Академический Документы

Профессиональный Документы

Культура Документы

Carbo

Загружено:

Kris Dela CruzАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Carbo

Загружено:

Kris Dela CruzАвторское право:

Доступные форматы

THE HYDROLYSIS OF GLYCOGEN BY GLYCEROL

EXTRACT OF MUSCLE

BY ALBERT CARRUTHERS AND WE1 YUNG LEE

(From the Department of Biochemistry, Peiping Union Medical College,

Peiping, China)

(Received for publication, July 24, 1934)

Downloaded from www.jbc.org by guest, on February 22, 2011

Barbour (1) has claimed that muscle amylase acting on glycogen

gives a trisaccharide as the sale product of hydrolysis. This find-

ing is strikingly different from those which have been obtained

with pancreatic, salivary, and malt amylases which, it is generally

agreed, produce maltose and, when conversion to disaccharide is

incomplete, also dextrin (2). Most investigations, it is true, have

been carried out with starch as substrate but the studies of Pring-

sheim (3) and Kuhn (4) lead one to suppose that there is no signifi-

cant difference between amylopectin, a constituent of starch, and

glycogen. Sodium fluoride extracts of muscle acting on glycogen

were found by Osborne and Zobel (5) to produce dextrins and

maltose and probably some glucose. Among the products of

glycogen hydrolysis by potassium chloride extracts of frog muscle

Lohmann (6) found glucose and a sugar identified as an amylo-

triose. If glycerol extracts of muscle split glycogen entirely and

solely to a trisaccharide, these extracts must have peculiar proper-

ties distinguishing them from other amylase systems. Case (7),

without giving any experimental data, stated that he was able to

confirm Barbour’s results. Experimental work reported here is

not in agreement with Barbour’s conclusions.

EXPERIMENTAL

Esperiment I-30 cc. of glycerol extract of rabbit muscle, pre-

pared by the method Barbour employed (1)) were mixed with 10 cc.

of phosphate buffer, pH 6.4, and 8.0 gm. of glycogen dissolved in

160 cc. of water. Toluene was added and the mixture was incu-

bated 46 hours. Protein was then removed by heat coagulation.

525

526 Glycogen Hydrolysis

The addition of 2 or 3 drops of dilute acetic acid facilitated coagu-

lation and filtration. To the clear filtrate 2 volumes of alcohol

were added to remove unchanged glycogen. After standing 24

hours in the ice box, the mixture was filtered and the filtrate con-

centrated under reduced pressure and at temperatures below 50”.

To the syrupy concentrate 95 per cent alcohol was added, which

gave a precipitate. After this precipitate was separated by centri-

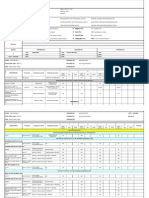

TABLE I

Properties of Sugar Fractions Isolated from

-

Glycogen-Muscle

-

Extract Digests

I I

Downloaded from www.jbc.org by guest, on February 22, 2011

GlllCOS9 Specific Acetyl product

equivalent rotation

t

Nature of fraction and

I

method of separation Acetyl

,

Mol. wt. con-

I tent

4

-- ~-

am. am. Pm Per

cent cent

Powder by alcohol 0.203 0.613 33

mtn. “ “ 0.3590.990 34 173

I Powder by alcohol- 0.632 0.695 90 126 70

ether pptn.

Total concentrate 4.4003.320 53 140

Powder by alcohol 1.295 2.905 45 162 60 1235 (A)

ppt*- 663 (B) 51.75

Residual syrup 50 161 62 602 49.40

Total concentrate 2.5926.176 42 171 65

Powder by alcohol 0.574 1.914 30 198 59 1414 (A)

mtn. 735 (B) 51.74

Powder by alcohol- 0.502 1.396 36 168 59

ether pptn.

I Residual syrup 1.205 1.890 64 133 60 625 52.55

-

fuging, the liquor was reconcentrated and absolute alcohol was

added to the concentrate. A second precipitate was separated

and the liquor was again concentrated. This time a mixture of

equal parts of alcohol and ether was added and a third precipitate

was obtained. These precipitates are referred to as Fractions I,

II, III in Table I, Experiment 1. All the fractions were very

sticky, owing to contamination with glycerol, and therefore the

analytical results, presented in Table I, were probably not reliable.

A. Carruthers and W. Y. Lee 527

Repeated washing of the precipitate with absolute alcohol and

ether removed some of the stickiness. Attempts to purify frac-

tions by precipitation with barium hydroxide were unsuccessful.

