Академический Документы

Профессиональный Документы

Культура Документы

Maintenance Management and Quality Evaluation of Electrical Installation in Oil and Gas Industries

Загружено:

fzrmcАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Maintenance Management and Quality Evaluation of Electrical Installation in Oil and Gas Industries

Загружено:

fzrmcАвторское право:

Доступные форматы

Imperial Journal of Interdisciplinary Research (IJIR)

Vol-3, Issue-6, 2017

ISSN: 2454-1362, http://www.onlinejournal.in

Maintenance Management and Quality

Evaluation of Electrical Installations in

Oil and Gas Industries.

Dr. Kamalu, U. A ; Ajodo, A. A

Abstract: Maintenance management is required for responsible for the maintenance of all electrical

the smooth and efficient running of any industrial equipment/ installations in their respective areas.

plant so as to improve productivity. The purpose of

maintenance management is to optimize the The purpose of maintenance is to ensure that

performance of productive facilities of an industry installed equipment remains fit and perform

by ensuring that these facilities function regularly optimally for its design purpose throughout its

and efficiently. This is achieved by preventing the useful life. A successful maintenance regime is one

failure or breakdown of such facilities through that minimises operating cost, whilst maximising

planned preventive maintenance activities. This equipment availability and ensuring that installed

paper focuses on maintenance management system equipment retains its designed safety integrity

as applied to maintenance and management of features.

electrical installations in the Nigeria Liquefied Maintenance Management Systems are used to plan

Natural Gas (NLNG). The paper also examines the activities and prepare work orders, and be so

quality of electrical installations as well as designed as to accept feedback of results so that

protection performance of the installations. equipment records can be updated [1].

It is not possible to provide definitive statements

Keywords: Installation, Maintenance, Neutral regarding the interval between maintenance on

Earthing Resistor, Oil and Gas Industry, Power equipment in all locations, as these will depend

management system, SCADA. greatly on factors such as age of the equipment,

environmental conditions, degree of criticality of

service, timing of plant shutdowns and

I. INTRODUCTION Manufacturer's recommendations [2]. Furthermore,

the process should be one of continual feedback

Maintenance management is the process of and fine tuning based on information on equipment

overseeing maintenance resources of an industry so condition found during the early years of any new

that the organization does not experience downtime scheme.

from broken equipment or waste money on Reliability Centred Maintenance techniques

inefficient maintenance procedures. Maintenance such as the Shell-RCM process (S-RCM), and Risk

management software programs can assist with the Based Analysis (RBA) should be applied to

process. The primary objectives of maintenance optimise the amount of maintenance work carried

management are to schedule work efficiently, out. Many potential problems can be avoided by

control costs and ensure regulatory compliance [1]. the most simple of checks. As a general principle,

Maintenance management is essential to the all electrical equipment rooms and plant areas

success of any oil and gas company because a should be visited on a regular basis. Personnel

poorly-organized maintenance program can bring should pay attention to the equipment's normal

the entire company to a halt. Maintenance operating characteristics, i.e. load, sound,

managers must ensure that all maintenance tasks temperature, smell, vibration, etc., in order to

are conducted in compliance with local, state and identify oncoming problems at an early stage [2].

federal laws as well as relevant standards and Where equipment is situated in remote locations

regulations. and regular site visit is impracticable then computer

The NLNG plant complex is grouped into 5 based remote monitoring such as PMS, SCADA

areas, A to E for ease of maintenance. The five and ENMC can be employed.

maintenance teams are PMA, PMB, PMC, PMD

and PME. Each team is composed of technicians, II. RESEARCH METHODS

operators, planner and field engineers and they are An in-depth case study was conducted in the

NLNG liquefaction plant complex, Bonny Island,

Imperial Journal of Interdisciplinary Research (IJIR) Page 1274

Imperial Journal of Interdisciplinary Research (IJIR)

