Академический Документы

Профессиональный Документы

Культура Документы

Priority Job List For ABC Inlet

Загружено:

Safrin SangiaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Priority Job List For ABC Inlet

Загружено:

Safrin SangiaАвторское право:

Доступные форматы

MEMO

CSD-CSC

Cement Services, Commissioning

Please find the below check list of the ABC- inlet cooler. These jobs to be completed before

start-up the system.

1. MFR pattern & all the MFR free movements.

2. Cooler Horse shoe castable layed as per design

3. Air leakage if any on the line between blaster out to the connection of the each grate

plate.

4. Inter-compartment leakage if any.

5. Cooler fans air flow calibration & specifications.

6. ABC compartment empty grate resistance at operating fan flow.

7. The communication from field to DCS to be checked for field instruments (grate plate

temperature thermocouple, under compartment pressure, compressed air pressure

switch etc)

8. Blaster operation sequences to be check with different program running & from the

field.

9. The entire grate must be covered with a protective layer of cold clinker nodules by

400mm height.

10. Cooler inlet refractory dry-out (as per refractory supplier recommendation).

11. Operational and safety interlocks verification in the system & check. (List of the

interlocks to be handed over)

12. Inspection door access and cooling air provision to be given.

13. FLS strongly recommends having a CCTV camera for cooler to monitor the ABC inlet

section for any accumulation, deposits, bed thickness, snowman etc., for better control

and steady operation of the system.

Thank you in advance.

Best regards,

N.Madhubabu.

Commissioning Engineer.

Вам также может понравиться

- Drying-Out of Newly Installed Refractory Materials: Doc. No.: 70001614-1.55Документ8 страницDrying-Out of Newly Installed Refractory Materials: Doc. No.: 70001614-1.55Safrin SangiaОценок пока нет

- Running Insp Sheet NewДокумент20 страницRunning Insp Sheet NewSafrin SangiaОценок пока нет

- Safety Working Time LimitsДокумент1 страницаSafety Working Time LimitsSafrin SangiaОценок пока нет

- Actions From Cilacap Burn Fatality ReportДокумент3 страницыActions From Cilacap Burn Fatality ReportSafrin SangiaОценок пока нет

- Data Bag Filter Narogong 2: Polyster Antistatis Polyster Antistatis Polyster Antistatis Polyster AntistatisДокумент7 страницData Bag Filter Narogong 2: Polyster Antistatis Polyster Antistatis Polyster Antistatis Polyster AntistatisSafrin SangiaОценок пока нет

- Spesification of Bag FilterДокумент14 страницSpesification of Bag FilterSafrin SangiaОценок пока нет

- 1108 Brazil CantagaloДокумент2 страницы1108 Brazil CantagaloSafrin SangiaОценок пока нет

- How To Access English TutorialДокумент21 страницаHow To Access English TutorialSafrin SangiaОценок пока нет

- Learn@LH Overview 071215 VFДокумент19 страницLearn@LH Overview 071215 VFSafrin SangiaОценок пока нет

- Patroller Development Program Overview (Rev5.3)Документ9 страницPatroller Development Program Overview (Rev5.3)Safrin SangiaОценок пока нет

- Pricing Policy FinalДокумент32 страницыPricing Policy FinalSafrin SangiaОценок пока нет

- AGC C-19-008 Offer For NarogongДокумент1 страницаAGC C-19-008 Offer For NarogongSafrin SangiaОценок пока нет

- Cost Centre Separation Rev.1Документ11 страницCost Centre Separation Rev.1Safrin SangiaОценок пока нет

- Eric Olsen Visit in Indonesia 20160119Документ11 страницEric Olsen Visit in Indonesia 20160119Safrin SangiaОценок пока нет

- Safety PauseДокумент4 страницыSafety PauseSafrin SangiaОценок пока нет

- Safety PauseДокумент4 страницыSafety PauseSafrin SangiaОценок пока нет

- Process and Production Introduction and Key Activities: © 2015 LafargeholcimДокумент8 страницProcess and Production Introduction and Key Activities: © 2015 LafargeholcimSafrin SangiaОценок пока нет

- Schedule Shift 2016Документ10 страницSchedule Shift 2016Safrin SangiaОценок пока нет

- Process Roadmap 2016Документ10 страницProcess Roadmap 2016Safrin SangiaОценок пока нет

- CPOH FlyerДокумент2 страницыCPOH FlyerSafrin SangiaОценок пока нет

- Daily AFR Material QualityДокумент2 страницыDaily AFR Material QualitySafrin SangiaОценок пока нет

- Daily Monitoring and Issue AFR Material: 51.46 High Moisture Content!Документ1 страницаDaily Monitoring and Issue AFR Material: 51.46 High Moisture Content!Safrin SangiaОценок пока нет

- Daily Monitoring and Issue AFR Material: 51.46 High Moisture Content!Документ1 страницаDaily Monitoring and Issue AFR Material: 51.46 High Moisture Content!Safrin SangiaОценок пока нет

- Ops Target Plan 2012-SlideДокумент3 страницыOps Target Plan 2012-SlideSafrin SangiaОценок пока нет

- NR.473-GQ1 Replace Roof, CasingДокумент8 страницNR.473-GQ1 Replace Roof, CasingSafrin SangiaОценок пока нет

- AFR Material Quality 18-Jul-2012Документ2 страницыAFR Material Quality 18-Jul-2012Safrin SangiaОценок пока нет

- Quotation Awal From DepotДокумент7 страницQuotation Awal From DepotSafrin SangiaОценок пока нет

- Schedule Install From ShinakawaДокумент1 страницаSchedule Install From ShinakawaSafrin SangiaОценок пока нет

