Академический Документы

Профессиональный Документы

Культура Документы

MN m100 Startupguide Eng PDF

Загружено:

Arief FibonacciОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MN m100 Startupguide Eng PDF

Загружено:

Arief FibonacciАвторское право:

Доступные форматы

Start-up guide of LSLV-M100

Download manual

For detailed information on installation and commissioning, full version of the M100

manual can be downloaded at www.lsis.com

Verify & Identify the delivery

• Inspect the drive for damage. If the drive appears LSLV 0022 M100 1EOFNS

damaged upon receipt, contact your supplier.

Motor capacity

• Verify receipt of the correct model by checking 0001 - 0.1kW 0008 - 0.75kW

the information on the nameplate as shown below. 0002 - 0.2kW 0015 - 1.5kW

If you have received the wrong model, contact your supplier. 0004 - 0.4kW 0022 - 2.2kW

Series name

Input voltage

1 - Single phase 200V - 240V

LSLV0022M100-1EOFNS

Keypad

INPUT 200-240V 1Phase 50/60Hz E - LED keypad

10.0A

OUTPUT 0-Input V 3Phase 0.01-400Hz UL type

3.8kVA O - UL open type

Ser. No 55025310146

Inspected by D. K. YU EMC filter

KCC-REM-LSR-XXXXXXX F - Built-in EMC filter[C2]

DC Reactor

N - No built-in DC reactor

I /O

S - Standard type A - Advanced type

Mount the drive

• Ensure that there is sufficient space to meet the clearance specifications, and that there are no obstacles

impeding the cooling fan’s air flow as shown below.

• When installing multiple drives into the same enclosure panel (Side-by-side installation), mount the drives

with the minimum clearance of 2 mm while removing optional top covers.

Installation space Side-by-side installation Mounting precaution

Optional top cover

10cm(4”)

5cm(2”) 5cm(2”)

minimum minimum

5cm(2”)

10cm(4”)

2mm

2mm

• Install the drive in an environment that meet the conditions such as ambient temperature (-10℃ to 50℃), Humanity

(95% relative humidity or free of condensation), altitude (below 1,000m) and vibration (below 1G [9.8 m/sec2])

• DIN-Rail mounting is available.

LSIS Co., Ltd. | 01

Start-up guide of LSLV-M100

Connect drive: power

• The following figures show main circuit terminal arrangement on the drive.

• WARNING! B1, B2 terminals are for the brake resistor. Do not connect B1, B2 terminals to earth ground.

• WARNING! Power supply cables must be connected to R and T terminals.

Connecting power cables to the U, V, and W terminals will cause internal damage to the drive.

0.1~0.2 kW (Single phase) 0.4–0.75 kW (Single phase) 1.5–2.2 kW (Single phase)

IM IM

IM IM IM

IM IM IM

IM

1-phase AC Motor 1-phase AC Motor 1-phase AC Motor

Input Input Input

Connect drive: control

• The figures below show the control circuit terminal arrangement on the drive.

• Refer to the list of factory default value as below.

SW1 Sink/Source selection

Digital input Digital input

Voltage/Current selection

P1 AO Analog P1 AO Analog SW2*

SW1

output output for terminal I2

P2 P2

NPN PNP SW1 SW3* RS485 termination resistor

P3 P24 24V P3 P24

NPN PNP

P4

CM

Q1 P5 C2

Relay

Analog input EG Open A2 output

VR collector CM

output Analog input

V1

VR

CM C1 C1

Relay V1 SW2 Relay

A1 output A1 output

CM V I

Analog Input

B1 B1

I2 SW3

RJ45 RJ45

ON OFF

Remote Termin ation Remote/

Resistor 485Com

< Standard I/O > < Advanced I/O >

Terminal Parameter Code Factory Default Terminal Parameter Code Factory Default

P1 In-65 Fx Q1/EQ** OU-32 Fault

P2 In-66 Rx A1/B1/C1 OU-31 Fault

P3 In-67 Emergency stop A2/C2* OU-32 Fault

P4* In-68 RESET AO OU-01 Output frequency

P5* In-69 JOG * This is available only on Advanced I/O

** This is available only on Standard I/O.

V1 - -

I2* - -

02 | LSIS Co., Ltd.

Keypad: description

No. Name Description

Displays current operational status and

➊ 7-Segment Display

parameter information.

➋ SET Indicator LED flashes in parameter setting mode.

LED is lit during operation while flashing during

➌ RUN Indicator

acceleration or deceleration.

➍ FWD Indicator LED is lit during forward operation.

➎ REV Indicator LED is lit during reverse operation.

Key Name Description

[RUN] key Starts the drive. (Activates RUN command.)

STOP MODE

RUN SHIFT

ENT

RESET

STOP: Stops

MODE

ENTthe drive.

[STOP/RESET] key

STOP

RUN

RESET: Resets the drive to clear fault situation.

RESET SHIFT

[▲]SHIFT

key, [▼] key Scrolls up and down to select parameter codes, setting values, etc.

