed performance. Figure 3 gives the bed

rate. Figure 1 is a range of expansion characteristics of

typical variation of adsorbents Sepabeads® EB in comparison with other

HETP with linear (Figure 2) have available matrices.

mobile phase been developed in It generally appears that EBA

velocity. It is particle sizes that technology has not achieved the

important to note make them useful potential that was once considered

that an increase in for both packed possible. A number of reasons may be

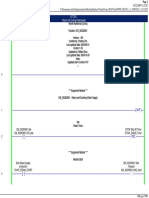

linear velocity does Figure 1 – Variation of HETP with flow velocity. bed and given. One reason seems to be the lack

not result in For a given CV/hour it is always safe to increase of variety of adsorbents intended for

expanded bed

linear velocity for scale-up and still have

increased HETP to operations. EBA EBA. An EBA adsorbent is given to far

reasonable number of N

the same degree. (Expanded Bed rougher environment than a packed bed

This implies that a column can be Adsorption) is useful when adsorption can adsorbent. Thus a rigid adsorbent may

operated at increased velocity for higher be possible directly from the particulate be preferred. Secondly, it appears that

throughput with lesser corresponding loss matter containing crudes without considerable care needs to be exercised

on number of plates. Hence, an intervening solid-liquid separation steps to ensure stable bed throughout the

important scale-up sequence of operations.

criterion can simply be An expanded bed can

to use higher bed destabilize either due to

height at highest incorrect hydrodynamic

allowable linear flow design of the column,

rate for the adsorbent and/or due to

in use. Naturally, rigid operational

adsorbents thus can discontinuities. In

be used with higher collaboration with

bed heights giving Hydro Air Research and

required number of Resindion, we have

plates at higher been into development

throughput in column of a column design with

diameters lesser than associated

those required for soft instrumentation that not

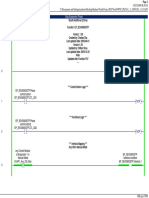

gel adsorbents. Figure 2 – Adsorbent range from some of the manufacturers. only provides steady

Both column Sepabeads® (Resindion); Toyopearl (Tosoh Bioscience); EMD (Merck): Acrylic state bed stability, but

performance polymers; Sepharose (GE Healthcare): Crosslinked agarose; Streamline also ensures stability

parameters HETP and (GE Healthcare): Agarose coated on quartz (for expanded bed) against ‘disturbances’

dynamic binding [From Part I] arising from switching

capacity are seriously feeds into the column

affected on scale-up unless proper like centrifugation and/or membrane and those arising from variation in feed

guidelines are followed. As mentioned in filtrations besides permitting high flow properties and flow rates.

Part I, HETP is a strong function of pore rates without the problem of back pressure The evolved EBA equipment design

diffusion. Small molecules like antibiotics (2,3). An adsorbent intended to be used and adsorbents has enabled us to

diffuse at high rate even in adsorbent pores in expanded bed format needs to meet develop cost effective single step

compared to diffusion rates of some additional criteria in addition to purification strategies for low price bulk

macromolecules like proteins and DNA. those required for traditional preparative products like penicillin G and rifamycin

Thus scale-up for adsorption of small scale adsorbent matrices. Besides being directly from their respective

molecules, e.g. antibiotics, can be based on hydrophilic and rigid, adsorbents for EBA fermentation broths.

mean residence time in terms of column should be heavier

volumes per hour. On the other hand, so that the bed not

macromolecules move rather sluggishly only permits high

and have serious effect of linear velocity on flow rates without

HETP, DBC and resolution. Scale-up unduly large bed

procedure for macromolecular expansion, but also

chromatographic separations therefore allows the

follows the dictate of linear velocity suspended matter

similarity. in the feed to flow

Synthetic polymer based through without

Sepabeads® range of adsorbents forms a retention. An EBA

useful platform for developing separation matrix can be made

technologies in the form of rigid and heavier by either

robust adsorbent matrices. Available in employing larger

different particle sizes they are suited to size, or using

scale-up from litre level to thousands of denser matrix, or

litres level. Further, availability in three both. Figure 3 – Bed Expansion with linear superficial mobile phase

mean pore sizes also make them flexible Sepabeads® EB range velocity (distilled water) for Streamline DEAE (Amersham

for a variety of products from small of adsorbents Biosciences), Sepabeads® EB-DA2 and Sepabeads® EB-DA3

molecules to large proteins. designed for EBA (Resindion Srl)

