Академический Документы

Профессиональный Документы

Культура Документы

Sop

Загружено:

arvindtiwari21Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sop

Загружено:

arvindtiwari21Авторское право:

Доступные форматы

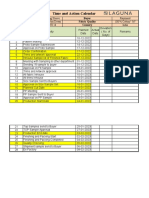

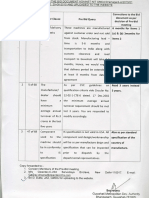

STANDARD OPERATING PROCEDURE CHART

Pre-poroduction meeting by merchant with R.&.D master ,cutting in-charge,pattern master,floor 15 min: no production file should be

1 incharge,sewing and finishing QA. accepted after 3 pm

2 File handover to R.N.D dept.

3 File handover to cutting dept for R&D cutting. same day

4 Shrinkage & width of fabric recived from fabric store by cutting master for concern style. same day

5 Sending file to CAD for marker. same day

6 Fabric reciving from fabric store by sample fabric request slip. same day

7 R&D cutting & issued to R&D dept. next day first half

4 days in case of size set and 3 days in

8 R&D report making, pattern correction and signature by R&D incharge and floor incharge and sewing Q.A case of R&D

Internal PP meeting including floor incharge,line supervisor,production QC,finishing incharge,finishing QC

9 and R&D master. before starting the pilot run

10 File handover to cutting dept for bulk cutting. same day

to be planned as per the cutting

11 Fabric width checking from store. requirement

to be planned as per the cutting

12 Sending file to CAD for cut plan making. requirement

to be planned as per the cutting

13 Request for layer average to merchant after reciving of cut plan. requirement

to be planned as per the cutting

14 Order process component making by fabric store. requirement/ same day when advised

to be planned as per the cutting

15 Lot cut making by cutting for fabric issuing. requirement

to be planned as per the cutting

requirement/ same day when lot cut

16 Reciving fabric from fabric store for bulk cutting. made

Cutting. Only pcs to 5% to be cut before cutting bulk. Minimum 100 pcs and maximum 500 pcs(including to be planned as per the cutting

17 TOP/base size) requirement

18 Cut part inspection by cutting Q.C. same day

19 Ticketing. same day

20 Emb,printing etc.(as per requirment) to be planned

21 Issuing cutting in sewing. when required

Inspection of ist 10 good pcs by production QC(before washing/after washing). Wash approval to be taken as soon as the pcs come out. In normal

22 by merchant. circumstances, to be done by next day

23 Pcs should be checked in front of R&D master so that he can advise if something is missing.

24 Report making by production QC,signature by floor incharge,line supervisor. same day

Finishing inspection by finishing QC and report making,signature by finishing incharge,floor incharge and

merchant,production manager. One finished and packed pc to be shown to merchant and packing approval

25 to be taken

26 proceed with bulk cutting

27 TOP,GPT(as per requirment).

Bulk production reciving from production line by kaaj button/ ewmbridery section by internal challan. First

28 5 pcs to be checked for thread color and to be shown to merchant as well

29 Kaaj/button,bartuk,layer sticker removal.

30 Issuing unfinished pcs. in washing by kaaj button section.

31 Washing

32 Issuing washed pcs from washing by kaaj button section.

33 Issuing washed pcs in finishing by internal challan.

Internal initial ,midline inspection by finishing Q.C. All the reports to be made daily and signed by stitching/

34 finishing and floor incharge.

35 Finishing & packing.

36 Packing list by finishing in-charge.

37 Shipment handover to packing department.

38 Final inspection by buying house QA.

NOTE: EVERY SATURDAY PRODUCTION MEETING OF ALL FLOOR INCHARGE,Q.A AND FINISHNG INCHARGE AT 11:30 IN SHOWROOM.

ISSUED BY;

PRODUCTION MANAGER

Вам также может понравиться

- UPU CatalogueStandardsCatalogueOfUpuStandardsEnДокумент28 страницUPU CatalogueStandardsCatalogueOfUpuStandardsEntrujillo66@yahooОценок пока нет

- Production and Operations ManagementДокумент284 страницыProduction and Operations Managementsnehal.deshmukh89% (28)

- Basic SOP For Cutting Section in Apparel MFGДокумент8 страницBasic SOP For Cutting Section in Apparel MFGFarhana Laeeq0% (3)

- FRM-WS-11 DWM Check Sheet (Weld SHP)Документ2 страницыFRM-WS-11 DWM Check Sheet (Weld SHP)Ashok PanchalОценок пока нет