STOP MODE

ENT

RESET

[MODE/SHIFT] key Moves the parameter groups or moves the cursor in parameter setting mode.

MODE

SHIFT

ENT

Moves the value setting mode from the parameter selection mode.

[ENTER] key Saves the set values after adjusting the parameter values.

MODE

SHIFT

ENT

Moves the drive status screen from the fault screen when a fault occurs.

[Volume] key Sets the output frequency.

Set parameters and monitor the operation

Set Parameters Monitor The Operating Status

※ Basic Parameters in Operation Group • Output Current Monitoring

• Only 18 parameters are shown in the first group to

run the drive basically.

• The other groups are shown when “1” is set in the

parameter OGr.

• Group Selection

N

STOP

RESET - The key allows to move from one group to the

MODE

SHIFT

ENT

next in one direction only. Operation

• Code Selection Operation

RUN

STOP

- The

RESET keys allow to select the parameter code.

MODE

SHIFT

ENT

• Parameters value setting • Fault Trip Monitoring

RUN

STOP

RUNRESET

STOP

- The

RESET keys allow to adjust parameter values.

MODE

SHIFT

MODE

ENT

SHIFT

ENT

- The set value is saved by pressing the key twice.

RUN

STOP

RESET

MODE

SHIFT

ENT

Operation

Operation

Output

Current

Output

Output

Current

frequency

Output

frequency

LSIS Co., Ltd. | 03

Start-up guide of LSLV-M100

Basic set-up procedure

Motor direction inspection Start/Stop and speed source settings

• In this step the motor is checked for proper direction • This step shows how to setup the sequence and

and operation. This test is to be performed solely from reference method of the drive. The sequence method

the Keypad. Apply power to the drive after all the determines how the drive receives its start and stop

electrical connections have been made and protective command and the reference method determines how

covers have been reattached. the speed of the motor is controlled. Make sure all

protective covers have been reattached and power is

turned on.

Operation • Select start / Stop method

Operation

ENT

0 Keypad Factory default

MODE

1 Fx/Rx-1

ENT ENT SHIFT Operation 2 Fx/Rx-2

3 RS-485 communication Advanced I/O

STOP STOP 24 P1 P2 P3 CM MODE MODE

ENT ENT

RUN RUN RESET RESET SHIFT SHIFT

MODE MODE MODE

ENT SHIFT SHIFT SHIFT

0: Keypad Fx Rx

1: Fx/Rx-1

RUN 2: Fx/Rx-2

ENT ENT Please refer to user’s manual

Operation

• Observe the motor’s rotation from the load side and • Select frequency method

ensure that the motor rotates counterclockwise

(forward). Operation

• If the motor rotation is not correct, change the

wiring of the motor. (ex. U-V-W > V-U-W)

0 Keypad 1 Factory default

1 Keypad 2

2 V0: 0–5 [V] Built-in volume

3 V1: 0–10 [V] External source

4 I2( I ): 0–20 [mA]

5 I2(V): 0–10 [V]

Advanced I/O

6 V0 + I2 ( I )

7 V0 + I2 (V)

8 V0 + V1

9 RS-485 communication Advanced I/O

10 Up-down operation

24 P1 P2 P3 CM 24 P1 P2 P3 CM

EG Q1 VR V1 A0 CM EG Q1 VR V1 A0 CM

+

0 ~ 10 Vdc Potentiometer: 1-5KΩ

2: VO, 0-5[V] 3: V1, 0-10[V]

04 | LSIS Co., Ltd.

Multi-Step frequency Auto restart

• This step shows how to set up and use the multi-step • This step shows how to set up and use an Auto Restart

frequency of the drive. function of the drive.

Group Code Name Parameter Setting • This feature is enabled only when a digital input

65 P1 function setting terminal is configured as a command input device.

66 P2 function setting 5: Multi-step speed–low Group Code Name Setting Range

In 67 P3 function setting 6: Multi-step speed–middle 09 Auto restart count 0~10

68* P4 function s etting 7: Multi-step speed–high

Pr Auto restart delay time

10 0.0~60.0 sec

69* P5 function setting after trip

* This is available only on Advanced I/O

※ If the reset signal is given manually via terminal or keypad,

• Example) the restart count initializes to the set no.

* Command source: Terminal in Pr-09_Auto restart count.

* I/O Type: Advanced I/O ※ When fault doesn’t occur for 30 seconds, the remaining

Group Code Setting Value restart count recovers 1 by 1.

