Академический Документы

Профессиональный Документы

Культура Документы

Learn About Oil and Gas Separators

Загружено:

Olivier WhettemОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Learn About Oil and Gas Separators

Загружено:

Olivier WhettemАвторское право:

Доступные форматы

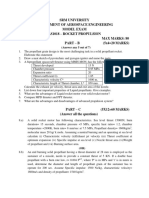

EPS Chemical Engineering B4.

4OD3 Oil and Gas Processing

3. Estimate the size of a horizontal 2 phase separator to process the following

Tutorial : Primary Separator Design fluid:

Gas flowrate 10 mmscfd at 0.6 specific gravity, oil rate 2000 bpd at 40° API.

The numerical answers are provided as a guide only as decisions and Operating pressure 1000 psia and temperature is 60°F. Compressibility

assumptions taken during the procedures will affect the end result. Please use the factor at operating conditions is Z=0.84

answers with discretion. You should make reasonable assumptions where

necessary, just as in the exam and in real life!. 4. Preliminary data for an offshore field predicts peak production rates of 40

mmscfd gas and 10,000 bbl/d oil. If the first stage separator operates at 500

1. Information on BP’s Single Well Oil Production Systems (SWOPS), suggests psia and 180°F estimate the following:

the process separators handle 6 mmscfd of gas and 15,000 bbl/d of oil. The a) Gas volumetric flow rate at separator conditions

first stage separator operates at an average pressure of 175 psia and b) Maximum allowable gas velocity and the minimum area for gas flow.

temperature of 75°C. Estimate the following: c) The hold up volume of oil required

d) The diameter, length and slenderness ratio assuming the gas occupies half

3

a) Actual volumetric flowrates of gas and oil in m /s at separator the available volume and that the gas phase constrains the design.

2

conditions. Assume Z=0.85 at separator conditions. e) Derive an expression of the form D L=function of oil flowrate, residence

time, filling factor and hence find the size of this vessel for a slenderness ratio

b) If the separator is a horizontal cylinder of diameter 2m by 7m in length of 4.

and operates half full of liquid, calculate the gas and liquid velocities.

c) The oil residence time Additional Data:

• Gas compressibility factor is 0.9

• Souder’s-Brown constant to be 0.12 m/s

Assume the produced gas is mainly methane. • Allow a 5 minute residence time.

3 3 • The gas is mainly methane

(Ans Qg=0.169 m /s ,Qo=0.028 m /s ug=0.108 m/s, uo=0.018 m/s, 5 mins)

• Oil density is 890 kg/m

3

2. Estimate the size of a horizontal 2 phase separator to process 50 mmscfd of 3 -1 3 -1

(Ans Qg=0.427m s , Qo=0.018 m /s, ug=0.57ms , Vo=5.5m , D=1.4m,

3

gas with a 0.6 specific gravity, oil rate 6000 bpd at 40° API. Operating 2

L=9,s=7.15, D L=kQt/(1-f), where k is a constant)

pressure 1000 psia and temperature is 60°F. Assume the compressibility

factor at operating conditions is Z=0.84. Neglect the level alarm positions but

make reasonable assumptions on other operating parameters. State any other

5. A medium sized horizontal separator 3m in diameter with an effective length

assumptions made.

of 10m is used to process 9000 kg/hr gas, 80,000 kg/hr oil and 30,000 kg/hr

water. The gas/oil level is set to 2m from the vessel base, and the oil/water

What would happen to the separator’s performance, if the liquid flowrate level is set to 0.7m above the base. Estimate the following:

increased by a factor of 50%, but ensuring the residence time was kept the

a) Axial velocities of water and oil layers

same?

b) Residence times of each phase

c) Size of the smallest water-in-oil drop which can be separated in this

(Ans: D=1.89m, L=6.6m, residence time 10 mins, slenderness ratio 3.5, 50%

separator

full, filling increases to 75%)

Physical properties are give in the table below

Revised 4 February, 2009 at 06:10 PM Page 1 of 2

Dr G.White

EPS Chemical Engineering B4.4OD3 Oil and Gas Processing

Gas Oil Water (Ans D=3.54m, L=9.73m at 75% liquid volume, how=1.934m, hgo=2.5m)

-3

Density (kg m ) 6 860 1070

Viscosity (cP) 10 1 8. In a production separator, the velocity of both oil and water phases is

measured to be 0.05 m/s. The residence time is 3 minutes and the separator

is 75% full of liquid. Using the information below, calculate the liquid levels, the

(Ans, uoil=6.9 mm/s, uwater=6.2 mm/s, toil=18 mins, twater=20 min, 335 diameter and length of the separator.

microns)

What changes to your calculation method would you expect to make if either

perforated plates or structured packing were to be used?

