Академический Документы

Профессиональный Документы

Культура Документы

Bridge Deck Construction - Insitu With Void Formers & Post-Tensioned

Загружено:

engrmasgharИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bridge Deck Construction - Insitu With Void Formers & Post-Tensioned

Загружено:

engrmasgharАвторское право:

Доступные форматы

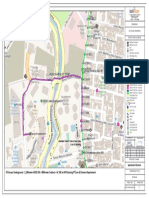

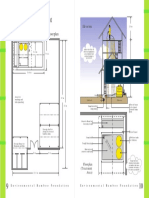

C:\Users\David Moloney\Desktop\Road Bridge 182 Infographic

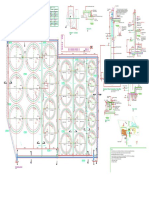

Bridge Deck Construction - Insitu with void formers & post-tensioned

David Moloney 22th Dec 2010

Step 1 - Falsework, Soffit Formwork & Bearings Step 2 - Fix Reinforcement Step 3 - Fix Ducts for stressing Step 4 - Fix Stop ends & Anchor Coens

Spiroflex 85 mm dia tubing & vent pipes

Vent Pipe Duct Profile curved

Anchor Anchor

Abutment Abutment Pier Abutment .

Pier Longitudinal Deck Section Duct

Walkway & Working Platform Grout Tube

Abutment Block

Wedges Coen

Falsework is the temporary scaffold system used to support the Formwork aka shuttering is the casing used to contain Strands

formwork to the deck soffit. concrete during placement and hardening Anchorage for Strand Tendon .

Sequence for Walls Pours Abutments davmol

C2 Bottom Adapt shutters Adapt shutters Alternatively done after Concreting

A2 Bottom C4 Bottom C6 Bottom Step 5 - Push in Stressing Strand Step 6 - Fix void Formers Step 7 - Pour Deck Step 8 - Pour Parapet Upstands

C2 Top A4 Bottom A6 Bottom Strand Dispenser & Pusher Material - Expanded polystyrene formers & metal fixings Concrete pumps 32 m boom x 2 nr

A2 Top C4 Top C6 Top Strand 15.2 mm dia high tensile Used to reduce the deadweight of the structure. 420 m3 of concrete or 61 loads, pump 8 loads per hour

A4 Top A6 Top Speed 40 to 60 m per minute

Typically 20 nr. strands per Tendon

Bridge 182 - Deck Pour Methodology

Materials

C 50 Slump 125 +/- 25

Concrete Volume 1,200 cu. M.

Approx 50m long x 24m wide x 1 m deep Step 9 - Stress deck & Erect Railing Step 10 - Strike Falsework & Formwork Step 11 - Grout Tendons Step 12 - Waterproof Deck

Plant Paths & Rubbing Strips

Batching Plants on Site. Located @ NDA Per Hour Asphalt to carriageway

2# Liebherr Betomix 2.25 outputs 60 cu m per hour each 100 cu m Jack 350 tonne multi stand & Hydraulic Pump. Grouting provides:- Grout Mixer & Pump

1# Turkish plant outputs 60 cu m per hour each 50 cu m Strand extensions are measured during loading. 1. Corrosion protection to the strands.

Concrete Pumps 2. A bond between the strands and the surrounding concrete.

Positioned on either side of deck, will be moved once during pour. Span centres lift during stressing.

42m Boom capacity 50 cu m per hour

42m Boom capacity 50 cu m per hour 100 cu m.

Duration; 12 hours

Lorries Capacity 8 cu m per load Note: the tendon profile lies in the bottom of the deck in the

Cycle time Load travel discharge & return to bataching plant = 60 minutes mid-span region and rises to the top of the deck over the

100 cu m per hour divided by Lorry 8 cm per hour = 13 lorries

supports. When the tendons are stressed the deck is

compressed in those regions where the load causes tensile

Vibrating Equipment 6 # 50mm dimeter Electrical internal poker vibrators

stress. Precompressing the tensile zones of the deck reduces

Concrete Finishing Equipment Levelled by Shovels & rakes Aluminium Screed by Hand cracking to produce more durable concrete deck.

