Академический Документы

Профессиональный Документы

Культура Документы

Alcofine 1206

Загружено:

Shiv Prakash SinghИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Alcofine 1206

Загружено:

Shiv Prakash SinghАвторское право:

Доступные форматы

SSRG International Journal of Civil Engineering (SSRG-IJCE) – volume 3 Issue 5 – May 2016

Use of alccofine 1206 to achieve high

performance durable concrete

1 2 3 4

Alok Kumar , Oshin Parihar , Rahul Chaudhary , Shiv Prakash Singh

1

Asst. professor, Poornima Institute of Engineering and Technology, Jaipur.

2,3,4

B. Tech. Students, Poornima Institute of Engineering and Technology, Jaipur.

Abstract partial replacement of OPC by Alccofine1206 which varies

This dissertation work is to study the influence of Alccofine 1206 a

from 5% to 15% at interval of 5% by total weight of OPC

mineral admixture in concrete when it is mixed in cement concrete for M25 grade of concrete.

for the green state and hardened state i.e. for workability and There are many waste products which are generated from

strength of concrete using OPC (43 grade). Alccofine 1206 has

industries and factories, dumped openly which cause

been added to OPC which varies from 5% to 15% at interval of

5% by total weight of OPC and partial replacement of OPC (43 environmental problems and also spread diseases. These

grade) by Alccofine 1206 which varies from 5% to 15% at interval waste products can be recycled in useful way to save the

of 5% by total weight of OPC. A total eighteen mixes (trial mix, environment. These waste material or so called by-products

control mix and variation mix) were prepared for grade M25 of are fly ash, silica fume, ground granulated blast furnace slag

concrete. This study investigates the performance of concrete and Alccofine which are being reused now a days in

mixture in terms of Compressive strength for 7days and 28 days, construction industries mainly by making few stabilized

Flexural strength of beam 28 days and Splitting tensile strength of changes in these waste materials.

Cylinder for 28 days respectively of M-25 grade concrete. The

addition levels of OPC by Alccofine 1206 were 5%, 10% and 15% In present days some waste material are used to produce

where addition levels of 1% super-plasticizer was used in all the

efficient & effective concrete as blending material or

test specimens for better workability at lower water-binder ratio

and to identify the sharp effects of Alccofine1206 on the properties

mineral admixture. Most common and known blending

of concrete. Water-binder ratio was kept 0.43 for all cases. Total materials or mineral admixture used in concrete production

number of specimens for cubes 24, cylinders 12 and beams 12 industries are marble powder, silica fume, fly ash, ground

which were casted for testing to study influence of Alccofine 1206 granulated blast furnace slag and new by product admixture

on concrete. These Concrete specimens were deep cured in water is Alccofine which is glass based and take from iron

under normal atmospheric temperature. On the basis of result that factories. This is due to the fact that recycling of industrial

addition of concrete from Alccofine 1206 was found to increase in wastes as blending materials has technical, economical and

all strength (Compressive, Flexural & Splitting Tensile strength) environmental benefits.

and durability of variation mix of concrete on all age when

compared to normal concrete its use should be promoted for better Containing mineral admixtures within pozzolanic concretes

performance as well as for environmental sustainability. are used extensively throughout the world for their good

Key Words:- Alccofine 1206, Compressive strength, Durability, performance and for ecological and economic reason and the

High Performance Concrete Workability, Compressive Strength, applications of such concretes are increasing day by day due

Flexural Strength, Splitting Tensile Strength. to their superior structural performance, environmental

friendliness and energy conserving implications. Mineral

I .Introduction admixture, super plasticizer and retarders etc are playing

The demand of better concrete is increasing day by day. effective role for high performance of concrete industries, a

Improved quality of concrete will only perform better if mineral admixture which performs in superior manner than

concrete improves workability, durability, flow ability & all admixture used in India is Alccofine 1206 will be better

resistance to chemical attack/corrosion and reduce w/c ratio, composite material with cement to mix with natural fine

heat of hydration & segregation mainly. For the fulfilment aggregate and coarse aggregate for measurement of

of above properties waste produced from the steel & other conventional concrete performance.

industries are used for effective & efficient strength & II. Objective of study

durability of concrete.