Op drv 1 (default: value)

24 P1 P2 P3 P4 P5 CM ※ The Auto Restart function will not be activated if the drive

65(P1) 0 (default: value)

stops due to the following fault trips:

67(P3) 5

In - Low voltage, Emergency stop (Bx), Inverter overheating,

68(P4) 6

69(P5) 7 or hardware diagnosis

• Example)

Output * Pr09=3, Pr09=5.0sec

Frequency

Speed7

Speed6

Trip

Speed5

Speed4

Output Pr10 Trip

Pr10 Occurrence

30 sec

Speed3 Frequency = 5sec Occurrence

= 5sec

Speed2 Restart

Speed1

Speed0 Trip Trip

Occurrence Occurrence

P3 Restart Restart

P4 Trip Status

P5

Remaining 3 2 1 2

Fx

Restart Count

Recover

1 count

Speed P5 P4 P3 Description

0 - - - Reference source set with the

Frq in the operation group

• Speed search - When a fault occurs, the motor is

1 - - bA51_Multi-step frequency 1

normally rotating at a free-run state. In order to

2 - - bA52_Multi-step frequency 2 operate the system without any additional fault due to

3 - bA53_Multi-step frequency 3 rotating motor, speed search feature needs to be

4 - - bA54_Multi-step frequency 4 activated.

5 - bA55_Multi-step frequency 5

Group Code Name BIT Function

6 - bA56_Multi-step frequency 6 Speed search --1- Initialization after

Cn 71

7 bA57_Multi-step frequency 7 selection (0010) a fault trip

LSIS Co., Ltd. | 05

Start-up guide of LSLV-M100

Basic parameter list

Drive 65 Multi-function input terminal P1

09 Control mode 66 Multi-function input terminal P2

11 Jog frequency 67 Multi-function input terminal P3

Operation 15 Torque boost 68 Multi-function input terminal P4

19 Starting frequency 69 Multi-function input terminal P5

20 Select rotation direction 70 PNP/NPN selection switch

Operation

26 Automatic torque boost filter gain 90 Input terminal block status display

0.00 Command frequency

27 Automatic torque boost motoring gain Output

ACC Acceleration time

28 Automatic torque boost regeneration gain 01 Analog output item setting

dEC Deceleration time

81 Select Monitor code 02 Analog output level adjustment

drv Command source

Frequency

Basic 31 Multi-function relay setting

Frq 04 Command source 2 32 Multi-function output 2 feature selection

Setting method

MkW Motor selection 05 Frequency source 2 41 Output terminal block status display

MrC Rated motor current 07 V/F pattern Communication

MbF Base frequency 08 Unit of acc/dec time setting 01 Inverter station ID

FrM Maximum frequency 09 Acc/dec frequency reference 02 Communication protocol setting

Iov Output voltage setting 11 Number of motor poles 03 Communication speed

Ftb Forward boost 12 Rated motor slip current 04 Parity/stop bit setting

MODE

Application

STOP

RESET Rtb ReverseSHIFT

boost ENT 14 Motor no-load current

Cur Output current 15 Motor efficiency 01 PID control setting

MODE

P

rPM Motor RPM

SHIFT

ENT 50 ~ Multi-step frequency 1~ 02 PID control unit selection

ET

56 Multi-step frequency 7 18 Amount of PID feedback

dCL Inverter DC voltage

vOL, POr, Advanced 19 PID reference

tOr, v1M, User select signal 01 Acceleration pattern 20 PID reference setting

I2M 02 Deceleration pattern 21 PID feedback setting

nOn Currently out of order 03 S-curve start point gradient 05 Output open-phase protection setting

OGr Open hidden groups 04 S-curve end point gradient 08 Operation on reset after fault trip

08 Stop mode selection Number of automatic restarts after

09

09 Forward and reverse run prevention fault trip

※ Basic Parameters in Operation 10 Starting with power on selection 10

Automatic restart delay time after

frult trip

• Only 18 parameters are shown 12 DC braking time at startup

18 Overload alarm level

in the first group to run the drive 13 DC braking rate at startup

19 Overload warning time

basically. 14 Output blocking time before DC braking

20 Overload warning selection

• The other groups are shown 15 DC braking time

21 Overload fault level

when “1” is set in the 16 DC braking rate

22 Overload fault time

parameter OGr. 17 DC braking frequency

50 Stall prevention selection

24 Frequency lower and upper limit

79 Operation at fan fault

Drive 25 Frequency lower limit

MODE 91 ~ Fault history 1 ~

SHIFT Basic

ENT 26 Frequency upper limit

95 Fault history 5

Advanced 51 Energy saving operation 2nd Motor

Control 63 Motor RPM display gain

04 2nd motor acceleration time

79 DB operation voltage

Input 05 2nd motor deceleration time

Control 07 2nd motor base frequency

Output

04 Carrier frequency settings 12 2nd motor rated current

Communication 71 Speed search selection

Configuration

Application Input 01 Display after power on

Protection 08 V1 Minimum input voltage 02 I/O Type

2nd Motor Frequency corresponding to V1

79 Software version

09

minimum input voltage

Configuration 93 Parameter initialization

10 V1 Maximum input voltage

94 Password registration

11 Frequency corresponding to V1

maximum input voltage 95 Parameter Lock

06 | LSIS Co., Ltd.

Frequently asked questions

Question: The motor does not rotate and the output current is too high at start.

