Академический Документы

Профессиональный Документы

Культура Документы

Commissioning Methodologies (CM) - MUS-07 Water Balancing Method Statement

Загружено:

Fahad MuhammadОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Commissioning Methodologies (CM) - MUS-07 Water Balancing Method Statement

Загружено:

Fahad MuhammadАвторское право:

Доступные форматы

Commissioning Methodologies (CM) – MUS-07

Water Balancing Method Statement

Client: Project Name: Project No:

Area: Drawing No’s: Date: Sheet: 1 of 2

Check Signature: Check Approved By: Signature:

Conducted

By:

INTRODUCTION

The test procedure guideline has been prepared to explain the minimum standard for water balancing of hydronic

systems.

Procedure recommended general checks

1. Prior to commencing any testing and adjustment of water distribution systems ensure that the circuits have

been successfully hydrostatically pressure tested, flushed and cleaned with approved methods are dosed with

appropriate water treatment and are properly vented

2. Ensure all the filter/strainers in the system are clean

3. Prepare single line drawings of the entire system highlighting the design flow rates required to be achieved,

pipe work sizes, measuring and adjustment valve locations

4. Produce a commissioning valve schedule showing valve types, sizes, design flow rates, design pressure drops

as appropriate

5. Confirm that all isolating valves and balancing valves are fully open

6. Confirm all measuring points are accessible

Procedure recommended for testing operation

1. Measure every branch flow rate using the branch balancing valves and check that the total flow rate of the

branches matches the pump flow rate

2. Calculate the percentage of flow rate to each branch

3. Identify the index branch

4. Starting with the index branch, measure the flow of each terminal unit on this branch by measuring the

pressure differential at the balancing valve of the terminal units and add the sum of the terminal units on this

branch and compare to the original branch measurement. If different investigate and redo until they are the

same.

5. Calculate the percentage to each terminal on the index branch to determine the index terminal

6. Using the index terminal as the datum compares the percentage of design flow rates against the percentage of

design flow at each branch. Adjust the regulating valve on the second branch until the percentage of design

flow matches the index circuit. Re-measure the index terminal branch and recalculate the % design flow and

use as the new datum for the index branch. Carry on doing this until all the terminal units on the index branch

are proportionally balanced against each other.

7. Once this is done move on the next branch and repeat. Carry on until all branches’ terminals are proportionally

balanced and all branches are proportionally balanced against each other.

8. When all branches are proportionally balanced check the total branch flows rates against the design flow rate

for the system and adjust the pump speed until the design flow is achieved

9. Record all final water flow figures at each measuring valve and at the pump

REFERENCE STANDARDS

CIBSE Commissioning Code W – Water Distribution Systems

NEBB Procedural Standards for Testing Adjusting and Balancing of Environmental Systems

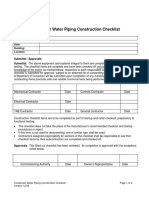

Commissioning Methodologies (CM) – MUS-07

Water Balancing Method Statement

CHECKLIST

AHU/FCU Reference

Drawing Number

VERIFICATION RESULT RESULT RESULT

ITEM METHOD

Check installation is complete, has been pressure tested, flushed, Site Inspection

1

chemically dosed and filled with water and is vented

Site Inspection

2 Check all filters/strainers are clean

Site Preparation

3 Prepare single line drawings of the entire system highlighting

design flows, design pressure drops, pipe sizes

Site Preparation

4 Produce a commissioning valve schedule

Site Inspection

5 Confirm all isolating valves and control valves are fully open

Site Inspection

6 Check all measuring points and adjustment points are accessible

Site Inspection

7 Measure each branch flow rate and check the sum of the

branches against the design flow rate from the pump

Calculate the percentage of flow from each branch to determine Site Inspection

8 the index branch

Site Inspection

9 Proportionally balance each terminal and then branch using the

index terminal on the index branch as a datum

10 Check the branch total flow rates against the design flow rate and Site Inspection

adjust the pump speed to match the design flow rate

Site Inspection

11 Record each branch, terminal and pump flows once system is fully

balanced

Certified By Sub Contractor (initial):

Date:

Confirmed By (Head Contractor / Client) (initial):

Date:

Вам также может понравиться

- Testing, Adjusting, and Balancing - TabДокумент19 страницTesting, Adjusting, and Balancing - TabAmal Ka100% (1)

- Testing & Commissioning of Chilled Water PumpsДокумент3 страницыTesting & Commissioning of Chilled Water Pumpsamg00733% (3)

- Well Testing ProcedureДокумент7 страницWell Testing ProceduremofiyinfoluОценок пока нет

- Booster Pump CommissioningДокумент24 страницыBooster Pump CommissioningOnur Sürücü100% (4)