On account of the difficulty experienced in isolating sugar frac-

tions from the digestion mixtures it was decided to remove glycerol

from the extract by dialysis. Extracts were dialyzed in collodion

sacks for 1 hour against running tap water, followed by 2 hours

against distilled water. The latter was changed at intervals of 15

minutes. The dialyzed extracts were found to be quite active and

therefore no sodium chloride was added to the digestion mixtures.

Buffer also was omitted in the hope that this would facilitate the

Downloaded from www.jbc.org by guest, on February 22, 2011

isolation of pure fractions.

Experiment S-60 cc. of glycerol extract, treated with toluene

and the toluene layer removed, were dialyzed as described and the

dialyzed preparation was mixed with 10 gm. of glycogen dissolved

in water. The volume of the mixture was 200 cc. A few drops of

toluene were added and the mixture was incubated for 46 hours at

37”. Protein and unchanged glycogen were removed as in Experi-

ment 1. The aqueous sugar solution was concentrated to a small

volume and absolute alcohol was added, giving a precipitate,

Fraction I. This precipitate was obtained as a white powder and

in contrast to the fractions of Experiment 1 the preparation was

not sticky. As Fraction I had a much higher glucose equivalent

than could possibly be given by a trisaccharide, no further frac-

tionation was attempted. The liquor from Fraction I was con-

centrated to a syrup and analyzed. Results of this experiment

are summarized in Table I.

Experiment S-50 cc. of glycerol extract, prepared as before,

were dialyzed and mixed with 8.0 gm. of glycogen in water and the

volume made to 200 cc. Toluene was added and the mixture was

incubated at 37” for 36 hours. Protein and unchanged glycogen

were removed and an aqueous concentrate prepared as in Experi-

ment 2. The results of this experiment are summarized in Table

I and full analytical details follow.

Analysis of Aqueous Concentrate-The total volume was 40.5

cc. 2 cc. of the concentrate were diluted to 20 cc. and the optical

activity was determined. To 10 cc. of the 20 cc. solution 0.66 cc.

of concentrated HCl was added and the mixture heated for 3 hours

in a boiling water bath, neutralized, and diluted to 20 cc. The

528 Glycogen Hydrolysis

optical activity was again determined. Reducing power of the

solution before and after acid hydrolysis was also determined.

Reducing power throughout this work was measured by the

Shaffer-Hartmann method as modified by Barbour (1).

(a) The glucose equivalent (by reducing power) in 40.5 cc. of

concentrate before hydrolysis = 2.592 gm.; (b) after hydrolysis =

6.176 gm.; (a)/(b) = 42 per cent.

Rotation before Hyldrolysis-a! = 5.23” 2 dm tube* C1 =

6.176 X 2/40.5 X 5 = 1.525; [c& = 17;‘. ’ ’

Rotation after Hydrolysis--a = l.OO”, 2 dm. tube; C = 1.52512 =

0.7625; [a]~~ = 65”.

Downloaded from www.jbc.org by guest, on February 22, 2011

Separation of Fractions-To the aqueous concentrate (38 cc.)

200 cc. of absolute alcohol were added, which gave a white precipi-

tate (Fraction I). To the alcoholic liquor, obtained after centri-

fuging off Fraction I, 100 cc. of ether were added, when a further

precipitate was obtained and, by centrifuging, this gave Fraction

II. The ether-alcohol mixture was not clear on separation, even

after prolonged cooling and it was therefore concentrated in vacua

below 50” to a syrup (Fraction III).

Analysis of Fractions-Fraction I was washed by stirring twice

with absolute alcohol and once with ether and then dried in a desic-

cator over sulfuric acid. Yield, 2.21 gm. 50 mg. dissolved in

20 cc. of water gave (a) a glucose equivalent before acid hydroly-

sis = 13.0 mg.; (b) after acid hydrolysis = 43.3 mg.; (a)/(b) = 30

per cent.

Rotation-a = 0.86”, 2 dm. tube; C = 43.3 X 5 = 0.2165;

[cf]Hg = 198”.

15 cc. of the above solution were hydrolyzed, neutralized, and

diluted to 20 cc. a! = 0.19”, 2 dm. tube; C = 15/20 X 5 X 43.3 =

0.162; [c& = 59”.

50 mg. of powder heated with 60 per cent KOH gave no reducing

substance after addition of alcohol and hydrolysis with acid,

showing the absence of glycogen.