38 NOVEMBER/DECEMBER 2005 DOWNSTREAM PROCESSING

Table II – HARSep Pilot Plant Unit Specifications with level operations. requirements. Figure 5 presents a picture of

HEBA G225 or S225 column Table II presents the peak profile that may be obtained using

details of a a non-binding tracer molecule. The method

standard pilot basically comprises injecting a finite pulse

scale expanded of a non-binding tracer into the mobile

bed set up that phase (normally the equilibrating buffer)

also serves well and recording the peak profile. Analysis of

for any packed peak profile can yield the following useful

bed operation in validating parameters (1,4):

both up flow – Mean Residence time (or peak time)

and down flow – Dimensionless Variance

modes. – HETP

Figure 4 is the – Peak skew ness

schematic flow – Peak asymmetry

diagram of the – Tailing factor

set up. Major Table III gives the formulae that can

issues with yield these parameters. A similar analysis

scaled-up of the product peak emerging from the

columns relate column in production cycle can also be

to their used as validating parameter. In addition,

hydrodynamic the Resolution parameter Rs (also given

performance in Table III) also quantifies the column

with respect to performance. Any variation in these

DESIGN AND SCALE-UP – Uniformity of packing density; parameters between runs can be

OF PACKED BED – Flow distribution (especially in large regarded as a matter of concern and

AND EXPANDED BED ADSORPTION diameter columns); and result of faulty column performance. A

– Deterioration of packing over time. faulty column performance should lead

Ironically, scale-up of expanded bed is There are several testing procedures for to aborting the run and emptying,

more constrained compared to packed estimating these parameters recommended cleaning and repacking the column.

bed on account of bed expansion and by column or media manufacturers. The It is essential that a column when

linear velocity limitations. Within this final choice rests with the user and it is packed and operated gives a performance

constraint, tall columns for small useful to lay down SOPs for determination that is consistent over a large number of

molecules and large diameter short of the above three aspects. Two simple and repeated cycles. There can be occasional

columns for macromolecules are very useful methodologies are deterioration of the column performance

accepted practice in plant scale – Devising non-binding tracer method to which is unacceptable from regulatory

operations for both packed and check column performance in between point of view. There is therefore a need to

expanded bed operation. Flat flow runs; and adopt procedures that quantify column

distribution of liquid or crude entering – Devising an in built performance performance from time to time not only

the column bed is a very essential evaluation method that quantifies each in terms of production related figures but

requirement for good column successive runs made on the column. also through the diagnostic parameters.

performance. In addition, uniformity of Both these can be built into the system The performance parameters listed in

packing throughout the bed diameter data logs to comply with regulatory Table III are a good measure of column

and height is also necessary for fault

free operation. Rigid adsorbent matrices

again are useful in the respect that they

permit packing procedures that are easy

to perform and reproduce without

damage to the adsorbent. A number of

column designs are on the market from

different companies some of which also

have presence in the adsorbent market.

Considerable work at our Institute, and

then in collaboration with Resindion Srl

and Hydro Air Research SpA, has lead

us to design column hardware for both

packed bed and expanded bed format

of adsorption chromatography. Packed

bed and expanded bed purification

technologies have been developed for

molecules from penicillin G, rifamycin,

vitamin B12, and β-carotene to proteins

like lactoferrin, lactoperoxidase,

lysozyme, bromelain, insulin etc. Hydro

Air Research offers laboratory scale to

plant scale column chromatography

setups complete with column, pumps,

piping system and measurement and

controls. These ready to use set ups Figure 4 – Schematic Flow Diagram of the HARSep-HEBA G225 Pilot Scale Expanded / Packed