- Garment Manufacturing Process Flow From Buyer To ShipmentДокумент27 страницGarment Manufacturing Process Flow From Buyer To Shipmenttallraj50% (2)

- Donner Company Group3 SectionEДокумент5 страницDonner Company Group3 SectionEYash VermaОценок пока нет

- Lesson 23 - Contract ManufacturingДокумент15 страницLesson 23 - Contract ManufacturingkannanОценок пока нет

- PF-9497 Chrysler PDFДокумент10 страницPF-9497 Chrysler PDFGustavo PereiraОценок пока нет

- Cutting Standard Operating Procedure SOP EnglishДокумент2 страницыCutting Standard Operating Procedure SOP Englisharvindtiwari21Оценок пока нет

- 4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1Документ7 страниц4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1ABHISHEKОценок пока нет

- Iso 19232 2 2013Документ9 страницIso 19232 2 2013NDT HITECHОценок пока нет

- Cricut Maker 3 Guide for Beginners: A Step-by-Step Guide to Master, Configure, and Take Care of Your Cricut Maker 3 MachineОт EverandCricut Maker 3 Guide for Beginners: A Step-by-Step Guide to Master, Configure, and Take Care of Your Cricut Maker 3 MachineОценок пока нет

- 1517618394299Документ26 страниц1517618394299Nagaraju Dummu100% (1)

- Work Order For Plaster VillaДокумент9 страницWork Order For Plaster VillaOm Krish Ram100% (1)

- 90 Days Lookahead Schedule & Daily Progress Report For SIFДокумент684 страницы90 Days Lookahead Schedule & Daily Progress Report For SIFVinit Kant MajumdarОценок пока нет

- Audit ComplianceДокумент1 страницаAudit ComplianceNitin SharmaОценок пока нет

- Vendor Rejection and Debit PolicyДокумент6 страницVendor Rejection and Debit PolicysharanОценок пока нет

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successОт EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Ssrs BookДокумент117 страницSsrs BookMajnu KhanОценок пока нет

- Cutting SOPДокумент8 страницCutting SOParvindtiwari21Оценок пока нет

- (Project Name) Business Case (Phase #) : Date: Month Day, YearДокумент13 страниц(Project Name) Business Case (Phase #) : Date: Month Day, Yearracringandhi100% (1)

- Apparel Internship (Aquarelle)Документ38 страницApparel Internship (Aquarelle)farid thashfin100% (1)

- KE26 Repost Accounting DocumentДокумент16 страницKE26 Repost Accounting Documentmahesh gokhale100% (1)

- Cutting Room PlanningДокумент28 страницCutting Room Planningsameer_mishra_589% (27)

- Pull Manufacturing: Kanban, Just in Time, Demand FlowДокумент53 страницыPull Manufacturing: Kanban, Just in Time, Demand FlowMej HagОценок пока нет

- BIM ModelingДокумент51 страницаBIM ModelingTony NguyenОценок пока нет

- Fabric StoreДокумент12 страницFabric Storemansoor akhterОценок пока нет

- Cut & Bend RebarsДокумент16 страницCut & Bend RebarsParam SaxenaОценок пока нет

- Maxmech Equipments PVT. LTD.: Service Department Contact DetailsДокумент1 страницаMaxmech Equipments PVT. LTD.: Service Department Contact DetailsDolabari to Jamuguri 4 Lane Road ProjectОценок пока нет

- Method Statement For Granite FrameДокумент7 страницMethod Statement For Granite FrameMonali Varpe100% (1)

- Materials Requirements Planning and Just in Time (JIT) : Ref: Factory Physics, Heizer BookДокумент49 страницMaterials Requirements Planning and Just in Time (JIT) : Ref: Factory Physics, Heizer BookFerda ÇetikОценок пока нет

- Time and Action CalendarДокумент2 страницыTime and Action CalendarAKSHAY NATHОценок пока нет

- PPC and Production: SystemsДокумент18 страницPPC and Production: Systemsayushnk6Оценок пока нет

- Sample SimulationДокумент1 страницаSample Simulationjucar fernandezОценок пока нет

- Cutting Problems & SolutionДокумент1 страницаCutting Problems & Solutionshamim hossainОценок пока нет

- Oprsn ProcessДокумент46 страницOprsn ProcessMayank DagaОценок пока нет

- Fashion Merchandising Assignment 2 TOPIC-Buying Process, TNA Calendar From Order Confirmation To DeliveryДокумент10 страницFashion Merchandising Assignment 2 TOPIC-Buying Process, TNA Calendar From Order Confirmation To DeliveryPratibha ChaudhryОценок пока нет