The main objective of this study is to use of Alccofine

Alccofine 1206 has been added into OPC which varies from 1206 as mineral admixture which is mixed (on addition of

5% to 15% at interval of 5% by total weight of OPC and Alccofine 1206 into OPC & partial replacement

ISSN: 2348 – 8352 www.internationaljournalssrg.org 30

Page 181

SSRG International Journal of Civil Engineering (SSRG-IJCE) – volume 3 Issue 5 – May 2016

of OPC by Alccofine 1206) with OPC to investigate the Aggregate selection

influence of Alccofine 1206 in concrete and to see the

suitability of Alccofine 1206 for use in concrete. Aggregates for concrete consist of gravel and sand which

To analyze the results of density, workability, represents the grain skeleton for the concrete. All cavities

compressive strength, flexural strength and splitting tensile which are within this skeleton need to be filled with binder

strength for M25 grade of concrete by using waste material paste as much as possible. Concrete aggregates occupy

of iron factories. approximately 80% of total concrete weight and 70 – 75%

To compare the engineering properties of improved of total concrete volume. Optimum use of the aggregates

concrete for M25 (mix with Alccofine 1206 by addition & quality and size improves the concrete quality, mainly

partial replacement) samples with conventional concrete ( coarse aggregate maintain better improvement for

M25 as per mix design). performance.

III. Methodology Table 1. Properties of coarse aggregates of 20mm

A.Binder selection Tests Coarse Aggregate

20mm

Mostly used OPC (Ordinary Portland Cement) and then

only few have used PPC (Portland pozzolana cement) for Density(OD) 1476 kg/m3

their research because of its durability, high strength (more

than 80-85 % strength is achieved within 28 days as Density(SSD) 1560 kg/m3

compare to that of PPC which only achieves 70-75 %

maximum within 28 days). Bulk Density(Dry) 1481 kg/m3

B.Additive selection Sp. Gravity(OD) 2.62

Mostly there are two types of additive, these are mineral Sp Gravity(SSD) 2.65

admixture and chemical admixture and research has been

performed by different researcher over all additive for their Water Absorption 0.44%

properties of performance and influence when mix with

Portland cement. As per demand of high strength, high

performance, durability, workability and anti corrosive Fine Aggregate

concrete. A mineral admixture which performs in superior There are four grading zone for fine aggregate as per IS-

manner than that of all other admixture found/use in India is 383:1970 and these are Grading Zones I, II, III & IV. These

Alccofine. grading zone classified as per percentage passing material

Table 1 Properties of Alccofine 1026 from various sieves and there are mainly four zones and they

all have different passing percentage limit for different

Analysis Alccofine 1026 sieves but there is only one sieve(600 micron) which is

Bulk Density (kg/m3) 750-850 almost common to all Zone specification .

Surface Area (cm2/gm) 8000 Table 2. Properties of fine aggregate

Particle Shape Irregular Tests Natural Fine aggregate

Particle Size N\A Density(OD) 1622 kg/m3

d10 N\A Density(SSD) 1670 kg/m3

d50 <7 micron

d95 <20 micron Bulk Density 1622 kg/m3

Specific Gravity 2.9 (Dry)

CaO (%) 30-34 Bulk Density 1670 kg/m3

(SSD)

Al2O3 (%) 18-25

Fe2O3 (%) Sp Gravity (OD) 2.61

0.8-0.3

SO3 (%) 0.1-0.4 Sp Gravity (SSD) 2.62

MgO (%) 6-10 Water Absorption 1.25%

SiO2 (%) 30-36

ISSN: 2348 – 8352 www.internationaljournalssrg.org 31

Page 182

SSRG International Journal of Civil Engineering (SSRG-IJCE) – volume 3 Issue 5 – May 2016

Compressive Strength

The compressive strength of all mixes was measured with

cube specimen of size 150mm(length) x 150mm(width) x

150mm(depth).The specimens were tested after curing for 7

days and 28 days fully immersed in water tank as per IS

516:1959 for method of tests for strength of concrete.

