Академический Документы

Профессиональный Документы

Культура Документы

Frame and Underbody: Section 9N

Загружено:

Jarry PotterОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Frame and Underbody: Section 9N

Загружено:

Jarry PotterАвторское право:

Доступные форматы

SECTION 9N

FRAME AND UNDERBODY

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9N-1 Floor Pan Insulators . . . . . . . . . . . . . . . . . . . . . . . 9N-2

Fastener Tightening Specifications . . . . . . . . . . . 9N-1 Engine Under Cover . . . . . . . . . . . . . . . . . . . . . . . 9N-3

Maintenance and Repair . . . . . . . . . . . . . . . . . . . . 9N-2 General Description and System

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . . . . . . 9N-2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9N-5

Alignment Checking . . . . . . . . . . . . . . . . . . . . . . . 9N-2 General Body Construction . . . . . . . . . . . . . . . . . 9N-5

Engine Under Covers . . . . . . . . . . . . . . . . . . . . . . 9N-5

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

Application NSm Lb-Ft Lb-In

Engine Under Cover Nuts 2 - 18

Front Fascia Splash Shield Screw 1.5 - 13

DAEWOO J-100 BL2 / BL3

9N -- 2 FRAME AND UNDERBODY

MAINTENANCE AND

REPAIR

ON-VEHICLE SERVICE

ALIGNMENT CHECKING

An accurate method of determining the alignment of the

underbody uses a measuring tram gauge. The tram

gauge set used to perform the recommended measuring

checks must include a vertical pointer.

Two types of measurements can be made with a tram

gauge: direct point-to-point measurements and mea-

surements calculated on a horizontal plane (datum line)

parallel to the underbody. Point-to-point measurements

are generally taken on steering and suspension engine

compartment parts and simply require the vertical point-

ers to be set equally.

For horizontal plane measurements, the vertical pointers

must be set as specified for each point to be measured.

Dimensions-to-gauge holes are measured to the center

of the holes and flush to the adjacent surface metal un-

less otherwise specified. It is recommended that the di-

agonal dimensions to the cross-body be checked on

both sides in order to verify the dimensional accuracy of

the vehicle underbody.

FLOOR PAN INSULATORS

The floor pan insulators have been designed for the

higher floor pan temperatures that result from the use

of the catalytic converter in the exhaust system. There-

fore, when servicing a vehicle, it is essential that any in-

sulators that may have been disturbed or removed be

reinstalled in the original sequence and location. Also, if

an insulator needs to be replaced, use only the insula-

tion specified for that location on the floor pan.

When servicing or replacing interior insulators, observe

the following instructions.

D Install the insulators in the original position and se-

quence. Butt the pieces together in order to avoid

gapping or overlapping.

D If it is necessary to replace an insulator, use only the

specified insulation.

D Use the original part to determine the amount of re-

placement material required and as a template for

cutting and fitting the new piece to the floor pan.

D When installing the insulator, do not enlarge any cut-

outs or holes that are used for the attachment of interi-

or parts such as the instrument panel or the floor

console.

DAEWOO J-100 BL2 / BL3

FRAME AND UNDERBODY 9N -- 3

D Route the cross-body harness for interior parts over

the floor pan insulators. Clip it in the original location.

D Do not apply spray-on deadeners or trim adhesives to

the top of the floor pan at the area directly over the

catalytic converter or the muffler.

Any insulator service repair or replacement should be

the same thickness, size, and location as the original

installation in the vehicle.

DAEWOO J-100 BL2 / BL3

9N -- 4 FRAME AND UNDERBODY

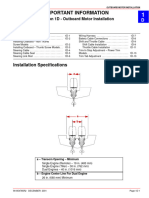

ENGINE UNDER COVER

Removal Procedure

1. Raise and suitably support the vehicle.

2. Remove the screws and the front fascia splash

shield.

B209N001

3. Remove the screws, the nuts, and the engine under

cover.

B209N002

Installation Procedure

1. Install the engine under cover with the screws and the

nuts.

Tighten

Tighten the engine under cover nuts to 2 NSm (18 lb-

in).

