Академический Документы

Профессиональный Документы

Культура Документы

TensarTech Ares

Загружено:

TouchАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TensarTech Ares

Загружено:

TouchАвторское право:

Доступные форматы

Many TensarTech Ares Structures are in Service - A Proven Success

TensarTech® ares™

earth retaining system for walls

and bridge abutments

Tensar Design Service

Tensar’s experienced civil engineers are able to help take your and systems on your project. Upon request, we can provide all

project onto the next stage. Our Design service is on-hand to necessary design certification and working calculations in a

provide standard Application Suggestions to establish form ready for checking, with drawings issued for

viability of Tensar’s products and systems and enable construction as well as all the crucial specification and

planning costs, right through to preparing certified detailed installation details.

design and construction drawings for using Tensar products

Contact Tensar or your local distributor to receive further

literature covering Tensar products and applications.

Also available on request are product specifications,

installation guides and specification notes.

The complete range of Tensar literature consists of:

Your local distributor is: • Tensar® Geosynthetics in Civil Engineering

A guide to products, systems and services

• Subgrade Stabilisation

Stabilising unbound layers in roads and trafficked areas

with a Tensar MSL

• Pavement Optimisation System

Improving the structural performance of whole

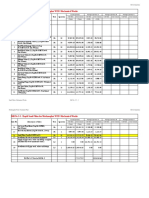

TensarTech Ares Wall Systems - Panel Walls

pavements with a Tensar MSL

• Asphalt Pavements

Reinforcing asphalt layers in roads and trafficked areas

Tensar uniaxial geogrids • TensarTech® Earth Retaining Systems

Bridge abutments, retaining walls and steep slopes

• Railways

Non-woven geotextile Mechanical stabilisation of track and sub-ballast

• TensarTech® Plateau™

Load transfer platform system over piled foundations

• Basal Reinforcement

Basetex high-strength geotextiles

• TensarTech® Stratum™

Cellular foundation mattress system for foundations

with controlled settlement

Q 05288 EMS 86463

ISO 9001:2008 ISO 14001:2004 • Tensar® Erosion Control

HDPE bodkin Tensar International Limited

A guide to products and systems

connection Units 2-4 Cunningham Court Copyright ©Tensar International Limited 2014

Printed March 2014, Issue 1, 485/03-2014

64 mm (min.) Shadsworth Business Park

The copyright in this brochure (including without limitation all text, photographs and diagrams) and all other intellectual property rights and proprietary rights herein belongs to Tensar International

geogrid embedment

Blackburn BB1 2QX Limited and/or its associated group companies and all rights are reserved. This brochure, whether in whole or in part, may not be copied or redistributed or reproduced or incorporated in any other

into concrete work or publication in any form whatsoever without the permission of Tensar International Limited. The information in this brochure supersedes any and all prior information for the products

Levelling pad United Kingdom referred to in previous versions of this brochure, is of an illustrative nature and supplied by Tensar International Limited free of charge for general information purposes only. This brochure is not

intended to constitute, or be a substitute for obtaining, project specific engineering, design, construction and/or other professional advice given by someone with full knowledge of a particular

5 project. It is your sole responsibility and you must assume all risk and liability for the final determination as to the suitability of any Tensar International Limited product and/or design for the use

Panel front face Tel: +44 (0)1254 262431

and in the manner contemplated by you in connection with a particular project. The contents of this brochure do not form part of any contract or intended contract with you. Any contract for the

provision of a Tensar International Limited product and/or design service will be on Tensar International Limited’s Standard Conditions in force at the time of entering into the contract. Whilst every

effort is made to ensure the accuracy of the information contained in this brochure at the time of printing, Tensar International Limited makes no representations about the suitability, reliability,

Fax: +44 (0)1254 266867 comprehensiveness and accuracy of the information, services and other content of this brochure. Save in respect of Tensar International Limited’s liability for death or personal injury arising out of

negligence or for fraudulent misrepresentation (if any), Tensar International Limited shall not be liable to you directly or indirectly in contract, tort (including negligence), equity or otherwise for any

e-mail: info@tensar.co.uk loss or damage whatsoever or howsoever arising in connection with the use of and/or any reliance placed upon the contents of this brochure including any direct, indirect, special, incidental or consequential

loss or damage (including but not limited to loss of profits, interest, business revenue, anticipated savings, business or goodwill). Tensar is a registered trademark. TensarTech is a registered

tensar-international.com trademark in Europe. In case of legal disputes between the parties, the original English version of this disclaimer shall prevail.

