Академический Документы

Профессиональный Документы

Культура Документы

QW483

Загружено:

Sc Tan0 оценок0% нашли этот документ полезным (0 голосов)

54 просмотров2 страницыASME PQR

Авторское право

© © All Rights Reserved

Доступные форматы

DOC, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документASME PQR

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

54 просмотров2 страницыQW483

Загружено:

Sc TanASME PQR

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOC, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

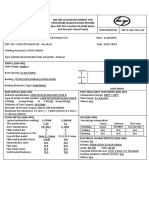

QW-483 (Form QA2002), Page 2/2

Procedure Qualifications Record (PQR)

(ASME Boiler and Pressure Vessel Code - Section IX)

Company Name :

Procedure Qualification Record No : Date :

WPS No :

Welding Process(es) :

Types (Manual, Automatic,Semi-Auto :

Joints (QW-402)

Groove Design of Test Coupon

(For combination qualifications, the deposit weld metal thickness shall be recorded for each metal or process used.)

Base Metal (QW-403) Postweld Heat Treatment (QW-407)

Material Spec : Temperature :

Type or Grade : Time :

S-No : Grp. No: To S-No : Grp. No: Other :

Thickness of Test Coupon :

Diameter of Test Coupon : Gas (QW-408)

Other : Percent Composition

Filler Metals (QW-404) Gas(es) (Mixture) Flow Rate

SFA Specification : Shielding :

AWS Specification : Trailing :

Filler Metal F-No : Backing :

Weld Metal Analysis A-No : Electrical Characteristics (QW-409)

Size of Filler Metal : Current :

Other : Polarity :

Deposit Weld Metal : Amps : Volts :

Position (QW-405) Tungsten Electrode Size :

Position of Groove : Other :

Weld Progression (Uphill, Downhill) : Technique (QW-410)

Other : N/A Travel Speed :

Preheat (QW-406) String or Weave Bead :

Preheat Temp : Oscillation :

Interpass Temp : Multipass or Single Pass (per side) :

Other : Single or Multiple Electrodes :

Others :

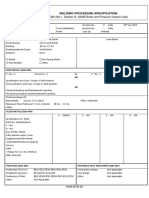

QW-483 (Form QA2002), Page 2/2

WQ-483 (Page 2) PQR No :

Tensile Test (QW-150)

Specimen Width Thickness Area Ultimate Total Load Ultimate Unit Type of Failure & Location

No. MM MM MM2 Kgf Stress

N/MM 2

1. TENSILE-ELONGATION TEST 2. TRANSVERSE TENSILE TEST 3. NICK BREAK TEST

Guided-Bend Tests (QW-160)

Type and Figure No. Results

Toughness Tests (QW-170)

Lateral Exp. Drop Weight

Specimen Notch Notch Test Temp Impact Values

No Location Type (J) % Shear Mils Break No Break

Fillet Weld Test (QW-180)

Result - Satisfactory : (Yes) (No) Penetration into Parent Metal : (Yes) (No)

Macro Results :

Other Tests

Type of Test :

Other :

Welders Name : Clock No : Stamp No:

Test Conducted By : Laboratory Test No :

(We certify that the statements in this record are correct and that the test welds were prepared, welded and tested in accordance with

the requirements of Section IX of the ASME code)

Date : Manufacturer :

By :

Вам также может понравиться

- 37507022-WPS-PQR-SS-316 LДокумент5 страниц37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- WPQ FormatДокумент8 страницWPQ FormatsanjaykumarmauryaОценок пока нет

- Materials Data for Cyclic Loading: Low-Alloy SteelsОт EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsРейтинг: 5 из 5 звезд5/5 (2)

- Operation of Portable Generators - IET Wiring GuideДокумент7 страницOperation of Portable Generators - IET Wiring GuideRyan Scott100% (1)

- PQR TipsДокумент2 страницыPQR TipsWaqas WaqasОценок пока нет

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDДокумент5 страницWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriОценок пока нет

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeДокумент6 страницWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberОценок пока нет

- PQR With-PwhtДокумент2 страницыPQR With-PwhtKarthikОценок пока нет

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelДокумент3 страницыWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanОценок пока нет

- WPS&PQR For PipeДокумент5 страницWPS&PQR For PipeKAMALОценок пока нет

- tp6140 PDFДокумент72 страницыtp6140 PDFjohnОценок пока нет

- Procedure Qualification Record PQRДокумент3 страницыProcedure Qualification Record PQRNMBaihakiARОценок пока нет

- Water Tree Cable JointsДокумент151 страницаWater Tree Cable JointsSellappan MuthusamyОценок пока нет