- NR.473-GQ1 Fab - and Repl. Bull NoseДокумент4 страницыNR.473-GQ1 Fab - and Repl. Bull NoseSafrin SangiaОценок пока нет

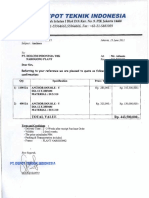

- Pt. Depot Teknik Indonesia: Pantai Indah Selatan Blok D/A Kav. No.9. PIK Jakarta 14460 Phone: Fax: +62-21-5881059Документ1 страницаPt. Depot Teknik Indonesia: Pantai Indah Selatan Blok D/A Kav. No.9. PIK Jakarta 14460 Phone: Fax: +62-21-5881059Safrin SangiaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- ASME Boiler Feed WaterДокумент30 страницASME Boiler Feed WaterHendri KurniawanОценок пока нет

- Chapter 9 and 10Документ18 страницChapter 9 and 10billОценок пока нет

- TMS Advanced TreeViewДокумент64 страницыTMS Advanced TreeViewDanilo CristianoОценок пока нет

- LANTUS XR Label InformationДокумент17 страницLANTUS XR Label InformationMichaelJonatanОценок пока нет

- MAE 322 Machine Design: Dr. Hodge Jenkins Mercer UniversityДокумент20 страницMAE 322 Machine Design: Dr. Hodge Jenkins Mercer UniversityDuslerinalargaОценок пока нет

- Kinetic Energy Recovery SystemДокумент2 страницыKinetic Energy Recovery SystemInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- 310 011 SДокумент34 страницы310 011 SvigneshwaranmОценок пока нет

- Elasticity Measurement of Local Taxes and Charges in Forecast of Own-Source Revenue (PAD) of Provincial Government in IndonesiaДокумент27 страницElasticity Measurement of Local Taxes and Charges in Forecast of Own-Source Revenue (PAD) of Provincial Government in Indonesiaayu desiОценок пока нет

- Discovering Vanishing Objects in POSS I Red Images Using The Virtual Observatory - Beatrice - V - Stac1552Документ12 страницDiscovering Vanishing Objects in POSS I Red Images Using The Virtual Observatory - Beatrice - V - Stac1552Bozidar KemicОценок пока нет

- Jet Powered BoatДокумент22 страницыJet Powered BoatMagesh OfficialОценок пока нет

- 1.bitwise OperatorsДокумент2 страницы1.bitwise OperatorsPaul kollamОценок пока нет

- Alex H.: Penguin ProjectДокумент13 страницAlex H.: Penguin Projectapi-504550016Оценок пока нет

- TUC5+ Modbus ID Details PDFДокумент10 страницTUC5+ Modbus ID Details PDFvijikeshОценок пока нет

- Principles of Gas Chromatography 2Документ12 страницPrinciples of Gas Chromatography 2Enanahmed EnanОценок пока нет

- Whats A Job in Linux: $ Sleep 100 & (1) 1302 $Документ2 страницыWhats A Job in Linux: $ Sleep 100 & (1) 1302 $Viraj BhosaleОценок пока нет

- Astar - 23b.trace - XZ Bimodal Next - Line Next - Line Next - Line Next - Line Drrip 1coreДокумент4 страницыAstar - 23b.trace - XZ Bimodal Next - Line Next - Line Next - Line Next - Line Drrip 1corevaibhav sonewaneОценок пока нет

- Transom Analysis ComparisonДокумент38 страницTransom Analysis ComparisonRifky NetriadyОценок пока нет

- Design of Inner Lid of Pressure Cooker With Circular Shape Having Straight EdgesДокумент5 страницDesign of Inner Lid of Pressure Cooker With Circular Shape Having Straight EdgesSecret SecretОценок пока нет

- 191 - 197 - Detection of Transaction Fraud Using Deep LearningДокумент28 страниц191 - 197 - Detection of Transaction Fraud Using Deep LearningADRINEEL SAHAОценок пока нет

- Project ManagementДокумент120 страницProject Managementdevilturn70Оценок пока нет

- Installation Manual: DPS 232 Differential Positioning SystemДокумент154 страницыInstallation Manual: DPS 232 Differential Positioning SystemVladimirs Arzeninovs100% (3)

- ME361 - Manufacturing Science Technology: Measurements and MetrologyДокумент20 страницME361 - Manufacturing Science Technology: Measurements and MetrologyKartikeyaОценок пока нет

- Universal Firmware Patcher for Protected Garmin DevicesGPS导航软件与地图国外GPS导航和地图资源Документ1 страницаUniversal Firmware Patcher for Protected Garmin DevicesGPS导航软件与地图国外GPS导航和地图资源MARCELO CORREAОценок пока нет

- Compaction Factor ExperimentДокумент23 страницыCompaction Factor ExperimentYI HEN ONGОценок пока нет

- 001-MBA-SPSS Applications - 10-06-2023Документ74 страницы001-MBA-SPSS Applications - 10-06-2023seyon sithamparanathanОценок пока нет

- Abstract of Talk by Dr. Nitin Oke For National Conference RLTДокумент2 страницыAbstract of Talk by Dr. Nitin Oke For National Conference RLTnitinОценок пока нет

- Pso NS2Документ6 страницPso NS2sankarideviОценок пока нет

- Western Dragon V3 Updated PDFДокумент19 страницWestern Dragon V3 Updated PDFMark Moldez94% (17)

- Palette For Colorfastness PilotДокумент25 страницPalette For Colorfastness Pilotjenal aripinОценок пока нет

- MB-339A User ManualДокумент196 страницMB-339A User Manualkepakko75% (4)