6. The first stage separator for the “Hutton” TLP was originally designed to cope

with a maximum oil rate of 117000 bpd, water at 50,000 bpd, and gas at 10 Gas Oil Water

mmscfd. Operating conditions were 16 barg, 105 °C. Oil API gravity was 20°. Flow rate 30 260 100 kg/s

Assuming the properties and conditions listed below estimate the following: Density 50 850 1022 kg/m

3

a) Diameter, length and liquid filling levels for this separator, assuming this Viscosity - 0.006 0.0004 Ns/m

2

separator operates at 75% full.

b) Size of the smallest water in oil drop that would be separated in this unit.

c) The typical response time for the gas/oil level controller.

Assume that

the oil viscosity as 10cP, water viscosity 1cP

Souder’s Brown constant is 0.15 m/s

Residence times are 3 minutes

(Ans D=3.2m, Lss=9.2m, Water NLL=0.89m, Oil NLL=2.25m, 1280 microns,

7. The first stage three phase separator on the “Gullfaks A” platform was

designed with the following production rates :

Flowrate Density Viscosity

3 -1 -3 -2

m h kg m Nsm

Gas 1640 49.7 0.000013

Oil 1840 831.5 0.00525

Water 287 1030 0.00043

* Physical properties are taken at separator conditions

Calculate the diameter, length and fill depths for this separator given:

• Water-in-oil drop size to separate, are less than 730 µm

• Souder’s-Brown constant : 0.13

Assume table above applies to separator conditions.

Revised 4 February, 2009 at 06:10 PM Page 2 of 2

Dr G.White

Вам также может понравиться

- Mid Exam 2020-2021Документ2 страницыMid Exam 2020-2021موسى جعفر احمد محمدОценок пока нет

- Separator Sizing SheetДокумент8 страницSeparator Sizing SheetCahyoОценок пока нет

- API-521_Flare_KOD_Design_and_Even_More__Part_2Документ6 страницAPI-521_Flare_KOD_Design_and_Even_More__Part_2Huy Nguyễn Võ XuânОценок пока нет

- Multiphase Flow - TutorialsДокумент7 страницMultiphase Flow - TutorialsOlusegun OyebanjiОценок пока нет

- 78HE-1 Sr. No. 7 Examination of Marine Engineer OfficerДокумент4 страницы78HE-1 Sr. No. 7 Examination of Marine Engineer Officeryosh gurtОценок пока нет

- ExamSlip - 148865 - 20190401 - 1520 VladДокумент23 страницыExamSlip - 148865 - 20190401 - 1520 VladNikolaus PanjaitanОценок пока нет

- Design Project 9.3 Lukman Martinus G G 02111540000115Документ12 страницDesign Project 9.3 Lukman Martinus G G 02111540000115Lukman Martinus GunawanОценок пока нет

- Droplet Size CalculationДокумент2 страницыDroplet Size Calculationsumathi@1985Оценок пока нет

- Cálculo de Diseño de SeparadoresДокумент4 страницыCálculo de Diseño de SeparadoresEdwardОценок пока нет

- Trickle Bed Reactor, Process and Mechanical DesignДокумент14 страницTrickle Bed Reactor, Process and Mechanical DesignkhawarОценок пока нет

- Jntuh BT Che 5 Mass-Transfer-Operations-I-2011Документ8 страницJntuh BT Che 5 Mass-Transfer-Operations-I-2011Sanjeev Kumar SuppalaОценок пока нет

- Tripoli University Chemical Engineering Department: Homework #4Документ2 страницыTripoli University Chemical Engineering Department: Homework #4Good BadОценок пока нет

- Design Continuous Stirred Tank ReactorДокумент71 страницаDesign Continuous Stirred Tank ReactorNoman AslamОценок пока нет

- Separator Design Basics.Документ58 страницSeparator Design Basics.Shijumon KpОценок пока нет

- Soal Coulson Richardson Page 696-706 (STHE Design)Документ11 страницSoal Coulson Richardson Page 696-706 (STHE Design)Glen gaylandОценок пока нет