Curing Equipment By liquid membrane using mechanical sprayer

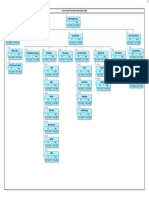

Deck Construction Sequence

Erect Falsework

Step 1 Hot Weather Concrete

Erect

Step 2 Soffit Formwork

Fix3 Bridge bearings

Step Specification requirements

Erect

Step 4 Formwork for Cantilever Ribs Max Placement Temperature 32*C

Fix5 Bottom matt of reinforcement & cages

Step Max Core Temperature 65*C

Fix6 ducts for tensioning

Step Maximum differential temperature 20*C

Fix7 stop ends and anchors for tensioning

Step

Fix8 void formers

Step Actions to ensure above

Pour

Step 9 deck & contilever ribs Flaked ice is used in mix to control temperature

Push

Step 10 in stressing strand Pour in evening in hot weather

Stress

Step 11 deck Proper Curing

Grout

Step 12 tendons

Pour

Step 13 parapet walls

Pour

Step 14 curved Masking Fascia

Strike

Step 15 Falsework

Deck Pour 1,400 m3 5am to 9pm 4# pumps Step 16 Other Works Trial Deck Section

Joints, Paths, Rubbing Strips, Surfacing, Railing, Painting

Pumps Capacity 42m boom 60m3 per hour 35m boom 40m3 per hour

Вам также может понравиться

- Traveller Beowulf Class Freetrader DeckplansДокумент1 страницаTraveller Beowulf Class Freetrader Deckplansnone100% (1)

- CNG Cylinder Design and SafetyДокумент53 страницыCNG Cylinder Design and SafetyMartha GamalОценок пока нет

- Qualcast Trucks Catalog2015Документ188 страницQualcast Trucks Catalog2015Edwin Javier Garavito100% (2)

- Exjobb1 MBRДокумент86 страницExjobb1 MBRNermeen ElmelegaeОценок пока нет

- Science6 - q1 - Mod1les3 - Factors Affecting Solubility - EDITEDДокумент10 страницScience6 - q1 - Mod1les3 - Factors Affecting Solubility - EDITEDGene-Beth Cacho Garce50% (2)

- Properties Value: Ug-23 Maximum Allowable Stress ValuesДокумент2 страницыProperties Value: Ug-23 Maximum Allowable Stress ValuesMohamad Faiz ZulkipliОценок пока нет

- Chemistry STPM Experiment 8 Qualitative Analysis (Second Term) (Cation Anion Inorganic)Документ3 страницыChemistry STPM Experiment 8 Qualitative Analysis (Second Term) (Cation Anion Inorganic)Ning Jie Lee89% (36)

- AWC WCD5 HeavyTimber ViewOnly 0402Документ24 страницыAWC WCD5 HeavyTimber ViewOnly 0402Sand'sZaoldyeckОценок пока нет

- BS 1881 201 1986 Testing ConcreteДокумент28 страницBS 1881 201 1986 Testing ConcreteShvan Najeeb100% (1)

- KKS CodesДокумент39 страницKKS Codeshamza shahzad100% (1)

- Company Welder & Welding Operator Register Based On Aws D1.5 2015Документ1 страницаCompany Welder & Welding Operator Register Based On Aws D1.5 2015REZKIОценок пока нет

- Layout Pig LauncherДокумент2 страницыLayout Pig LauncherBang Jeck100% (1)

- Birch-King Flow DirectionДокумент4 страницыBirch-King Flow DirectionBruceОценок пока нет

- Concerte Portal FrameДокумент1 страницаConcerte Portal FrameMuskan KhanОценок пока нет

- Standard Tele® Configuration: 1 Volume, 1 Tone Pot - 3-Way SwitchДокумент1 страницаStandard Tele® Configuration: 1 Volume, 1 Tone Pot - 3-Way SwitchMarcelo ClarosОценок пока нет

- Blowup Isometric View "A" Blowup Isometric View "B": Construction of Concepcion Feeder PortДокумент1 страницаBlowup Isometric View "A" Blowup Isometric View "B": Construction of Concepcion Feeder Portalezandro del rossiОценок пока нет

- Structure List HimanchalДокумент27 страницStructure List Himanchaltatsam yadavОценок пока нет

- Typical Bungalow Plans and SectionsДокумент1 страницаTypical Bungalow Plans and SectionsabercrombieОценок пока нет