B209N002

DAEWOO J-100 BL2 / BL3

FRAME AND UNDERBODY 9N -- 5

2. Install the front fascia splash shield with the screws.

Tighten

Tighten the front fascia splash shield screw to

1.5 NSm (13 lb-in).

3. Lower the vehicle.

B209N001

DAEWOO J-100 BL2 / BL3

9N -- 6 FRAME AND UNDERBODY

GENERAL DESCRIPTION AND SYSTEM OPERATION

GENERAL BODY CONSTRUCTION operations. The underbody parts should be properly

sealed and rustproofed whenever body repair operations

This vehicle is constructed with a unitized body which in-

destroy or damage the original sealing and rustproof-

corporates integral front and rear frame side rails.

ing. When rustproofing critical underbody parts, use a

The front suspension lower control arms are bolted to good-quality type of air-dry primer, such as a corrosion-

and retained by supports, one each on the right and left resistant chromate or an equivalent material. Combina-

sides. The front suspension lower control arm supports tion-type primer/surfacers are not recommended.

are attached to the underbody with three bolts at two

locations. The engine is bolted to the integral front side

rails. The suspension strut towers must be dimensional-

ENGINE UNDER COVERS

ly correct in relation to the remainder of the underbody in The engine under covers are molded pieces of plastic

order to maintain specified suspension strut and caster/ that serve as shields for the underside of the engine. The

camber angles. covers help protect the engine from small rocks, gravel

and other objects that would otherwise come into contact

Since the individual underbody parts contribute directly

with the engine during normal driving conditions.

to the overall strength of the body, it is essential to ob-

serve proper welding techniques during service repair

DAEWOO J-100 BL2 / BL3

Вам также может понравиться

- M39n Frame and Underbody PDFДокумент6 страницM39n Frame and Underbody PDFNenad MisicОценок пока нет

- Frame and Underbody Specifications and Repair GuideДокумент7 страницFrame and Underbody Specifications and Repair Guidemiguelx69Оценок пока нет

- 50TFF-008 014Документ44 страницы50TFF-008 014adolfomarcОценок пока нет

- 138-110 ManualДокумент16 страниц138-110 Manuall_aguilar_mОценок пока нет

- Installation, Start-Up and Service Instructions: 50TJQ008-012 Single-Package Rooftop Heat Pump UnitsДокумент36 страницInstallation, Start-Up and Service Instructions: 50TJQ008-012 Single-Package Rooftop Heat Pump UnitsMouradОценок пока нет

- Si 50TFF007-014 Installation 50tff-C1siДокумент40 страницSi 50TFF007-014 Installation 50tff-C1sicalvin.bloodaxe4478Оценок пока нет

- 50 TJ 016Документ32 страницы50 TJ 016hamgasclimatisation100% (1)

- Installation, Start-Up and Service InstructionsДокумент48 страницInstallation, Start-Up and Service InstructionsjavpfrioОценок пока нет

- Operating Instructions and Parts List for Drill Press Model 103.23620Документ6 страницOperating Instructions and Parts List for Drill Press Model 103.23620Argens ValenteОценок пока нет

- Frame Procedures: Repair InstructionsДокумент23 страницыFrame Procedures: Repair InstructionsStacy WoodsОценок пока нет

- Winsmith R-A Reducer ManualДокумент6 страницWinsmith R-A Reducer ManualCesar Augusto Areinamo PerezОценок пока нет

- Daihatsu workshop manual sectionsДокумент294 страницыDaihatsu workshop manual sectionsManuel Guillen100% (1)

- Daihatsu Charade Engine Manual For (Cb23 Cb60 61 Cb70 80)Документ294 страницыDaihatsu Charade Engine Manual For (Cb23 Cb60 61 Cb70 80)adiefred100% (3)

- John Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)Документ17 страницJohn Deere PowerTech 10.5L Diesel Base Engine Service Repair Technical Manual (CTM100)laopaodunОценок пока нет

- Rear SealДокумент9 страницRear SealHammad Uddin JamilyОценок пока нет

- Ford Ranger Torsion Bar Key Kit Installation GuideДокумент8 страницFord Ranger Torsion Bar Key Kit Installation GuideomarОценок пока нет

- Overload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleДокумент4 страницыOverload Clutches For Index Drives (Type D-Sa, Adjustable) : Operating PrincipleSuhas KODREОценок пока нет

- Important Information: Section 1D - Outboard Motor InstallationДокумент13 страницImportant Information: Section 1D - Outboard Motor InstallationDr. Centelha Mecânica NaúticaОценок пока нет

- Installation and Maintenance GuideДокумент17 страницInstallation and Maintenance GuideAvinash GamitОценок пока нет

- Wipers/Washer Systems: Section 9DДокумент24 страницыWipers/Washer Systems: Section 9DJarry PotterОценок пока нет