Compressive strength = P/A (Unit = N/mm2 or MPa) Where

P = Load,,A = Area of Specimen

Fig3. Splitting Tensile strength Test

Splitting Tensile Strength = 2P/πld (Unit = N/mm2 or

MPa)Where,P = Load,l = Length of Specimen,d = Diameter

of specimen

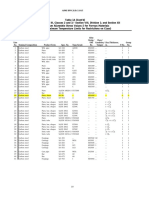

Table 3. Compressive Strength of Cube on Replacement of OPC by

Alccofine for M25 Grade for 7 Days

Mix(Cement+

S.no Alccofine) Average for compressive

2

Load(N) Strength(N/mm )

Fig 1. Compressive Testing machine

1 OPC+AL(100+0) 493333 21.93

Flexural Strength 2 OPC+AL(95+5) 433333 22.1

The Flexural strength of all mixes was measured with beam 3 OPC+AL(90+10) 485000 22.95

specimen of size 700mm(length) x 150mm(width) x 4 OPC+AL(85+15) 513333 24.2

150mm(depth).The specimens were tested after curing for

28 days fully immersed in water tank as per IS 516:1959 for

method of tests for strength of concrete. The central point Graph 1. Compressive Strength For 7 Days

loading method was used for this testing.

30

25

20

15 Avg.

for

comp

.stren

gth

10

Fig2. Flexural strength Test (for single loading) 5

0

Flexural Strength = 3PL/2bd2 = 3PL/2d3 (b=d,due to size of

b and d are equal) (Unit = N/mm2 or MPa) Where, P = Load

,L = Distance From Centre of Two Support ,b = Depth of

Specimen ,d = Width of Specimen. Table 4. Average Compressive Strength of cube on replacement of

OPC for M25 for 28 Days

Splitting Tensile Strength

Mix(Cement+

The split tensile strength of all mixes was measured with

S.no Alccofine) Average for compressive

cylinder specimen of size 300mm(length) x

150mm(diameter).The specimens were tested after curing 2

Load(N) Strength(N/mm )

for 28 days fully immersed in water tank as per IS

5816:1999 for method of test splitting tensile strength of 1 OPC+AL(100+0) 681666 30.30

concrete. 2 OPC+AL(95+5) 750000 33.33

3 OPC+AL(90+10) 790000 35.11

4 OPC+AL(85+15) 838333 37.26

ISSN: 2348 – 8352 www.internationaljournalssrg.org 32

Page 183

SSRG International Journal of Civil Engineering (SSRG-IJCE) – volume 3 Issue 5 – May 2016

Graph 2. Compressive strength for 28 Days Graph 3. Flexural strength For 28 Days

Average 25000

40 20000

for 15000

20 10000 Average

compressi 5000

0 for

ve 0

Flexural

Strength

Load(N)

(N/mm2)…

Table 5. Comparison of Average Compressive Strength of cube on

replacement of OPC for M25 for 7 Days & 28 Days

Mix(Cement+ Average for compressive

2 Table 7. Splitting Tensile strength of cylinder on Replacement of

S.no. Alccofine) Strength (N/mm ) OPPC by Alccofine for M25 Grade for 28 days.

Mix(Cement+

7 Days 28 Days

S.no Alccofine) Average for Splitting

1 OPC+AL(100+0) 21.93 30.3 2

Load(N) Strength(N/mm )

2 OPC+AL(95+5) 22.1 33.33

1 OPC+AL(100+0) 150333 2.13

3 OPC+AL(90+10) 22.95 35.11

2 OPC+AL(100+5) 162666 2.30

4 OPC+AL(85+15) 24.2 37.26

3 OPC+AL(100+10) 184333 2.61

4 OPC+AL(100+15) 197666 2.80

Graph 3. Comparison of Average compressive strength of M25 at 7

Days & 28 Days

Graph 4. Splitting Strength for 28 Days

40

30 250000

Average 200000

20 for 150000

Comp. 100000 Average

50000 for

strength

2 0 Splitting

10 (N/mm )

Load(N)

0

Table 6. Flexural Strength on replacement of OPC by Alccofine for RESULTS AND ANALYSIS

M25 Grade for 28 Days

There had been various mixes of different type i.e. two

Mix(Cement+ variations with cement had been made. First one was to add

S.no Alccofine) Average for Flexural few percentage of Alccofine to cement which varies from

0% to 15% at interval of 5% and second one was to replace

Strength(N/mm )

2 few percentage of cement with Alccofine which varies from

Load(N)

0% to 15% at interval of 5% for both concrete mix of M25.