About 1.0 gm. of substance was acetylated after the method of

Pringsheim (3). The acetylated product, after standing 2 days in

water, was thoroughly broken up, stirred with water, and the mix-

1 Concentration throughout this work was calculated on the basis of

reducing power after acid hydrolysis. This is not strictly correct, but is

satisfactory as an approximation.

A. Carruthers and W. Y. Lee 529

t’ure centrifuged. The brownish colored residue was dissolved in

about 20 cc. of chloroform and the chloroform solution was shaken

three times with water. To the washed chloroform extract cal-

cium chloride was added and the clear extract filtered after stand-

ing several hours. The filtrate was evaporated in vacua to dryness

and the residue was taken up in hot absolute alcohol. The alcohol

solution was decdorized by repeated boiling with charcoal, the

solution being filtered through charcoal each time. The alcohol

solution, about 200 cc., was allowed to stand for several days at

room temperature. With Fraction I a few mg. of a grayish white

powder separated, sufficient only for molecular weight determina-

Downloaded from www.jbc.org by guest, on February 22, 2011

tions. Molecular weight determinations by Rast’s method (8)

on this and all other fractions are given in Table II.

TABLE II

Molecular Weight Determinations on Acetyl Derivatives of Sugar Fractions

Fraction Weight of M. p.

substance depression Mol. wt.

%?. mg. “C.

Precipitate A, Frac- 5.710 1.053 4.95 1416

tion I 4.317 0.758 4.32 1412

Residue B, Fraction I 4.298 0.508 6.30 711

4.867 0.740 7.60 760

Fraction III 3.478 0.514 9.3 603

3.790 0.582 9.0 648

After removal of this small amount of precipitate no more sub-

stance separated and therefore the alcohol solution was evaporated

to dryness. Residue B was thoroughly dried in a desiccator over

sulfuric acid. The determination of acetyl content of this frac-

tion was performed by the method of Pringsheim (3). The results

are given in Table III.

Fraction II-After washing with alcohol and ether and drying

over sulfuric acid, the weight of powder obtained was 1.50 gm.

150 mg. dissolved in 15 cc. of water gave (a) a glucose equivalent

before acid hydrolysis = 50.2 mg.; (b) after acid hydrolysis =

139.0 mg.; (a)/(b) = 36 per cent.

Rotation before Hydrolysis--cu = 3.11”, 2 dm. tube; C = 0.139 X

100/15 = 0.927; [culHB = 168”.

530 Glycogen Hydrolysis

Rotation after Hydrolysis300 mg. of powder, dissolved and

hydrolyzed and the volume after hydrolysis made up to 20 cc.,

gave (Y = 1.64, 2 dm. tube; C = 1.39; [cy]ng = 59”.

Fraction III-The syrup dissolved in 20 cc. of water gave (a)

a glucose equivalent before acid hydrolysis = 1.205 gm.; (b)

after acid hydrolysis = 1.890 gm.; (a) /(b) = 64 per cent.

Rotation before Hydrolysis-2 cc. of solution diluted to 25 cc.

gave a! = 2.02”, 2 dm. tube; C = 0.756; [~y]n~= 133”.

Rotation after Hydrolysis-10 cc. of the diluted solution hydro-

lyzed and the volume made to 20 cc. gave Q! = 0.45”, 2 dm. tube;

c = 0.378; [a]& = 60”.

Downloaded from www.jbc.org by guest, on February 22, 2011

TABLE III

Determination of Acetyl Content of Acetyl Derivatives of Sugar Fractions

Fraction‘ Weight of substance 0.1 N NaOH A&y: content

I

gm. cc. per cent

Residue B, Fraction I 0.0934 11.21 51.62

0.0825 9.95 51.86

Fraction III 0.0772 9.50 52.90

0.1006 12.20 52.20

Part of the aqueous syrup was dried as thoroughly as possible,

finally over phosphorus pentoxide, and an acetyl product was

prepared and analyzed (seeTables II and III).

DISCUSSION

The results of Experiment 1 were considered unreliable because

the sugar fractions isolated were very impure. The results of

Experiment 2 seemedto indicate that the digestion had produced

a mixture of sugars containing mainly disaccharide with, possibly,

somemonosaccharide. The fraction isolated by alcohol precipita-

tion gave a glucose equivalent much higher than that possible

for a trisaccharide. The results of Experiment 3, however, illus-

trated the mixed nature of the products and showed the presence

of polysaccharide more complex than disaccharide, of disaccharide,

and of monosaccharide. The significance of the analytical values

is made clearer by comparing them with the values given, either

theoretically or experimentally, by glucose, maltose, and a possible

trisaccharide. The latter are summarized in Table IV.

