Академический Документы

Профессиональный Документы

Культура Документы

Sew Motor Weighfeeder PDF

Загружено:

toktok santosОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sew Motor Weighfeeder PDF

Загружено:

toktok santosАвторское право:

Доступные форматы

Drive Technology \ Drive Automation \ System Integration \ Services

Installation Instructions

EI7. Encoder

Service Kit

Edition 12/2013 20197349 / EN

SEW-EURODRIVE—Driving the world

1 Service Kit Content ................................................................................................ 4

2 Procedure ............................................................................................................... 5

2.1 Recommended accessories........................................................................... 5

2.2 Waste disposal............................................................................................... 5

3 Conversion of Encoder Generation A to Encoder Generation B....................... 6

3.1 Without brake ................................................................................................. 6

3.1.1 Removal of the EI7.A encoder ............................................................ 6

3.1.2 Installation of the new EI7.B encoder ............................................... 10

3.1.3 Wiring the EI7.B encoder to the connection box ............................... 12

3.1.4 Wiring the EI7.B encoder to the connection unit ............................... 17

3.2 With brake .................................................................................................... 20

3.2.1 Removal of EI7.A encoder ................................................................ 20

3.2.2 Installation of the new EI7.B encoder ............................................... 25

3.2.3 Wiring the EI7.B encoder to the connection box ............................... 27

3.2.4 Wiring the EI7.B encoder to the connection unit ............................... 32

4 Replacement of Encoder Generation B with Encoder Generation B .............. 35

4.1 Without brake ............................................................................................... 35

4.1.1 Removal of the EI7.B encoder .......................................................... 35

4.1.2 Installation of the new EI7.B encoder ............................................... 39

4.1.3 Wiring the EI7.B encoder to the connection box ............................... 41

4.1.4 Wiring the EI7.B encoder to the connection unit ............................... 46

4.2 With brake .................................................................................................... 49

4.2.1 Removal of the EI7.B encoder .......................................................... 49

4.2.2 Installation of the new EI7.B encoder ............................................... 54

4.2.3 Wiring the EI7.B encoder to the connection box ............................... 55

4.2.4 Wiring the EI7.B encoder to the connection unit ............................... 60

5 Appendix ............................................................................................................... 63

5.1 Pin assignment for 8-pin M12 connector (AVRE) ........................................ 63

5.1.1 Connection box ................................................................................. 63

5.1.2 Connection via M12 connector ......................................................... 63

5.2 Pin assignment for 4-pin M12 connector (AVSE)......................................... 64

5.2.1 Connection box ................................................................................. 64

5.2.2 Connection via M12 connector ......................................................... 64

5.3 Pin assignment without M12 connector ....................................................... 65

5.3.1 Connection unit ................................................................................. 65

Service Kit – EI7. Encoder 3

Service Kit Content

1

1 Service Kit Content

[132] [119]

[632]

[131] [1524]

[1522] [1635]

[1552]

[1632]

[1526][1520] [1517][1518] [36]

[112]

[129]

[1546]

[1545]

[1539]

[1534]

[1525]

[1529]

18014401416894731

The different EI7.B service kits “Connection box with M12 connector” or “Connection

unit without M12 connector” have the following part numbers and contain the following

parts:

Connection box with M12 connector Connection unit without M12 connector

Motor Part number Motor Part number

DR.71: 28214366 DR.71: 28214404

DR.80: 28214374 DR.80: 28214420

DR.90/100: 28214382 DR.90/100: 28214447

DR.112/132: 28214390 DR.112/132: 28214463

Connection box with M12 connector Connection unit without M12 connector

Position Designation Position Designation

[1517] Encoder module [119] Screw M5x20

[1518] Flat head screw M5x10 [632] Screw M4x8

[1520] Spacer [1517] Encoder module

[9997] Spacer [1518] Flat head screw M5x10

[9998] Hex nut M4 [1520] Spacer

[1524] Terminal washer [9997] Spacer

[1526] Grommet [9998] Hex nut M4

[1534] Glass fiber sheathing 10x50 [1522] Connection unit

[1552] Glass fiber sheathing 7x22 [1524] Terminal washer

[1632] Connection box [1526] Grommet

[1635] Cable ties [1635] Cable ties

4 Service Kit – EI7. Encoder

Procedure

Recommended accessories

2

2 Procedure

The following table is used to help find the correct encoder installation description:

Type of installation

DR motor with encoder generation A and end DR motor with encoder generation B and end

shield generation A shield generation B

Conversion Replacement of

of EI7. generation A to EI7. generation B EI7. generation B

Motor without brake Distinguishing features: Distinguishing features:

• EI7.A encoder • EI7.B encoder

• End shield generation A (M5) • End shield generation B (M4)

Motor with Distinguishing features: Distinguishing features:

brake/backstop • EI7.A encoder • EI7.B encoder

• End shield generation A (M5) • End shield generation B (M4)

• Spacing bushings • Spacers

Encoder identification (generation A or generation B)

Generation A Generation B

9735160075 9735161995

Designation on the nameplate: EI7. Designation on the nameplate: EI7.B

2.1 Recommended accessories

SEW-EURODRIVE recommends the following accessories for the work to be

performed:

• Molykote® assembly paste from Dow Corning

• LUB-I wire lubricant from 3M

• 0.4 x 2.0 mm screw driver from Phoenix Contact, manufacturer part number 1205202

2.2 Waste disposal

Dispose of waste separately in accordance with the applicable regulations, for example:

iron, aluminum, copper, plastic, electronic components, oil and grease (not mixed with

solvents).