•Cause: the load is too high. It can be solved by using manual/auto torque boost and changing some parameters.

Slightly increase the Forward or reverse boost in Ftb or rtb.

1 Manual Torque Boost If the torque boost level is too high, a trip may occurs such as IOL.

Set dr15I to 1 to activate ATB. It is necessary to reduce manual boost values (ex. 0~2%) in Ftb or rtb,

2 Auto Torque Boost(ATB) and then to adjust the values in dr26, dr27 or dr28.

3 Starting Frequency Slightly increase the starting frequency in dr19.(ex. 0.5 → 1.0 → 1.5 → 2.0Hz)

When bA07 is set to 2 (User V/F), User V/F pattern can be set up according to the applications and

4 User V/F Pattern motor characteristics.

Question: The motor makes humming sound or loud noises.

•Answer: Slightly increase or decrease the carrier frequency in Cn04.

Question: When the drive is running, the Earth-leakage circuit breaker(ELCB) is activated.

•Cause: The ELCB will disconnect the power if leakage current flows to grounding during drive operation.

•Answer1: Connect the drive to grounding terminal.

•Answer2: Check if the ground resistance is less than 100 Ω for 200V class.

•Answer3: Check the capacity of ELCB and connect it to the drive according to the rated current of the drive.

•Answer4: Reduce the carrier frequency in Cn04.

•Answer5: Attempt to keep the cable distance from the drive to motor short as possible.

Question: How do I reset the drive back to factory default settings?

•Answer: Set CF93 to 1 (All groups) and press the [ENT] key. CF93 is displayed again when the initialization has been completed.

Question: How do I adjust the time it takes the motor to speed up or slow down?

•Answer: Adjust the acceleration time in ACC and deceleration time in dEC.

Question: How do I prevent the drive from tripping on an OV fault (overvoltage) while the motor is ramping down?

•Answer 1: Increase deceleration time in dEC.

•Answer 2: Activate stall prevention in Pr50. To enable it during deceleration, set Pr50 to “-1-” as Bit 2..

Question: How do I prevent the drive from tripping on an OLT(overload) while the motor is ramping up and down?

•Answer: Verify motor rated current in MrC and motor overload parameter settings such as Pr20 (Overload trip selection),

Pr21 (Overload trip level) and Pr22 (Overload trip time).

Question: How do I run the motor above the nominal motor speed?

•Answer: Increase Maximum Frequency in FrM.

Question: Does the drive create harmonics? If so, are they a problem?

•Answer: All standard drives create 5th and 7th harmonic frequencies. Occasionally, and this depends on the applications

there may be issues and harmonics can cause problems such as transformer heating or interference with other

communication devices installed near the drive. To reduce interference, the installation of noise filters or line filters may be

required. Additionally it may be helpful to adjust the carrier frequency to the minimum value in Cn04.

LSIS Co., Ltd. | 07

Start-up guide of LSLV-M100

Troubleshoot faults

Item Type Cause Remedy

OLt The load is greater than the motor’s rated capacity. Replace the drive and motor with lager models.

Latch

(Over Load) The set value of Overload trip level in Pr21 is too low. Increase the set value for of Overload trip level.

Acc/Dec times are too short compared to the load inertia (bA16). Increase Acc/Dec times.

The drive load is greater than the rated capacity. Replace the drive with a lager model.

OCt Latch

(Over Current) Run the drive after the motor has stopped or

The drive output is active while the motor is rotating.

Activate the speed search function (Cn71).

The mechanical brake on the motor is activated too fast. Check the mechanical brake.

Deceleration time is too short compared to the load inertia

Increase Deceleration time.

Ovt in bA16.

Latch

(Over Voltage) A generative load occurs at the drive output. Use a braking option.

The input voltage is too high. Check if the input voltage is above the specified value.

Check if the input voltage is below the specified value

The input voltage is too low.

and adjust the drive input voltage value in bA19.

Lvt Level

The loads on the line power supply is greater than rated

Increase the power capacity.

(Low Voltage) capacity such as welding machine, DOL motor, etc.

The magnetic contactor on the line power supply line is

Replace the magnetic contactor.

defective.

GFt Ground fault has occurred in the out circuit. Check the wiring in the drive.

Latch

(Ground Trip) The motor insulation has been damaged. Replace the motor.

The motor has overheated. Decrease the load or reduce the motor operation.

EtH The drive load is greater than the rated capacity. Replace the drive with a large model.

Latch

(E-Thermal) Replace the motor that has a cooling fan sourced by

The drive has been running at low speed for a long time.

independent power.

OPO The magnetic contactor in the output circuit is defective. Check the magnetic contactor in the output circuit..

Latch

(Out Phase Open) The wiring to the output is defective. Check the wiring to the output.

IOL The load is greater than the rated capacity of drive. Replace the drive and motor with lager models.

Latch

(Inverter OLT) The torque boost level is too high. Decrease the torque boost level.