- ME604 Thermal Engineering Sem VI exam questionsДокумент2 страницыME604 Thermal Engineering Sem VI exam questionsYash BeleОценок пока нет

- A3 SeparatorДокумент59 страницA3 SeparatorHaziq YussofОценок пока нет

- 05 MEP 461 Final Examination 2020Документ5 страниц05 MEP 461 Final Examination 2020Ahmed Shaaban Soliman HamedОценок пока нет

- B41OA Datasheet 2017-2018Документ7 страницB41OA Datasheet 2017-2018Turkan AliyevaОценок пока нет

- Cycle Test 2 Rocket PropulsionДокумент3 страницыCycle Test 2 Rocket Propulsionapi-271354682Оценок пока нет

- ME 554 Problem Set-06 Solid Rocket Motors PDFДокумент3 страницыME 554 Problem Set-06 Solid Rocket Motors PDFBHASKAR SARMAОценок пока нет

- ME 554 Problem Set-06 Solid Rocket Motors PDFДокумент3 страницыME 554 Problem Set-06 Solid Rocket Motors PDFBHASKAR SARMAОценок пока нет

- IIT Bombay Chemical Engineering Exam QuestionsДокумент4 страницыIIT Bombay Chemical Engineering Exam QuestionsSwapnil GudmalwarОценок пока нет

- Jntuk 2 1 Thermodynamics Nov 2017 Q.PДокумент8 страницJntuk 2 1 Thermodynamics Nov 2017 Q.PsaiОценок пока нет

- Topic 7 Oil and Gas Pipeline SolutionsДокумент17 страницTopic 7 Oil and Gas Pipeline SolutionsImranMajidli100% (1)

- Group 2 ReportДокумент5 страницGroup 2 ReportJo odОценок пока нет

- THERMODYNAMICS Oct-Nov 2019Документ8 страницTHERMODYNAMICS Oct-Nov 2019Karthik CruiseОценок пока нет

- Heriot-Watt University Department of Petroleum Engineering: Course:-28117 Class: - 289033bДокумент39 страницHeriot-Watt University Department of Petroleum Engineering: Course:-28117 Class: - 289033bali100% (1)

- Heriot-Watt University Department of Petroleum Engineering: Course:-28117 Class: - 289033bДокумент8 страницHeriot-Watt University Department of Petroleum Engineering: Course:-28117 Class: - 289033bijkОценок пока нет

- B. Tech - 3rd Semester Semester End Supplementary Examination, Feb-2019Документ2 страницыB. Tech - 3rd Semester Semester End Supplementary Examination, Feb-2019Anonymous uDuusWmdtОценок пока нет

- Two Phase (Gas - Oil) Vertical Separator: As Per "Petroleum and Gas Field Processing - Hussein K. Abdel-Aal, Mohamed Aggour, M. A. Fahim"Документ1 страницаTwo Phase (Gas - Oil) Vertical Separator: As Per "Petroleum and Gas Field Processing - Hussein K. Abdel-Aal, Mohamed Aggour, M. A. Fahim"Vu TranОценок пока нет

- EPS-443 - Properties of Petroleum Reservoirs Fall Semester 2005Документ9 страницEPS-443 - Properties of Petroleum Reservoirs Fall Semester 2005Vicky ApriliaОценок пока нет

- Topic 2 - A: F M M Multiphase Flow Tutorial QuestionsДокумент7 страницTopic 2 - A: F M M Multiphase Flow Tutorial QuestionsAnjo VasquezОценок пока нет

- Thermodyamics R07Документ9 страницThermodyamics R07hhjjОценок пока нет

- Simulation basis & Equipment designДокумент12 страницSimulation basis & Equipment designBhuran AkshayОценок пока нет

- Comprehensive Exam 2022 Part 2Документ6 страницComprehensive Exam 2022 Part 2Annie LОценок пока нет

- Engineering Thermodynamics Exam QuestionsДокумент2 страницыEngineering Thermodynamics Exam QuestionsAnonymous uDuusWmdtОценок пока нет

- Engg. CalculationДокумент5 страницEngg. CalculationVijaya PatilОценок пока нет

- A Simulation Study of The (103A) Field, Zuetina Terminal Crude Oil PipelineДокумент7 страницA Simulation Study of The (103A) Field, Zuetina Terminal Crude Oil PipelineteaОценок пока нет