Service Kit – EI7. Encoder 5

Conversion of Encoder Generation A to Encoder Generation B

3 Without brake

3 Conversion of Encoder Generation A to Encoder Generation B

3.1 Without brake

3.1.1 Removal of the EI7.A encoder

• Loosen the screws on the terminal box and

remove the terminal box cover.

9007208700802827

If a connection box with a 4-pin M12 connector is

used:

• Remove the terminals on the encoder cables.

• Dispose of the terminals.

This step is not necessary if a connection box with

an 8-pin M12 connector is used.

9007208700732811

• Unscrew the M12 connector.

• Disconnect the conductors of the encoder

cable from the M12 connector.

9007208763132939

6 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

Without brake

3

If a connection unit without M12 connector is used:

• Disconnect the conductors of the encoder

cable from the wiring terminal.

• Loosen the screws in the terminal box and

remove the wiring terminal.

• Dispose of the wiring terminal.

9007208846667659

• Loosen the screw for fastening the shielding on

the terminal box.

• Bend the terminal washer open and remove the

encoder cable shielding together with the

conductor end sleeve

• Dispose of the terminal washer.

9007208700736651

Service Kit – EI7. Encoder 7

Conversion of Encoder Generation A to Encoder Generation B

3 Without brake

• Loosen the screws on the fan guard and

2. remove the fan guard.

• Remove the retaining ring of the plastic fan.

3.

1.

9445974539

• Apply a puller to the bushing on the plastic fan

and remove the plastic fan.

Important! Applying direct force to the plastic fan

can damage it.

9445978379

9744815115

8 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

Without brake

3

• Place the bushing of the plastic fan on a

> 1 min. warming plate and heat it up to a maximum

temperature of 80°C.

While doing so, ensure that the plastic fan does

< 80 °C not come into direct contact with the warming

plate.

Any thermally conductive component [1] (e.g. a

metal ring) can be used as a contact surface.

This step is necessary for re-assembly.

[1]

9007208700734731

• Loosen the screws on the encoder and remove

the encoder.

• Dispose of the screws.

9445970699

• Remove the old grommet from the cable

bushing of the terminal box.

• Dispose of the old grommet.

9445989899

Service Kit – EI7. Encoder 9

Conversion of Encoder Generation A to Encoder Generation B

3 Without brake

3.1.2 Installation of the new EI7.B encoder

• Push the grommet [1526] onto the cable end of

the encoder module [1517]. The inside diameter

[1517]

of the grommet may not exceed the maximum

inside diameter of 12 mm.

[1526]

Ø 3.7 mm Ø ≤ 12 mm

9446005259

• Coat the cable jacket with wire lubricant. Using

a rotating movement, carefully pull the cable

through the grommet into the terminal box.

While doing so, ensure that the grommet does

not inadvertently slide through into the terminal

2.

box.

I

b-

Lu

3M The minimum bending radius of 28 mm must be

observed.

1.

r > 28 mm

9445987979

10 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

Without brake

3

• Install the spacers [9997] on the end shield.

The tightening torque must be 5 Nm ± 10%.

[9998] • Fasten the encoder board onto the end shield

using 2 nuts [9998]. The tightening torque must

be 2.5 Nm ± 10%.

[9997]

9445997579

Service Kit – EI7. Encoder 11

Conversion of Encoder Generation A to Encoder Generation B

3 Without brake

3.1.3 Wiring the EI7.B encoder to the connection box

4-pin:

1.

Ø10 x 50 mm • Push the long glass fiber sheathing [1534] over

the single conductors of the encoder cable.

Lay the shielding [S] in the opposite direction.

[1534]

[S]

RD, BU,

WH, GN

2. [1552]

GY, PK,

• Push the short glass fiber sheathing [1552] over

YE, BN the single conductors.

Ø7 x 22 mm

RD, BU,

WH, GN

3.

GY, PK, • Install the terminal washer [1524].

YE, BN

[1524]

9007208719152779

8-pin:

1.

Ø10 x 50 mm • Push the long glass fiber sheathing [1534] over

the single conductors of the encoder cable.

Lay the shielding [S] in the opposite direction.

[1534]

[S]

RD, BU

2. [1552]

GY, PK, BN,

• Push the short glass fiber sheathing [1552] over

WH, YE, GN the single conductors.

Ø7 x 22 mm

RD, BU

3.

GY, PK, BN, • Install the terminal washer [1524].

WH, YE, GN

[1524]

9007208719150475

12 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

Without brake

3

• Route the conductors through the thread

reduction out of the terminal box to the outside.

• Connect the M12 connector as shown in the

wiring diagram.

The wiring diagrams for 4 and 8-pin connectors are

included in the appendix (→ p. 64).

• Screw on and secure the conductors with the

M12 connector. The tightening torque must be

0.8 Nm ± 10%.

• Fasten the connector.

9007208763131019

• Wire the connection box [1632] (in accordance

with the previously installed encoder type).

The wiring diagrams for 4 and 8-pin connectors are

included in the appendix (→ p. 64).

[1632]

9007208700748171

Service Kit – EI7. Encoder 13

Conversion of Encoder Generation A to Encoder Generation B

3 Without brake

• Fasten the short glass fiber sheathing [1552]

using a cable tie.

• Fasten the connection box using a cable tie

[1552] [1635] as close to the conductor end sleeves on

the glass fiber sheathing as possible.

9007208700723211

• Screw on and secure the shielding on the

terminal box. The tightening torque must be

5 Nm ± 10%.

9007208700725131

14 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

Without brake

3

• Apply assembly paste to the shaft.