1 OPC+AL(100+0) 17700 4.72 Tests had been conducted for result of compressive strength,

2 OPC+AL(95+5) 19050 5.08 flexure strength & splitting tensile strength. The

compressive strength of all mixes was measured with cube

3 OPC+AL(90+10) 19333 5.16 specimen of size 150mm(length) x 150mm(width) x

4 OPC+AL(85+15) 20000 5.33 150mm(depth).The specimens were tested after curing for 7

days and 28 days fully immersed in water tank as per IS

516:1959 for method of tests for strength of concrete.

ISSN: 2348 – 8352 www.internationaljournalssrg.org 33

Page 184

SSRG International Journal of Civil Engineering (SSRG-IJCE) – volume 3 Issue 5 – May 2016

The Flexural strength of all mixes was measured with beam Alccofine 1206 into OPC & replacement of OPC

specimen of size 700mm (length) x 150mm(width) x by Alccofine 1206 for M25 grade of cement is

150mm(depth) .The specimens were tested after curing for required to be done.

28 days fully immersed in water tank as per IS 516:1959 for 4. The comparative study on addition of Silica fume

method of tests for strength of concrete. The central point & Alccofine 1206 with OPC and partial

loading method was used for this testing. replacement of OPC by Silica fume & Alccofine

1206 for M25 grade concrete is required to be

The split tensile strength of all mixes was measured with

studied.

cylinder specimen of size 300mm(length) x

150mm(diameter).The specimens were tested after curing References

for 28 days fully immersed in water tank as per IS 1. http://www.concretetechnologyforum.org/2010CSCDubai

5816:1999 for method of test splitting tensile strength of Proceedings

concrete. 2. IS code 2386, IS code 516

3. Parekh D. N. and Dr. Modhera C. D. “Assessment of

CONCLUSIONS Recycled Aggregate Concrete” publish by JERS/Vol.II/

Issue I/January-March 2011.

By analyzing the results of Compressive Strength test, 4. Y P Gupta “USE Of Recycled Aggregate In Concrete

Flexural Strength test and Splitting Tensile Strength test. Construction : A Need For Sustainable Environment” 34 th

5. Conference on OUR WORLD IN CONCRETE &

Following conclusions have been drawn: STRUCTURES: 16 – 18 August 2009, Singapore

6. Best Practice Guide for the use of “Recycled Aggregates

1. Compressive strength of concrete was increased in in New Concrete” published by the Cement & Concrete

mix M25, when Alccofine 1206 was added to OPC Association of New Zealand (CCANZ) in October 2011.

or partial replacement of OPC by Alccofine 1206 7. S R Yadav, S R Pathak, “Use Of Recycled Concrete

Aggregate In Making Concrete- An Overview” 34th

but higher strength (21.61% for M25) was found Conference on OUR WORLD IN CONCRETE &

on 15% addition of Alccofine 1206 with M25. STRUCTURES: 16 – 18 August 2009, Singapore.

2. On 15% addition of Alccofine 1206 into OPC and

partial replacement of OPC by Alccofine 1206 of

M25 grade concrete, the compressive strength was

observed 26.67 N/mm2 and 24.20 N/mm2

respectively.

3. Compressive strength of concrete was increased in

mix M25, when Alccofine 1206 was added to OPC

or partial replacement of OPC by Alccofine 1206

but higher strength (by 26.43% for M25) was

found on 15% addition of Alccofine 1206 with

both M20 & M25.

4. Flexural strength of concrete was increased in mix

M25, when Alccofine 1206 was added to OPC or

partial replacement of OPC by Alccofine 1206 but

higher strength (by 19.49 % for M25) was found

on 15% addition of Alccofine 1206 with M25.

5. Splitting tensile strength was increased in mix

M25, when Alccofine was added to OPC partial

replacement of OPC by Alccofine but higher

strength (by 35.45% for M25) was found on 15%

addition of Alccofine 1206 with M25.

Future Scope of the Work

1. The durability study of M25 grade concrete with

addition of Alccofine 1206 into OPC and partial

replacement of OPC by Alccofine 1206 is required

to be done.