- Chiller Testing Procedure Rev 1Документ15 страницChiller Testing Procedure Rev 1Ali AimranОценок пока нет

- QSLP 150 Bulk CompressorДокумент56 страницQSLP 150 Bulk CompressorJ&CОценок пока нет

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFДокумент3 страницыTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid Shaikh100% (1)

- Water System Validation ExampleДокумент6 страницWater System Validation Exampledvdynamic1100% (2)

- 23 0593 - Testing, Adjusting, and Balancing For Hvac PDFДокумент9 страниц23 0593 - Testing, Adjusting, and Balancing For Hvac PDFMohamed FawzyОценок пока нет

- Testing & Commissioning of Chilled Water Pressurization UnitsДокумент3 страницыTesting & Commissioning of Chilled Water Pressurization Unitsvin ssОценок пока нет

- Method Statement For The Flushing of Firefighting Pipes.R7Документ9 страницMethod Statement For The Flushing of Firefighting Pipes.R7adel rihanaОценок пока нет

- Test Procedures AIR BALANCEДокумент1 страницаTest Procedures AIR BALANCEhabebeОценок пока нет

- Nebb Standards Section-9 Hydronic System Tab ProceduresДокумент17 страницNebb Standards Section-9 Hydronic System Tab ProceduresAjay Raju.b100% (1)

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFДокумент2 страницыProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhОценок пока нет

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineОт EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineРейтинг: 5 из 5 звезд5/5 (1)

- OSD Calculation 09238Документ10 страницOSD Calculation 09238Anonymous O404LiV4CОценок пока нет

- Condenser Water Piping Construction Checklist: Project: Date: Building: LocationДокумент4 страницыCondenser Water Piping Construction Checklist: Project: Date: Building: LocationGopinath GopiОценок пока нет

- SRDK Cryocooler Service Manual: For Service Personnel OnlyДокумент151 страницаSRDK Cryocooler Service Manual: For Service Personnel OnlyOtávio PagnoncelliОценок пока нет

- Chiller Testing Procedure Rev 3Документ11 страницChiller Testing Procedure Rev 3Ali AimranОценок пока нет

- Veolia Containerised WTP BrochureДокумент8 страницVeolia Containerised WTP BrochureJim TsikasОценок пока нет

- Pump Performance Test Procedure Sheet 3Документ4 страницыPump Performance Test Procedure Sheet 3renjithv_4Оценок пока нет

- Hvac Water BalancingДокумент5 страницHvac Water BalancingAwais Jalali100% (2)

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFДокумент3 страницыTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid ShaikhОценок пока нет

- Páginas desdeAPI MPMS 4.8 - PROVER RECALIBRATION FREQUENCY PDFДокумент2 страницыPáginas desdeAPI MPMS 4.8 - PROVER RECALIBRATION FREQUENCY PDFAngel AvilaОценок пока нет

- EG307 Fire Protection Systems Rev. 1Документ18 страницEG307 Fire Protection Systems Rev. 1Ali MehrpourОценок пока нет

- Test Procedure:: Functional Testing Guidance Pump PerformanceДокумент10 страницTest Procedure:: Functional Testing Guidance Pump PerformanceSagar Naduvinamani100% (1)

- Solution of Multiple Effect Evaporator ProblemsДокумент20 страницSolution of Multiple Effect Evaporator ProblemsAni KushwahaОценок пока нет

- Procedure For Testing & Commissioning of Water Booster Jockey PumpsДокумент3 страницыProcedure For Testing & Commissioning of Water Booster Jockey Pumpsvin ssОценок пока нет

- Liquid Meter Proving TechniquesДокумент6 страницLiquid Meter Proving Techniquesanafado100% (1)

- Liquid Seal Drums: AdvantagesДокумент1 страницаLiquid Seal Drums: Advantagesbinapaniki6520Оценок пока нет

- Procedure For Testing and Commissioning of Water Booster Jockey Pumps PDFДокумент2 страницыProcedure For Testing and Commissioning of Water Booster Jockey Pumps PDFHumaid ShaikhОценок пока нет

- Method Statement For Air & Water BalancingДокумент7 страницMethod Statement For Air & Water BalancingKidesu Ramadhani100% (1)

- SECTION 15954 Hvac Systems Testing, Adjusting, and BalancingДокумент6 страницSECTION 15954 Hvac Systems Testing, Adjusting, and Balancinghitokiri_knives100% (1)

- Minimize Evaporation Losses by Calculating Boiloff Gas in LPG Storage TanksДокумент5 страницMinimize Evaporation Losses by Calculating Boiloff Gas in LPG Storage TanksSanju ChauhanОценок пока нет

- Booster Pump: Testing & Commissioning Method StatementДокумент15 страницBooster Pump: Testing & Commissioning Method Statementselcuk peken100% (1)

