Академический Документы

Профессиональный Документы

Культура Документы

Static Water Level - Final

Загружено:

AljonPantaleonValentosОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Static Water Level - Final

Загружено:

AljonPantaleonValentosАвторское право:

Доступные форматы

wellcare® information for you about

Determining Static Water

Level in a Well

If your household is one of the millions that depend upon private water wells, you and your well rely

on groundwater. An adequate, dependable supply of ground water, replenished throughout the year

by rainfall and melted snow is essential to make sure your well provides you with the water you

need. Drought and other weather conditions can influence the amount of water in your well. This

information sheet explains what is involved in determining the static level of water in your well. WSC

recommends you contact a licensed water well contractor for this and whenever you need well

maintenance.

What is Static Water Level?

Static water level refers to the level of water in a well under normal, undisturbed, no-pumping

conditions. Static water level is best determined when the well has not been pumped for several

hours prior to measuring. You may get a false reading if the well was pumped just before the static

water level is measured.

How is Static Water Level Measured?

There are several ways to measure the static water level including: an electric sounder or electric

depth gauge, wetted tape or an air line.

Electric Sounder or Electric Depth Gauge

An electric sounder or depth gauge is the most practical method for measuring well water levels. It

consists of a weight suspended on stranded insulated wire with depth markings and an ammeter to

indicate a closed circuit. Current flows through the circuit when the end of the wire touches the

water surface. Current is supplied by a small 9 or 12-volt battery.

To collect a reading, the contractor lowers the electric wire or sounding line until the needle deflects

then reads the distance from the water to the top of the casing on the line. He marks the reference

point on the casing where he measured the depth. And, then he uses a standard tape measure to

measure the distance between the marks on the line.

Wetted Tape

This method is accurate for measuring water levels to depths up to about 90 feet. To use this

method, you must know the approximate depth to water in your well.

In this method, a lead weight is attached to the end of a 100 foot steel measuring tape. Eight to ten

feet of tape end is dried and coated with carpenter’s chalk before each measurement. The tape is

lowered into the well until a part of the chalked section is below the water. The contractor will align

and note an even foot mark on the tape exactly at the top of the casing or some other measuring

point. Then, the tape is pulled up to read the mark where the line is wet. He can determine the

actual depth from the top of the casing to water level by subtracting the wetted mark from the mark

he held at the top of the casing.

wellcare® information on Static Water Level in a Well December

June2011

2014

wellcare® information on Static Water Level in a Well Page

Page 22

Air Line

An air line may be the best method for repeated testing of deep wells over 300 feet.

This method consists of a small diameter pipe or tube long enough to extend from the top of the well

to a point about 20 feet below the lowest anticipated water level. Air is pumped into the line and

excess air bubbles are forced out the end, equalizing the pressure in the line with the pressure

created by the depth of water outside the line. Quarter-inch copper or brass tubing, or ¼-inch steel or

plastic pipe are commonly used for this method.

For this method, the exact length of air line is measured as it is placed in the well. The contractor

makes sure the air line is airtight by hanging it vertically, taking care that it doesn’t spiral inside the

well casing. The best way is to attach the air line securely to a known point on the pump column. The

end of the air line is attached low enough so that it’s submerged when the pump operates at full

discharge. NOTE: The air line has to be at least 5 feet above the suction intake of the pump to

avoid pulling air through the pump.

By noting the number of pipe joints, the contractor will know the depth of the air line tip. He will fit the

upper end with a tee and pressure gauge plus a valve to which a hand pump is attached. Then he

can calibrate the gauge to indicate pressure directly in feet of water or pounds per square inch (psi).

Once installed with the pressure gauge connected, the contractor will pump air into the air line until

the pressure shown by the gauge levels off at a constant maximum indicating that all water has been

forced out of the line. At this point, air pressure in the tube (as shown by the gauge) just supports the

column of water from water level in the well to the bottom of the tube. This water column length is

equal to the amount of air line submerged.

Deduct this pressure, converted to feet (pounds pressure x 2.31 = feet), from the known length of the

air line to determine the amount of submergence.

FOR MORE INFORMATION to help you maintain your well and protect your water supply

wellcare® is a program of the Water Systems Council (WSC). WSC is the

only national organization solely focused on protecting the health and water

supply of the 43 million people nationwide who depend on household wells for

their water supply.

This publication is one in a series of wellcare® information sheets. There are more than 90

information sheets available FREE at www.watersystemscouncil.org.

Well owners and others with questions about wells or groundwater can also contact the FREE

wellcare® Hotline at 1-888-395-1033 or visit www.wellcarehotline.org.

JOIN THE WELLCARE® WELL OWNERS NETWORK!

By joining the FREE wellcare® Well Owners Network, you will receive regular information on how

to maintain your well and protect your well water.

Contact us at 1-888-395-1033 or visit www.watersystemscouncil.org or www.wellcarehotline.org.