A. Carruthers and W. Y. Lee 531

Considering Experiment 3, it is seen that after removal of un-

changed glycogen the digestion mixture contained 6.176 gm. of

sugar expressed as glucose. The specific rotation and reducing

power were nearly those of maltose. Crude fractionation with

alcohol and ether, however, indicated the presence of more than

one substance. The first precipitate by alcohol, Fraction I, gave

a lower reducing power and a higher specific rotation than the

original mixture, suggesting the presence in this fraction of either

a trisaccharide or a mixture of polysaccharides, some more complex

than disaccharide, with possibly some monosaccharide. From

Downloaded from www.jbc.org by guest, on February 22, 2011

this fraction a few mg. of acetyl derivative (Fraction I, A) were

obtained which, while probably not a pure substance, gave a

TABLE IV

Properties of Glucose, Maltose, and a Trisaccharide

I Specific rotation A&y1 product

GlUC~e

equivdenl t-

by “;+i ;‘c”l”d’

reducing Acetyl

powder h ydrolysis hydrolysi. s Mol. wt. content

Ia’lHg [OIH,

- --

degrees degrees per cent

Glucose (calculated). ... ... 100 62 390 55.10

Maltose “ . .. ... ... 163 62 678 50.70

(‘ (found). . . . . . . . . . . 43 161 66 664 51.17

Trisaccharide (calculated). . 62 966 48.96

- -

molecular weight indicating a high polysaccharide. The bulk of

the acetyl derivative (Fraction I, B), separated after concentration

of the alcohol solution, gave a molecular weight and an acetyl

number closely approximating those for a disaccharide. Fraction

I therefore seemed to be predominantly disaccharide mixed with

possibly some polysaccharide such as dextrin. The sugar sepa-

rated by alcohol-ether, Fraction II, showed a slightly higher reduc-

ing power and a lower specific rotation consistent with there being

lesspolysaccharide than in the first fraction. The residual syrup,

after removal of Fractions I and II, showed a relatively high

reducing power and a low rotation, suggesting that here propor-

tionately more monosaccharide was present. In conformity with

this suggestion an acetyl product from this syrup gave a molecu-

532 Glycogen Hydrolysis

lar weight slightly lower and an acetyl number slightly higher than

those for a disaccharide. The original sugar mixture contained

6.176 gm. and the fractions totaled 5.194 gm. As all of the

products isolated were amorphous, the analytical data did not

establish the absolute identity of any particular compound.

However, failure to obtain crystalline products was to be expected,

since a mixture of substances, probably containing dextrin, was

being dealt with. As a control crystalline octaacetyl maltose

was prepared from pure maltose with comparative ease; the analy-

sis of this compound is presented in Table IV. Of the evidence

outlined the molecular weight determinations most convindingly

Downloaded from www.jbc.org by guest, on February 22, 2011

support the view that a disaccharide and not a trisaccharide was

the main constituent of the digestion mixture. It is certain, how-

ever, that a mixture of sugars was present.

Barbour observed that the glucose equivalent of a glycogen-

muscle extract determined at any time over 36 hours corresponded

almost exactly to 30 per cent of the glycogen hydrolyzed. (In

Table V of Barbour’s paper the increase in reducing power from

0 to 6 hours should be 0.219 and not 0.142. The corrected value

gives a glucose equivalent of 45 per cent.) Pringsheim et al.

(9) have repeatedly found amylases to yield 70 to 80 per cent only

of the theoretical amount of maltose. The remaining 20 to 30 per

cent of the polysaccharide, glycogen or starch, is converted to a

“limit dextrin.” The reducing power of maltose, as measured by

the modified Shaffer-Hartmann procedure adopted by Barbour,

gives a glucose equivalent of 43 per cent. If muscle amylase

behaved as other amylases in yielding say 70 per cent of the

theoretical amount of maltose, the glucose equivalent of the mix-

ture would be 0.7 X 43 = 30.1 per cent. Such a value therefore

would not necessarily indicate the formation of a trisaccharide.

Barbour claimed, however, that the isolated product (open chain

compound) also gave a glucose equivalent of 30 per cent and this

would suggest that the muscle amylase did not behave as do

other amylases, but unfortunately he did not present evidence to

establish the absolute purity of the isolated sugar.