- Coagulation FlocculationДокумент71 страницаCoagulation FlocculationDeepa Singh100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- WPS E6013+e7018Документ2 страницыWPS E6013+e7018Anvesh Vaddi100% (1)

- Shape Cutting Systems From EsabДокумент36 страницShape Cutting Systems From EsabJhun Aquino100% (1)

- SCN0046 P410 MSZДокумент2 страницыSCN0046 P410 MSZCristian ChiruОценок пока нет

- DP Test ProcedureДокумент8 страницDP Test ProcedureAjith KumarОценок пока нет

- Procedure Qualification RecordДокумент2 страницыProcedure Qualification RecordDan ClarkeОценок пока нет

- Power Calculation For Solar PanelДокумент24 страницыPower Calculation For Solar PanelMasroor KhanОценок пока нет

- KAESER SX6 Service ManualДокумент100 страницKAESER SX6 Service ManualYassin AlkadyОценок пока нет

- Wps Format Asme Sec - IxДокумент2 страницыWps Format Asme Sec - IxDeepu ChandranОценок пока нет

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDДокумент5 страницWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedОценок пока нет

- PQR A106 HAL-1Документ1 страницаPQR A106 HAL-1Budi Setia RahmanОценок пока нет

- WPQ Format - SMAWДокумент3 страницыWPQ Format - SMAWBalkishan DyavanapellyОценок пока нет

- QW 483Документ2 страницыQW 483delta lab sangliОценок пока нет

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Документ2 страницыQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghОценок пока нет

- Form PQR 1 AsmeДокумент6 страницForm PQR 1 AsmeZam Zam NoorОценок пока нет

- Qw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Документ3 страницыQw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Zam Zam NoorОценок пока нет

- BPVC Ix qw-483 PDFДокумент2 страницыBPVC Ix qw-483 PDFEmma DОценок пока нет

- BPVC Ix qw-483 PDFДокумент2 страницыBPVC Ix qw-483 PDFDwi Agus YuliyantoОценок пока нет

- BPVC Ix qw-483 PDFДокумент2 страницыBPVC Ix qw-483 PDFEmma DОценок пока нет

- BPVC Ix qw-483 PDFДокумент2 страницыBPVC Ix qw-483 PDFedinson castrilloОценок пока нет

- BPVC Ix qw-483 PDFДокумент2 страницыBPVC Ix qw-483 PDFazizОценок пока нет

- BPVC Ix qw-483 PDFДокумент2 страницыBPVC Ix qw-483 PDFEmma DОценок пока нет

- PQR FormatДокумент2 страницыPQR FormatBE GОценок пока нет

- Fillet Inspection SheetДокумент2 страницыFillet Inspection SheetShankey JAlanОценок пока нет

- Form PQR 2 AsmeДокумент6 страницForm PQR 2 AsmeZam Zam NoorОценок пока нет

- SAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Документ2 страницыSAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Lovedeep SinghОценок пока нет

- Base Metals (Qw-403) Postweld Heat Treatment (Qw-407)Документ2 страницыBase Metals (Qw-403) Postweld Heat Treatment (Qw-407)beyОценок пока нет

- Procedure Qualification Record (PQR)Документ3 страницыProcedure Qualification Record (PQR)surjithkocherilОценок пока нет

- PRN005Документ2 страницыPRN005beyОценок пока нет

- Suggested Format PQRДокумент2 страницыSuggested Format PQRAngel RebolloОценок пока нет

- JOINTS (QW-402) : Groove Design of Test CouponДокумент2 страницыJOINTS (QW-402) : Groove Design of Test CouponbeyОценок пока нет

- Sample WPS Format PDFДокумент1 страницаSample WPS Format PDFait.koufiОценок пока нет

- JOINTS (QW-402) : Groove Design of Test CouponДокумент2 страницыJOINTS (QW-402) : Groove Design of Test CouponbeyОценок пока нет

- PRN004Документ2 страницыPRN004beyОценок пока нет

- Procedure Qualification RecordДокумент6 страницProcedure Qualification RecordGaurang PandyaОценок пока нет

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Документ3 страницыAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyОценок пока нет

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeДокумент4 страницыQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86Оценок пока нет

- 4 2PQRДокумент2 страницы4 2PQRsaravanans1891Оценок пока нет

- QW - 482 Welding Procedure Specifications (WPS) : BASE METAL (S) (QW-403) : JOINTS (QW-402) : or ToДокумент2 страницыQW - 482 Welding Procedure Specifications (WPS) : BASE METAL (S) (QW-403) : JOINTS (QW-402) : or ToattaullaОценок пока нет

- Welding Procedure Specification (WPS) (Asme Sec - Ix) : Manual Semi-Automatic Automatic MachineДокумент1 страницаWelding Procedure Specification (WPS) (Asme Sec - Ix) : Manual Semi-Automatic Automatic Machinesoroushsadeghi60Оценок пока нет