- Darmouth College Design November 15, 2007 & Construction GuidelinesДокумент6 страницDarmouth College Design November 15, 2007 & Construction GuidelinesAhmed MostafaОценок пока нет

- Commissioning Methodologies (CM) - MUS 11 PAC Unit Testing Method StatementДокумент3 страницыCommissioning Methodologies (CM) - MUS 11 PAC Unit Testing Method StatementMazen OudОценок пока нет

- Measuring Water FlowДокумент3 страницыMeasuring Water Flowdanijel.borovinsekОценок пока нет

- Commissioning Methodologies (CM) - MUS-01 Pipework Flushing and Cleaning Method StatementДокумент3 страницыCommissioning Methodologies (CM) - MUS-01 Pipework Flushing and Cleaning Method StatementMohammad OsmanОценок пока нет

- 12/23/2021 /conversion/tmp/activity - Task - Scratch/566319865Документ5 страниц12/23/2021 /conversion/tmp/activity - Task - Scratch/566319865tristan guarinoОценок пока нет

- Commissioning Methodologies (CM) - MUS-06 AHU/FCU Testing Method StatementДокумент3 страницыCommissioning Methodologies (CM) - MUS-06 AHU/FCU Testing Method StatementJM ArcillaОценок пока нет

- MUS-5 Cooling Tower TestingДокумент3 страницыMUS-5 Cooling Tower TestingHaider FaresОценок пока нет

- Method of Statemnet For Testing Commissioning of Chilled Water PumpsДокумент3 страницыMethod of Statemnet For Testing Commissioning of Chilled Water PumpsHasan V SОценок пока нет

- HVAC Water Balancing and Flow Testing ProcedureДокумент3 страницыHVAC Water Balancing and Flow Testing ProcedureReda Guellil50% (2)

- Method Statement For The Testing of Domestic PumpДокумент11 страницMethod Statement For The Testing of Domestic Pumpa100% (1)

- Dinamica de Fluido Sucker Rod PumpДокумент26 страницDinamica de Fluido Sucker Rod PumpyeralhОценок пока нет

- CO2 Sensor Testing Method StatementДокумент3 страницыCO2 Sensor Testing Method StatementReginaОценок пока нет

- Factory Performance Testing of Vertical Turbine PumpsДокумент3 страницыFactory Performance Testing of Vertical Turbine PumpsSrećko BlaževićОценок пока нет

- Method Statement of Sprinkler System Without LogoДокумент9 страницMethod Statement of Sprinkler System Without LogokiranramОценок пока нет

- Test Report FormateДокумент27 страницTest Report FormateRobin JamesОценок пока нет

- Method Statement T&C FIRE PROTECTION SYSTEMДокумент10 страницMethod Statement T&C FIRE PROTECTION SYSTEMcic engineeringОценок пока нет

- TestingAndCommissioningPlan SprinklerFireFightingSystemДокумент3 страницыTestingAndCommissioningPlan SprinklerFireFightingSystemReda GuellilОценок пока нет

- 1009 HotWaterSystemPumpTestДокумент9 страниц1009 HotWaterSystemPumpTestnt_long76Оценок пока нет

- 220593.00 - Testing, Adjusting and Balancing For Plumbing SystemsДокумент12 страниц220593.00 - Testing, Adjusting and Balancing For Plumbing Systemsvin ssОценок пока нет

- 03 - Revised MOS - AIR BALANCINGДокумент8 страниц03 - Revised MOS - AIR BALANCINGEditor EditorОценок пока нет

- Commissioning Methodologies (CM) - MUBS-12 Modulating Valve + Actuator Testing Method StatementДокумент3 страницыCommissioning Methodologies (CM) - MUBS-12 Modulating Valve + Actuator Testing Method StatementNikhil AggarwalОценок пока нет

- 557113822Документ7 страниц557113822Billy BrownОценок пока нет

- 4th Article On Small Volume Prover (SVP)Документ7 страниц4th Article On Small Volume Prover (SVP)Chijioke ObiОценок пока нет

- SECTION 15950 Testing, Adjusting, and Balancing General 1.1: - Page 1 of 10 September 2011 - Rev 0Документ10 страницSECTION 15950 Testing, Adjusting, and Balancing General 1.1: - Page 1 of 10 September 2011 - Rev 0Munir RasheedОценок пока нет

- What Is Your Actual Pump Flow Rate?: Norman F. Perkins, P.E. Philip S. StacyДокумент10 страницWhat Is Your Actual Pump Flow Rate?: Norman F. Perkins, P.E. Philip S. StacyANILОценок пока нет

- Method Statement PDFДокумент17 страницMethod Statement PDFAnurag KumbhareОценок пока нет