Vol-3, Issue-6, 2017

ISSN: 2454-1362, http://www.onlinejournal.in

where the author works as an electrical engineer, supply with proven features. The PMS also allows

working on the project assets integrity management for a more critical design of the plants’ electrical

strategy (AIMS) involving As-built field equipment [4]. It rearranges generation,

verification and documentation. Site visit, importation and loading so that the individual

observation, group discussion with maintenance generators, reactors, transformers and tie-lines

planners, engineers and technician were used to operate well within their specification limits. Tight

collect the primary data related to the maintenance integration and serial communication – with motor

management systems applied in the NLNG. control centres (MCCs), protection units, governor

and excitation controllers, variable speed drives

and other sub-systems – reduce both wiring and

III. POWER MANAGEMENT SYSTEM (PMS) maintenance costs, creating substantial savings.

The power management system (PMS) prevents IV. SCADA

blackouts and disturbances of NLNG operations,

while at the same time controlling energy costs, A SCADA system is an industrial process

enhances safety and mitigates both environmental automation system used to collect data from

and health impacts. The PMS provides an instruments and sensors located at remote sites and

integrated set of control, supervision and to transmit data at a central site for either

management functions for power generation, monitoring or controlling purposes. The collected

distribution and supply in industrial plants. In this data from sensors and instruments is usually

context, the PMS encompasses functions that are viewed on one or more SCADA host computers

available in sub systems that are also known under that are located at the central control room (CCR).

alternative names, such as: Depending on the information received from the

Power Distribution Control System remote stations, automated or operator-driven

(PDCS) supervisory commands can be pushed to remote

Load Management System (LMS) station control devices, often referred to as field

Electrical Network Monitoring & Control devices or distributed control systems (DCS).

System (ENMCS) SCADA software receives the information from

Electrical Control System (ECS) programmable logic controllers (PLCs) or remote

Electrical Integrated Control System terminal units (RTUs), which in turn receive their

(ELICS) information from sensors or inputted values entered

Integrated Protection and Control System manually. In a power system, SCADA is used to

(IPCS) collect, analyse and monitor the data effectively,

which reduces waste potential and improves the

The load sharing system operates on the running efficiency of the entire system by prompt response

generators to equalize the power between to changes in equipment behaviour and scheduling

interconnected systems and maintain the system maintenance activities adequately [7].

frequency. With the use of Programmable Logic Controllers

The PMS continuously monitor the plant power (PLC) hardware and some powerful bus

against the spinning reserve power for any group of communication links along with SCADA software

interconnected sets [1]. When the spinning reserve and hardware in power generating stations,

drops below the pre-set critical level then the delivering an optimum solution for each process

system shall provide an alarm to allow operator to operation is flexible with advanced control

synchronise two split systems or to start any structures. SCADA supervises several operations,

available non running set. including protection, controlling and monitoring.

The synchronization of each single generator SCADA function in power generation include:

with the system is carried out by the

turbine/generator control panels, through a local Continuous monitoring of speed and

command or by remote auto-synch command from frequency

DCS. The PMS system provides the system synch Supervising the status of circuit

across the tie breakers of each single 33kv board breakers, protective relays and other

and the link breakers. For Plant monitoring and related safety operations

control, the PMS is provided with a visual display Active and reactive power control

unit for graphical one line diagram, histogram, Turbine protection etc.

active alarm pages status info etc. [4]

Industrial plants require a stable and optimized Power distribution system deals with

electrical network. To achieve this goal, the PMS transmission of electric power from generating

controls and supervises power generation and station to the loads with the use of transmission and

Imperial Journal of Interdisciplinary Research (IJIR) Page 1275

Imperial Journal of Interdisciplinary Research (IJIR)

Vol-3, Issue-6, 2017

ISSN: 2454-1362, http://www.onlinejournal.in

distribution stations. Most of public power Load balance studies are done to calculate the

distribution or utility companies rely on manual required power supply, transformer sizing and bus

labour to perform the distribution tasks such as bar sizing. In addition, active, reactive power and

interrupting the power to loads, parameter hourly power factor for each bus and entire system is

checking, and fault diagnosis. The use of SCADA calculated.

in power distribution in oil and gas industry Another study that is necessary is the load flow

reduces the manual labour operation and its cost as study. This is the determination of all bus voltages,

well as facilitating automatic and smooth branch power factor, currents and power flow

operations with minimal disruptions. throughout the plant electrical system.