2. The study on addition of natural fibres to improve

upon the toughness and crack resistance of M25

grade concrete with addition of Alccofine 1206

into OPC and partial replacement of OPC by

Alccofine 1206 is required to be done.

3. The study on use of crusher dust as partial

replacement with natural sand and addition of

ISSN: 2348 – 8352 www.internationaljournalssrg.org 34

Page 185

Вам также может понравиться

- Un Estudio de La Resistencia A La Compresión Del Hormigón PorДокумент10 страницUn Estudio de La Resistencia A La Compresión Del Hormigón PorgОценок пока нет

- Experimental Investigation On Alccofine Concrete IJERTV8IS040362Документ3 страницыExperimental Investigation On Alccofine Concrete IJERTV8IS040362245120741005Оценок пока нет

- High Performance Concrete With Partial Replacement of Cement by ALCCOFINE & Fly AshДокумент6 страницHigh Performance Concrete With Partial Replacement of Cement by ALCCOFINE & Fly AshvitusstructuresОценок пока нет

- Use of Rice Husk Ash As Strength-Enhancing Additive in Lightweight Cementitious Composite MortarsДокумент12 страницUse of Rice Husk Ash As Strength-Enhancing Additive in Lightweight Cementitious Composite MortarsFolorunsho AyomideОценок пока нет

- Development of Eco-Efficient and Cost-Effective Reinforced Self-Consolidation Concretes With Hybrid Industrial - Recycled Steel FibersДокумент13 страницDevelopment of Eco-Efficient and Cost-Effective Reinforced Self-Consolidation Concretes With Hybrid Industrial - Recycled Steel FibersDiego SukОценок пока нет

- 2018 Articulo Characterization and Optimization of Hardened Properties of 2018 CompositesДокумент15 страниц2018 Articulo Characterization and Optimization of Hardened Properties of 2018 Compositeserika guerreroОценок пока нет

- Performance of High Strength Concrete Consisting oДокумент10 страницPerformance of High Strength Concrete Consisting ojayОценок пока нет

- A Study of Compressive Strength of Concrete by Using Sugarcane Baggase Ashjournal of Physics Conference SeriesДокумент10 страницA Study of Compressive Strength of Concrete by Using Sugarcane Baggase Ashjournal of Physics Conference SeriesCARLOS ALTAMIRANO GUPIOCОценок пока нет

- Assessment of High Volume Replacement Fly Ash Concrete - Concept of Performance IndexДокумент6 страницAssessment of High Volume Replacement Fly Ash Concrete - Concept of Performance IndexKaraline MarcesОценок пока нет

- 2016 Experimental Analysis of Strength and Durability Properties of Quaternary Cement Binder and MortarДокумент8 страниц2016 Experimental Analysis of Strength and Durability Properties of Quaternary Cement Binder and MortarTiago BragaОценок пока нет

- Singhal D2018 (Alccofine)Документ10 страницSinghal D2018 (Alccofine)swathi manianОценок пока нет

- Dec 269Документ9 страницDec 269245120741005Оценок пока нет

- The Use of Rice Husk Ash As Admixture in ProducingДокумент8 страницThe Use of Rice Husk Ash As Admixture in ProducingDEINA GERAUDY BARON ATUESTAОценок пока нет

- Investigación CientíficaДокумент16 страницInvestigación CientíficaAnalia Sucari CalloОценок пока нет

- Construction and Building Materials: F.N. Okoye, J. Durgaprasad, N.B. SinghДокумент7 страницConstruction and Building Materials: F.N. Okoye, J. Durgaprasad, N.B. SinghHasu MehtaОценок пока нет

- Effect of Superplasticizer On Workability and PropДокумент8 страницEffect of Superplasticizer On Workability and PropStephen John ClementeОценок пока нет

- Properties of Self-Compacting Concrete Prepared With Coarse and Fine Recycled Concrete AggregatesДокумент6 страницProperties of Self-Compacting Concrete Prepared With Coarse and Fine Recycled Concrete AggregatesCristine RussellОценок пока нет

- Accepted Manuscript: Studies in Construction MaterialsДокумент20 страницAccepted Manuscript: Studies in Construction MaterialsHidayat Ullah-17BNCIV0897Оценок пока нет

