Академический Документы

Профессиональный Документы

Культура Документы

Pages From Petroleum Refining - 3

Загружено:

ashraf0 оценок0% нашли этот документ полезным (0 голосов)

15 просмотров1 страницаPetroleum Refining

Оригинальное название

Pages From Petroleum Refining -3

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документPetroleum Refining

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

15 просмотров1 страницаPages From Petroleum Refining - 3

Загружено:

ashrafPetroleum Refining

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

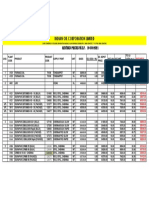

cnapters Process Furnaces 173

i T

Designation :

Type Maximum

according | *00F4iNg '© | working

‘rench

to AIST AENOR temperature

United States! anaards CC)

Carbon

steel | ‘TU42F 480

Alloy steels | 1.25% Cr-0.5% Mo TU 10 CD 5-05 600

with 2.25% Cr- 1% Mo TU10CD 9.40 635

5% Cr-0.5% Mo TUZ 12 CD 05-05 650

9 %Cr - 1% Mo TUZ 10 CD 08 700

Stainless 18 Cr-8Ni 304 | 26CN 18:10 870

steels 18Cr-8Ni-Th 321 | Z6CNT 18-10 870

18Cr-8Ni_ | 18Cr-8Ni-Cb 347 | Z6CNNb 18:10 870

18 Cr-8 Ni-Mo 316 | Z6CND 17-12 870

Wrought heat | 35 Ni 20 Cr 43 Fe 985

resistant {alloy 800 H)

steels T2Ni 15 Cr 8 Fe 1100

(alloy 600)

Centrifugally | 25 Cr 20 Ni (HK 40) 1010

cast heat

resistant

steels 35 Ni25 Cr Nb 1100

* Grade H is generally used! in furnaces as the earbon content contro! allows better mechanical

strength at high temperatures,

“] Table

5.2 | Most commonly used tube materials and maximum working temperatures.

5.2 Tube Coil Supports

Free expansion of tube coil elements is the basic principle of support systems.

‘The materials used must withstand:

* flue gases,

* oxidation,

+ corrosion by liquid fuel ash (vanadates, sulfates, etc.) and exhibit good

hot mechanical strength (creep and elastic range).

In some cases metals with little or no alloys are used, but they are pro-

tected from flue gas effects (temperature, oxidation) by a refractory lining.

‘This is true especially of end supports in convection sections.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Ready for School Grades Prek to 1 Part24Документ1 страницаReady for School Grades Prek to 1 Part24ashrafОценок пока нет

- My First AbcДокумент1 страницаMy First AbcashrafОценок пока нет

- Ready for School Grades Prek to 1 Part20Документ1 страницаReady for School Grades Prek to 1 Part20ashrafОценок пока нет

- Simple Patterns for Developing Part19Документ2 страницыSimple Patterns for Developing Part19ashrafОценок пока нет

- Ready for School Grades Prek to 1 Part20Документ1 страницаReady for School Grades Prek to 1 Part20ashrafОценок пока нет

- DocumentДокумент1 страницаDocumentashrafОценок пока нет

- My First AbccДокумент1 страницаMy First AbccashrafОценок пока нет

- Simple_Patterns_for_Developing_Part3Документ2 страницыSimple_Patterns_for_Developing_Part3ashrafОценок пока нет

- My First AДокумент1 страницаMy First AashrafОценок пока нет

- Registry Entries For VSTO Add-Ins - Visual Studio (Windows) - Microsoft LearnДокумент7 страницRegistry Entries For VSTO Add-Ins - Visual Studio (Windows) - Microsoft LearnashrafОценок пока нет

- Kali Linux 2.0 Top 10 Post Install TipsДокумент1 страницаKali Linux 2.0 Top 10 Post Install TipsashrafОценок пока нет

- Dynamic HysysДокумент1 страницаDynamic HysysashrafОценок пока нет

- Pages From Applied Process Design C Hemical Petrochemical Plants1Документ1 страницаPages From Applied Process Design C Hemical Petrochemical Plants1ashrafОценок пока нет

- Pages From AppliedProcessDesignChemicalPetrochemicalPlants1-3Документ1 страницаPages From AppliedProcessDesignChemicalPetrochemicalPlants1-3ashrafОценок пока нет

- Text MIN MAX FIX Cost Group SPG LGA NAP PRO ETH : Table BuyДокумент4 страницыText MIN MAX FIX Cost Group SPG LGA NAP PRO ETH : Table BuyashrafОценок пока нет

- Cylindrical Horizontal Tank Volume CalculationДокумент21 страницаCylindrical Horizontal Tank Volume CalculationashrafОценок пока нет

- Compatibility With Plastics and Elastomers: TitleДокумент2 страницыCompatibility With Plastics and Elastomers: TitleashrafОценок пока нет

- Star - Wars.the - last.Jedi.2017.720p.bluray.H264.AAC RARBGДокумент74 страницыStar - Wars.the - last.Jedi.2017.720p.bluray.H264.AAC RARBGashrafОценок пока нет

- Carl Sagan's cosmOS Part IV Heaven and HellДокумент2 страницыCarl Sagan's cosmOS Part IV Heaven and HellashrafОценок пока нет

- BBC.shock.and.Awe.the.Story.of.Electricity.2of3.the.age.of.invention.pdtv.XviD.mp3.MVGroup.orgДокумент85 страницBBC.shock.and.Awe.the.Story.of.Electricity.2of3.the.age.of.invention.pdtv.XviD.mp3.MVGroup.orgashrafОценок пока нет