Stability studies are also carried out to determine

V. ELECTRICAL NETWORK MONITORING both the transient performance and steady state

& CONTROL SYSTEM (ENMC) performance of the system. Transient performance

of the system and its generators is of great concern

Electrical network monitoring and control (ENMC) when relatively large disturbances are applied, like

is a fully customized and user friendly integrated starting large motors, switching out loaded feeders

solution for reliable and accurate energy and recovery from fault clearance

management. The system solution centralizes

monitoring data, control, disturbance recording and Oil-filled power transformers are installed

data collection providing a window into the system outdoors in a fenced-in area of the substation. The

for analysis and reporting through an integrated fences have minimum of two lockable gates

network of metering and protection devices across depending on the size of the substation.

a single or multiple facility locations. It also Transformers are mounted on a flat concrete base

supports a multitude of advanced system energy and the transformer yards are filled with gravel to

management functions such as load shedding, minimise step potential and touch potential

energy cost allocation, motor control and power voltages. Gravel also prevents growth of plants and

monitoring [6]. Other functions of the ENMC weeds in the transformer yards.

include: All cables from transformer are laid underground

Intelligent load shedding and they enter the substation through a raised floor.

Control of voltage, frequency, power, Electrical and instrument cables run in separate

MVAr/power factor trenches and load carrying cables are laid in single

Generator set management/dispatch layer formation while non-load-carrying cables are

installed either as an additional layer on top of the

Load start inhibits

load-carrying cables or as a block adjacent to the

Load reconnection

load-carrying cables.

Transformer tap-changer control and Above ground cables are supported by cable racks,

monitoring trays or cable ladders all the way up to their

Controlled load reduction (e.g. VSDs) terminations. The cable racks, trays or ladders are

well bonded to the metallic equipment enclosures,

VI. QUALITY OF INSTALLATIONS. junction boxes or structures where the cables are

terminated.

Electrical installations in oil and gas industries Individual cables emerging from floors or soil are

are guided by several international standards and usually protected against mechanical

codes and there is strict adherence to quality and damage by means of galvanised steel pipes or rigid

safety. Area classifications is one major PVC pipes.

consideration so that electrical equipment are not Plant lighting circuits are fed from dedicated

installed in zone zero of hazardous area lighting distribution boards installed in each

classification except where there is no alternative substation. Conduit wiring systems are used for

for such installation in which case the equipment lighting, communications and convenience outlets

must be equipped with appropriate protection in closed buildings and metallic parts of the

suitable for such hazardous area. lighting installations are properly earthed. All

Several studies are carried out during FEED stage conduit installations are made with rigid PVC

of the design before approval for construction is conduit and non-metallic conduit boxes. Fixed

given. Such studies include: SAFOP, HAZOP etc. emergency lightings are installed in strategic

Electrical power cables are properly size for locations in the switch rooms, control room, fire

ampacity, short circuit withstand current and time location and the main entrances and emergency

as well as steady state and transient voltage drops. exits.

Environmental condition is also a factor to be

considered in the selection of cables.

Imperial Journal of Interdisciplinary Research (IJIR) Page 1276

Imperial Journal of Interdisciplinary Research (IJIR)

Vol-3, Issue-6, 2017

ISSN: 2454-1362, http://www.onlinejournal.in

VII. PROTECTION PERFORMANCE

The need to act quickly to protect circuits and

equipment as well as personnel often requires

protective relays to respond and trip a breaker

within a few milliseconds.

Circuit breakers combined with electronic

protection relays bring many protections

Selectivity benefits, including: coordination with

upstream and downstream devices; discrimination

of inrush currents; detection of low level of phase

to phase and phase to earth fault currents. There are

several relays used in electrical installations, some

of which are given below.