- KD List AIRIS II-2Документ5 страницKD List AIRIS II-2Rafael Ortega - meajudarafaОценок пока нет

- Port Terminal Building Plumbing Isometric View: Rehabilitation and Expansion of Puntales Feeder PortДокумент1 страницаPort Terminal Building Plumbing Isometric View: Rehabilitation and Expansion of Puntales Feeder Portalezandro del rossiОценок пока нет

- Port Terminal Building Plumbing Isometric View: Construction of Concepcion Feeder PortДокумент1 страницаPort Terminal Building Plumbing Isometric View: Construction of Concepcion Feeder Portalezandro del rossiОценок пока нет

- Front Elevation 1:100 West Elevation 1:100: E E D D C C B B A AДокумент1 страницаFront Elevation 1:100 West Elevation 1:100: E E D D C C B B A AKamagara Roland AndrewОценок пока нет

- GeoborДокумент13 страницGeoborLuis Edgardo Fuentes MartinezОценок пока нет

- HVAC FITTING - Products-Web-CatalogДокумент28 страницHVAC FITTING - Products-Web-CatalogAntonio LantiguaОценок пока нет

- Blowup Isometric View "A" Blowup Isometric View "B": Rehabilitation and Expansion of Puntales Feeder PortДокумент1 страницаBlowup Isometric View "A" Blowup Isometric View "B": Rehabilitation and Expansion of Puntales Feeder Portalezandro del rossiОценок пока нет

- (Updated) Plumbing 4-6Документ1 страница(Updated) Plumbing 4-6alezandro del rossiОценок пока нет

- Borelog CP.101Документ1 страницаBorelog CP.101radixkusumaОценок пока нет

- Borelog CP.73Документ1 страницаBorelog CP.73radixkusumaОценок пока нет

- Almana: Schedule of Loads For Panel Board 1 (Lp-1) L.O. & C.O Schedule of Loads For Panel Board 2 (Pp1)Документ4 страницыAlmana: Schedule of Loads For Panel Board 1 (Lp-1) L.O. & C.O Schedule of Loads For Panel Board 2 (Pp1)Jet ArcaОценок пока нет

- General Notes: Vicinity MapДокумент3 страницыGeneral Notes: Vicinity MapKenneth MolinaОценок пока нет

- Design of Column Footings For UNHCR Schools: Structural Engineer: Aziz Ul HakeemДокумент2 страницыDesign of Column Footings For UNHCR Schools: Structural Engineer: Aziz Ul HakeemyasirjurabaОценок пока нет

- 4Документ1 страница4Sudhir Man ShresthaОценок пока нет

- Sps and Wetwell NTL 3Документ1 страницаSps and Wetwell NTL 3Project ManagerStructuresОценок пока нет

- Block Div PPK 1.2-ModelДокумент1 страницаBlock Div PPK 1.2-ModelErjuki Lumban GaolОценок пока нет

- 230510-MS-LS-301B-9F-T Surface and Subsurface Drainage Layout R03Документ1 страница230510-MS-LS-301B-9F-T Surface and Subsurface Drainage Layout R03Mateen JawreОценок пока нет

- Bukit Gasing Map2Документ1 страницаBukit Gasing Map2GiGi Ang Chun EeОценок пока нет

- Escoramento de ValasДокумент1 страницаEscoramento de ValasPablo OliveiraОценок пока нет

- F 20 Template Rev2 E SheetДокумент1 страницаF 20 Template Rev2 E SheetalfredОценок пока нет

- BR124-04A Construction Section & SpecificationsДокумент1 страницаBR124-04A Construction Section & SpecificationsLaurentiu NaeОценок пока нет

- Parts of Pipe Supports As Used in Petro and Chemical IndustryДокумент1 страницаParts of Pipe Supports As Used in Petro and Chemical Industrysowman tungОценок пока нет

- TOWER - 1 External Finishing Works Status As of 25-03-2012: NorthДокумент4 страницыTOWER - 1 External Finishing Works Status As of 25-03-2012: NorthVinay KumarОценок пока нет

- Polamco Product Finder PDFДокумент1 страницаPolamco Product Finder PDFpaula09Оценок пока нет

