Академический Документы

Профессиональный Документы

Культура Документы

How To Make A CANE

Загружено:

Neng MaysaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

How To Make A CANE

Загружено:

Neng MaysaАвторское право:

Доступные форматы

Danish Version of this page:

http://sciencelakes.com/en-rigtig-paen-made-at-tjene-canes/ by

Einar Solbakken.

A Really Neat Way to Make Canes

John Gilbertson in MN was kind enough to want to SHARE his

findings with the world so he snail-mailed me a CD with a lot of

super photos, a letter and a wood template for a cane handle.

THANK YOU, John!

Here is the letter John sent with the CD which had 43 full-size

photos on it:

"A few years back, I developed a method of attaching a handle

to a diamond willow shaft. I prepared a pictorial to

demonstrate this method. I thought you might like to look at

this and maybe share it with your fellow woodworkers. I don't

have the skills to add commentary to he pictures, but they are

pretty much self explanatory.

The first part is shaping the handle. A solid, approximately 3"

piece of d. willow is necessary. The 6 1/2" cutoff is flattened

on two sides. A template is used to trace the shape on the

cutoff. A bandsaw cuts the shape and the sides are tapered.

Using a 7/8" forstner bit, a hole is drilled in the handle.

Next, the end of the shaft is rounded. Use a

1 1/16" deep holesaw with a quarter inch

pilot bit to do this. A preliminary centered

hole is drilled (very shallow) to locate the

holesaw pilot bit. With the shaft clamped

tightly to a work surface, carefully cut all

the way to total depth of the hole saw. Trim

the outer excess, again very carefully so that you do not nick

the rounded surface.

The shaft end will be slightly too big to fit into the 7/8 inch

hole in the handle,so, using a sanding block with 50 grit

abrasive, round the end to make a perfect tight fit.

When satisfied with fit, mark the handle and shaft to line up

the cane for best balance. Insert the shaft and make a mark

for depth for when you glue the pieces.

Cut a piece of quarter inch threaded steel

to insert* in hole made by the pilot bit.

Using a sharp knife, make some glue relief

grooves on the rounded shaft end. I use

yellow carpenters' glue. Make sure the

handle goes all the way down to your

depth mark and stick 'em together.

Now, the finishing is up to the individual. Grinders, sanders,

carving knives, whatever works. Just be very careful to NOT

remove much material away from the space immediately

below the joint."

Later, John told me this:

"Ken, I don't have the technical knowledge to set up a website.

But I do want to share the technique with other stick people.

Perhaps you'd like to slip it into your site alongside your other

cane making tutorial. Whatever suits you best if you'd like to

use it. Otherwise, try it on your own pieces if you want. I've

had a lot of success with the method, not only on diamond

willow, but with many other kinds of wood, domestic and

exotic. My best known customer was King Hussein of Jordan

who purchased a black ash cane of mine when he was a

patient at the Mayo Clinic in Rochester MN. ( This was back in

'92). The handle was approved by the orthopedic division at

that clinic.

Anyway, use it any way you wish.

Sincerely, John"

Here are the photos John provided; NOTE that I had to make them

a lot smaller and also had to REDUCE the quality of them so that

you would not have to wait until the cows came home before this

page would be loaded.

* Later, John said "The purpose of fliling the holesaw hole with

threaded steel is simply to reinforce the joint between handle

and shaft. It could also be filled with a wood dowel."

NOTE new page for Diamond Willow sticks FOR CANES at this

page:

http://www.sticksite.com/cane-sticks/index.html.

As John said, the pictures pretty well speak for themselves.

I can see making a binder of all the pictures printed out, as a

teaching guide.

As for the tip at the BOTTOM of the stick, John said: "

Ken, I use rubber furniture tips for cane ends. They are

inexpensive, last as long as more expensive cane tips, and

are easily replaced at almost any hardware store. The tip

can be removed to adjust the length of the cane. And, they

are available in many sizes; I find 7/8 inch to be the most

popular diameter for my uses.

AND That's It, Folks; Thanks again to John.

Personally, I use the same rubber tips and get them in

BULK from Astro-Tex Company in Plano, Texas. Here is a

pic:

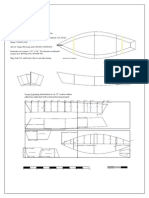

P.S. Here is the wood template John included for the handle; his

is 6 1/8 inch from tip to tip.