- Time N Action Calendar TemplateДокумент3 страницыTime N Action Calendar TemplatecucumucuОценок пока нет

- E&C ScheduleДокумент1 страницаE&C ScheduleThinley PelzangОценок пока нет

- Shipment Business Process Flow Document-SAGДокумент57 страницShipment Business Process Flow Document-SAGMisty NguyễnОценок пока нет

- Technodry System Engineering PVT - LTD: Meeting PointsДокумент3 страницыTechnodry System Engineering PVT - LTD: Meeting PointsAshishraje GhogareОценок пока нет

- Derrick S Domino Manufacturing Company Learned That One of Its CuttingДокумент1 страницаDerrick S Domino Manufacturing Company Learned That One of Its CuttingTaimour HassanОценок пока нет

- Cryogenic Tank InsulatioДокумент1 страницаCryogenic Tank Insulatioscbd83Оценок пока нет

- Week 7 MRPДокумент32 страницыWeek 7 MRPYunus Emre ÖztürkОценок пока нет

- Executive Shirt Co - HoutДокумент6 страницExecutive Shirt Co - HoutARYA BARANWAL IPM 2018 BatchОценок пока нет

- PIPELINE ALL ACTIVITY-Updated-19.03.2020Документ10 страницPIPELINE ALL ACTIVITY-Updated-19.03.2020subudhiprasannaОценок пока нет

- Storage LocationsДокумент2 страницыStorage LocationsK Raghunatha ReddyОценок пока нет

- HR Corner:: Property Assessment Placement of OrdersДокумент1 страницаHR Corner:: Property Assessment Placement of OrdersARTURO GARCIAОценок пока нет

- Business Process Steps & Transactions: SL - No Transaction T.codeДокумент6 страницBusiness Process Steps & Transactions: SL - No Transaction T.codeK Raghunatha ReddyОценок пока нет

- Mba07220 C VsmendtermДокумент6 страницMba07220 C VsmendtermTRIBIKRAM DEBANGSHIОценок пока нет

- Collection Point Opening ProcessДокумент2 страницыCollection Point Opening ProcesssajjadОценок пока нет

- SOP For ReactorДокумент4 страницыSOP For ReactorqualityОценок пока нет

- Tyre Retreading (By Cold Process)Документ23 страницыTyre Retreading (By Cold Process)reddy426935Оценок пока нет

- Material Requirements Planning (MRP) and Just in Time (JIT)Документ70 страницMaterial Requirements Planning (MRP) and Just in Time (JIT)laithОценок пока нет

- Cutting Room ProjectДокумент26 страницCutting Room ProjectSakshi Yadav100% (1)

- Pulp Machine ScheduleДокумент1 страницаPulp Machine SchedulewidarningsihОценок пока нет

- DFM03 - Design For ManufactureДокумент46 страницDFM03 - Design For ManufactureAnh Hoang TuanОценок пока нет

- Donner Case WorksheetДокумент3 страницыDonner Case WorksheetZhuoqi LiОценок пока нет

- Domestic LPG Stove (Project Report)Документ6 страницDomestic LPG Stove (Project Report)Prashant KhaireОценок пока нет

- Precure Retread Building ProcessДокумент9 страницPrecure Retread Building ProcessLucky TraderОценок пока нет

- DorДокумент4 страницыDordhimankuldeep19Оценок пока нет

- PERI Services Formwork AssemblyДокумент16 страницPERI Services Formwork AssemblyPatrick LegaspiОценок пока нет

- Slno NSC Package: Sensitivity: LNT Construction Internal UseДокумент7 страницSlno NSC Package: Sensitivity: LNT Construction Internal UseBaladaru Krishna PrasadОценок пока нет

- GMDA Turnover CriteriaДокумент1 страницаGMDA Turnover CriteriaPrasenjit DeyОценок пока нет

- Time and Action CalendarДокумент6 страницTime and Action CalendarnidhisanjeetОценок пока нет

- Inventory MGT TechniquesДокумент21 страницаInventory MGT TechniquesTambe Chalomine AgborОценок пока нет

- 5121 Garment PP Form Version 2 1Документ9 страниц5121 Garment PP Form Version 2 1zakaria hossainОценок пока нет