- API Review: PR0A028I Issue/Rev. 0.0 (7/07) - Slide 1Документ33 страницыAPI Review: PR0A028I Issue/Rev. 0.0 (7/07) - Slide 1IChan ItuIchsanОценок пока нет

- Flow Meter Proving by E. L. Upp 1970'sДокумент6 страницFlow Meter Proving by E. L. Upp 1970'sSofyan HadiОценок пока нет

- Modern Total Well Management PDFДокумент14 страницModern Total Well Management PDFXXXXОценок пока нет

- SECTION 15990 Testing, Adjusting, and Balancing: ANC Terminal 15990-1 Feb 2003 Construction Standards DraftДокумент3 страницыSECTION 15990 Testing, Adjusting, and Balancing: ANC Terminal 15990-1 Feb 2003 Construction Standards DraftZineddine ALICHEОценок пока нет

- Chilled Water Piping Construction Checklist: Project: Date: Building: LocationДокумент4 страницыChilled Water Piping Construction Checklist: Project: Date: Building: LocationGopinath Gopi100% (1)

- Quality Systems Manual Method Statement: Vacuum Dewatering SystemДокумент9 страницQuality Systems Manual Method Statement: Vacuum Dewatering SystemLloyd MariОценок пока нет

- Virtual Flow MeasurementsДокумент17 страницVirtual Flow MeasurementsAivin YongОценок пока нет

- Rayleigh-Bénard Convection With A Melting Boundary: B. Favier, J. Purseed and L. DucheminДокумент36 страницRayleigh-Bénard Convection With A Melting Boundary: B. Favier, J. Purseed and L. DucheminManu K VasudevanОценок пока нет

- Grundfos SQ SQE SP Submersible Pump Product Guide SeДокумент13 страницGrundfos SQ SQE SP Submersible Pump Product Guide SeHeymonth ChandraОценок пока нет

- SuspensionДокумент72 страницыSuspensionUkash sukarmanОценок пока нет

- Maxseal Solenoid Operated Valves: Ico3S 1/4" 3/2 TPMRДокумент4 страницыMaxseal Solenoid Operated Valves: Ico3S 1/4" 3/2 TPMR4122acaОценок пока нет

- DS TSB100-4-Daily Thermetrics DHTW Daily Helix ThermowellДокумент4 страницыDS TSB100-4-Daily Thermetrics DHTW Daily Helix ThermowellJeromeОценок пока нет

- The Netherlands: Vehicle Technology DivisionДокумент24 страницыThe Netherlands: Vehicle Technology DivisionВасилий ТретьяковОценок пока нет

- Chapter 4 - Compressible FlowДокумент32 страницыChapter 4 - Compressible FlowNicholas EmildasОценок пока нет

- Flow of Water Through Schedule 40 Steel Pipe: Table B8.8Документ2 страницыFlow of Water Through Schedule 40 Steel Pipe: Table B8.8LUDERОценок пока нет

- TDS Water Curtain Pump - R1Документ22 страницыTDS Water Curtain Pump - R1SachinDivateОценок пока нет

- Zwick Tri Con Application ESD PDFДокумент2 страницыZwick Tri Con Application ESD PDFJorge DomínguezОценок пока нет

- 4 THC FD ConferenceДокумент11 страниц4 THC FD ConferenceMohmmed MahmoudОценок пока нет

- Conservation of Mass: 1. ObjectivesДокумент4 страницыConservation of Mass: 1. ObjectivesMohamedMostafaОценок пока нет

- Variable Speed Chillers With PicvДокумент1 страницаVariable Speed Chillers With PicvPradeep SukumaranОценок пока нет

- Bau Sadhal Buried Pipe IJHMTДокумент10 страницBau Sadhal Buried Pipe IJHMTSurjit DuttaОценок пока нет

- Fluid Flow, 13 (2) :106-115, 1992: ReferencesДокумент6 страницFluid Flow, 13 (2) :106-115, 1992: ReferencesShah KalpitОценок пока нет

- Chap5 Open SystemДокумент19 страницChap5 Open SystemRoberto Pu100% (4)

- Technical Information Series F: Flow Control ValvesДокумент4 страницыTechnical Information Series F: Flow Control ValvesAde Indra Wijaya100% (1)

- Objectives: Chapter 4 Sludge Treatment and DisposalДокумент37 страницObjectives: Chapter 4 Sludge Treatment and Disposalashe zinabОценок пока нет

- Instruction Manual: HM 150 Basic Hydraulics BenchДокумент13 страницInstruction Manual: HM 150 Basic Hydraulics Benchs_nimalanОценок пока нет

- Fluke 922 Tub PitotДокумент2 страницыFluke 922 Tub PitotLupu VasileОценок пока нет

- Mechanical Seals: The BasicsДокумент2 страницыMechanical Seals: The Basicssyed_Pro07Оценок пока нет