- Introduction About Two-Phase Vertical Separator Vertical Separator Design ConclusionДокумент19 страницIntroduction About Two-Phase Vertical Separator Vertical Separator Design ConclusionYè Paing OoОценок пока нет

- Double Pipe Heat Exchanger DesignДокумент4 страницыDouble Pipe Heat Exchanger DesignHemanth Peddavenkatappa GariОценок пока нет

- BD-XXX-XX-XX-95XX Nitrogen and Compressor DemandДокумент24 страницыBD-XXX-XX-XX-95XX Nitrogen and Compressor DemandJofanny Ferdian RahmansyahОценок пока нет

- Final ExamДокумент5 страницFinal ExamWaqasОценок пока нет

- Ar13 Me 2404Документ2 страницыAr13 Me 2404Anonymous uDuusWmdtОценок пока нет

- Ar13 Me 2404Документ2 страницыAr13 Me 2404Anonymous uDuusWmdtОценок пока нет

- Week Two Homework Problem Solutions: Fundamentals of ! Fluid PowerДокумент6 страницWeek Two Homework Problem Solutions: Fundamentals of ! Fluid PowerhellfireОценок пока нет

- Week 2 Solutions V2Документ6 страницWeek 2 Solutions V2mfpau23Оценок пока нет

- Week Two Homework Problem Solutions: Fundamentals of ! Fluid PowerДокумент6 страницWeek Two Homework Problem Solutions: Fundamentals of ! Fluid PowerhellfireОценок пока нет

- Week Two Homework Problem Solutions: Fundamentals of ! Fluid PowerДокумент6 страницWeek Two Homework Problem Solutions: Fundamentals of ! Fluid PowerAtik IslamОценок пока нет

- Week Two Homework Problem Solutions: Fundamentals of ! Fluid PowerДокумент6 страницWeek Two Homework Problem Solutions: Fundamentals of ! Fluid Powermustafa1011Оценок пока нет

- Fundamentals of Fluid Power Homework SolutionsДокумент6 страницFundamentals of Fluid Power Homework SolutionsAmarnathОценок пока нет

- Separator Sizing and DesignДокумент45 страницSeparator Sizing and DesignSedemОценок пока нет

- Process Equipment Design IДокумент2 страницыProcess Equipment Design IMONALIОценок пока нет

- DJM-MBA-PCS-CA-005 De-Etanizer Accumulator REV-1Документ6 страницDJM-MBA-PCS-CA-005 De-Etanizer Accumulator REV-1DIANTOROОценок пока нет

- Thermal 6Документ1 страницаThermal 6Clash GodОценок пока нет

- INDEX AND DATA FOR 1X500 MW THERMAL POWER PLANTДокумент34 страницыINDEX AND DATA FOR 1X500 MW THERMAL POWER PLANTMahendra PrasadОценок пока нет

- UASB Design Calculations - S.I Units: Workbook ContentsДокумент12 страницUASB Design Calculations - S.I Units: Workbook Contentsdiego100% (1)

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingОт EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingОценок пока нет

- CFD Modelling of A Horizontal Three-PhaseДокумент18 страницCFD Modelling of A Horizontal Three-PhaseEmmanuel IkhaiduworОценок пока нет

- Two People Meet...Документ2 страницыTwo People Meet...Olivier WhettemОценок пока нет

- Advanced Control TutorialДокумент10 страницAdvanced Control TutorialOlivier WhettemОценок пока нет

- Ey Global Oil and Gas Tax Guide PDFДокумент762 страницыEy Global Oil and Gas Tax Guide PDFOlivier Whettem100% (1)

- A Simple PDFДокумент2 страницыA Simple PDFJaheer MakalОценок пока нет

- A Simple PDFДокумент2 страницыA Simple PDFJaheer MakalОценок пока нет

- A Simple PDFДокумент2 страницыA Simple PDFJaheer MakalОценок пока нет

- A Simple PDFДокумент2 страницыA Simple PDFJaheer MakalОценок пока нет

- Fugacity Calculation ExampleДокумент1 страницаFugacity Calculation ExampleOlivier WhettemОценок пока нет

- UK Energy PricesДокумент16 страницUK Energy Pricesangry_granОценок пока нет

- 1263 3507 1 PBДокумент5 страниц1263 3507 1 PBJohn TorrezОценок пока нет

- Password RemoverДокумент3 страницыPassword RemoverStanley WongОценок пока нет

- EagleBurgmann ZY Cyclone Separators enДокумент6 страницEagleBurgmann ZY Cyclone Separators enhafizuddinrazaliОценок пока нет