- An Experimental Study On Strength Properties of Concrete Using Recycled Aggregate As Replacement in Coarse AggregateДокумент12 страницAn Experimental Study On Strength Properties of Concrete Using Recycled Aggregate As Replacement in Coarse Aggregatemomin sialОценок пока нет

- Replacement of Cement Using Fly AshДокумент22 страницыReplacement of Cement Using Fly Ashkaushal yadavОценок пока нет

- Construction and Building Materials: Yimmy Fernando Silva, Rafael Andres Robayo, Pedro Enrique Mattey, Silvio DelvastoДокумент6 страницConstruction and Building Materials: Yimmy Fernando Silva, Rafael Andres Robayo, Pedro Enrique Mattey, Silvio DelvastoSurender SinghОценок пока нет

- 13 50 PDFДокумент18 страниц13 50 PDFraviteja036Оценок пока нет

- Impact Properties of Geopolymer Based Extrudates Incorporated With y Ash and PVA Short FiberДокумент14 страницImpact Properties of Geopolymer Based Extrudates Incorporated With y Ash and PVA Short FiberDerLorenaОценок пока нет

- Mechanical Properties of Fly Ash and Ggbs Blended Geo Polymer Concrete Using Different Fine AggregatesДокумент5 страницMechanical Properties of Fly Ash and Ggbs Blended Geo Polymer Concrete Using Different Fine AggregatesVienRiveraОценок пока нет

- Swamy Nadh 2018Документ6 страницSwamy Nadh 2018swamyОценок пока нет

- Experimental Study On Partial Replacement of Cement Using AlccofineДокумент8 страницExperimental Study On Partial Replacement of Cement Using AlccofineNavik BhandariОценок пока нет

- ALL-RCA+GGBS and RCA+SF, Kou Et Al., 2011Документ8 страницALL-RCA+GGBS and RCA+SF, Kou Et Al., 2011Yara MounaОценок пока нет

- Fly Ash Based Geopolymer Binders Perspective Materials For Sustainable BuildingДокумент7 страницFly Ash Based Geopolymer Binders Perspective Materials For Sustainable BuildingimroicohОценок пока нет

- 821 PDFДокумент9 страниц821 PDFarifОценок пока нет

- Experimental Study On Concrete Using AlccofineДокумент7 страницExperimental Study On Concrete Using AlccofineIJRASETPublicationsОценок пока нет

- Usage of Cement Kiln Dust in Cement Products - Research ReviewДокумент7 страницUsage of Cement Kiln Dust in Cement Products - Research ReviewhawdinОценок пока нет

- 282PДокумент6 страниц282PNarasimha ReddyОценок пока нет

- 40 - Nano Clay - GeopolymerДокумент16 страниц40 - Nano Clay - Geopolymerfs friedaОценок пока нет

- Strength and WorkabilityДокумент12 страницStrength and WorkabilitytonydisojaОценок пока нет

- The Use of Blast Furnace Slag As A Supplementary CДокумент13 страницThe Use of Blast Furnace Slag As A Supplementary CCivil manОценок пока нет

- Final MAJOR ProjectДокумент40 страницFinal MAJOR Projectmurad seidОценок пока нет

- Project Management ReportingДокумент9 страницProject Management ReportingDIPCV GAGAN M SОценок пока нет

- Construction and Building MaterialsДокумент13 страницConstruction and Building MaterialsAshfaq AhmedОценок пока нет

- Effects of Use of Metakaolin and Pond Ash in Different Types of ConcreteДокумент5 страницEffects of Use of Metakaolin and Pond Ash in Different Types of ConcreteNalina Amith VijayanandОценок пока нет

- Sec 11 2Документ8 страницSec 11 2yasmin redaОценок пока нет

- Aydin & Baradin, 2014Документ7 страницAydin & Baradin, 2014Adit GendhonОценок пока нет

- Effect of Raffia Palm Ash (RPA) On The Compressive Strength of ConcreteДокумент6 страницEffect of Raffia Palm Ash (RPA) On The Compressive Strength of ConcreteInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Copper Slag As Sand Replacement For HighДокумент6 страницCopper Slag As Sand Replacement For HighANURAG CHAUHANОценок пока нет