3. • Install the plastic fan that has been heated.

• Fasten the plastic fan using a retaining ring.

2.

-

LY

O E

M T

1. C

O

9445999499

• Mount the fan guard and fasten it with screws.

1. The tightening torque must be 3.3 Nm ± 10%.

2.

9446001419

Service Kit – EI7. Encoder 15

Conversion of Encoder Generation A to Encoder Generation B

3 Without brake

• Mount the terminal box cover and fasten it with

screws. The tightening torque must be 3.5 –

4.0 Nm ± 10%.

9007208718113291

16 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

Without brake

3

3.1.4 Wiring the EI7.B encoder to the connection unit

• Wire the connection unit [1522] in accordance

with the previously installed encoder type and

10 = GN = B the applicable wiring diagrams.

9 = YE = B c

The wiring diagrams for connection without M12

8 = WH = A d

7 = BN = A connector are included in the appendix (→ p. 66).

6 = PK = GND 1 4

RD

BU

5 = GY = +UB

BU RD

1< TF < 10

EI71 c1 d4

EI72 c1 d3

EI76 c1 d2

EI7C c1 d1

TF

9591928587

TF

TF

9656059787

• Fasten the connection unit using screws [119]

[119] 5.0 Nm or [632] (dependent on the terminal box). The

[632] 1.8 Nm

[1522] tightening torque must be 5.0 Nm ± 10% for

[119] and 1.8 Nm ± 10% for [632].

BU

RD

9007208847313419

Service Kit – EI7. Encoder 17

Conversion of Encoder Generation A to Encoder Generation B

3 Without brake

• Apply assembly paste to the shaft.

3. • Install the plastic fan that has been heated.

• Fasten the plastic fan using a retaining ring.

2.

-

LY

O E

M T

1. C

O

9445999499

• Mount the fan guard and fasten it with screws.

1. The tightening torque must be 3.3 Nm ± 10%.

2.

9446001419

18 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

Without brake

3

• Mount the terminal box cover and fasten it with

screws. The wiring terminal tightening torque

must be 3.5 – 4.0 Nm ± 10%.

9007208718113291

Service Kit – EI7. Encoder 19

Conversion of Encoder Generation A to Encoder Generation B

3 With brake

3.2 With brake

3.2.1 Removal of EI7.A encoder

• Loosen the screws on the terminal box and

remove the terminal box cover.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592975883

If a connection box with a 4-pin M12 connector is

used:

• Remove the terminals on the encoder cables.

• Dispose of the terminals.

This step is not necessary if a connection box with

an 8-pin M12 connector is used.

9592968203

• Unscrew the M12 connector.

• Disconnect the conductors of the encoder

cable from the M12 connector.

9007208847705355

20 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

With brake

3

If a connection unit without M12 connector is used:

• Disconnect the conductors of the encoder

cable from the wiring terminal.

• Loosen the screws in the terminal box and

remove the wiring terminal.

• Dispose of the wiring terminal.

9592972043

• Loosen the screw for fastening the shielding on

the terminal box.

• Bend the terminal washer open and remove

the encoder cable shielding together with the

conductor end sleeve.

• Dispose of the terminal washer.

9592973963

Service Kit – EI7. Encoder 21

Conversion of Encoder Generation A to Encoder Generation B

3 With brake

• Loosen the screws on the fan guard and

remove the fan guard.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592954763

• Apply a puller to the bushing of the plastic fan

and remove the plastic fan.

Important! Applying direct force to the plastic fan

can damage it.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9683086219

9744815115

22 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

With brake

3

• Place the bushing of the plastic fan on a

> 1 min. warming plate and heat it up to a maximum

temperature of 80°C.

While doing so, ensure that the plastic fan does

< 80 °C not come into direct contact with the warming

plate.

Any thermally conductive component [1] (e.g. a

metal ring) can be used as a contact surface.

This step is necessary for re-assembly.

[1]

9007208700734731

• Loosen the screws on the encoder and remove

the encoder.

• Dispose of the screws.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

9592962443

Service Kit – EI7. Encoder 23

Conversion of Encoder Generation A to Encoder Generation B

3 With brake

• Dispose of the old spacing bushings.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9595142539

• Remove the old grommet from the cable

bushing of the terminal box.

• Dispose of the old grommet.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

9595719051

24 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

With brake

3

3.2.2 Installation of the new EI7.B encoder

• Install the spacers [1520] on the end shield.

[1520] The tightening torque must be 5 Nm ± 10%.

5 Nm

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592977803

• Push the grommet [1526] onto the cable end of

the encoder module [1517]. The inside diameter

[1517]

of the grommet may not exceed the maximum

inside diameter of 12 mm.

[1526]

Ø 3.7 mm Ø ≤ 12 mm

9446005259

Service Kit – EI7. Encoder 25

Conversion of Encoder Generation A to Encoder Generation B

3 With brake

• Coat the cable jacket with wire lubricant. Using

[1517] [1526]

2. a rotating movement, carefully pull the cable

through the grommet into the terminal box.

I

While doing so, ensure that the grommet does

b-

3M

Lu

not inadvertently slide through into the terminal

box.

1.

The minimum bending radius of 28 mm must be

observed.

[1517]

[1520]

4

a 5

a

5

a

r > 28 mm

3

a 4

2

a 3

1

2

1

9592966283

• Fasten the encoder board to the spacers using

[1518] 2 screws [1518]. The tightening torque must be

2,5 Nm

2.5 Nm ± 10%.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592979723

26 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

With brake

3

3.2.3 Wiring the EI7.B encoder to the connection box

4-pin:

1.