Check if there is a foreign object in the air inlet, outlet,

There is a problem with the cooling system.

OHt or vent.

Latch

(Over Heat) The cooling fan of the drive has been operated for a long time. Replace the cooling fan.

The ambient temperature is too high. Keep the ambient temperature below 50℃.

The ambient temperature is too low. Keep the ambient temperature above -10℃.

ntC Latch

(NTC Open) Contact your supplier or authorized service distributor

The internal temperature sensor has been damaged.

of LSIS.

FAn Foreign object is in the air vent of the drive. Remove the foreign object from the air inlet or outlet.

Latch

(Fan Trip) The lifespan of cooling fan is over. Replace the cooling fan.

EtA, Etb Latch

When the multi-function input terminal is set to EtA or EtB,

Adjust the parameters related to External trip.

(External Trip A,B) the terminal is assigned as the its signal.

COM It occurs when communication between the Main DSP and

(Communication Latch -

Trip) the IO CPU is disconnected for more than 500ms

It occurs when the output current of the drive is below

nbr Latch the value set in Ad41 while OU31 or OU32 is set to Adjust the parameters related to brake control.

19 (Brake signal).

*Level : automatically terminates when the failure is solved. This is not saved in the failure history.

*Latch : terminates when the reset signals are input after the failure is solved.

■ Head Quarter

LS-ro 127(Hogye-dong) Dongan-gu, Anyang-si, Gyeonggi-Do, 14119, Korea Tel: 82-2-2034-4907 E-Mail: hjchoi@lsis.com

2018. 08 ⓒ 2018.08 LSIS Co.,Ltd. All rights reserved. / (01) 2018. 08 Human Power

Вам также может понравиться

- 3300 Version 2Документ20 страниц3300 Version 2ibiОценок пока нет

- SR4 Generator and Control Panels - Operation and Maintenance Manual PDFДокумент64 страницыSR4 Generator and Control Panels - Operation and Maintenance Manual PDFMischa CHO94% (16)

- Synergy Element Brochure LowДокумент16 страницSynergy Element Brochure Lowangela1590Оценок пока нет

- Implementation Checklist For ISO 9001 2015 Transition enДокумент10 страницImplementation Checklist For ISO 9001 2015 Transition enSagar Panda100% (1)

- Elevator History and Functions and The Invention of This Amazing Piece of WorkДокумент69 страницElevator History and Functions and The Invention of This Amazing Piece of Workjay vallejosОценок пока нет

- Vacon NX IO Boards User Manual DPD00884A UK PDFДокумент84 страницыVacon NX IO Boards User Manual DPD00884A UK PDFMin Jiang100% (1)

- Cat-CMP Cable GlandДокумент64 страницыCat-CMP Cable GlandSyahirul Alim100% (1)

- Hidral RES540 enДокумент1 страницаHidral RES540 enpaul5791Оценок пока нет

- Yas j3000Документ186 страницYas j3000gangan555Оценок пока нет

- PLCДокумент23 страницыPLCNarendra ChaurasiaОценок пока нет

- Homex SVTДокумент23 страницыHomex SVTAlan TacherОценок пока нет

- Operating Manual: Measuring Amplifier For Instrument Panel MountingДокумент68 страницOperating Manual: Measuring Amplifier For Instrument Panel Mountingrmdoucet100% (1)

- Botnet SetupДокумент18 страницBotnet Setupjajaj moneseОценок пока нет

- S7-300 - Module SpecificationsДокумент588 страницS7-300 - Module SpecificationsTetsusaiga100% (1)

- Programmable Logic Controller (PLC)Документ41 страницаProgrammable Logic Controller (PLC)giriaj kokareОценок пока нет

- DAC STM Application NoteДокумент19 страницDAC STM Application NoteLaura JimenezОценок пока нет

- Ele-Hl en 01 PDFДокумент40 страницEle-Hl en 01 PDFMohd Abu Ajaj100% (2)

- ElevatorДокумент38 страницElevatorÇisem Filiz100% (1)

- Aerodynamicists Directory SAROD2015 PDFДокумент180 страницAerodynamicists Directory SAROD2015 PDFsantoshsОценок пока нет

- Agustawestland Aw189 Search and Rescue: Confidence in Flight. WorldwideДокумент30 страницAgustawestland Aw189 Search and Rescue: Confidence in Flight. Worldwidethomas100% (1)

- Impeler PDFДокумент1 страницаImpeler PDFArief FibonacciОценок пока нет

- VVPДокумент50 страницVVPPhan Tam100% (1)

- ELRV 450 - 10 - 10 - 01eДокумент51 страницаELRV 450 - 10 - 10 - 01eabaelwalid01Оценок пока нет

- Catalog PDFДокумент21 страницаCatalog PDFFakhrur RoziОценок пока нет

- Draft Methodology (G-14)Документ14 страницDraft Methodology (G-14)Javed ParachaОценок пока нет

- Minor Project On Abcd Parameter of Transmission LineДокумент17 страницMinor Project On Abcd Parameter of Transmission LineUjjawal DarvaikarОценок пока нет