have been helpful in developing the Bed plant. Several on-off valves control the direction of the flow upward or downward through

technologies and scaling them for plant the column and to different outlets

DOWNSTREAM PROCESSING NOVEMBER/DECEMBER 2005 39

Table III – Parameters for chromatographic Typically, a 300 µm mean quantify column performances between

peak analysis particle size is considered and during the runs. Distributor designs

good for scale-up and can and operation protocols with respect to

give up to 500 plates/m stream switching and changes in flow

bed. Again, as mentioned rate need special attention to details.

earlier larger bed depths Chromatographic assembly hardware

required for such thus should not only be designed well,

adsorbents necessitate but must also be supported by

that the adsorbent matrix adequate software to operate, control

is stable under its own and quantify its performance both

weight. Soft gel matrices during a run and in between runs.

can cause more

problems

compared to rigid

beads like

Sepabeads®.

SUMMARY

Scale-up and

design of plant

scale column

chromatography

can follow different

Figure 5 – Peak profile obtained using a non-binding

guidelines for

tracer molecule (or during product elution)

small molecule

adsorption and

macromolecular REFERENCES

adsorption.

Macromolecule 1) LIGHTFOOT E.N., MOSCARELLO J.S., TEETERS

adsorption is far more M.A., ROOT T.W. “Interaction of Mass

diffusion limited than Transfer and Fluid Mechanics” in Scale-up

and Optimization in Preparative

small molecules, and

Chromatography; Rathore A.S., Velayudhan

hence while small A. Eds.; Chromatographic Science Series,

molecule Marcel Dekker, 2003

chromatography can be 2) CHASE H.A. “Purification of Proteins by

scaled up using simpler Adsorption Chromatography in Expanded

mean residence time Beds” Trends Biotechnol. 1994, 12,

criterion, macromolecule 296-303

behaviour during operation as well, and chromatography required more careful 3) LALI A.M. “Expanded Bed Affinity

can be used in analyzing product peak scale up. Larger the product molecule Chromatography” in Methods for Affinity

(e.g. pDNA) larger is the effect of fluid based Separations of Enzymes and

profiles.

Proteins; Gupta M.N. Ed.; Birkhauser Verlag:

In large columns use of small particle dynamics on binding capacity and peak

Basel, 2002

size adsorbent is more likely to result in resolutions. 4) RATHORE, A.S., KENNEDY R.M., O’DONNELL

variation of performance between Production scale packed and J.K., BEMBERIS I., KALTENBRUNNER O.,

subsequent packing. Hence, larger particle expanded bed adsorption columns “Quantification of a Chromatographic Column,

size may be preferred even at the expense need specific attention to design details Why and How to Do It” Biopharm

of the lower efficiency in terms of HETP. and use of methods to check and International 2003, March 30

40 NOVEMBER/DECEMBER 2005 DOWNSTREAM PROCESSING

Вам также может понравиться

- Wa0009Документ1 страницаWa0009BabbooОценок пока нет

- EM_3VA53601 - Ladder Diagram Concentrate Valves ModuleДокумент11 страницEM_3VA53601 - Ladder Diagram Concentrate Valves ModuleBabbooОценок пока нет

- Scan Doc by CamScannerДокумент1 страницаScan Doc by CamScannerBabbooОценок пока нет

- Scan Doc by CamScannerДокумент1 страницаScan Doc by CamScannerBabbooОценок пока нет

- (STCW) Steam and Cooling WatersupplyДокумент19 страниц(STCW) Steam and Cooling WatersupplyBabbooОценок пока нет

- U 3ev53600 Ep 3ev53600cipДокумент21 страницаU 3ev53600 Ep 3ev53600cipBabbooОценок пока нет

- EM_3SW53601 - Sealwater to pumps module ladder diagramДокумент7 страницEM_3SW53601 - Sealwater to pumps module ladder diagramBabbooОценок пока нет