I asked John what he thought about using a piece of BIRCH for

the handle and he replied:

Your second question poses an interesting problem. Do you

want a "pure" diamond willow cane, or is it OK to combine

different kinds of wood. I know the birch material would be

easier to find in the thicker dimensions, and it would probably

be stronger than willow. But I prefer willow on willow. I cut

thick live willow as rot free as possible and dry it for several

years with the bark on. I don't worry too much about

diamonds on these pieces because when you slice deeply

into the wood, you get the rich heart wood color and usually

enough sapwood contrast to match the colors of the shaft.

Any diamonds or other depressions are bonuses.

So, with that in mind, I'll offer a piece of birch in SOME of the

packages of Diamond Willow, 36-inch cane sticks I'll offer at

http://www.sticksite.com/cane-sticks/index.html.

Вам также может понравиться

- Chipmunk 22Документ6 страницChipmunk 22rleblanc1Оценок пока нет

- Building The Osborne PlatterДокумент9 страницBuilding The Osborne PlatterHeman Lee50% (2)

- BSA Kayak PlansДокумент25 страницBSA Kayak PlansTodd R Taylor50% (2)

- One Sheet SampanДокумент5 страницOne Sheet Sampanleather_nunОценок пока нет

- A Reed Making Process For The Great Highland BagpipeДокумент11 страницA Reed Making Process For The Great Highland BagpipekriktsemajОценок пока нет

- Basic Marquetry and Beyond: Expert Techniques for Crafting Beautiful Images with Veneer and InlayОт EverandBasic Marquetry and Beyond: Expert Techniques for Crafting Beautiful Images with Veneer and InlayРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Vertov Dziga Kino-Eye The Writings of Dziga VertovДокумент406 страницVertov Dziga Kino-Eye The Writings of Dziga VertovCaca100% (3)

- Quick Canoe Made From PlywoodДокумент43 страницыQuick Canoe Made From PlywoodKades100% (1)

- Ferrocement A Versitile Construction MaterialДокумент113 страницFerrocement A Versitile Construction MaterialplutocowОценок пока нет

- 'Blondie' (8'4" X 4'3") 2001-John Bell, Kennesaw, GA JMB-002Документ13 страниц'Blondie' (8'4" X 4'3") 2001-John Bell, Kennesaw, GA JMB-002Isaac Perez Garcia100% (1)

- Study Plans For A Small Outboard Powered BoatДокумент4 страницыStudy Plans For A Small Outboard Powered BoatjancudakОценок пока нет

- Table Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!Документ8 страницTable Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!LinОценок пока нет

- Building A Wood Epoxy SharpieДокумент12 страницBuilding A Wood Epoxy SharpieAmy Rodriguez0% (2)

- X Class ConstructionДокумент21 страницаX Class Constructiontdfsks50% (2)

- KayakДокумент3 страницыKayaklymantabОценок пока нет

- United States Marine MRCP 3-1a - 23 Feb 1999 - Part01Документ124 страницыUnited States Marine MRCP 3-1a - 23 Feb 1999 - Part01Darryl Rhea100% (1)

- Preparedness ListsДокумент21 страницаPreparedness ListsAziz Azad DuralОценок пока нет

- One OffarticleДокумент6 страницOne OffarticleBOREBGK100% (1)

- Tipi Howto MenДокумент16 страницTipi Howto MensamirjaimesОценок пока нет

- Archery - StringsДокумент2 страницыArchery - StringsCalujnaiОценок пока нет

- Duck SkiffДокумент61 страницаDuck SkiffKay Pratt100% (2)

- Once Upon A Time in The WestДокумент3 страницыOnce Upon A Time in The WestAlex LuОценок пока нет

- Wood BoatДокумент1 страницаWood BoatTony RayeОценок пока нет

- Collection - PDF .44 SpecialДокумент5 страницCollection - PDF .44 SpecialRonnie RensburgОценок пока нет

- Cal 20 Owners ManualДокумент33 страницыCal 20 Owners ManualWil StuckeyОценок пока нет

- BlondieДокумент21 страницаBlondieOmar Valencia CastillónОценок пока нет

- Gyro Skipper PlansДокумент5 страницGyro Skipper PlansJayantha KandegamaОценок пока нет

- Indestructible Corner Clamp (Jig) For Welding ProjectsДокумент1 страницаIndestructible Corner Clamp (Jig) For Welding ProjectsTomas Tom MlОценок пока нет