Ø10 x 50 mm • Push the long glass fiber sheathing [1534] over

the single conductors of the encoder cable.

Lay the shielding [S] in the opposite direction.

[1534]

[S]

RD, BU,

WH, GN

2. [1552]

GY, PK,

• Push the short glass fiber sheathing [1552] over

YE, BN the single conductors.

Ø7 x 22 mm

RD, BU,

WH, GN

3.

GY, PK, • Install the terminal washer [1524].

YE, BN

[1524]

9007208719152779

8-pin:

1.

Ø10 x 50 mm • Push the long glass fiber sheathing [1534] over

the single conductors of the encoder cable.

Lay the shielding [S] in the opposite direction.

[1534]

[S]

RD, BU

2. [1552]

GY, PK, BN,

• Push the short glass fiber sheathing [1552] over

WH, YE, GN the single conductors.

Ø7 x 22 mm

RD, BU

3.

GY, PK, BN, • Install the terminal washer [1524].

WH, YE, GN

[1524]

9007208719150475

Service Kit – EI7. Encoder 27

Conversion of Encoder Generation A to Encoder Generation B

3 With brake

• Route the conductors through the thread

reduction out of the terminal box to the outside.

• Connect the M12 connector as shown in the

wiring diagram.

The wiring diagrams for 4 and 8-pin connectors are

included in the appendix (→ p. 64).

• Screw on and secure the conductors with the

M12 connector. The tightening torque must be

0.8 Nm ± 10%.

• Fasten the connector.

9007208847722635

• Wire the connection box [1632] (in accordance

with the previously installed encoder type).

The wiring diagrams for 4 and 8-pin connectors are

included in the appendix (→ p. 64).

[1632]

9007208847724555

28 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

With brake

3

• Fasten the short glass fiber sheathing [1635]

using a cable tie.

• Fasten the connection box using a cable tie as

[1552] close to the conductor end sleeves on the glass

fiber sheathing as possible.

9592958603

• Screw on and secure the shielding on the

terminal box. The tightening torque must be

5 Nm ± 10%.

9592960523

Service Kit – EI7. Encoder 29

Conversion of Encoder Generation A to Encoder Generation B

3 With brake

• Apply assembly paste to the shaft.

3. • Install the plastic fan that has been heated.

• Fasten the plastic fan using a retaining ring.

2.

-

LY

O E

M T

1. C

O

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9656061707

• Mount the fan guard and fasten it with screws.

The tightening torque must be 3.3 Nm ± 10%.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592956683

30 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

With brake

3

• Mount the terminal box cover and fasten it with

screws. The tightening torque must be 3.5 –

4.0 Nm ± 10%.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592987403

Service Kit – EI7. Encoder 31

Conversion of Encoder Generation A to Encoder Generation B

3 With brake

3.2.4 Wiring the EI7.B encoder to the connection unit

• Wire the connection unit [1522] in accordance

with the previously installed encoder type and

10 = GN = B the applicable wiring diagrams.

9 = YE = B c

The wiring diagrams for connection without M12

8 = WH = A d

7 = BN = A connector are included in the appendix (→ p. 66).

6 = PK = GND 1 4

RD

BU

5 = GY = +UB

BU RD

1< TF < 10

EI71 c1 d4

EI72 c1 d3

EI76 c1 d2

EI7C c1 d1

TF

9591928587

TF

TF

9656059787

• Fasten the connection unit using screws [119]

[119] 5.0 Nm

or [632] (dependent on the terminal box). The

[632] 1.8 Nm

[1522] tightening torque must be 5.0 Nm ± 10% for

[119] and 1.8 Nm ± 10% for [632].

BU

RD

9592985483

32 Service Kit – EI7. Encoder

Conversion of Encoder Generation A to Encoder Generation B

With brake

3

• Apply assembly paste to the shaft.

3. • Install the plastic fan that has been heated.

• Fasten the plastic fan using a retaining ring.

2.

-

LY

O E

M T

1. C

O

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9656061707

• Mount the fan guard and fasten it with screws.

The tightening torque must be 3.3 Nm ± 10%.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592956683

Service Kit – EI7. Encoder 33

Conversion of Encoder Generation A to Encoder Generation B

3 With brake

• Mount the terminal box cover and fasten it with

screws. The wiring terminal tightening torque

must be 3.5 – 4.0 Nm ± 10%.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592987403

34 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

Without brake

4

4 Replacement of Encoder Generation B with Encoder Generation B

4.1 Without brake

4.1.1 Removal of the EI7.B encoder

• Loosen the screws on the terminal box and

remove the terminal box cover.

9007208700802827

If a connection box with M12 connector is used:

• Disconnect the conductors from the connection

box.

SEW-EURODRIVE recommends using the

1205202 screw driver from Phoenix

9007208700709771

• Unscrew the M12 connector.

• Disconnect the conductors of the encoder

cable from the M12 connector.

9007208763132939

Service Kit – EI7. Encoder 35

Replacement of Encoder Generation B with Encoder Generation B

4 Without brake

If a connection unit without M12 connector is used:

• Disconnect the conductors of the encoder

cable from the connection unit.

SEW-EURODRIVE recommends using the

1205202 screw driver from Phoenix

BU

RD

9007208846671499

• Loosen the screw for fastening the shielding on

the terminal box.

• Bend the terminal washer open and remove

the encoder cable shielding together with the

conductor end sleeve

• Dispose of the terminal washer.