Independent Assessment and Approval

HAPAS (Highway Authorities Product Approval Scheme) was

Tensar® Technology – proven, practical solutions set up in 1995 to establish a nationally recognised approval

scheme for innovative products and systems used in highway

and the know-how to get them designed and built. works. Successful HAPAS assessment results in the issue of a

Certificate or Report which provides highway engineers with

TENSAR RE AND RE500 GEOGRIDS FOR TENSAR RE AND RE500 GEOGRIDS FOR

product performance, design and installation data invaluable to REINFORCED SOIL EMBANKMENTS REINFORCED SOIL RETAINING WALL AND

BRIDGE ABUTMENTS

the product choice and project planning processes.

Selected Tensar geogrids have been awarded HAPAS approval

allowing their design and specification in highways structures

Tensar Technology is widely adopted for Pavement

and bridge abutments with a 120 year design life and also a 120

Optimisation and Subgrade Stabilisation to improve the

year design life for strengthened embankments. The BBA

structural performance of paved roads and unbound roads

certificates are evidence that the certified Tensar geogrids have

and platforms. Tensar Technology is also adopted for Earth

been evaluated independently as fit for their intended use.

Retaining Systems for cost effectiveness and versatility

over other traditional methods. By delivering real savings in

cost and time, Tensar Technology can help you improve the

bottom line on your project as well as preserving the

invested capital.

TensarTech Ares Wall System for Proven Construction of

Building in Confidence with the TensarTech Ares Wall System ® ™

Retaining Walls and Bridge Abutments Unsurpassed Experience and Reliability, Proven in the Field

The TensarTech Ares Wall System consists of concrete panels NO METAL – NO CORROSION The cost effectiveness and versatility of the TensarTech As testimony to the durability of the Ares Wall Systems, one reinforcement. In fact, some of the first Ares installations

in combination with Tensar geogrids which reinforce the soil Ares Wall System offers clients, specifiers and contractors of the first Tensar geogrid-reinforced panel walls was built as were instrumented and carefully observed to verify the

With soil reinforcement geogrid that is 100% polymeric,

mass behind. The high efficiency connection between panel many advantages over other traditional methods, such as a seawall on the Gaspe Peninsula in Canada. After 20 years of effectiveness and long-term performance of the systems.

TensarTech Ares is a proven concrete panel system that

facing and geogrid is a distinctive feature of the system, reinforced concrete, for the construction of retaining walls North Atlantic storms and constant exposure to salt water,

eliminates corrosion concerns. Ares Wall Systems offer the

creating strong and durable, maintainence free retaining wall and bridge abutments: there are no signs of corrosion or deterioration of the soil

cost advantages of an reinforced soil retaining wall without

structures.

the long-term consequences of exposure to chlorides, • Rapid and economical construction

Either pre-cast factory produced or wet-cast on-site, panels sulfates, low-resistivity soils or stray electric current • Attractive range of panel finishes from smooth concrete

made to exacting standards and close tolerances are combined potential. This makes Ares Wall Systems the logical choice for

to specialist fractured fin or ribbed finishes

with high-density polyethylene (HDPE) geogrid reinforcement use with contaminated backfill soils, transformer platform

to provide resilient permanent retaining walls and bridge areas and electrified rail systems. • Durable with little or no maintenance

abutments which can have design lives up to 120 years.

THE ARES WALL SYSTEMS ADVANTAGE • Often no specialist construction skills necessary

The ability to utilise non-metallic earth reinforcement makes the • Greater tolerance of differential settlement

Ares Wall System inert to chemical and electrical corrosion. The • Can be used where seismic design is required to offer Ares Wall Systems typically require propping on the first course of panels

inert properties of Tensar geogrids permit the use of a wide range only to ensure correct installion occurs from foundation level.

high resistance to earthquake loadings

of backfills, including recycled materials, which can provide savings

in cost and time and the potential for a sustainable design. • Optimises the use of available space

• Possibility of using site-won, marginal or recycled

granular fill materials

• Low bearing pressure may avoid expensive foundation

treatment

• Panels can be cast on-site or pre-cast to suit project

requirements

• Construction of attractive highways structures with a

120 year design life

2 • HDPE bodkin connector for high connection efficiency 4

without the concern of corrosion

TensarTech Ares panels are laid on a concrete Architectural finishes are easily achieved by the use A feature common to all TensarTech Wall Systems is Constuction of demanding highways or railway structures with a 120 year Tanque Verde Interchange, Tucson, Arizona - Constructed in 1984-85, this was one of the first Tensar Walls ever built. This demonstrates the long-term

levelling pad and subsequent lifts of panels are dry of rubber liners during panel casting. the high efficiency connection between geogrid and design life. performance of the TensarTech Ares Wall System.

laid. facing system.