- Comparative Study of Strength of Fibre Reinforced Geo Polymer Concrete and Conventional (OPC) ConcreteДокумент6 страницComparative Study of Strength of Fibre Reinforced Geo Polymer Concrete and Conventional (OPC) ConcreteEditor IJTSRDОценок пока нет

- Partial Replacement of ConcreteДокумент12 страницPartial Replacement of ConcreteGbenge JoshuaОценок пока нет

- Materials Today: Proceedings: Richa Palod, S.V. Deo, G.D. RamtekkarДокумент6 страницMaterials Today: Proceedings: Richa Palod, S.V. Deo, G.D. RamtekkarWalid YahiaouiОценок пока нет

- 7 - Sakshar ReportДокумент47 страниц7 - Sakshar ReportSakshar HОценок пока нет

- Roller Compacted Concrete Made of Electric Arc Furnance SlagДокумент14 страницRoller Compacted Concrete Made of Electric Arc Furnance SlagJamman Shahid ShiblyОценок пока нет

- Effect of Polythene Modified Bitumen On Properties of Hot Mix AsphaltДокумент6 страницEffect of Polythene Modified Bitumen On Properties of Hot Mix Asphaltsaurabh agrahariОценок пока нет

- Compressive Strength and Durability Properties of Roller-Compacted Concrete Pavement Containing Electric Arc Furnace Slag Aggregate and Fly AshДокумент11 страницCompressive Strength and Durability Properties of Roller-Compacted Concrete Pavement Containing Electric Arc Furnace Slag Aggregate and Fly AshMJundiОценок пока нет

- Long Term Study of Mechanical Properties, Durability and Environmental Impact of Limestone Cement ConcreteДокумент18 страницLong Term Study of Mechanical Properties, Durability and Environmental Impact of Limestone Cement ConcretePritha DasОценок пока нет

- Effect of Mineral Admixtures On Properties of Self Compacting ConcreteДокумент6 страницEffect of Mineral Admixtures On Properties of Self Compacting ConcreteShamseldin AbdoОценок пока нет

- (TV) Thirugnanasambandam, S. Kumaravel, S. Flexural Behaviour of Reinforced Low Calcium Fly Ash Based Geopolymer Concrete BeamДокумент8 страниц(TV) Thirugnanasambandam, S. Kumaravel, S. Flexural Behaviour of Reinforced Low Calcium Fly Ash Based Geopolymer Concrete Beamdmt7nzztcmОценок пока нет

- Investigation of Rheological and Fatigue Properties of Asphalt Mixtures Containing Polyester Fibers 2008 Construction and Building MaterialsДокумент5 страницInvestigation of Rheological and Fatigue Properties of Asphalt Mixtures Containing Polyester Fibers 2008 Construction and Building MaterialsMoslem AghapourОценок пока нет

- 1 s2.0 S235271022201751X MainДокумент14 страниц1 s2.0 S235271022201751X MainSofia Ximenes LopesОценок пока нет

- Binary and Quaternary Blends in High Strength ConcreteДокумент5 страницBinary and Quaternary Blends in High Strength ConcreteKalashОценок пока нет

- Construction and Building Materials: Mostafa Jalal, Alireza Pouladkhan, Omid Fasihi Harandi, Davoud JafariДокумент15 страницConstruction and Building Materials: Mostafa Jalal, Alireza Pouladkhan, Omid Fasihi Harandi, Davoud JafariDraganОценок пока нет

- Construction and Building Materials Vol 120.A28Документ10 страницConstruction and Building Materials Vol 120.A28Syed Hussain AliОценок пока нет

- Final Project Report 2Документ8 страницFinal Project Report 2Mallesh MaranurОценок пока нет

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessОт EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessОценок пока нет

- A-36 - Pages From Section II Part D (Customary)Документ3 страницыA-36 - Pages From Section II Part D (Customary)siswantoОценок пока нет

- Various Types of Shear Connectors in ComДокумент4 страницыVarious Types of Shear Connectors in ComraviciviltОценок пока нет

- Bus Bar & Cable ChartДокумент3 страницыBus Bar & Cable Chartdickey1976 JafriОценок пока нет