- Frame Saw Manual 1902Документ111 страницFrame Saw Manual 1902wolf143Оценок пока нет

- Elerick Ron Cynthia 1981 SouthAfricaДокумент5 страницElerick Ron Cynthia 1981 SouthAfricathe missions networkОценок пока нет

- Rolling Home by John WintersДокумент3 страницыRolling Home by John WintersSwift Canoe And Kayak100% (1)

- How To Build A Wood Paddle BoardДокумент8 страницHow To Build A Wood Paddle BoardJavi JaviОценок пока нет

- The "How-To-Do-It" Books 1Документ130 страницThe "How-To-Do-It" Books 1Gutenberg.org100% (2)

- United States Patent (19) : VicardДокумент4 страницыUnited States Patent (19) : Vicard155100% (1)

- Trebuchet MathДокумент58 страницTrebuchet Mathreader27Оценок пока нет

- Mistral HullДокумент5 страницMistral HullmikeОценок пока нет

- 1904-Instruments For Forest Work-NeДокумент33 страницы1904-Instruments For Forest Work-NespaytОценок пока нет

- Adirondack Chair PlansДокумент9 страницAdirondack Chair PlansBEA18Оценок пока нет

- Hand Tools: An Educational Guide ForДокумент20 страницHand Tools: An Educational Guide Forsaeedbhatti100% (2)

- Self Defence With A Stick For SeniorsДокумент16 страницSelf Defence With A Stick For Seniorssifujuan100% (1)

- 2012.08 The Choctaw BlowgunДокумент2 страницы2012.08 The Choctaw BlowgunMonica StanОценок пока нет

- How To Make Rock Thin Sections, Without Much Equipment - How - To - Make - Rock - Thin - SectionsДокумент2 страницыHow To Make Rock Thin Sections, Without Much Equipment - How - To - Make - Rock - Thin - SectionstwinscrewcanoeОценок пока нет

- Instructions For Making "Home-Made" Ballistic GelatinДокумент3 страницыInstructions For Making "Home-Made" Ballistic Gelatinbrowar444Оценок пока нет

- Fao Buildin A Double Ended Cambodian Design PDFДокумент27 страницFao Buildin A Double Ended Cambodian Design PDFfridomeroОценок пока нет

- Fokker d7 ElectricДокумент2 страницыFokker d7 ElectricEmerson URОценок пока нет

- PLANS Folding KayakДокумент15 страницPLANS Folding KayakecalzoОценок пока нет

- The Jersey Albatross - A Free-Flight Model Airplane (Glider)Документ4 страницыThe Jersey Albatross - A Free-Flight Model Airplane (Glider)Bob Kowalski100% (1)

- Chauchat LMG PDFДокумент9 страницChauchat LMG PDFS84SОценок пока нет

- NW-Semi Automatic Shotgun-ManualДокумент19 страницNW-Semi Automatic Shotgun-ManualNorth Weapon100% (1)

- The Duck - A Free-Flight Model AirplaneДокумент6 страницThe Duck - A Free-Flight Model AirplaneBob Kowalski100% (1)

- Dowel - WikipediaДокумент23 страницыDowel - Wikipediamuti_khan20006003100% (1)

- 4 Foot Westerner p4Документ4 страницы4 Foot Westerner p4Negru CiprianОценок пока нет

- Investigation of Airfoil Profile Design Using Reverse Engineering Bezier CurveДокумент10 страницInvestigation of Airfoil Profile Design Using Reverse Engineering Bezier CurveBala MuruganОценок пока нет

- Robot Blocs de BoisДокумент42 страницыRobot Blocs de BoisLuc PoiretОценок пока нет

- Placa de Chladni CaseraДокумент11 страницPlaca de Chladni CaseraVVANDERОценок пока нет

- Whatnot Dish: The Ideal Gift BowlДокумент5 страницWhatnot Dish: The Ideal Gift BowlMarcos R. Hernández M.Оценок пока нет

- Making A Thumb PianoДокумент20 страницMaking A Thumb PianoUmberto AttianeseОценок пока нет

- (Article) Absolute Cheapskate Way To Start Making KnivesДокумент17 страниц(Article) Absolute Cheapskate Way To Start Making Knivesalquimico8Оценок пока нет