Barbour stated that from aqueous glycerol concentrates an

anhydrous trisaccharide was isolated, the formation of the anhy-

dride being attributed to the action of glycerol during concentra-

tion. This we were not able to confirm. It should be pointed out,

A. Carruthers and W. Y. Lee

however, that from the data given by Barbour the molecular

weight and the specific rotation are incorrectly calculated and

should be 240 and 374 respectively and not 481 and 187 as stated.

SUMMARY

While the arguments and the evidence presented here do not

disprove the possibility that a trisaccharide may be one of the

products of glycogen hydrolysis by glycerol extracts of muscle,

they prove that trisaccharide is not the sole product and they

suggest that maltose (a disaccharide) is the main product.

Downloaded from www.jbc.org by guest, on February 22, 2011

BIBLIOGRAPHY

1. Barbour, A. D., J. Biol. Chem., 86,29 (1929-30).

2. Pringsheim, H., The chemistry of the monosaccharides and of the poly-

saccharides, New York, 247 (1932).

3. Pringsheim, H., Ber. them. Ges., 67, 1581 (1924).

4. Kuhn, R., Ann. Chem., 443, 1 (1925).

5. Osborne, W. A., and Zobel, S., J. Physiol., 29, 1 (1903).

6. Lohmann, K., Biochem. Z., 178,444 (1926).

7. Case, E. M., Biochem. J., 26, 561 (1931).

8. Rast, K., Ber. &em. Ges., 66, 1051 (1922).

9. Pringsheim, H., and Fuchs, W., Bet-. them. Ges., 66, 1762 (1923). See also

Pringsheim, H., and Schmalz, K., Biochem. Z., 142, 108 (1923).

Вам также может понравиться

- Military Specification for Heat Cured Corrosion Inhibiting Solid Film LubricantДокумент21 страницаMilitary Specification for Heat Cured Corrosion Inhibiting Solid Film LubricantGoogle User100% (1)

- Isolation and Hydrolysis of Casein From MilkДокумент8 страницIsolation and Hydrolysis of Casein From MilkELYKA CHARLETTE ANTONINOОценок пока нет

- Extraction of Total Lipids From Chicken Egg Yolk and Qualitative Test For LipidsДокумент4 страницыExtraction of Total Lipids From Chicken Egg Yolk and Qualitative Test For LipidsKizer Dela CruzОценок пока нет

- Preparation of Synthetic ScentsДокумент7 страницPreparation of Synthetic ScentsRica PitogoОценок пока нет

- Isolation and Characterization of Glycogen from Chicken LiverДокумент5 страницIsolation and Characterization of Glycogen from Chicken LiverGrace Aquino67% (6)

- An experimental study on partial replacement of cement with rice husk ashДокумент4 страницыAn experimental study on partial replacement of cement with rice husk ashArunima DineshОценок пока нет

- Lesson 2 - Diversity of Materials in The EnvironmentДокумент46 страницLesson 2 - Diversity of Materials in The EnvironmentGianina De LeonОценок пока нет

- Nmat ReviewДокумент14 страницNmat ReviewJohn Wilbern L. AlmeriaОценок пока нет

- Aluminum Casting FundamentalДокумент9 страницAluminum Casting FundamentalchinwaihoongОценок пока нет

- Activity 3 Alcoholic FermentationДокумент4 страницыActivity 3 Alcoholic FermentationBenjamen Hatae BuklasanОценок пока нет

- GeneralChemistry1 - Q2 - Module-5 - Molecular Geometry and Polarity - v5Документ15 страницGeneralChemistry1 - Q2 - Module-5 - Molecular Geometry and Polarity - v5JESSAMEN DOLORICANОценок пока нет

- J. Biol. Chem.-1934-Meyer-629-34Документ7 страницJ. Biol. Chem.-1934-Meyer-629-34Khalis ZОценок пока нет

- Glycogen Isolation and Determination ofДокумент14 страницGlycogen Isolation and Determination ofChristian De LeonОценок пока нет

- Journal GlycogenДокумент4 страницыJournal GlycogenJuvinch R. Vicente100% (2)

- Experiment No. 6: Alcohol Fermentation RatesДокумент12 страницExperiment No. 6: Alcohol Fermentation RatesAlleah MendozaОценок пока нет

- Assay of Tissue GlycogenДокумент26 страницAssay of Tissue GlycogenTiyah TimothyОценок пока нет