- Unit Cost AnalysisДокумент1 страницаUnit Cost Analysismanolito cresencioОценок пока нет

- PPPPPPДокумент2 страницыPPPPPPsam pjptОценок пока нет

- Type 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Документ3 страницыType 1 Drawing Rosemount 2140 Level Detector Vibrating Fork 2d PDF en 8218834Tien Nguyen TatОценок пока нет

- Public Address System EstimationДокумент3 страницыPublic Address System EstimationtienОценок пока нет

- Goidhoo S & B OutfallДокумент4 страницыGoidhoo S & B OutfallAli AafaaqОценок пока нет

- Hep FlowДокумент4 страницыHep Flowpeter3972Оценок пока нет

- Estate Layout Mech-Layout2Документ1 страницаEstate Layout Mech-Layout2pastorgeeОценок пока нет

- ReeeДокумент1 страницаReeeSigit HimawanОценок пока нет

- 10 - Truck Driver's Accommodation UnitДокумент1 страница10 - Truck Driver's Accommodation UnitfebousОценок пока нет

- US Units Design Case: Released To The Following CompanyДокумент2 страницыUS Units Design Case: Released To The Following CompanyPappu Kishore KumarОценок пока нет

- 19PG0089 - Plans Page 9-17Документ9 страниц19PG0089 - Plans Page 9-17asebdcivilengОценок пока нет

- Pipe Ring Product Selector: Light-Duty Galvanized Pipe RingsДокумент1 страницаPipe Ring Product Selector: Light-Duty Galvanized Pipe RingsReem Ahmed KhalilОценок пока нет

- Reference Layout & Details of Tank Farm Foundations & Dyke Wall Ana-A1Документ1 страницаReference Layout & Details of Tank Farm Foundations & Dyke Wall Ana-A1Lalith VasudevОценок пока нет

- Traffic Rail T80HT (00000002)Документ3 страницыTraffic Rail T80HT (00000002)tianjinshin100% (1)

- Proposed Admin Building Schedule of Columns, Roof Beam, Column Footing, Truss & Truss DetailsДокумент1 страницаProposed Admin Building Schedule of Columns, Roof Beam, Column Footing, Truss & Truss DetailsL.J. IlaganОценок пока нет

- 797Документ4 страницы797RossellPumaОценок пока нет

- sd1 ALL 0223Документ10 страницsd1 ALL 0223Anurag sharmaОценок пока нет

- Boundary Diagram - Draft Boundary Diagram - DraftДокумент1 страницаBoundary Diagram - Draft Boundary Diagram - DraftAndrew DoОценок пока нет

- Planning A Treatment Center: FloorplanДокумент1 страницаPlanning A Treatment Center: FloorplanbabakaroОценок пока нет

- General Layout With MarkationДокумент1 страницаGeneral Layout With MarkationMuhammad ZainОценок пока нет

- WD SeriesДокумент2 страницыWD SeriesahammedsuhailmОценок пока нет

- Mapa Mental InglesДокумент1 страницаMapa Mental InglesJastin Sebastián Freddy Gutiérrez LauraОценок пока нет

- TSE 10 07 00 1 FT - Doc AngДокумент2 страницыTSE 10 07 00 1 FT - Doc AngEduardo CastilloОценок пока нет

- Lampiran A Diagram Alir Proses Pks Sei. GaluhДокумент1 страницаLampiran A Diagram Alir Proses Pks Sei. GaluhrikonaldosaputraОценок пока нет

- Case Study Embodied Carbon Routes To Reduction 20200402Документ7 страницCase Study Embodied Carbon Routes To Reduction 20200402Iulia ŢeneaОценок пока нет

- North: OB-1 OB-2 OB-1a OB-1bДокумент1 страницаNorth: OB-1 OB-2 OB-1a OB-1bDareen BaredОценок пока нет