- Daihatsu CB23 CB60 61 CB70 80 Engine ManualДокумент294 страницыDaihatsu CB23 CB60 61 CB70 80 Engine ManualKuvita GarcíaОценок пока нет

- Emd Mi315Документ6 страницEmd Mi315Jesse BarnettОценок пока нет

- SM 44Документ8 страницSM 44خليل مقبوعОценок пока нет

- Checking for Blade SlippageДокумент3 страницыChecking for Blade SlippageAlexis KidemaОценок пока нет

- Propeller Maintenance Manual 132A: Page 7-50 Rev. 22 Dec/20Документ3 страницыPropeller Maintenance Manual 132A: Page 7-50 Rev. 22 Dec/20Alexis KidemaОценок пока нет

- Motor Drive Mount InstructionsДокумент4 страницыMotor Drive Mount InstructionsfettickОценок пока нет

- Power Plant Mount: Group 32Документ14 страницPower Plant Mount: Group 32Toponari MedveОценок пока нет

- Basic Louver Installation, Operation & Maintenance InstructionsДокумент5 страницBasic Louver Installation, Operation & Maintenance InstructionsJane RoОценок пока нет

- Operating Instructions for Vertical Spindle Well PumpsДокумент30 страницOperating Instructions for Vertical Spindle Well PumpsDouglas DuarteОценок пока нет

- 79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)Документ12 страниц79U, E Spring Return and Double Acting Pneumatic Quarter-Turn Actuators Operations (2000)COILED TUBINGОценок пока нет

- Explosive Atmospheres Brochure 3AUA0000037223 REVC en LowresДокумент98 страницExplosive Atmospheres Brochure 3AUA0000037223 REVC en LowresQIUPEILINОценок пока нет

- H6 Compressor Revs Sensor TSBДокумент3 страницыH6 Compressor Revs Sensor TSBSolomanTrismosinОценок пока нет

- Instruction Manual-Smc 33KVДокумент9 страницInstruction Manual-Smc 33KVRAKESH CHANDRA PATRAОценок пока нет

- Electro-Motive: Division of General Motors Corporotion, La GrangeДокумент4 страницыElectro-Motive: Division of General Motors Corporotion, La GrangeVladimir ArsicОценок пока нет

- Glass and Mirrors: Section 9LДокумент18 страницGlass and Mirrors: Section 9LJarry PotterОценок пока нет

- 97-99 Mitsubishi Eclipse Electrical ManualДокумент540 страниц97-99 Mitsubishi Eclipse Electrical Manualdustyboner98% (60)

- Modification Instruction: Truck, Medium, Mc2, Unimog - All TypesДокумент3 страницыModification Instruction: Truck, Medium, Mc2, Unimog - All TypesmichaelОценок пока нет

- Nissan Td42 EngineДокумент100 страницNissan Td42 Enginearjun c75% (4)

- Technical Guide Description: SimplicityДокумент40 страницTechnical Guide Description: SimplicityGRUPO FRIGOОценок пока нет

- Installation Instructions: CautionДокумент32 страницыInstallation Instructions: CautionCristian MejiaОценок пока нет

- 204 - 02 Rear SuspensionДокумент6 страниц204 - 02 Rear Suspensiontechnical trainer 011cОценок пока нет

- Boogie Type MTD-WI-02Документ15 страницBoogie Type MTD-WI-02vinothОценок пока нет

- Wood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsДокумент4 страницыWood Propellers: Installation, Operation, & Maintenance Integral Flange CrankshaftsPOUETОценок пока нет

- 50TQN240 (E) - Manual de InstalaciónДокумент40 страниц50TQN240 (E) - Manual de Instalaciónfloro cortes. tОценок пока нет

- 48T 6SI ManualДокумент82 страницы48T 6SI ManualGene Williams Jr.Оценок пока нет

- CBN Series 2000 Emerson BrowningДокумент20 страницCBN Series 2000 Emerson BrowningLuis Ramón Argüello RealОценок пока нет

- SB96-7C Torque Limits TCM (1)Документ13 страницSB96-7C Torque Limits TCM (1)Christian Enrique Casique PajarОценок пока нет

- John Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)Документ16 страницJohn Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)laopaodunОценок пока нет

- Manual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components SystemsДокумент30 страницManual Maintenance Lubrication Champion 710 740a 750 780a Motor Graders Service Engine Components SystemsRoussel Florez ZuloagaОценок пока нет

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationОт EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationОценок пока нет

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationОт EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003От EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Рейтинг: 5 из 5 звезд5/5 (1)