9007208700736651

36 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

Without brake

4

• Loosen the screws on the fan guard and

2. remove the fan guard.

• Remove the retaining ring of the plastic fan.

3.

1.

9445976459

• Apply a puller to the bushing of the plastic fan

and remove the plastic fan.

Notice: Applying direct force to the plastic fan can

damage it.

9445980299

9744815115

Service Kit – EI7. Encoder 37

Replacement of Encoder Generation B with Encoder Generation B

4 Without brake

• Place the bushing of the plastic fan on a

> 1 min. warming plate and heat it up to a maximum

temperature of 80°C.

While doing so, ensure that the plastic fan does

< 80 °C not come into direct contact with the warming

plate.

Any thermally conductive component [1] (e.g. a

metal ring) can be used as a contact surface.

This step is necessary for re-assembly.

[1]

9007208700734731

• Loosen the screws on the encoder and remove

the encoder.

• Dispose of the screws.

9445972619

• Remove the old grommet from the cable

bushing of the terminal box.

• Dispose of the old grommet.

9445989899

38 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

Without brake

4

4.1.2 Installation of the new EI7.B encoder

• Push the grommet [1526] onto the cable end of

the encoder module [1517]. The inside diameter

[1517]

of the grommet may not exceed the maximum

inside diameter of 12 mm.

[1526]

Ø 3.7 mm Ø ≤ 12 mm

9446005259

• Coat the cable jacket with wire lubricant. Using

a rotating movement, carefully pull the cable

through the grommet into the terminal box.

While doing so, ensure that the grommet does

not inadvertently slide through into the terminal

2.

box.

I

b-

Lu

3M The minimum bending radius of 28 mm must be

observed.

1.

r > 28 mm

9445987979

Service Kit – EI7. Encoder 39

Replacement of Encoder Generation B with Encoder Generation B

4 Without brake

• Fasten the encoder board to the end shield

using the screws [1518] included in the service

kit. The tightening torque must be 2.5 Nm

[1518] ± 10%.

9463370379

40 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

Without brake

4

4.1.3 Wiring the EI7.B encoder to the connection box

4-pin:

1.

Ø10 x 50 mm • Push the long glass fiber sheathing [1534] over

the single conductors of the encoder cable.

Lay the shielding [S] in the opposite direction.

[1534]

[S]

RD, BU,

WH, GN

2. [1552]

GY, PK,

• Push the short glass fiber sheathing [1552] over

YE, BN the single conductors.

Ø7 x 22 mm

RD, BU,

WH, GN

3.

GY, PK, • Install the terminal washer [1524].

YE, BN

[1524]

9007208719152779

8-pin:

1.

Ø10 x 50 mm • Push the long glass fiber sheathing [1534] over

the single conductors of the encoder cable.

Lay the shielding [S] in the opposite direction.

[1534]

[S]

RD, BU

2. [1552]

GY, PK, BN,

• Push the short glass fiber sheathing [1552] over

WH, YE, GN the single conductors.

Ø7 x 22 mm

RD, BU

3.

GY, PK, BN, • Install the terminal washer [1524].

WH, YE, GN

[1524]

9007208719150475

Service Kit – EI7. Encoder 41

Replacement of Encoder Generation B with Encoder Generation B

4 Without brake

• Route the conductors through the thread

reduction to the outside.

• Connect the M12 connector as shown in the

wiring diagram.

The wiring diagrams for 4 and 8-pin connectors are

included in the appendix (→ p. 64).

• Screw on and secure the conductors with the

M12 connector. The tightening torque must be

0.8 Nm ± 10%.

• Fasten the connector.

9007208763131019

• Wire the connection box [1632] (in accordance

with the previously installed encoder type).

The wiring diagrams for 4 and 8-pin connectors are

included in the appendix (→ p. 64).

[1632]

9007208700748171

42 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

Without brake

4

• Fasten the short glass fiber sheathing [1635]

using a cable tie.

• Fasten the connection box using a cable tie as

[1552] close to the conductor end sleeves on the glass

fiber sheathing as possible.

9007208700723211

• Screw on and secure the shielding on the

terminal box. The tightening torque must be

5 Nm ± 10%.

9007208700725131

Service Kit – EI7. Encoder 43

Replacement of Encoder Generation B with Encoder Generation B

4 Without brake

• Apply assembly paste to the shaft.

3. • Install the plastic fan that has been heated.

• Fasten the plastic fan using a retaining ring.

2.

-

LY

O E

M T

1. C

O

9445999499

• Mount the fan guard and fasten it with screws.

1. The tightening torque must be 3.3 Nm ± 10%.

2.

9446001419

44 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

Without brake

4

• Mount the terminal box cover and fasten it with

screws. The tightening torque must be 3.5 –

4.0 Nm ± 10%.

9007208718113291

Service Kit – EI7. Encoder 45

Replacement of Encoder Generation B with Encoder Generation B

4 Without brake

4.1.4 Wiring the EI7.B encoder to the connection unit

• Wire the connection unit [1522] in accordance

with the previously installed encoder type and

10 = GN = B the applicable wiring diagrams.

9 = YE = B c

The wiring diagrams for connection without M12

8 = WH = A d

7 = BN = A connector are included in the appendix (→ p. 66).

6 = PK = GND 1 4

• Fasten the connection unit using screws [119]

RD

BU

5 = GY = +UB

or [632] (dependent on the terminal box). The

BU RD tightening torque must be 5.0 Nm ± 10% for

1< < 10

TF

EI71 c1 d4 [119] and 1.8 Nm ± 10% for [632].