- Wps FormatДокумент2 страницыWps FormatParminder SinghОценок пока нет

- Welder Certificate Akilesh YadavДокумент1 страницаWelder Certificate Akilesh Yadavtripatipankaj023Оценок пока нет

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Документ2 страницыQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Vaibhav GuptaОценок пока нет

- PQR Editable SampleДокумент2 страницыPQR Editable SampleKoya ThangalОценок пока нет

- WPS FormatДокумент3 страницыWPS Formatvivek bhangaleОценок пока нет

- Qw-483 Suggested Format For Welding Procedure Qualification Records (PQR)Документ4 страницыQw-483 Suggested Format For Welding Procedure Qualification Records (PQR)aliОценок пока нет

- Joints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateДокумент3 страницыJoints: (QW - 402) : Wps No.: Bpscl/Shel/Wps - 04 DateAmjad PathanОценок пока нет

- Mechanical Engineering M.Abdul GhoziДокумент4 страницыMechanical Engineering M.Abdul GhoziRizaldy PhoenksОценок пока нет

- PQR ForДокумент3 страницыPQR ForAkash Singh TomarОценок пока нет

- Welding Procedure Specification (WPS) : JOINTS (QW-402)Документ4 страницыWelding Procedure Specification (WPS) : JOINTS (QW-402)Andhira FarizkiОценок пока нет

- Welding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Документ2 страницыWelding Procedure Specification (WPS) : Owner: (As Per QW 482 of ASME Section IX)Saravanan Palanisamy Lakshmi100% (1)

- Sample Editable WPSДокумент2 страницыSample Editable WPSsbmmlaОценок пока нет

- Welding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2Документ2 страницыWelding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2RahmadiОценок пока нет

- Identify The Following: Cien 3090 Construction Materials & Testing Midterm ExamДокумент1 страницаIdentify The Following: Cien 3090 Construction Materials & Testing Midterm Examacurvz2005Оценок пока нет

- Nanotech in ComputersДокумент7 страницNanotech in ComputersGopi SatyaОценок пока нет

- PT South East Asia Pipe Industries - Downloaded From Steelads ComДокумент10 страницPT South East Asia Pipe Industries - Downloaded From Steelads ComRizki TrisnasariОценок пока нет

- ParthsarthiДокумент423 страницыParthsarthiMahatab HasanОценок пока нет

- MPSP Mill - Simhadri1Документ18 страницMPSP Mill - Simhadri1santoshkumar777Оценок пока нет

- Paschen's LawДокумент6 страницPaschen's LawKhan YousafzaiОценок пока нет

- Catálogo Qualipoly PDFДокумент14 страницCatálogo Qualipoly PDFpekena_fer2059Оценок пока нет

- Usg Gypsum Board Arc Spec en 09260 092116Документ27 страницUsg Gypsum Board Arc Spec en 09260 092116mariutza_luciaОценок пока нет

- Sealfix Engl POI BДокумент4 страницыSealfix Engl POI BacarisimovicОценок пока нет

- OverpressureДокумент2 страницыOverpressureampowersidОценок пока нет

- Unit V Mass Transfer PDFДокумент11 страницUnit V Mass Transfer PDFArivazhagan SundaraganesanОценок пока нет

- Danfoss DML Filter DriersДокумент16 страницDanfoss DML Filter DrierswidhiantoОценок пока нет

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterДокумент1 страницаYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterHarish Kumar MahavarОценок пока нет

- Windsor Steampac WT Boiler Brochure 2019Документ2 страницыWindsor Steampac WT Boiler Brochure 2019AnthonyОценок пока нет

- UNF Vs BSFДокумент18 страницUNF Vs BSFJonathan GentОценок пока нет

- Case Study Story Line SVT May 23 Gema QuintanillaДокумент25 страницCase Study Story Line SVT May 23 Gema QuintanillaPearl NarangОценок пока нет

- Enercon-Experiment 1Документ10 страницEnercon-Experiment 1Aldrin QuiambaoОценок пока нет

- Acm UNIT 1Документ19 страницAcm UNIT 1Samreen KhanОценок пока нет

- 4 Ponchon Savarit MethodДокумент47 страниц4 Ponchon Savarit Methodivanlawms6745Оценок пока нет

- Schaeffler Kolloquium 2014 02 enДокумент9 страницSchaeffler Kolloquium 2014 02 enNazif MisnanОценок пока нет

- Elements - turbine-Turbo-TOC KaydonДокумент3 страницыElements - turbine-Turbo-TOC KaydonnguyenanhtuanbОценок пока нет