A synchronism checking relay provides a contact

closure when the frequency and phase of two

sources are similar to within some tolerance margin. Fig. 1 Transformer protection relay

A "synch check" relay is often applied where two

power systems are interconnected, such as at a Neutral Earthing Resistors (NERs) are used in

switchyard connecting two power grids, or at a medium voltage AC distribution networks to limit

generator circuit breaker to ensure the generator is the fault current for safety of equipment and

synchronized to the system before connecting it. personnel in industrial systems.

The differential protection relay responds to In solid grounding, the system is directly grounded

faults within its protected zone. The boundary of and only the soil resistance limits the fault current.

the protected zone is uniquely defined by the The fault current can be very high and can damage

location of the current transformers. Time grading the transformers, generators, motors, wiring and

with other protection systems is therefore not other equipment in the system. The NERs are

required, allowing for tripping without additional inserted between neutral and ground in order to

delay. increase the net resistance thereby limiting the

Differential protection can be used to provide current that would flow through the neutral point of

protection for plants with multiple terminals and a transformer or generator in an event of earth fault.

can be used to protect lines, generators, motors, The fault current values are usually limited to a

transformers, and other electrical plant. value that can be safely handled by the machine or

An overcurrent relay is a type of protective relay transformer. It also needs to be high enough to be

which operates when the load current exceeds a sensed by the earth fault protection relays. If the

pickup value. The ANSI device number is 50 for an NER resistance value is too high, the fault current

instantaneous over current (IOC) or a Definite will be very low and will not be able to activate the

Time Overcurrent (DTOC). In a typical application earth fault protection relay during earth fault

the over current relay is connected to a current conditions.

transformer and calibrated to operate at or above a Fault current and transient over-voltage events can

specific current level. When the relay operates, one be costly in terms of networks availability,

or more contacts will operate and energize to trip equipment costs and compromised safety.

(open) a circuit breaker. Interruption of electricity supply, considerably

Protective relays can also be classified by the type damage to equipment at the fault point, premature

of measurement they make. A protective relay may ageing of equipment at other points on the system

respond to the magnitude of a quantity such as and a heightened safety risk to personnel are all

voltage or current. fault situation consequences.

In a three phase star connection, capacitances are

formed with the ground. In the event of an earth

fault, these capacitances may charge up by the line

voltage and may cause transient overvoltage. The

NER should have a value that permits a let-through

current, which enables the capacitances to

discharge. The installation of a Neutal Earthing

Resistor in electrical networks in oil and gas

industry helps to:

Imperial Journal of Interdisciplinary Research (IJIR) Page 1277

Imperial Journal of Interdisciplinary Research (IJIR)

Vol-3, Issue-6, 2017

ISSN: 2454-1362, http://www.onlinejournal.in

Reduce the single phase fault currents for Condensation forms due to fluctuating temperature,

securing each equipment in MV electrical even in sealed enclosures. In combination with dust

networks. and aggressive gases condensation causes corrosion

Reduce the transient overvoltage which can which results in stray currents and arcing. Too high

occur during an earth fault, and be a temperature, or too low a temperature, can also

monitored and used to activate the earth lead to serious component failure. The safety risk is

fault relay. enormous and the cost of operational delays as a

Increase protection of generators, consequence is incalculable.

transformers and related equipment, Only constant optimum climatic conditions allow

Reduced operation/maintenance costs. components to function properly. The right climate

Increase safety. can be attained by a temperature and moisture

Provide simple, reliable, selective means of control system. When temperatures are too low or

protection. when temperature differences (e.g. night / day) are

large, heating is required. It may also be necessary

Allows the use of equipment, and in

to keep components cool by controlled ventilation.

particular cables with lower insulation

The heaters are used in enclosures where

levels than for an insulated neutral scenario.

condensation is to be prevented or the temperature

Reduce the step voltage

may not fall below a minimum value. In this way

Extend life of connected distribution

corrosion is avoided and an even temperature is

equipment such as transformers

maintained.