- Citric Acid: Frank H. Verhoff, Miles Laboratories, Elkhart, Indiana 46515, United StatesДокумент6 страницCitric Acid: Frank H. Verhoff, Miles Laboratories, Elkhart, Indiana 46515, United StatesHannah MaeОценок пока нет

- Full Report Carbs On 161.1Документ23 страницыFull Report Carbs On 161.1Kim Leonard BolandosОценок пока нет

- AMINO ACID COMPOSITIONДокумент14 страницAMINO ACID COMPOSITIONfkamaliyahОценок пока нет

- Simulacao Da Prod de EtanolДокумент4 страницыSimulacao Da Prod de EtanolLuann KarlosОценок пока нет

- Isolation, Hydrolysis, and Characterization of GlycogenДокумент4 страницыIsolation, Hydrolysis, and Characterization of GlycogenRyan Enriquez100% (1)

- A Study of The Amylolytic System of Schwanniomyces CasteliiДокумент8 страницA Study of The Amylolytic System of Schwanniomyces CasteliiAndalib TabassumОценок пока нет

- Dawes 1971Документ163 страницыDawes 1971antrios123Оценок пока нет

- Egg protein content measurement methodsДокумент5 страницEgg protein content measurement methodsThessa Vee Capuno RioОценок пока нет

- Carbohydrate Hydrolysis ComparisonДокумент5 страницCarbohydrate Hydrolysis ComparisonVince PaelmoОценок пока нет

- Name: K K ID#: Lab Partner: V S Date: Wednesday 22 Course Code: BIOL 2363 - Metabolism Title of Lab: Assay of Tissue GlycogenДокумент7 страницName: K K ID#: Lab Partner: V S Date: Wednesday 22 Course Code: BIOL 2363 - Metabolism Title of Lab: Assay of Tissue GlycogenKarina KhanОценок пока нет

- Experimental Work: Chapter No.3Документ28 страницExperimental Work: Chapter No.3saabiaanОценок пока нет

- BC34.1 E6 Isolation of GlycogenДокумент7 страницBC34.1 E6 Isolation of GlycogenGlenn Vincent Tumimbang0% (1)

- Chapter 4Документ10 страницChapter 4Patrick LenguajeОценок пока нет

- Isolation of Ecgonidine Methyl Ester From Coca SeedДокумент3 страницыIsolation of Ecgonidine Methyl Ester From Coca SeedJames McNeeОценок пока нет

- Extraction of Glycogen on Mild Condition Lacks AIG FractionДокумент7 страницExtraction of Glycogen on Mild Condition Lacks AIG FractionMaika DoronelaОценок пока нет

- Formal Report in BioChem LabДокумент6 страницFormal Report in BioChem LabmegmayorОценок пока нет

- Results and Discussion CarbohydratesДокумент4 страницыResults and Discussion CarbohydratesVincent A. Sunggayan-NiezОценок пока нет

- 14 Chapter 3Документ50 страниц14 Chapter 3Shahid pin100% (1)

- 6.1 Estimation of Total PhenolicsДокумент8 страниц6.1 Estimation of Total PhenolicsYogesh BagadОценок пока нет

- Alcohol Fermentation ExperimentДокумент8 страницAlcohol Fermentation Experimentexo kaiОценок пока нет

- REDUCING NON-SUGARS AND TRUE SUGAR IN HUMAN BLOODДокумент12 страницREDUCING NON-SUGARS AND TRUE SUGAR IN HUMAN BLOODgibrambo5770Оценок пока нет

- User Manual: XF Glycolysis Stress Test KitДокумент21 страницаUser Manual: XF Glycolysis Stress Test KitSusan HsiaoОценок пока нет

- Yulistiani 2019 J. Phys. Conf. Ser. 1295 012032Документ9 страницYulistiani 2019 J. Phys. Conf. Ser. 1295 012032Zanariah HashimОценок пока нет

- Lab Rep 6Документ4 страницыLab Rep 6Bella LopezОценок пока нет

- Bio InformeДокумент8 страницBio Informemalaver528Оценок пока нет

- In Vim: U. R., W. E. E., D. W. LДокумент4 страницыIn Vim: U. R., W. E. E., D. W. LVũ NguyễnОценок пока нет

- Countercurrent Extraction of 2,3-Butanediol: Dr. Sadhana VishwakarmaДокумент4 страницыCountercurrent Extraction of 2,3-Butanediol: Dr. Sadhana VishwakarmaAtika SaraswatiОценок пока нет

- Estimating Alcohol Protein ContentДокумент15 страницEstimating Alcohol Protein ContentHAFSA KHANОценок пока нет