EI72 c1 d3

EI76 c1 d2

EI7C c1 d1

TF

9591928587

TF

TF

9656059787

[119] 5.0 Nm

[632] 1.8 Nm

[1522]

BU

RD

9007208847313419

46 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

Without brake

4

• Apply assembly paste to the shaft.

3. • Install the plastic fan that has been heated.

• Fasten the plastic fan using a retaining ring.

2.

-

LY

O E

M T

1. C

O

9445999499

• Mount the fan guard and fasten it with screws.

1. The tightening torque must be 3.3 Nm ± 10%.

2.

9446001419

Service Kit – EI7. Encoder 47

Replacement of Encoder Generation B with Encoder Generation B

4 Without brake

• Mount the terminal box cover and fasten it with

screws. The tightening torque must be 3.5 –

4.0 Nm ± 10%.

9007208718113291

48 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

With brake

4

4.2 With brake

4.2.1 Removal of the EI7.B encoder

• Loosen the screws on the terminal box and

remove the terminal box cover.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592975883

If a connection box with M12 connector is used:

BU • Disconnect the conductors from the connection

box.

RD

SEW-EURODRIVE recommends using the

1205202 screw driver from Phoenix

9592952843

• Unscrew the M12 connector.

• Disconnect the conductors of the encoder

cable from the M12 connector.

9007208847705355

Service Kit – EI7. Encoder 49

Replacement of Encoder Generation B with Encoder Generation B

4 With brake

If a connection unit without M12 connector is used:

• Disconnect the conductors of the encoder

cable from the connection unit.

SEW-EURODRIVE recommends using the

1205202 screw driver from Phoenix

BU

RD

9592970123

• Loosen the screw for fastening the shielding on

the terminal box.

• Bend the terminal washer open and remove

the encoder cable shielding together with the

conductor end sleeve

• Dispose of the terminal washer.

9592973963

50 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

With brake

4

• Loosen the screws on the fan guard and

remove the fan guard.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9683088139

• Apply a puller to the bushing on the plastic fan

and remove the plastic fan.

Notice: Applying direct force to the plastic fan can

damage it.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9656067723

9744815115

Service Kit – EI7. Encoder 51

Replacement of Encoder Generation B with Encoder Generation B

4 With brake

• Place the bushing of the plastic fan on a

> 1 min. warming plate and heat it up to a maximum

temperature of 80°C.

While doing so, ensure that the plastic fan does

< 80 °C not come into direct contact with the warming

plate.

Any thermally conductive component [1] (e.g. a

metal ring) can be used as a contact surface.

This step is necessary for re-assembly.

[1]

9007208700734731

• Loosen the screws on the encoder and remove

the encoder.

• Dispose of the screws.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9656069643

52 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

With brake

4

• Remove the old grommet from the cable

bushing of the terminal box.

• Dispose of the old grommet.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

9656065803

Service Kit – EI7. Encoder 53

Replacement of Encoder Generation B with Encoder Generation B

4 With brake

4.2.2 Installation of the new EI7.B encoder

• Push the grommet [1526] onto the cable end of

the encoder module [1517]. The inside diameter

[1517]

of the grommet may not exceed the maximum

inside diameter of 12 mm.

[1526]

Ø 3.7 mm Ø ≤ 12 mm

9446005259

• Coat the cable jacket with wire lubricant. Using

[1517] [1526]

2. a rotating movement, carefully pull the cable

through the grommet into the terminal box.

I

While doing so, ensure that the grommet does

b-

3M

Lu

not inadvertently slide through into the terminal

box.

1.

The minimum bending radius of 28 mm must be

observed.

[1517]

[1520]

4

a 5

a

5

a

r > 28 mm

3

a 4

2

a 3

1

2

1

9592966283

54 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

With brake

4

• Fasten the encoder board to the spacers using

[1518] 2 screws [1518]. The tightening torque must be

2,5 Nm

2.5 Nm ± 10%.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592979723

Service Kit – EI7. Encoder 55

Replacement of Encoder Generation B with Encoder Generation B

4 With brake

4.2.3 Wiring the EI7.B encoder to the connection box

4-pin:

1.

Ø10 x 50 mm • Push the long glass fiber sheathing [1534] over

the single conductors of the encoder cable.

Lay the shielding [S] in the opposite direction.

[1534]

[S]

RD, BU,

WH, GN

2. [1552]

GY, PK,

• Push the short glass fiber sheathing [1552] over

YE, BN the single conductors.

Ø7 x 22 mm

RD, BU,

WH, GN

3.

GY, PK, • Install the terminal washer [1524].

YE, BN

[1524]

9007208719152779

8-pin:

1.

Ø10 x 50 mm • Push the long glass fiber sheathing [1534] over

the single conductors of the encoder cable.

Lay the shielding [S] in the opposite direction.

[1534]

[S]

RD, BU

2. [1552]

GY, PK, BN,

• Push the short glass fiber sheathing [1552] over

WH, YE, GN the single conductors.

Ø7 x 22 mm

RD, BU

3.

GY, PK, BN, • Install the terminal washer [1524].

WH, YE, GN

[1524]

9007208719150475

56 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

With brake

4

• Route the conductors through the thread

reduction out of the terminal box to the outside.

• Connect the M12 connector as shown in the

wiring diagram.

The wiring diagrams for 4 and 8-pin connectors are

included in the appendix (→ p. 64).