- 3500 MAB ZZ XX DC A 00110 BMW Swindon Planning Conditions Tracker S4 P03Документ7 страниц3500 MAB ZZ XX DC A 00110 BMW Swindon Planning Conditions Tracker S4 P03Călin CâmpianuОценок пока нет

- Cutting Room PlanningДокумент33 страницыCutting Room PlanningSreedhara AkankshaОценок пока нет

- Report (RMG) On Zaheen Knitwear's Ltd.Документ16 страницReport (RMG) On Zaheen Knitwear's Ltd.MD. Ibrahim KhalilОценок пока нет

- 5S - Lean Management (DNG Academy)Документ40 страниц5S - Lean Management (DNG Academy)arvindtiwari21Оценок пока нет

- Manpower Planning For New Styles: Thread Cutting Final/Mmt Checking Folding Initial CheckingДокумент1 страницаManpower Planning For New Styles: Thread Cutting Final/Mmt Checking Folding Initial Checkingarvindtiwari21Оценок пока нет

- Inputs - Details Related To Fabric Such As Face Side /shade Bands Etc.Документ1 страницаInputs - Details Related To Fabric Such As Face Side /shade Bands Etc.arvindtiwari21Оценок пока нет

- EAT 340 UNIT 1 LESSON 10 - Resource Planning and Scheduling Study NotesДокумент12 страницEAT 340 UNIT 1 LESSON 10 - Resource Planning and Scheduling Study NotesNhật DuyОценок пока нет

- Project ProposalДокумент4 страницыProject ProposalSele KondoОценок пока нет

- World Audio Level Reference PDFДокумент1 страницаWorld Audio Level Reference PDFHector Herrera ChavezОценок пока нет

- MICHIGAN MOTORZ - New Engine Warranty InformationДокумент2 страницыMICHIGAN MOTORZ - New Engine Warranty InformationDaddyos Marine EnginesОценок пока нет

- FLYFokker Leaflet GatewayДокумент2 страницыFLYFokker Leaflet GatewayFredyBrizuelaОценок пока нет

- Zclassic - Investors GuideДокумент12 страницZclassic - Investors GuideAnthonyОценок пока нет

- How To Use Transaction SOST & SCOT For Chec..Документ2 страницыHow To Use Transaction SOST & SCOT For Chec..ghenno18Оценок пока нет

- Part Numbering ConventionДокумент69 страницPart Numbering ConventionHasan PashaОценок пока нет

- PVC Pipes & Fittings ManufacturerДокумент5 страницPVC Pipes & Fittings ManufacturershandgroupОценок пока нет

- 2017 CacДокумент70 страниц2017 CacHorațiu FerchiuОценок пока нет

- RSL Etn 501Документ5 страницRSL Etn 501CatherineRinОценок пока нет

- Weldedmesh Adets B500a b500bДокумент4 страницыWeldedmesh Adets B500a b500bFiraz Kaot'zОценок пока нет

- Selecting ERPs PDFДокумент17 страницSelecting ERPs PDFlucky414Оценок пока нет

- Prism Cement Limited: Investor Update Feb 2014Документ5 страницPrism Cement Limited: Investor Update Feb 2014abmahendruОценок пока нет

- Objectives: Sujith Sam Email: Mob Bangalore:+91 8553039459Документ2 страницыObjectives: Sujith Sam Email: Mob Bangalore:+91 8553039459SAIBINОценок пока нет

- Is 17406 - 2020 Transportation, Storage, Installation and Tensioning of Wire Ropes For Passenger Ropeway - Code of PracticeДокумент12 страницIs 17406 - 2020 Transportation, Storage, Installation and Tensioning of Wire Ropes For Passenger Ropeway - Code of PracticeSandeep Kumar JaiswalОценок пока нет

- RICI Clients 2018Документ8 страницRICI Clients 2018bjayОценок пока нет

- CMPMДокумент3 страницыCMPMJaphet BumaatОценок пока нет

- Residents Air Objections Despite $76 Tax Cut: Salary Increases, Ipads in New Municipal BudgetДокумент20 страницResidents Air Objections Despite $76 Tax Cut: Salary Increases, Ipads in New Municipal BudgetelauwitОценок пока нет

- Data Mining From A Z 104937 PDFДокумент14 страницData Mining From A Z 104937 PDFPedro Rodrigo SantosОценок пока нет

- Final Tesla Communications Plan PDFДокумент21 страницаFinal Tesla Communications Plan PDFbtec1005m0% (2)

- Design Research Guide (Arch. Sampan)Документ40 страницDesign Research Guide (Arch. Sampan)crono66Оценок пока нет