- Experiment 6 Glycogen Intro and MethodsДокумент6 страницExperiment 6 Glycogen Intro and Methodsvanessa olgaОценок пока нет

- ISO Common Name Chemical Name Empirical Formula RMM M.P. V.P. SolubilityДокумент5 страницISO Common Name Chemical Name Empirical Formula RMM M.P. V.P. SolubilityDennis Limaymanta YupanquiОценок пока нет

- Fermentation Rates of Maltose and Glucose in Alkaline SolutionsДокумент7 страницFermentation Rates of Maltose and Glucose in Alkaline Solutionsgibrambo5770Оценок пока нет

- Acrolein Test and Ester Test For LipidsДокумент3 страницыAcrolein Test and Ester Test For LipidsRaymond Malubay100% (11)

- Purine and Pyrimidine Contents of Desoxypentose Nucleic AcidsДокумент14 страницPurine and Pyrimidine Contents of Desoxypentose Nucleic AcidsNur AnindyaОценок пока нет

- Enzymatic Hydrolysis of GlycogenДокумент17 страницEnzymatic Hydrolysis of GlycogenMaria EvansОценок пока нет

- A Study of A Decolorizing Carbon by Joseph C. Bock 1920Документ6 страницA Study of A Decolorizing Carbon by Joseph C. Bock 1920Sergio Tlaotani Rodríguez CruzОценок пока нет

- Short Communication: Jozi'RnalofchromatographyДокумент4 страницыShort Communication: Jozi'RnalofchromatographyZulОценок пока нет

- Phenolic Resin PreparationДокумент7 страницPhenolic Resin PreparationmitaasthaОценок пока нет

- Experiment 5 PDFДокумент6 страницExperiment 5 PDFKami TazuОценок пока нет

- Electrophoresis and Fractionation of Wheat GlutenДокумент14 страницElectrophoresis and Fractionation of Wheat GlutensecucaОценок пока нет

- Photometric Method Determines Proline in Biological SamplesДокумент7 страницPhotometric Method Determines Proline in Biological SamplesNehaОценок пока нет

- Isolation and Quantification of ProteinsДокумент9 страницIsolation and Quantification of ProteinsJake GerolagaОценок пока нет

- Extract Wort WortДокумент4 страницыExtract Wort WortJulio SantosОценок пока нет

- Simple Method for Isolating Morphine GlucuronideДокумент6 страницSimple Method for Isolating Morphine GlucuronideHanuš KoumelesОценок пока нет

- Lxx. The Mechanism of Starch by Amylases.: NatureДокумент4 страницыLxx. The Mechanism of Starch by Amylases.: NatureJohn Bowen BrownОценок пока нет

- EXPERIMENT 5 Robinson Annulation ReactionДокумент13 страницEXPERIMENT 5 Robinson Annulation ReactionMuhammad Amirul Afifi100% (1)

- I. The Role of Pyruvate As An Intermediate Bruno Rosenfeld Ernst SimonДокумент11 страницI. The Role of Pyruvate As An Intermediate Bruno Rosenfeld Ernst SimonreynaldiОценок пока нет

- 1949 - Moore - Chromatography of Amino Acids On Starch Columns Solvent Mixtures For The Fractionation of Protein HydrolysatesДокумент26 страниц1949 - Moore - Chromatography of Amino Acids On Starch Columns Solvent Mixtures For The Fractionation of Protein HydrolysatesAngelico ObilleОценок пока нет

- Glycoconjugate Research: Proceedings of the Interior Symposium on GlycoconjugatesОт EverandGlycoconjugate Research: Proceedings of the Interior Symposium on GlycoconjugatesОценок пока нет

- Solutions to Sample Test 2 Binomial DistributionДокумент4 страницыSolutions to Sample Test 2 Binomial DistributionKris Dela CruzОценок пока нет

- Experiment 9Документ3 страницыExperiment 9cherokeeОценок пока нет

- Carbohydrates: Color Reactions and TestsДокумент19 страницCarbohydrates: Color Reactions and TestsAjith KumarОценок пока нет

- Adsorption and Hydrolysis of GlycogenДокумент11 страницAdsorption and Hydrolysis of GlycogenKris Dela CruzОценок пока нет

- Acid Hydrolysis of Organic Materials: Sessions Biogeochemistry Lab July, 2009Документ2 страницыAcid Hydrolysis of Organic Materials: Sessions Biogeochemistry Lab July, 2009Kris Dela CruzОценок пока нет