- (CPVL) CIP ValvesДокумент11 страниц(CPVL) CIP ValvesBabbooОценок пока нет

- Vital Laboratories Warning Letter SummaryДокумент4 страницыVital Laboratories Warning Letter SummaryBabbooОценок пока нет

- Ladder Diagram for Water Phase TransitionДокумент14 страницLadder Diagram for Water Phase TransitionBabbooОценок пока нет

- EM_3SN53602 - CIP Supply Line Ladder DiagramДокумент10 страницEM_3SN53602 - CIP Supply Line Ladder DiagramBabbooОценок пока нет

- (WFD) Wait For DensityДокумент7 страниц(WFD) Wait For DensityBabbooОценок пока нет

- U 3EV53600 Phase MiscДокумент36 страницU 3EV53600 Phase MiscBabbooОценок пока нет

- U 3ev53600 Ep 3ev53600stpДокумент10 страницU 3ev53600 Ep 3ev53600stpBabbooОценок пока нет

- U 3ev53600 Ep 3ev53600w2pДокумент26 страницU 3ev53600 Ep 3ev53600w2pBabbooОценок пока нет

- U 3EV53600 MainRoutineДокумент16 страницU 3EV53600 MainRoutineBabbooОценок пока нет

- U 3ev53600 Ep 3ev53600esdДокумент20 страницU 3ev53600 Ep 3ev53600esdBabbooОценок пока нет

- U 3EV53600 MainДокумент1 страницаU 3EV53600 MainBabbooОценок пока нет

- U 3ev53600 Ep 3ev53600w2pДокумент10 страницU 3ev53600 Ep 3ev53600w2pBabbooОценок пока нет

- U 3ev53600 Ep 3ev53600w2pДокумент10 страницU 3ev53600 Ep 3ev53600w2pBabbooОценок пока нет

- U 3EV53600 Parameter SettingДокумент26 страницU 3EV53600 Parameter SettingBabbooОценок пока нет

- 52-year-old Quality Expert Seeks New OpportunityДокумент4 страницы52-year-old Quality Expert Seeks New OpportunityBabbooОценок пока нет

- Safe Work Permits: R. Chiodi 03/25/1997 Rev 04/16/2001Документ33 страницыSafe Work Permits: R. Chiodi 03/25/1997 Rev 04/16/2001amir khaledОценок пока нет

- WarehouseДокумент18 страницWarehouseBabbooОценок пока нет

- C (//77) SV PreliminaryДокумент5 страницC (//77) SV PreliminaryBabbooОценок пока нет

- Temporary Heaters: Propane SafetyДокумент19 страницTemporary Heaters: Propane SafetyBabbooОценок пока нет

- Occupational Exposures To Hazardous Chemicals in LaboratoriesДокумент42 страницыOccupational Exposures To Hazardous Chemicals in LaboratoriesBabbooОценок пока нет

- Division of Youth Corrections: Fall Protection: Slips, Trips, and FallsДокумент10 страницDivision of Youth Corrections: Fall Protection: Slips, Trips, and FallsBabbooОценок пока нет

- Back Injuries Are The 2nd-Most Common Workplace ProblemДокумент6 страницBack Injuries Are The 2nd-Most Common Workplace ProblemBabbooОценок пока нет

- Lincoln County Health Department Presents Lead and Lead-Based Paint Hazards ConferenceДокумент52 страницыLincoln County Health Department Presents Lead and Lead-Based Paint Hazards ConferenceBabbooОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Honda CBR600RR Rear Set User ManualДокумент4 страницыHonda CBR600RR Rear Set User ManualFoggy211Оценок пока нет

- Bed Making: Occupied Bed Unoccupied BedДокумент16 страницBed Making: Occupied Bed Unoccupied BedHakdog ShermolangОценок пока нет

- Frac SandДокумент3 страницыFrac Sandcrazy boyОценок пока нет

- Pxe-R500 OmДокумент13 страницPxe-R500 OmNattachai BoonchooОценок пока нет

- Activity 1Документ13 страницActivity 1Marving ZОценок пока нет

- 01 Total-Station GPS-1 PDFДокумент113 страниц01 Total-Station GPS-1 PDFAdam senoОценок пока нет