- PERT View 2 - A3Документ1 страницаPERT View 2 - A3engrmasgharОценок пока нет

- WBS Chart 2 - A3Документ1 страницаWBS Chart 2 - A3engrmasgharОценок пока нет

- WBS Chart 1 - A3Документ1 страницаWBS Chart 1 - A3engrmasgharОценок пока нет

- PERT View 1 - A3Документ1 страницаPERT View 1 - A3engrmasgharОценок пока нет

- BBS FootingДокумент6 страницBBS FootingengrmasgharОценок пока нет

- Pert ChartДокумент3 страницыPert ChartengrmasgharОценок пока нет

- Pert ChartДокумент3 страницыPert ChartengrmasgharОценок пока нет

- Pert ChartДокумент3 страницыPert ChartengrmasgharОценок пока нет

- Pert ChartДокумент3 страницыPert ChartengrmasgharОценок пока нет

- Pert ChartДокумент3 страницыPert ChartengrmasgharОценок пока нет

- Pert ChartДокумент3 страницыPert ChartengrmasgharОценок пока нет

- Pert ChartДокумент3 страницыPert ChartengrmasgharОценок пока нет

- Pert ChartДокумент3 страницыPert ChartengrmasgharОценок пока нет

- Pert ChartДокумент3 страницыPert ChartengrmasgharОценок пока нет

- Pert ChartДокумент3 страницыPert ChartengrmasgharОценок пока нет

- MasterTop BSFДокумент3 страницыMasterTop BSFnawazkhan23Оценок пока нет

- 7.14.2 - Composite and Non-Metallic NCДокумент17 страниц7.14.2 - Composite and Non-Metallic NCAhmed Aman IbrahimОценок пока нет

- Chemicals Used & Modes of Actions of DisinfectantsДокумент25 страницChemicals Used & Modes of Actions of DisinfectantsjayОценок пока нет

- Worksheet Ch1Документ36 страницWorksheet Ch1Shazia FarheenОценок пока нет

- (Tom Schanz) Experimental Unsaturated Soil MechaniДокумент490 страниц(Tom Schanz) Experimental Unsaturated Soil MechaniChristopher CarrilloОценок пока нет

- (HT-13) Hardness Conversion Table by Temperature (E-7, E-15)Документ1 страница(HT-13) Hardness Conversion Table by Temperature (E-7, E-15)Dung Do ThanhОценок пока нет

- Mullion Transom Connector BS-EN-1991-1-1 V2.0Документ2 страницыMullion Transom Connector BS-EN-1991-1-1 V2.0Giri DharanОценок пока нет

- Adiabatic Dryers PresentationДокумент27 страницAdiabatic Dryers PresentationJunaid IqbalОценок пока нет

- Note On Mac 1 Casting Process 1. Draw Block Diagram of Foundry Layout. Discuss Objectives of Good Plant LayoutДокумент28 страницNote On Mac 1 Casting Process 1. Draw Block Diagram of Foundry Layout. Discuss Objectives of Good Plant LayoutBVoc AutomobileОценок пока нет

- 7-B. Beam Bearing PlatesДокумент14 страниц7-B. Beam Bearing PlatesMelchizedek EllОценок пока нет

- Assignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemДокумент6 страницAssignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemR. Deepa - AОценок пока нет

- Allen CCP 25.7.21 Jee Main Unit Test Nurture Ques Jee 2023Документ13 страницAllen CCP 25.7.21 Jee Main Unit Test Nurture Ques Jee 2023sounitbОценок пока нет

- Aquafilter CatalogДокумент24 страницыAquafilter CatalogLordWaderОценок пока нет

- Maaping With 3D DataДокумент5 страницMaaping With 3D Datanasir.hdip8468Оценок пока нет

- Ashirvad UndergroundДокумент27 страницAshirvad Undergroundjinalshah1012713Оценок пока нет

- Failure Analysis Question BankДокумент29 страницFailure Analysis Question BankAbd-Elaleem Abdallah SosaОценок пока нет

- Key Concept Chapter 10 ElectrolysisДокумент20 страницKey Concept Chapter 10 ElectrolysisKim KatОценок пока нет

- Chemical Bonding and StructureДокумент199 страницChemical Bonding and StructureRichard Nestor100% (1)

- First Law of ThermodynamicsДокумент7 страницFirst Law of Thermodynamics1155016764Оценок пока нет

- 1 s2.0 S0950061820318560 MainДокумент7 страниц1 s2.0 S0950061820318560 MainElias SoaresОценок пока нет

- Techno-Economic Assessment About Propylene GlycolДокумент4 страницыTechno-Economic Assessment About Propylene GlycolIntratec SolutionsОценок пока нет