- Fantastic Book of Canes, Pipes, and Walking Sticks, 3rd Edition: A Sketchbook of Designs for Collectors, Woodcarvers, and ArtistsОт EverandFantastic Book of Canes, Pipes, and Walking Sticks, 3rd Edition: A Sketchbook of Designs for Collectors, Woodcarvers, and ArtistsРейтинг: 4 из 5 звезд4/5 (1)

- The Middle Eastern SoundДокумент21 страницаThe Middle Eastern SoundKevin DoeОценок пока нет

- TM Physics 10th PSR Digital BooksДокумент84 страницыTM Physics 10th PSR Digital BooksvishalОценок пока нет

- Tom's Favourite Subjects Are English and MathsДокумент3 страницыTom's Favourite Subjects Are English and MathsOana Maria StãnescuОценок пока нет

- CV Camille R. Sangalang 2015Документ4 страницыCV Camille R. Sangalang 2015Mica RegalaОценок пока нет

- Japan Views The PhilippinesДокумент6 страницJapan Views The PhilippinesEljhon GervacioОценок пока нет

- Método - Marimba - Thomas McMillanДокумент41 страницаMétodo - Marimba - Thomas McMillanMaria Alice Pereira Tucci100% (1)

- Peter Zumthor - Thinking Architecture PDFДокумент33 страницыPeter Zumthor - Thinking Architecture PDFDiana Sterian73% (11)

- I Got A Camera To Spy On My CatДокумент3 страницыI Got A Camera To Spy On My CatAlfonso El SabioОценок пока нет

- Demo Paper BeadsДокумент12 страницDemo Paper Beadsbandiolaangela2Оценок пока нет

- Pfaff Tiptronic 1029Документ40 страницPfaff Tiptronic 1029Juhász MariannОценок пока нет

- Arts Week 3Документ6 страницArts Week 3geraldine belandresОценок пока нет

- Bagor - A Late Mesolithic Settlement In: North-West IndiaДокумент23 страницыBagor - A Late Mesolithic Settlement In: North-West IndiaSoumyajit DasОценок пока нет

- Theme From Magic Flute: W.A. Mozart AllegrettoДокумент1 страницаTheme From Magic Flute: W.A. Mozart AllegrettomueploisОценок пока нет

- 'Methods of Power & Striking According To The Body's Upper & Lower Seven Stars.-1Документ2 страницы'Methods of Power & Striking According To The Body's Upper & Lower Seven Stars.-1Liew Yetmeng100% (1)

- Olmec CivilizationДокумент4 страницыOlmec CivilizationChristine PasayloОценок пока нет

- WK 3 4 Contemporary End TermДокумент8 страницWK 3 4 Contemporary End TermHagine CelestreОценок пока нет

- Ss CVДокумент8 страницSs CVapi-285473111Оценок пока нет

- Final Synopsis For ThesisДокумент17 страницFinal Synopsis For ThesisDeepak singhОценок пока нет

- AFV - Modeller July-Aug 2016Документ68 страницAFV - Modeller July-Aug 2016Prplknite100% (5)

- The Book of Dota 2 PDFДокумент9 страницThe Book of Dota 2 PDFKathryn BaileyОценок пока нет

- Augustus J. C. Hare-StoryOfTwoLives - Vol.3Документ548 страницAugustus J. C. Hare-StoryOfTwoLives - Vol.3MatthewDelNevoОценок пока нет

- ToyДокумент8 страницToySamm VilltorrОценок пока нет

- EDPM-Manuscript Signs ExerciseДокумент6 страницEDPM-Manuscript Signs ExerciseAngelo BengocheaОценок пока нет

- World's 25 Tallest BuildingsДокумент4 страницыWorld's 25 Tallest Buildingsalexandra garcia100% (1)

- History of Modern DesignДокумент8 страницHistory of Modern DesignTanya TangОценок пока нет

- Chibi Alpaca Pattern From La PandustriaДокумент4 страницыChibi Alpaca Pattern From La PandustriaCamila Eduarda100% (1)

- 4 Shaft WeavingДокумент14 страниц4 Shaft WeavingKathryn Bax100% (1)

- 2023 Seniors Week HMC Culmact - PostingДокумент17 страниц2023 Seniors Week HMC Culmact - PostingAkohItoОценок пока нет

- Elizabethan Theatre 1Документ9 страницElizabethan Theatre 1Bryan WilliamsОценок пока нет