- Manual of Instructions For Bernette Sew and Go 8Документ80 страницManual of Instructions For Bernette Sew and Go 8Anna Costalonga50% (2)

- Aqa 8461 Hodder SampleДокумент23 страницыAqa 8461 Hodder SampleVeer RamloghunОценок пока нет

- MAZAYDEH V COMMISSIONER FOR SOCIAL HOUSING Residential Tenancies 2021 ACAT 115Документ33 страницыMAZAYDEH V COMMISSIONER FOR SOCIAL HOUSING Residential Tenancies 2021 ACAT 115Tacey MakoriОценок пока нет

- Innovative Products and AdaptationДокумент7 страницInnovative Products and AdaptationThamada UdayОценок пока нет

- Electronics For You TruePDF-December 2015 PDFДокумент148 страницElectronics For You TruePDF-December 2015 PDFGeorge Petrakos100% (5)

- Softcel U 1000 - en - 05494931 15528154 15528156Документ3 страницыSoftcel U 1000 - en - 05494931 15528154 15528156s0n1907Оценок пока нет

- 2019 - Draft-Ich-Guideline-M10-Bioanalytical-Method-Validation-Step-2b - enДокумент60 страниц2019 - Draft-Ich-Guideline-M10-Bioanalytical-Method-Validation-Step-2b - enCamilo Fuentes PeñaОценок пока нет

- 05 Olen 2023 Subiect X Sectiunea AДокумент4 страницы05 Olen 2023 Subiect X Sectiunea AcosminaОценок пока нет

- Manuskrip Jurnal IndahДокумент6 страницManuskrip Jurnal IndahindahОценок пока нет

- SWM Complete Notes PDFДокумент96 страницSWM Complete Notes PDFvara pulakhandamОценок пока нет

- Lecture 3 (Week 2) : BIOLOGY 201/winter 2018 Dr. Ian FergusonДокумент5 страницLecture 3 (Week 2) : BIOLOGY 201/winter 2018 Dr. Ian FergusonMohammad FotovatОценок пока нет

- Zen4 ManualДокумент29 страницZen4 Manualsingulares2199Оценок пока нет

- Brochure LEET 2013 14 FinalДокумент114 страницBrochure LEET 2013 14 FinalAnsh SharmaОценок пока нет

- EMI and Cable's Role in EMC ComplianceДокумент3 страницыEMI and Cable's Role in EMC Compliancekrishna_ScrbidОценок пока нет

- Jovy Expenses 1Документ1 188 страницJovy Expenses 1MarionAgency MimaОценок пока нет

- Nursing Proces NewДокумент10 страницNursing Proces NewBrandy SangurahОценок пока нет

- Hcis Class-1Документ11 страницHcis Class-1shate2099Оценок пока нет

- 11-6A Championship Full Meet ProgramДокумент19 страниц11-6A Championship Full Meet ProgramJason JeffriesОценок пока нет

- Mechanical - PVLДокумент9 страницMechanical - PVLrkssОценок пока нет

- 5121-Article Text-18003-1-10-20230208Документ20 страниц5121-Article Text-18003-1-10-20230208Trisna SanjayaОценок пока нет

- Vendors for H.T. Line MaterialsДокумент587 страницVendors for H.T. Line MaterialsAnonymous RjIueYSlОценок пока нет

- Nanotechnology - Google Scholar MetricsДокумент1 страницаNanotechnology - Google Scholar MetricspalkybdОценок пока нет

- Ultra PhysicsДокумент30 страницUltra PhysicsnidharshanОценок пока нет

- Winsem2015 16 Cp0409 20 Jan 2016 Rm01 Amt Unit I Question BankДокумент5 страницWinsem2015 16 Cp0409 20 Jan 2016 Rm01 Amt Unit I Question BankAnit JainОценок пока нет