- Automatic Transaxle Drive Axle: Section 3AДокумент14 страницAutomatic Transaxle Drive Axle: Section 3AJarry PotterОценок пока нет

- Power Booster: Section 4CДокумент13 страницPower Booster: Section 4CJarry PotterОценок пока нет

- DAEWOO J-100 Brake GuideДокумент21 страницаDAEWOO J-100 Brake GuideJarry PotterОценок пока нет

- Horns: Section 9CДокумент5 страницHorns: Section 9CJarry PotterОценок пока нет

- Bumpers and Fascias: Section 9OДокумент14 страницBumpers and Fascias: Section 9OJarry PotterОценок пока нет

- Manual Transaxle Drive Axle: Section 3BДокумент17 страницManual Transaxle Drive Axle: Section 3BJarry PotterОценок пока нет

- Section 4F: Daewoo J-100 Bl2 / Bl3Документ217 страницSection 4F: Daewoo J-100 Bl2 / Bl3Jarry PotterОценок пока нет

- Wipers/Washer Systems: Section 9DДокумент24 страницыWipers/Washer Systems: Section 9DJarry PotterОценок пока нет

- J 4bДокумент11 страницJ 4bJarry PotterОценок пока нет

- J - 2e NubiraДокумент12 страницJ - 2e NubiraJarry PotterОценок пока нет

- Section 2D: General SpecificationsДокумент33 страницыSection 2D: General SpecificationsJarry PotterОценок пока нет

- Lighting Systems: Section 9BДокумент51 страницаLighting Systems: Section 9BJarry PotterОценок пока нет

- Waterleaks: Section 9IДокумент6 страницWaterleaks: Section 9IJarry PotterОценок пока нет

- Glass and Mirrors: Section 9LДокумент18 страницGlass and Mirrors: Section 9LJarry PotterОценок пока нет

- J 8bДокумент82 страницыJ 8bJarry PotterОценок пока нет

- Cruise Control System: Section 9UДокумент19 страницCruise Control System: Section 9UJarry PotterОценок пока нет

- Frame and Underbody: Section 9NДокумент6 страницFrame and Underbody: Section 9NJarry PotterОценок пока нет

- Exterior Trim: Section 9MДокумент5 страницExterior Trim: Section 9MJarry PotterОценок пока нет

- Body Wiring System: Section 9AДокумент11 страницBody Wiring System: Section 9AJarry PotterОценок пока нет

- Seats: Section 9HДокумент17 страницSeats: Section 9HJarry PotterОценок пока нет

- Audio Systems: Section 9FДокумент15 страницAudio Systems: Section 9FJarry PotterОценок пока нет

- Interior Trim: Section 9GДокумент25 страницInterior Trim: Section 9GJarry PotterОценок пока нет

- Wipers/Washer Systems: Section 9DДокумент24 страницыWipers/Washer Systems: Section 9DJarry PotterОценок пока нет

- Remote Keyless Entry and Perimeter/Ultrasonic Anti-Theft SystemДокумент27 страницRemote Keyless Entry and Perimeter/Ultrasonic Anti-Theft SystemJarry PotterОценок пока нет

- Lighting Systems: Section 9BДокумент51 страницаLighting Systems: Section 9BJarry PotterОценок пока нет

- Body Front End: Section 9RДокумент14 страницBody Front End: Section 9RJarry PotterОценок пока нет

- Horns: Section 9CДокумент5 страницHorns: Section 9CJarry PotterОценок пока нет

- Squeaks and Rattles: Section 9KДокумент3 страницыSqueaks and Rattles: Section 9KJarry PotterОценок пока нет

- Rear Body Service GuideДокумент18 страницRear Body Service GuideJarry PotterОценок пока нет

- Windnoise: Section 9JДокумент2 страницыWindnoise: Section 9JJarry PotterОценок пока нет

- GF - 4 - GF - 6 - 790 700 337 - 01 - enДокумент2 страницыGF - 4 - GF - 6 - 790 700 337 - 01 - enAdrianОценок пока нет

- Plagiarized Bio-Nanoelectronics in "Journal of The American Chemical Society"Документ7 страницPlagiarized Bio-Nanoelectronics in "Journal of The American Chemical Society"Rostyslav SKLYAR, Dr. (Eng)Оценок пока нет

- Sunward Rotary Drilling Rig Maintenance ManualДокумент35 страницSunward Rotary Drilling Rig Maintenance ManualPaul Kenneth AbayataОценок пока нет