- Managing Sand-Laden ManureДокумент10 страницManaging Sand-Laden ManureOdilon NetoОценок пока нет

- J SERIES Installation Operation ManualДокумент4 страницыJ SERIES Installation Operation ManualArnara VerdiawanОценок пока нет

- 3 - Guideline Energy Efficiency in The Confectionery IndustryДокумент12 страниц3 - Guideline Energy Efficiency in The Confectionery IndustryNasional GotongroyongОценок пока нет

- Manual Flejadora PNSC2-34Документ20 страницManual Flejadora PNSC2-34Jacobo SuarezОценок пока нет

- Scrubber NATCOДокумент22 страницыScrubber NATCOkalikamalaОценок пока нет

- Pt. Tahaqquq Beno Nusantara: Engineering, Procurement, Construction, Installation & CommissioningДокумент15 страницPt. Tahaqquq Beno Nusantara: Engineering, Procurement, Construction, Installation & CommissioningulinnuhaОценок пока нет

- Course 1 - Raw Material Extraction: 1.2 Water Drainage SystemsДокумент26 страницCourse 1 - Raw Material Extraction: 1.2 Water Drainage SystemsAnonymous iI88LtОценок пока нет

- Gennie Filter SCC-133-ABДокумент3 страницыGennie Filter SCC-133-ABZeeshan ShamsiОценок пока нет

- Hydrate Inhibition MethodsДокумент111 страницHydrate Inhibition MethodskaitokidH3MОценок пока нет

- British Petroleum Standard Multiphase Design ManualДокумент547 страницBritish Petroleum Standard Multiphase Design ManualSakhib100% (2)

- Collection of Geothermal Fluids For Chemical AnalysisДокумент17 страницCollection of Geothermal Fluids For Chemical AnalysisPajooheshОценок пока нет

- AspenHYSYSUpstreamV7 3 OptДокумент304 страницыAspenHYSYSUpstreamV7 3 Opti786zzyОценок пока нет

- Separador BifásicoДокумент42 страницыSeparador BifásicoAldoDeLaCerda100% (1)

- Manual de Mantenimiento Rs30-37Документ16 страницManual de Mantenimiento Rs30-37roger100% (1)

- Offshore - Introduction LayoutДокумент131 страницаOffshore - Introduction LayoutgeorgiadisgОценок пока нет

- Flare TypeДокумент44 страницыFlare Typecanada_198020008918100% (1)

- Manual Skit Deb 1.8 Facelift v2 EngДокумент24 страницыManual Skit Deb 1.8 Facelift v2 EngSimonaMauna0% (1)

- R410A Quick Reference GuideДокумент52 страницыR410A Quick Reference GuideTagelОценок пока нет

- Carrier 30g Ecologic Chillers Series 1,2Документ100 страницCarrier 30g Ecologic Chillers Series 1,2pkumar68Оценок пока нет

- PSP Fat Procedure - TemplateДокумент6 страницPSP Fat Procedure - TemplateMichael HaiseОценок пока нет

- GT 12 Separator ManualДокумент214 страницGT 12 Separator ManualRaghunath MajeeОценок пока нет

- Instruction Book 50-90VSD PDFДокумент32 страницыInstruction Book 50-90VSD PDFSaif AliОценок пока нет

- Early Production Facilities PL WebДокумент4 страницыEarly Production Facilities PL Webbono8950% (2)

- Worthington Instruction Book PCI07 enДокумент28 страницWorthington Instruction Book PCI07 ensebastian100% (8)

- 2020.4 GNZCQ Vacuum Degasser Manual (REV01)Документ36 страниц2020.4 GNZCQ Vacuum Degasser Manual (REV01)GeorgeОценок пока нет

- Petrogas Processiing Calgary Plant - H. W. MANLEYДокумент8 страницPetrogas Processiing Calgary Plant - H. W. MANLEYAlvaro Andres Blanco GomezОценок пока нет

- Interstage Coolers A Hot ItemДокумент5 страницInterstage Coolers A Hot Itemlbh6417320Оценок пока нет

- Total Well Management IIДокумент14 страницTotal Well Management IIEdgar Tellez100% (1)

- Guhan K E&I Engineer & Atex Inspector: Professional SummaryДокумент4 страницыGuhan K E&I Engineer & Atex Inspector: Professional Summarykspguhan1987Оценок пока нет