- TDS - Dicyanex 1200 (Evonik)Документ2 страницыTDS - Dicyanex 1200 (Evonik)LIM YE HENGОценок пока нет

- Thermocouple Wire Reference Guide: WWW - Omega.co - Uk +44 (0) 161 777 6611 WWW - Omega.co - Uk +44 (0) 161 777 6611Документ1 страницаThermocouple Wire Reference Guide: WWW - Omega.co - Uk +44 (0) 161 777 6611 WWW - Omega.co - Uk +44 (0) 161 777 6611Mohamed MaltiОценок пока нет

- Plating: Plating Is A Surface Covering in Which AДокумент6 страницPlating: Plating Is A Surface Covering in Which ASonti Mani kumarОценок пока нет

- Surface 8Документ31 страницаSurface 8Narkedamilli Tulasi RadhaОценок пока нет

- 6005-T6 Aluminum: Mechanical PropertiesДокумент2 страницы6005-T6 Aluminum: Mechanical PropertiesEvandro BorgesОценок пока нет

- Post Tensioned SlabДокумент38 страницPost Tensioned Slabmadz heussafОценок пока нет

- Aashto List T PDFДокумент8 страницAashto List T PDFsb hasanОценок пока нет

- Paint Matrix ANGSI BSDPA - BSOEДокумент8 страницPaint Matrix ANGSI BSDPA - BSOEZafarul Naim JamaludinОценок пока нет

- Concrete Slope ProtectionДокумент10 страницConcrete Slope ProtectionTAHER AMMARОценок пока нет

- Pipe SpecificationДокумент14 страницPipe SpecificationAdam NumalОценок пока нет

- GypsumДокумент28 страницGypsumMoatz HamedОценок пока нет

- Final Project Report 8th SemДокумент34 страницыFinal Project Report 8th SemTirth ShahОценок пока нет

- TDS Paht CF15Документ2 страницыTDS Paht CF15Felipe TeixeiraОценок пока нет

- Kemapox HF 381: Product InformationДокумент1 страницаKemapox HF 381: Product InformationAmr RagabОценок пока нет

- Tender Schedule Renovation of Vadakkechira Bus StandДокумент61 страницаTender Schedule Renovation of Vadakkechira Bus Standsuji91Оценок пока нет

- SiCare Silicone Product Brochure - Version 2023Документ26 страницSiCare Silicone Product Brochure - Version 2023IsabellaОценок пока нет

- SP-2888 RG PDSДокумент5 страницSP-2888 RG PDSreza ashtariОценок пока нет

- Watertite CL 51: 1-Component Sealing FilmДокумент2 страницыWatertite CL 51: 1-Component Sealing Filmsriatul2006Оценок пока нет

- Mechanical Properties of Metals - Lecture 9, MetE 143Документ53 страницыMechanical Properties of Metals - Lecture 9, MetE 143陈小花Оценок пока нет

- Carbon Nanofibers - Structure and FabricationДокумент16 страницCarbon Nanofibers - Structure and FabricationJeffery NguОценок пока нет

- Brief of Variables: Smaw Gtaw Gmaw SawДокумент3 страницыBrief of Variables: Smaw Gtaw Gmaw SawAdilMunirОценок пока нет

- Cromax 4140 PDFДокумент2 страницыCromax 4140 PDFDidik PrihantoroОценок пока нет

- Duct Bank InformationДокумент19 страницDuct Bank InformationGaneshОценок пока нет

- Unit 34 The Importance in Reusing, Reducing and Recycling MaterialsДокумент9 страницUnit 34 The Importance in Reusing, Reducing and Recycling MaterialsNurul huda MohammadОценок пока нет

- Lesson Pure SubstanceДокумент25 страницLesson Pure SubstanceCreamverly ArroyoОценок пока нет

- Research Letter: Properties of Reinforced Concrete Steel Rebars Exposed To High TemperaturesДокумент5 страницResearch Letter: Properties of Reinforced Concrete Steel Rebars Exposed To High TemperaturesCarlos BernabeОценок пока нет

- Basf Masterseal 912 Tds PDFДокумент2 страницыBasf Masterseal 912 Tds PDFDhananjay ShindeОценок пока нет