- Mapping of Significant Natural Resources: Category: Bodies of WaterДокумент3 страницыMapping of Significant Natural Resources: Category: Bodies of WaterDei HernandezОценок пока нет

- Standard 2Документ10 страницStandard 2Bridget GumboОценок пока нет

- Viavi: Variable Optical Attenuators (mVOA-C1)Документ6 страницViavi: Variable Optical Attenuators (mVOA-C1)gwОценок пока нет

- Cylindrical Plug Gage DesignsДокумент3 страницыCylindrical Plug Gage DesignskkphadnisОценок пока нет

- Quiz 2 ReviewДокумент17 страницQuiz 2 ReviewabubakkarОценок пока нет

- XG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial NumbersДокумент153 страницыXG25-XG30: 44208060100 REV.003 03/2008 This Catalogue Is Valid For Trucks As From Serial Numbersalexandre donizetiОценок пока нет

- Hydrocarbon TechnologyДокумент21 страницаHydrocarbon Technologyghatak2100% (1)

- PCH (R-407C) SeriesДокумент53 страницыPCH (R-407C) SeriesAyman MufarehОценок пока нет

- Jack of All Trades ArchetypeДокумент2 страницыJack of All Trades ArchetypeGwazi MagnumОценок пока нет

- Mobile Phone Addiction 12 CДокумент9 страницMobile Phone Addiction 12 Cvedang agarwalОценок пока нет

- Speedface-V5L (Ti) : Face & Palm Verification and Thermal Imaging Temperature Detection TerminalДокумент2 страницыSpeedface-V5L (Ti) : Face & Palm Verification and Thermal Imaging Temperature Detection TerminalardiОценок пока нет

- Lesson Plan in Science 10 2nd QuarterДокумент5 страницLesson Plan in Science 10 2nd QuarterJenevev81% (21)

- Alvi Hanif Adil Ahmed Vveinhardt Impact of Organizational Culture On Organizational Commitment and Job Satisfaction-LibreДокумент11 страницAlvi Hanif Adil Ahmed Vveinhardt Impact of Organizational Culture On Organizational Commitment and Job Satisfaction-LibreLeilane AlvesОценок пока нет

- 3 - Big Data CharacteristicsДокумент32 страницы3 - Big Data CharacteristicsWong pi wenОценок пока нет

- EEG Signal Classification Using K-Means and Fuzzy C Means Clustering MethodsДокумент5 страницEEG Signal Classification Using K-Means and Fuzzy C Means Clustering MethodsIJSTEОценок пока нет

- Software Engineering Poject SampleДокумент15 страницSoftware Engineering Poject SamplemostafajoonОценок пока нет

- WINTER 2021 SYLLABUS All Lab Classes - Docx-2Документ7 страницWINTER 2021 SYLLABUS All Lab Classes - Docx-2Sushi M.SОценок пока нет

- USTHB Master's Program Technical English Lesson on Reflexive Pronouns and Antenna FundamentalsДокумент4 страницыUSTHB Master's Program Technical English Lesson on Reflexive Pronouns and Antenna Fundamentalsmartin23Оценок пока нет

- Grade-3-DLL MATHEMATICS-3 Q1 W4Документ3 страницыGrade-3-DLL MATHEMATICS-3 Q1 W4Jonathan Corveau IgayaОценок пока нет

- Yoshimi Advanced User ManualДокумент297 страницYoshimi Advanced User Manualfby999Оценок пока нет

- Manual de Diagnostico D3E PDFДокумент72 страницыManual de Diagnostico D3E PDFJosé Luis Contreras Calderón100% (3)

- McMurdo SART S4 v1 A4 06-13-2019Документ2 страницыMcMurdo SART S4 v1 A4 06-13-2019Felipe OliveiraОценок пока нет

- Gabriel Feltran. "The Revolution We Are Living"Документ9 страницGabriel Feltran. "The Revolution We Are Living"Marcos Magalhães Rosa100% (1)

- Asphalt Laboratory Manual RevДокумент13 страницAsphalt Laboratory Manual RevKurian C ChackoОценок пока нет

- Organizational Change & Development - VIL2021 - 22Документ3 страницыOrganizational Change & Development - VIL2021 - 22Rahul TRIPATHIОценок пока нет

- Spe 143287 MS PДокумент11 страницSpe 143287 MS PbvkvijaiОценок пока нет

- 38-13-10 Rev 2Документ128 страниц38-13-10 Rev 2Gdb HasseneОценок пока нет