• Screw on and secure the conductors with the

M12 connector. The tightening torque must be

0.8 Nm ± 10%.

• Fasten the connector.

9007208847722635

• Wire the connection box [1632] (in accordance

with the previously installed encoder type).

The wiring diagrams for 4 and 8-pin connectors are

included in the appendix (→ p. 64).

[1632]

9007208847724555

Service Kit – EI7. Encoder 57

Replacement of Encoder Generation B with Encoder Generation B

4 With brake

• Fasten the short glass fiber sheathing [1635]

using a cable tie.

• Fasten the connection box using a cable tie as

[1552] close to the conductor end sleeves on the glass

fiber sheathing as possible.

9592958603

• Screw on and secure the shielding on the

terminal box. The tightening torque must be

5 Nm ± 10%.

9592960523

58 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

With brake

4

• Apply assembly paste to the shaft.

3. • Install the plastic fan that has been heated.

• Fasten the plastic fan using a retaining ring.

2.

-

LY

O E

M T

1. C

O

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9656061707

• Mount the fan guard and fasten it with screws.

The tightening torque must be 3.3 Nm ± 10%.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592956683

Service Kit – EI7. Encoder 59

Replacement of Encoder Generation B with Encoder Generation B

4 With brake

• Mount the terminal box cover and fasten it with

screws. The tightening torque must be 3.5 –

4.0 Nm ± 10%.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592987403

60 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

With brake

4

4.2.4 Wiring the EI7.B encoder to the connection unit

• Wire the connection unit [1522] in accordance

with the previously installed encoder type and

10 = GN = B the applicable wiring diagrams.

9 = YE = B c

The wiring diagrams for connection without M12

8 = WH = A d

7 = BN = A connector are included in the appendix (→ p. 66).

6 = PK = GND 1 4

RD

BU

5 = GY = +UB

BU RD

1< TF < 10

EI71 c1 d4

EI72 c1 d3

EI76 c1 d2

EI7C c1 d1

TF

9591928587

TF

TF

9656059787

• Fasten the connection unit using screws [119]

[119] 5.0 Nm

or [632] (dependent on the terminal box). The

[632] 1.8 Nm

[1522] tightening torque must be 5.0 Nm ± 10% for

[119] and 1.8 Nm ± 10% for [632].

BU

RD

9592985483

Service Kit – EI7. Encoder 61

Replacement of Encoder Generation B with Encoder Generation B

4 With brake

• Apply assembly paste to the shaft.

3. • Install the plastic fan that has been heated.

• Fasten the plastic fan using a retaining ring.

2.

-

LY

O E

M T

1. C

O

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9656061707

• Mount the fan guard and fasten it with screws.

The tightening torque must be 3.3 Nm ± 10%.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592956683

62 Service Kit – EI7. Encoder

Replacement of Encoder Generation B with Encoder Generation B

With brake

4

• Mount the terminal box cover and fasten it with

screws. The wiring terminal tightening torque

must be 3.5 – 4.0 Nm ± 10%.

a

5

a

4

a 5

3

a 4

2

a 3

1

2

1

9592987403

Service Kit – EI7. Encoder 63

Appendix

5 Pin assignment for 8-pin M12 connector (AVRE)

5 Appendix

5.1 Pin assignment for 8-pin M12 connector (AVRE)

5.1.1 Connection box

EI7C B EI76 B

1 2 3 4 1 2 3 4

GND n. c. n. c. n. c. c GND n. c. n. c. n. c. c

(BU) (BU)

EI7C n. c. n. c. n. c. d n. c. EI76 n. c. n. c. d

(RD) (RD)

EI72 B EI71 B

1 2 3 4 1 2 3 4

GND n. c. n. c. n. c. c GND n. c. n. c. n. c. c

(BU) (BU)

n. c. n. c. EI72 n. c. d n. c. n. c. n. c. EI71 d

(RD) (RD)

1 4

9586175883

5.1.2 Connection via M12 connector

There is an 8-pin M12 connector for connection.

M12 AVRE

Male Pin 1: +VB GY

Pin 2: GND PK

2 1 Pin 3: A BN

3

8

7 Pin 4: A WH

6

4 5 Pin 5: B YE

Pin 6: B GN

Pin 7: TF1

Pin 8: TF1

64 Service Kit – EI7. Encoder

Appendix

Pin assignment for 4-pin M12 connector (AVSE)

5

5.2 Pin assignment for 4-pin M12 connector (AVSE)

5.2.1 Connection box

EI7C B EI76 B

1 2 3 4 1 2 3 4

GND n. c. B A c GND n. c. B A c

(BU) (GN) (WH) (BU) (GN) (WH)

EI7C n. c. n. c. n. c. d n. c. EI76 n. c. n. c. d

(RD) (RD)

EI72 B EI71 B

1 2 3 4 1 2 3 4

GND n. c. B A c GND n. c. B A c

(BU) (GN) (WH) (BU) (GN) (WH)

n. c. n. c. EI72 n. c. d n. c. n. c. n. c. EI71 d

(RD) (RD)

1 4

9586175883

5.2.2 Connection via M12 connector

There is a 4-pin M12 connector for connection.

M12 AVSE

Male Pin 1: +VB GY

Pin 2: B YE

Pin 3: GND PK

2 1

Pin 4: A BN

3 4

Service Kit – EI7. Encoder 65

Appendix

Pin assignment without M12 connector

5

5.3 Pin assignment without M12 connector

5.3.1 Connection unit

a

c

d

b

1 10 1 4

8324612747

1 2 3 4 5 6 7 8 9 10 1 2 3 4

a TF1 TF1 TF2 TF2 +UB GND A A B B EI7.B c

Opt. Opt. (GY) (PK) (BN) (WH) (YE) (GN)

b TF1 TF1 TF2 TF2 +UB GND A A W W EI7.B d

Opt. Opt.