WELL WATER - NATURALLY BETTER®

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Ev Wireless Charging 5 PDFДокумент27 страницEv Wireless Charging 5 PDFJP GUPTAОценок пока нет

- Concordia: The Lutheran Confessions - ExcerptsДокумент39 страницConcordia: The Lutheran Confessions - ExcerptsConcordia Publishing House28% (25)

- Type of MorphologyДокумент22 страницыType of MorphologyIntan DwiОценок пока нет

- Financial Performance Report General Tyres and Rubber Company-FinalДокумент29 страницFinancial Performance Report General Tyres and Rubber Company-FinalKabeer QureshiОценок пока нет

- Prof. Monzer KahfДокумент15 страницProf. Monzer KahfAbdulОценок пока нет

- Psychology Research Literature Review ExampleДокумент5 страницPsychology Research Literature Review Exampleafdtsebxc100% (1)

- Foucault, M.-Experience-Book (Trombadori Interview)Документ11 страницFoucault, M.-Experience-Book (Trombadori Interview)YashinОценок пока нет

- IIT JEE Physics Preparation BooksДокумент3 страницыIIT JEE Physics Preparation Booksgaurav2011999Оценок пока нет

- Journal Entry EnrepДокумент37 страницJournal Entry Enreptherese lamelaОценок пока нет

- Frbiblio PDFДокумент16 страницFrbiblio PDFreolox100% (1)

- Responsive Docs - CREW Versus Department of Justice (DOJ) : Regarding Investigation Records of Magliocchetti: 11/12/13 - Part 3Документ172 страницыResponsive Docs - CREW Versus Department of Justice (DOJ) : Regarding Investigation Records of Magliocchetti: 11/12/13 - Part 3CREWОценок пока нет

- Task 1: MonologueДокумент4 страницыTask 1: MonologueLaura Cánovas CabanesОценок пока нет

- Pharmaniaga Paracetamol Tablet: What Is in This LeafletДокумент2 страницыPharmaniaga Paracetamol Tablet: What Is in This LeafletWei HangОценок пока нет

- ICTSAS601 Student Assessment Tasks 2020Документ30 страницICTSAS601 Student Assessment Tasks 2020Lok SewaОценок пока нет

- Https Emedicine - Medscape.com Article 1831191-PrintДокумент59 страницHttps Emedicine - Medscape.com Article 1831191-PrintNoviatiPrayangsariОценок пока нет

- Designing HPE Server Solutions: Supporting ResourcesДокумент3 страницыDesigning HPE Server Solutions: Supporting ResourcesKARTHIK KARTHIKОценок пока нет

- Final Test General English TM 2021Документ2 страницыFinal Test General English TM 2021Nenden FernandesОценок пока нет

- Precertification Worksheet: LEED v4.1 BD+C - PrecertificationДокумент62 страницыPrecertification Worksheet: LEED v4.1 BD+C - PrecertificationLipi AgarwalОценок пока нет

- Product Training OutlineДокумент3 страницыProduct Training OutlineDindin KamaludinОценок пока нет

- Qafqaz UniversityДокумент3 страницыQafqaz UniversityQafqazlife QUОценок пока нет

- PUERPERAL SEPSIS CoverДокумент9 страницPUERPERAL SEPSIS CoverKerpersky LogОценок пока нет

- Newspaper OrganisationДокумент20 страницNewspaper OrganisationKcite91100% (5)

- Aqualab ClinicДокумент12 страницAqualab ClinichonyarnamiqОценок пока нет

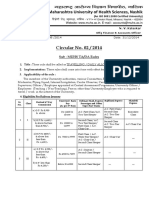

- Circular No 02 2014 TA DA 010115 PDFДокумент10 страницCircular No 02 2014 TA DA 010115 PDFsachin sonawane100% (1)

- Mendoza - Kyle Andre - BSEE-1A (STS ACTIVITY 5)Документ1 страницаMendoza - Kyle Andre - BSEE-1A (STS ACTIVITY 5)Kyle Andre MendozaОценок пока нет

- The Permission Wheel Hawkes L PDFДокумент8 страницThe Permission Wheel Hawkes L PDFNandita Asthana SankerОценок пока нет

- Iii. The Impact of Information Technology: Successful Communication - Key Points To RememberДокумент7 страницIii. The Impact of Information Technology: Successful Communication - Key Points To Remembermariami bubuОценок пока нет

- Jurnal Perdata K 1Документ3 страницыJurnal Perdata K 1Edi nur HandokoОценок пока нет

- What Is An Ethical Dilemma?: Decision-Making ProcessДокумент7 страницWhat Is An Ethical Dilemma?: Decision-Making ProcessGauravsОценок пока нет

- 44) Year 4 Preposition of TimeДокумент1 страница44) Year 4 Preposition of TimeMUHAMMAD NAIM BIN RAMLI KPM-GuruОценок пока нет