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Design Calculation-Parapet Steel StructureДокумент5 страницDesign Calculation-Parapet Steel Structuremsiddiq1Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- FoundationДокумент517 страницFoundationRoberto MorenoОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Fib HandbookДокумент75 страницFib Handbooknandi_scrОценок пока нет

- Library Booklist - Updated On 31.03.2018Документ171 страницаLibrary Booklist - Updated On 31.03.2018Sumit GhoseОценок пока нет

- Design and Evaluation of Tailings DamsДокумент73 страницыDesign and Evaluation of Tailings DamsEvan Buntoro100% (1)

- Secant Pile ConstructionДокумент2 страницыSecant Pile ConstructionMohammed Azhar100% (2)

- Midterm Exam - MCQ - TFQ - ENGI8690-9114 - W2019Документ5 страницMidterm Exam - MCQ - TFQ - ENGI8690-9114 - W2019Mohammad HaqОценок пока нет

- Technical Guidance Note (Level 1, No. 8) - Derivation of Loading To Retaining StructuresДокумент3 страницыTechnical Guidance Note (Level 1, No. 8) - Derivation of Loading To Retaining StructuresMohanОценок пока нет

- EC3 - Tension Member - 2021Документ27 страницEC3 - Tension Member - 2021MUHAMMAD AMIRUL ASYRAF BIN MOHD RANIОценок пока нет

- The Electricians Guide To The Building Regulations Part PДокумент1 страницаThe Electricians Guide To The Building Regulations Part PSangar KarimОценок пока нет

- CE6405 Soil MechanicsДокумент13 страницCE6405 Soil MechanicsshanmugamОценок пока нет

- Schell Memorial Bridge DesignsДокумент14 страницSchell Memorial Bridge DesignsJoshua SolomonОценок пока нет

- MAR For Single Bubble InsulationДокумент23 страницыMAR For Single Bubble InsulationResearcherОценок пока нет

- 10e. Groundwater GeochemistryДокумент11 страниц10e. Groundwater GeochemistrysudhakarОценок пока нет

- Paper On Fuzzy Logic in Selecting Piles For Testing PDFДокумент13 страницPaper On Fuzzy Logic in Selecting Piles For Testing PDFHarshana MolligodaОценок пока нет

- Design and Analysis of Bridge Girders Using Different Codes IJERTV8IS070188Документ8 страницDesign and Analysis of Bridge Girders Using Different Codes IJERTV8IS070188Pritesh RAIОценок пока нет

- Flood Routing Material & ExcerciseДокумент8 страницFlood Routing Material & Excercisegoo od100% (1)

- Civil715 S2 2018Документ9 страницCivil715 S2 2018Cheng FuОценок пока нет

- Synopsis of Changes in Section IV E2023Документ40 страницSynopsis of Changes in Section IV E2023yathi sОценок пока нет

- Moisture and Fire Resistant Gypsum Board-WRFR-2020Документ3 страницыMoisture and Fire Resistant Gypsum Board-WRFR-2020ogtОценок пока нет

- Detail of Floor Drain Detail of Floor Cleanout Vent Thru Roof DetailДокумент1 страницаDetail of Floor Drain Detail of Floor Cleanout Vent Thru Roof DetailLhewiz BrionesОценок пока нет

- Compression Test On Cast IronДокумент11 страницCompression Test On Cast IronEvan BoaloyОценок пока нет

- PART2of2-High Performance Building Exterior Continuous InsulationДокумент49 страницPART2of2-High Performance Building Exterior Continuous InsulationoutmatchОценок пока нет

- Use of Grade 25 Concrete in Design of Water Retaining Structures Based On Bs 8007 RecommendationsДокумент8 страницUse of Grade 25 Concrete in Design of Water Retaining Structures Based On Bs 8007 RecommendationsEngr Ishfaque TunioОценок пока нет

- Subject Lecturer: Ban Ahmed Khaleel: Experiment No. (1) : "Determination of Slump of Fresh Concrete"Документ4 страницыSubject Lecturer: Ban Ahmed Khaleel: Experiment No. (1) : "Determination of Slump of Fresh Concrete"AL SniperОценок пока нет

- Data Sheet For Al 800 AltairДокумент4 страницыData Sheet For Al 800 Altairirfan vpОценок пока нет

- Column CFRP11Документ15 страницColumn CFRP11Lenielle AmatosaОценок пока нет

- DIN 931 4.6 / 5.6 / 5.8 / 6.8 / 8.8 / 10.9 BOLT: Technical Drawing Characteristics Reference StandardДокумент12 страницDIN 931 4.6 / 5.6 / 5.8 / 6.8 / 8.8 / 10.9 BOLT: Technical Drawing Characteristics Reference StandardPınar YeloğluОценок пока нет

- Masterinject 1315 TdsДокумент2 страницыMasterinject 1315 TdsMoatz HamedОценок пока нет

- Filter MideaДокумент22 страницыFilter MideaMahibul HasanОценок пока нет