Reduce operation and maintenance

expenses. VIII. Conclusion

Improvement in network security and

reduction in unplanned shutdowns. It is very important for any organization to have

a robust and effective maintenance management

and repair policies to ensure optimum performance

of its facilities.

A successful maintenance regime is one that

minimises operating cost, whilst maximising

equipment availability and ensuring that installed

equipment retains its designed safety integrity

features. Although, It is not possible to provide

definitive statements regarding the interval between

maintenance on equipment in all locations, as these

will depend greatly on factors such as age of the

equipment, environmental conditions, degree of

criticality of service, timing of plant shutdowns and

Manufacturer's recommendations, it is

recommended that organizations carry out a detail

study on the maintenance management needs of its

facilities so as to avoid a total breakdown and

stoppage of production.

Fig.2 Neutral Earthing Resistor

NERs must absorb and dissipate a huge amount of

References

energy for the duration of the fault event without

exceeding temperature limitations as recommended [1] Alan L. Sheldrake (2003). Handbook of

in IEEE32. It is therefore important in the design Electrical Engineering: John Willey & Sons

and selection of an NER to ensure equipment and limited, England.

personnel safety as well as continuity of supply.

[2] Geoffrey Bottril, Derek Cheyne, G.

Anti-condensation space Heaters are installed to Vijayraghavan (2005). Electrical Equipment

maintain the temperature of an electrical enclosure. and Installations in Hazardous Areas:

They also provide frost protection by keeping the Newness books, Netherlands.

internal temperature of electrical enclosure above

the freezing temperature. The anti-condensation [3] Wan Hasrulnizzam Wan Mahmood et al

space heaters prevent condensation through (2009). Maintenance Management System

convection. for Upstream Operations in Oil and Gas

Imperial Journal of Interdisciplinary Research (IJIR) Page 1278

Imperial Journal of Interdisciplinary Research (IJIR)

Vol-3, Issue-6, 2017

ISSN: 2454-1362, http://www.onlinejournal.in

Industry: International Journal of

Mechanical, Aerospace, Industrial,

Mechatronic and Manufacturing

Engineering Vol.3, No. 12, 2009.

[4]

http://www.littelfuse.com/~/media/electrical

/brochures/littelfuse-electrical-oil-and-gas-

brochure-pf153.pdf [Accessed: 14th April,

2017].

[5] http://www2.schneider-

electric.com/documents/product-

services/en/product launch/electrical-

installation

guide/electricalinstallationguide.pdf?tsk=60

593P&pc=42553T&keycode=60593P&pro

mocode=42553T&promo_key=42553T

[Accessed: 14th April, 2017].

[6] http://www.senergy.com.my/solutions/swift-

power-solutions/electrical-network-

monitoring-control-system-enmc [Accessed:

20th April, 2017].

[7] http://www.powersystem.org/scada

[Accessed: 20th April, 2017].

Imperial Journal of Interdisciplinary Research (IJIR) Page 1279

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Sastha Technology ST-999MiniДокумент7 страницSastha Technology ST-999MiniSathiswebОценок пока нет

- Data Sheet 6ES7231-4HF32-0XB0: General InformationДокумент4 страницыData Sheet 6ES7231-4HF32-0XB0: General InformationafiОценок пока нет

- Calefón Eco Smart 24 KWДокумент2 страницыCalefón Eco Smart 24 KWPabloRobertoMachucaОценок пока нет

- PowerLogic PM5000 Series - METSEPM5100Документ2 страницыPowerLogic PM5000 Series - METSEPM5100janier linaresОценок пока нет

- Cotech Solar Poly Modules CS6P20-220-250W PDFДокумент2 страницыCotech Solar Poly Modules CS6P20-220-250W PDFΑλοϊσιοςΔαεληςОценок пока нет

- Energy Part6Документ15 страницEnergy Part6kdОценок пока нет

- Eim BacolodДокумент2 страницыEim BacolodJoahnne Tagolimot DajaoОценок пока нет

- 978-1-84919-290-3 TocДокумент13 страниц978-1-84919-290-3 Toctyberius711% (19)