EI7C B EI76 B

1 2 3 4 1 2 3 4

GND n. c. n. c. n. c. c GND n. c. n. c. n. c. c

(BU) (BU)

EI7C n. c. n. c. n. c. d n. c. EI76 n. c. n. c. d

(RD) (RD)

EI72 B EI71 B

1 2 3 4 1 2 3 4

GND n. c. n. c. n. c. c GND n. c. n. c. n. c. c

(BU) (BU)

n. c. n. c. EI72 n. c. d n. c. n. c. n. c. EI71 d

(RD) (RD)

Service Kit – EI7. Encoder 66

SEW-EURODRIVE—Driving the world

SEW-EURODRIVE

Driving the world

SEW-EURODRIVE GmbH & Co KG

P.O. Box 3023

76642 BRUCHSAL

GERMANY

Phone +49 7251 75-0

Fax +49 7251 75-1970

sew@sew-eurodrive.com

www.sew-eurodrive.com

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- SAIC-Q-1043 Asphalt Core Density Testing InspectionДокумент3 страницыSAIC-Q-1043 Asphalt Core Density Testing InspectionAbdul HannanОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Inlet DuctДокумент14 страницInlet DuctAhmad ArmanОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Formula Notes For Cracking Fluid Mechanics For Gate by Jain SirДокумент27 страницFormula Notes For Cracking Fluid Mechanics For Gate by Jain SirSachin Saini93% (27)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- As204-80, As204-80Lf: Gaas Ic Sp4T Nonreflective Switch With Driver 300 Khz-3.5 GHZДокумент4 страницыAs204-80, As204-80Lf: Gaas Ic Sp4T Nonreflective Switch With Driver 300 Khz-3.5 GHZnjesraОценок пока нет

- MC 10115610 9999Документ5 страницMC 10115610 9999Eddie Kelvin Isidro LauraОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Inspection References CaterpillarДокумент58 страницInspection References CaterpillarRforceIbañez100% (2)

- Harsh SukhramaniДокумент6 страницHarsh SukhramaniHarsh SukhramaniОценок пока нет

- Condensation Reactions AДокумент28 страницCondensation Reactions ANino FelicesОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Fletcher Expanding Tables 2013 v7Документ59 страницFletcher Expanding Tables 2013 v7Silviu Prise100% (1)

- A Biometric Model For Examination Screening and Attendance Monitoring in Yaba College of TechnologyДокумент6 страницA Biometric Model For Examination Screening and Attendance Monitoring in Yaba College of TechnologyWorld of Computer Science and Information Technology JournalОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- VCS Commands Ease Coverage Efforts - Speed Simulation PDFДокумент6 страницVCS Commands Ease Coverage Efforts - Speed Simulation PDFAnonymous k2nUzQgO6HОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Marking and Ordering Code System (Capacitors)Документ6 страницMarking and Ordering Code System (Capacitors)José TurinОценок пока нет

- Gapura Company Profile - 17mar17Документ43 страницыGapura Company Profile - 17mar17als izmiОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- PMAC720Документ3 страницыPMAC720felipeОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- General Purpose Hydraulic Valves: Float Level Control ValveДокумент2 страницыGeneral Purpose Hydraulic Valves: Float Level Control Valvevelikimag87Оценок пока нет

- Interurban RMC Rail Bus ManualДокумент4 страницыInterurban RMC Rail Bus ManualSteven GardnerОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- UNNPX206R3Документ4 страницыUNNPX206R3David OlayaОценок пока нет

- NAPCA TrainingДокумент149 страницNAPCA TrainingalejandroОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- SS2 Agv200 0300 01Документ12 страницSS2 Agv200 0300 01RaymondIlyasОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Aerobic Respiration in PeasДокумент2 страницыAerobic Respiration in PeasMatt Schiavo100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Chapter ThreeДокумент29 страницChapter ThreeAbel OmweriОценок пока нет

- L6B TFT-LCD TV Service ManualДокумент35 страницL6B TFT-LCD TV Service ManualFrank PaceОценок пока нет

- General Sir John Kotelawala Defence University: Application For A Detailed Degree Certificate/TranscriptДокумент3 страницыGeneral Sir John Kotelawala Defence University: Application For A Detailed Degree Certificate/TranscriptNatasha de SilvaОценок пока нет

- Internal Arc IEC 61641 - EN - V07Документ24 страницыInternal Arc IEC 61641 - EN - V07arkupi100% (1)

- Unit 1 Vehicle Components - BackДокумент20 страницUnit 1 Vehicle Components - BackCarlos CabreraОценок пока нет

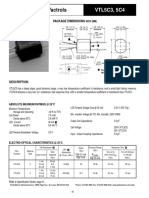

- Low Cost Axial Vactrols: VTL5C3, 5C4Документ2 страницыLow Cost Axial Vactrols: VTL5C3, 5C4sillyОценок пока нет

- Computer Graphics - Lesson PlanДокумент15 страницComputer Graphics - Lesson PlansoniadrallОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Guidelines For Ceiling Framing WorksДокумент3 страницыGuidelines For Ceiling Framing WorksRal GLОценок пока нет

- Seicos 21l IntrustionДокумент61 страницаSeicos 21l IntrustionkhoaОценок пока нет