- Chromatography Encyclopedia of Separation Science Elsevier Part 6Документ775 страницChromatography Encyclopedia of Separation Science Elsevier Part 6RobocopОценок пока нет

- Polar and NonpolarДокумент6 страницPolar and NonpolarShashank DeshpandeОценок пока нет

- Profiles of Drug Substances Excipients and Related Methodology Volume 32 2005Документ282 страницыProfiles of Drug Substances Excipients and Related Methodology Volume 32 2005ChristianrodriguezruОценок пока нет

- 25 May Acids Bases and Salts PPTДокумент72 страницы25 May Acids Bases and Salts PPTShubham Sharma100% (1)

- B. Sc. Semester (Two Paper System) 2022-23Документ24 страницыB. Sc. Semester (Two Paper System) 2022-23yash.azad2005Оценок пока нет

- TACO HARDWARE BOOK - DigitalДокумент32 страницыTACO HARDWARE BOOK - DigitalembenОценок пока нет

- Synthesis of Trans-9 - (2-Phenylethyenyl) Anthracene Via Wittig Reaction Mitchell Cardow Chem 213W, Spring 2018Документ8 страницSynthesis of Trans-9 - (2-Phenylethyenyl) Anthracene Via Wittig Reaction Mitchell Cardow Chem 213W, Spring 2018mitchОценок пока нет

- Creation of Moisture Sorption Isotherms for Hygroscopic MaterialsДокумент15 страницCreation of Moisture Sorption Isotherms for Hygroscopic Materialsoscar16865Оценок пока нет

- Natural Products ChemistryДокумент26 страницNatural Products Chemistrybharathi dasanОценок пока нет

- Wrought Iron-PipeДокумент19 страницWrought Iron-PipeFronda Jerome BlasОценок пока нет

- Kech 10Документ46 страницKech 10Vijaya PrakashОценок пока нет

- Iodium Pada Telur AsinДокумент6 страницIodium Pada Telur AsinBayu WaeОценок пока нет

- EagleBurgmann - Chemstar L 6226 - L - ENДокумент2 страницыEagleBurgmann - Chemstar L 6226 - L - ENDinesh AdwaniОценок пока нет

- Soal Termo B.inggrisДокумент5 страницSoal Termo B.inggrisBe13enОценок пока нет

- Developments in The Components of Metal-Free Photoinitiated Organocatalyzed-Atom Transfer Radical Polymerization (O-ATRP)Документ16 страницDevelopments in The Components of Metal-Free Photoinitiated Organocatalyzed-Atom Transfer Radical Polymerization (O-ATRP)divyaОценок пока нет

- A New Synthetic Method For The Preparation of 5-Deazaflavins and 5-Deaza-10-OxaflavinsДокумент2 страницыA New Synthetic Method For The Preparation of 5-Deazaflavins and 5-Deaza-10-OxaflavinsThéoОценок пока нет

- In Vitro Antioxidant Activity of Guibourtia TessmanniiДокумент8 страницIn Vitro Antioxidant Activity of Guibourtia TessmanniiClaudio Luis VenturiniОценок пока нет

- Electrochemical Chloride Extraction Impact on ConcreteДокумент10 страницElectrochemical Chloride Extraction Impact on ConcreteLeonardo Medina RosarioОценок пока нет

- Protective DTM Acrylic Primer/Finish Product DescriptionДокумент4 страницыProtective DTM Acrylic Primer/Finish Product DescriptionVernon Jiménez FonsecaОценок пока нет

- Active Ingredients in Pain RelieverДокумент13 страницActive Ingredients in Pain RelieverkatrinaarnaizОценок пока нет

- Itp For Casing, Ducting, StackaaaaaaaaaaaДокумент4 страницыItp For Casing, Ducting, Stackaaaaaaaaaaaaymanmalah100% (1)

- Hybrid Additive Manufacturing TechnologiesДокумент11 страницHybrid Additive Manufacturing TechnologiesmaheshboobalanОценок пока нет

- Electron Counting Methods 1) Neutral Ligand / Covalent MethodДокумент8 страницElectron Counting Methods 1) Neutral Ligand / Covalent MethodRakshitTiwariОценок пока нет

- Fluorspar FlotationДокумент7 страницFluorspar Flotationmushava nyokaОценок пока нет

- CLEAPPS Student Safety SheetsДокумент105 страницCLEAPPS Student Safety SheetsQuan nguyen minhОценок пока нет