- Programación de Recarga de Vehículos Eléctricos en Una Estación de Carga de Un Centro ComercialДокумент7 страницProgramación de Recarga de Vehículos Eléctricos en Una Estación de Carga de Un Centro ComercialMiguel López IranzoОценок пока нет

- JFR FMCW Radar Level Transmitter - B0 - 65774187Документ10 страницJFR FMCW Radar Level Transmitter - B0 - 65774187ciocioi iancuОценок пока нет

- 4.2 Current Bidirectional Switches PDFДокумент7 страниц4.2 Current Bidirectional Switches PDFJahangeer SoomroОценок пока нет

- Installation Guidelines: For Stationary Industrial GeneratorsДокумент84 страницыInstallation Guidelines: For Stationary Industrial GeneratorsthyagoenergОценок пока нет

- Power SupplyДокумент9 страницPower SupplyMuhammed HuzaifaОценок пока нет

- Earthing Switch 12kV - 24kV Instruction ManualДокумент19 страницEarthing Switch 12kV - 24kV Instruction ManualАлександар СтевићОценок пока нет

- Questions On DC Circuit - Electrical4uДокумент16 страницQuestions On DC Circuit - Electrical4udhineshp0% (2)

- SunPower P19 Product Data SheetДокумент2 страницыSunPower P19 Product Data SheetUrfan AshrafОценок пока нет

- Display Panel Voltmeter DMS-40PC PDFДокумент6 страницDisplay Panel Voltmeter DMS-40PC PDFafonsomoutinhoОценок пока нет

- TOA Ev20rДокумент24 страницыTOA Ev20rCheco PachecoОценок пока нет

- Dell Rack BrochureДокумент8 страницDell Rack BrochureRochdi BouzaienОценок пока нет

- RF Based Remote Control For Home Electrical Appliances: N K KaphungkuiДокумент3 страницыRF Based Remote Control For Home Electrical Appliances: N K KaphungkuichetanaОценок пока нет

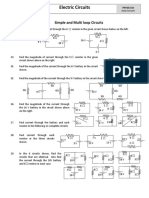

- STD 12 Electric Circuits Worksheets Part 2 (Simple and Multi Loop Circuits) - 1587984854220 - 86LHQ PDFДокумент2 страницыSTD 12 Electric Circuits Worksheets Part 2 (Simple and Multi Loop Circuits) - 1587984854220 - 86LHQ PDFSrihari SrikanthОценок пока нет

- 08 - REG 670 FuntionalityДокумент29 страниц08 - REG 670 FuntionalityMarko GlavasОценок пока нет

- 02 VRV IV Service TRGДокумент109 страниц02 VRV IV Service TRGMohammed EzzatОценок пока нет

- Physics 1 Honors Formula SheetДокумент11 страницPhysics 1 Honors Formula SheetCody JohnsonОценок пока нет

- TV Haier 32 Led LE32F2220a PDFДокумент54 страницыTV Haier 32 Led LE32F2220a PDFJuan Jose100% (1)

- FAN7382 Half-Bridge Gate Driver: Features DescriptionДокумент14 страницFAN7382 Half-Bridge Gate Driver: Features DescriptionEriflonaОценок пока нет

- Internship ReportДокумент32 страницыInternship ReportAli AkbarОценок пока нет

- Data Sheet Compact ControllerДокумент12 страницData Sheet Compact ControllerRizqy LuthfiantoОценок пока нет

- Brochure - Continuous Cartoning Machine-ACM-100Документ2 страницыBrochure - Continuous Cartoning Machine-ACM-100infinityautomatedsolutionsОценок пока нет

- Sx460 Automatic Voltage Regulator (Avr) : Specification, Installation and AdjustmentsДокумент4 страницыSx460 Automatic Voltage Regulator (Avr) : Specification, Installation and AdjustmentsstmeuОценок пока нет