- PCB Relay G5laДокумент4 страницыPCB Relay G5laRamón ColónОценок пока нет

- Manual Led ControlДокумент19 страницManual Led ControlLuis ParedesОценок пока нет

- Data Sheet: 品 名:Power Supply SupervisorДокумент9 страницData Sheet: 品 名:Power Supply SupervisoranjgarОценок пока нет

- Tir 60-120Документ9 страницTir 60-120GITANOSOFT GARCIAОценок пока нет

- Busduct CatalogueДокумент38 страницBusduct CataloguesarodepiyushОценок пока нет

- Modernisation Kits: A3 / EN81-21 / Transformation / Cabin MaximisationДокумент5 страницModernisation Kits: A3 / EN81-21 / Transformation / Cabin MaximisationyounesОценок пока нет

- Banasthali University: (Programmable Logiccontroller)Документ21 страницаBanasthali University: (Programmable Logiccontroller)goblockuОценок пока нет

- Inspire 2.1 2500 Eng QSG Rev.AДокумент2 страницыInspire 2.1 2500 Eng QSG Rev.AHaris SmansaОценок пока нет

- BAYNE Taskmaster ManualДокумент33 страницыBAYNE Taskmaster Manualstainless31620039126Оценок пока нет

- Iastar Door DriveДокумент75 страницIastar Door DriveSyed iliyasОценок пока нет

- Gma EДокумент5 страницGma EDull Rahim100% (1)

- Lab MatlabДокумент23 страницыLab MatlabKASHIF KHANОценок пока нет

- Emesa CAR FRAMES 1Документ2 страницыEmesa CAR FRAMES 1Ken LeeОценок пока нет

- Control Unit Vk-2C: User ManualДокумент12 страницControl Unit Vk-2C: User ManuallacОценок пока нет

- 00f4lebk300 PDFДокумент108 страниц00f4lebk300 PDFDull RahimОценок пока нет

- Gps Based Ferry Tracking SystemДокумент10 страницGps Based Ferry Tracking SystemTiamiyu Olalekan TajudeenОценок пока нет

- Fujitec Research Note 3Документ2 страницыFujitec Research Note 3api-249461242Оценок пока нет

- EP Board PDFДокумент2 страницыEP Board PDFReza KühnОценок пока нет

- Car Parking SP SystemДокумент4 страницыCar Parking SP System61engineer61Оценок пока нет

- UtbsДокумент41 страницаUtbsGaurav ChauhaanОценок пока нет

- Aluminium Enclosed Conductor SystemsДокумент32 страницыAluminium Enclosed Conductor SystemsAtilio PesquinОценок пока нет

- Transformer Terminal RET 54 - : Single Transformer System Without Tap Changer ControlДокумент44 страницыTransformer Terminal RET 54 - : Single Transformer System Without Tap Changer ControlBata ZivanovicОценок пока нет

- An75320 001-75320 PDFДокумент34 страницыAn75320 001-75320 PDFVictor CuellarОценок пока нет

- Instruction Manual: LM2A SeriesДокумент73 страницыInstruction Manual: LM2A SeriesроманОценок пока нет

- Control Unit Omega 804: User ManualДокумент12 страницControl Unit Omega 804: User ManualAlexsandro CenteioОценок пока нет

- Light Curtain Guide For ElevatorsДокумент10 страницLight Curtain Guide For ElevatorsFERNSОценок пока нет

- Emergency Stop Examples Sistema Ver 100Документ16 страницEmergency Stop Examples Sistema Ver 100Wer AdОценок пока нет

- SMPS Half Bridge Compacta - EsquemaДокумент1 страницаSMPS Half Bridge Compacta - EsquemaLourival da Silva100% (1)

- Transformer-1 /75W Battery Group: 12V 12V 12V 12V 12VДокумент1 страницаTransformer-1 /75W Battery Group: 12V 12V 12V 12V 12VKen LeeОценок пока нет

- UTL ProfileДокумент13 страницUTL ProfileImran BashaОценок пока нет

- OpampДокумент31 страницаOpampahimsa_katangi100% (5)

- JSA07924E-AA - E-Com Local Wiring (V300)Документ17 страницJSA07924E-AA - E-Com Local Wiring (V300)Mahmoud Omar RobОценок пока нет

- Led 7 SegmentДокумент11 страницLed 7 SegmentCường VũОценок пока нет

- Vacon NXL Lift ALFIFF28 Application Manual UD00973Документ44 страницыVacon NXL Lift ALFIFF28 Application Manual UD00973TanuTiganuОценок пока нет

- LCDv3 33-Rev1AДокумент338 страницLCDv3 33-Rev1AderbalijalelОценок пока нет

- Fr-d700 Instruction Manual (Basic)Документ61 страницаFr-d700 Instruction Manual (Basic)Toni MirandaОценок пока нет