- Carl Sagan's cosmOS Part I The Shores of The CosmicДокумент62 страницыCarl Sagan's cosmOS Part I The Shores of The CosmicashrafОценок пока нет

- BBC Shock and AweДокумент64 страницыBBC Shock and AweashrafОценок пока нет

- Autocad Plant3d Quick Reference GuideДокумент2 страницыAutocad Plant3d Quick Reference GuideashrafОценок пока нет

- Introduction To Boolean AlgebraДокумент6 страницIntroduction To Boolean AlgebraashrafОценок пока нет

- VelocityДокумент1 страницаVelocityashrafОценок пока нет

- Catalyst Changes, Downstream Improvements Increase FCC Propylene YieldsДокумент8 страницCatalyst Changes, Downstream Improvements Increase FCC Propylene Yieldsrishabh jainОценок пока нет

- Marlin 100 EFI Owner's ManualДокумент64 страницыMarlin 100 EFI Owner's ManualZeeОценок пока нет

- Introduction To Oil and Gas DrillingДокумент1 страницаIntroduction To Oil and Gas DrillingkekaОценок пока нет

- Infrared LEL Gas Sensors - Risk or Reward - PDFДокумент7 страницInfrared LEL Gas Sensors - Risk or Reward - PDFAnas AzzedineОценок пока нет

- Solution Gas Oil Ratio, RsДокумент6 страницSolution Gas Oil Ratio, RsAhmed AmirОценок пока нет

- Pinoy English American English British English: Come Again?Документ4 страницыPinoy English American English British English: Come Again?Muzically Inspired100% (1)

- Natural GasДокумент86 страницNatural GasNikhil TiwariОценок пока нет

- MD (BD) - Dwg-Cep-In-1101 Emergency Shutdown System Cause & Effect Charts Rev0 PDFДокумент33 страницыMD (BD) - Dwg-Cep-In-1101 Emergency Shutdown System Cause & Effect Charts Rev0 PDFKook PengОценок пока нет

- Bitumen & FO Price Rate 16.03.2021Документ1 страницаBitumen & FO Price Rate 16.03.2021Dontha VenkateshОценок пока нет

- Process STD 1003 Rev0 Utilities - Steam SystemsДокумент68 страницProcess STD 1003 Rev0 Utilities - Steam SystemsSteve WanОценок пока нет

- Emergency Response Plan For Algiers Refinery: ClassДокумент24 страницыEmergency Response Plan For Algiers Refinery: ClassMehdi MessОценок пока нет

- Wisconsin Model Vg4D: Downloaded From Manuals Search EngineДокумент46 страницWisconsin Model Vg4D: Downloaded From Manuals Search EngineDAVID JОценок пока нет

- Headline Min. 24 - MAX. 36: Industrial Diesel Engine For Pump Drive ApplicationДокумент3 страницыHeadline Min. 24 - MAX. 36: Industrial Diesel Engine For Pump Drive ApplicationIonut-alexandru IordacheОценок пока нет

- Form 3 LPG Linking Form - PAHAL / DBTLДокумент1 страницаForm 3 LPG Linking Form - PAHAL / DBTLkayalontheweb100% (2)

- Contrasting EV and ICE VehiclesДокумент6 страницContrasting EV and ICE VehiclesJoshua Michael MarianiОценок пока нет

- 01-02 Heterogeneous Homogeneous and Pure Worksheet - AnswersДокумент1 страница01-02 Heterogeneous Homogeneous and Pure Worksheet - AnswersNOVA LESLIE AGAPAYОценок пока нет

- @perkins: 4000 Series 4016TAG2 4016TAG2AДокумент2 страницы@perkins: 4000 Series 4016TAG2 4016TAG2AIman AkbariОценок пока нет

- Study of Design Improvement of Intake Ma PDFДокумент9 страницStudy of Design Improvement of Intake Ma PDFashok_abclОценок пока нет

- Cold Start Emissions of An SI Engine Using Ethanol-Gasoline Blended FuelДокумент5 страницCold Start Emissions of An SI Engine Using Ethanol-Gasoline Blended FuelDarel DalmassoОценок пока нет

- ELF EVOLUTION 900 SXR 5w30 Engine OilДокумент1 страницаELF EVOLUTION 900 SXR 5w30 Engine OilCristiBvОценок пока нет

- Boyles C5 BrochureДокумент8 страницBoyles C5 BrochureElias JapiОценок пока нет

- 11 Facts About Global WarmingДокумент1 страница11 Facts About Global WarmingGabrielОценок пока нет

- PIPE Enhancement 2Документ29 страницPIPE Enhancement 2Jan Cris PatindolОценок пока нет

- Um12pd1 Miscellaneous PartsДокумент2 страницыUm12pd1 Miscellaneous PartsBurik8Оценок пока нет

- Advantages and Disadvantages of Natural Gas Energy - Conserve EДокумент7 страницAdvantages and Disadvantages of Natural Gas Energy - Conserve ETuba KhanОценок пока нет

- HPCL Erdmp PDFДокумент167 страницHPCL Erdmp PDFVarun SharmaОценок пока нет

- 5.12 Resource Consumption External CostsДокумент30 страниц5.12 Resource Consumption External Costskalite123Оценок пока нет

- Testing of An Electronically Controlled Engine With A Gasoline Direct Injection SystemДокумент6 страницTesting of An Electronically Controlled Engine With A Gasoline Direct Injection SystemMishu MarcelОценок пока нет

- Tartarini TM 7 TQ Ball ValvesДокумент3 страницыTartarini TM 7 TQ Ball ValvesadrianioantomaОценок пока нет

- Fuel Cell SystemДокумент1 страницаFuel Cell SystemIllu SoryОценок пока нет