- M100+Start+up+guide Catalog Letter 202007Документ8 страницM100+Start+up+guide Catalog Letter 202007salvorgОценок пока нет

- LS G100 Quick SettingДокумент8 страницLS G100 Quick SettingtrunghieutcОценок пока нет

- SF320Документ7 страницSF320hanifbudi1Оценок пока нет

- GB Assy New BathДокумент1 страницаGB Assy New BathArief FibonacciОценок пока нет

- Foil Plough Folding ASSY PDFДокумент1 страницаFoil Plough Folding ASSY PDFArief FibonacciОценок пока нет

- Housing Bearing MAT SUS Casting Qty 1: All Sharp Edges C0.3-0.5Документ1 страницаHousing Bearing MAT SUS Casting Qty 1: All Sharp Edges C0.3-0.5Arief FibonacciОценок пока нет

- Rak Material: Dilarang Menaruh Barang, Kecuali Material ProduksiДокумент6 страницRak Material: Dilarang Menaruh Barang, Kecuali Material ProduksiArief FibonacciОценок пока нет

- Gambar Penawaran Check Ulang Kalau Sudah Dapaat PO: All Sharp Edges C0.3-0.5Документ1 страницаGambar Penawaran Check Ulang Kalau Sudah Dapaat PO: All Sharp Edges C0.3-0.5Arief FibonacciОценок пока нет

- Foil Plough Folding ASSYДокумент1 страницаFoil Plough Folding ASSYArief FibonacciОценок пока нет

- WhatsApp Image 2019-11-08 at 13.34.52Документ1 страницаWhatsApp Image 2019-11-08 at 13.34.52Arief FibonacciОценок пока нет

- Gambar Penawaran Check Ulang Kalau Sudah Dapaat PO: All Sharp Edges C0.3-0.5Документ1 страницаGambar Penawaran Check Ulang Kalau Sudah Dapaat PO: All Sharp Edges C0.3-0.5Arief FibonacciОценок пока нет

- Gambar Penawaran Check Ulang Kalau Sudah Dapaat PO: All Sharp Edges C0.3-0.5Документ1 страницаGambar Penawaran Check Ulang Kalau Sudah Dapaat PO: All Sharp Edges C0.3-0.5Arief FibonacciОценок пока нет

- Gambar Penawaran Check Ulang Kalau Sudah Dapaat PO: PULLEY Ø165x70Документ1 страницаGambar Penawaran Check Ulang Kalau Sudah Dapaat PO: PULLEY Ø165x70Arief FibonacciОценок пока нет

- Gambar Penawaran Check Ulang Kalau Sudah Dapaat PO: HousingДокумент1 страницаGambar Penawaran Check Ulang Kalau Sudah Dapaat PO: HousingArief FibonacciОценок пока нет

- Gambar Penawaran Check Ulang Kalau Sudah Dapaat PO: PULLEY Ø165x70Документ1 страницаGambar Penawaran Check Ulang Kalau Sudah Dapaat PO: PULLEY Ø165x70Arief FibonacciОценок пока нет

- Impeler MAT SUS Casting Qty 1: All Sharp Edges C0.3-0.5Документ1 страницаImpeler MAT SUS Casting Qty 1: All Sharp Edges C0.3-0.5Arief FibonacciОценок пока нет

- Harga Cover Unimix Cpi - 20190617 - 0001Документ1 страницаHarga Cover Unimix Cpi - 20190617 - 0001Arief FibonacciОценок пока нет

- Pompa Oval: All Sharp Edges C0.3-0.5Документ1 страницаPompa Oval: All Sharp Edges C0.3-0.5Arief FibonacciОценок пока нет

- Gambar Penawaran Check Ulang Kalau Sudah Dapaat PO: SHAFT Ø60x442Документ1 страницаGambar Penawaran Check Ulang Kalau Sudah Dapaat PO: SHAFT Ø60x442Arief FibonacciОценок пока нет

- AssyДокумент1 страницаAssyArief FibonacciОценок пока нет

- Cover Housing MAT SUS Casting Qty 1Документ1 страницаCover Housing MAT SUS Casting Qty 1Arief FibonacciОценок пока нет

- HousingДокумент1 страницаHousingArief FibonacciОценок пока нет

- Trial Insert - 20190612 - 0001Документ1 страницаTrial Insert - 20190612 - 0001Arief FibonacciОценок пока нет

- As Ulir M12: All Sharp Edges C0.3-0.5Документ1 страницаAs Ulir M12: All Sharp Edges C0.3-0.5Arief FibonacciОценок пока нет

- PULLEY Ø165x70: All Sharp Edges C0.3-0.5Документ1 страницаPULLEY Ø165x70: All Sharp Edges C0.3-0.5Arief FibonacciОценок пока нет

- Shaft Oval Pump Ø60X442: All Sharp Edges C0.3-0.5Документ1 страницаShaft Oval Pump Ø60X442: All Sharp Edges C0.3-0.5Arief FibonacciОценок пока нет

- Assy Pompa OvalДокумент1 страницаAssy Pompa OvalArief FibonacciОценок пока нет

- Sambungan Rantai 220419 PDFДокумент1 страницаSambungan Rantai 220419 PDFArief FibonacciОценок пока нет

- Cover Housing: All Sharp Edges C0.3-0.5Документ1 страницаCover Housing: All Sharp Edges C0.3-0.5Arief FibonacciОценок пока нет

- R200 85 4xM14 4xM10 PCD 195 4xM12 30 PCD 130 12x 14 PCD 320 4xM12 PCD 150Документ1 страницаR200 85 4xM14 4xM10 PCD 195 4xM12 30 PCD 130 12x 14 PCD 320 4xM12 PCD 150Arief FibonacciОценок пока нет

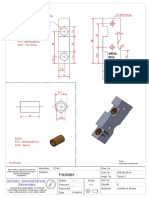

- Holder: Holder P.N: 409.06.0016 MAT.: AL - AlloyДокумент1 страницаHolder: Holder P.N: 409.06.0016 MAT.: AL - AlloyArief FibonacciОценок пока нет

- Sambungan Rantai 220419 PDFДокумент1 страницаSambungan Rantai 220419 PDFArief FibonacciОценок пока нет

- InstallationДокумент2 страницыInstallationAlona AcotОценок пока нет

- Aircon Brochure PDFДокумент6 страницAircon Brochure PDFhhhhhhhhaaОценок пока нет

- Gary White Network EngineerДокумент14 страницGary White Network EngineerUgochukwu FidelisОценок пока нет

- Arduino LCD Set Up2Документ10 страницArduino LCD Set Up2Mikaela MosqueraОценок пока нет

- Variabile: Atribuire - Greeting "Hello" Echo $greetingДокумент8 страницVariabile: Atribuire - Greeting "Hello" Echo $greetingTina CondracheОценок пока нет

- Computer Science 2210 Class 9 Revised Syllabus Break Up2020-21-23Документ5 страницComputer Science 2210 Class 9 Revised Syllabus Break Up2020-21-23MohammadОценок пока нет

- VESDA Programmer ManualДокумент6 страницVESDA Programmer ManualAbdul SamadОценок пока нет

- AOM No. SDOI-2022-018 Mlchelle Dg. Arlola Evelyn A. NisperosДокумент3 страницыAOM No. SDOI-2022-018 Mlchelle Dg. Arlola Evelyn A. NisperosRafael EncarnacionОценок пока нет

- Bagting Marvin: Positions HeldДокумент2 страницыBagting Marvin: Positions HeldMarvin BagtingОценок пока нет

- Excel Budget TemplateДокумент5 страницExcel Budget TemplateChiranjib BanerjeeОценок пока нет

- Brushless DC Motor DriverДокумент3 страницыBrushless DC Motor Driverkvamsee112Оценок пока нет

- Computer Science Syllabus For 4th SemesterДокумент17 страницComputer Science Syllabus For 4th SemesterAnkur Goel67% (3)

- Fortios v7.0.0 Release NotesДокумент91 страницаFortios v7.0.0 Release NotesSandro Henrique de OliveiraОценок пока нет

- An Honest Account of The Humbling Experi PDFДокумент424 страницыAn Honest Account of The Humbling Experi PDFGayatriОценок пока нет

- Aristotelis OperaДокумент921 страницаAristotelis OperaAllison HobbsОценок пока нет

- 1 2 3 4 Bro Smart TC Eng PDFДокумент4 страницы1 2 3 4 Bro Smart TC Eng PDFnguyenОценок пока нет

- 1574158341-Resume AjayLanjewar QA 8YrsExp1Документ7 страниц1574158341-Resume AjayLanjewar QA 8YrsExp1ragunath90Оценок пока нет

- Applicability Guide PDFДокумент2 страницыApplicability Guide PDFtriplbingaziОценок пока нет

- ED-EDM-P1-F1 Service Information Sheet PDFДокумент4 страницыED-EDM-P1-F1 Service Information Sheet PDFMohammed sabatinОценок пока нет

- Ccs352-Maa - SyllabusДокумент3 страницыCcs352-Maa - SyllabusReshma Radhakrishnan0% (1)

- FAQ AWS AcademyДокумент3 страницыFAQ AWS AcademyMohamed Chiheb BEN CHAABANEОценок пока нет

- 1.introduction To Bigdata Chap1Документ35 страниц1.introduction To Bigdata Chap1Snoussi OussamaОценок пока нет

- Electric and Hybrid Electric Vehicles 1 Edition James D Halderman Full ChapterДокумент63 страницыElectric and Hybrid Electric Vehicles 1 Edition James D Halderman Full Chaptersusie.menefee409100% (7)

- Software-Defined Networking (SDN) : Antônio Marcos AlbertiДокумент16 страницSoftware-Defined Networking (SDN) : Antônio Marcos AlbertiAmira DhorbaniОценок пока нет