Академический Документы

Профессиональный Документы

Культура Документы

Pulley Lagging Combi Lagg

Загружено:

Jorge A Vilal0 оценок0% нашли этот документ полезным (0 голосов)

86 просмотров1 страницаweb

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документweb

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

86 просмотров1 страницаPulley Lagging Combi Lagg

Загружено:

Jorge A Vilalweb

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

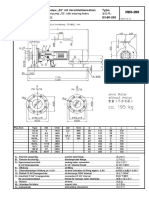

Combi-Lagg®

Ceramic Pulley Lagging Combi-Lagg®

For years Richwood has been developing the most Max Ceramic Available

Thickness Width Max PIW

innovative and durable pulley lagging products in the Length Type Compound

industry. The technological advances behind our 5/8” 19” 120” <1500 Dimpled SBR, MSHA

Combi-Lagg® Ceramic Lagging are the result of extensive 3/4” 19” 120” >1500 Dimpled SBR, MSHA

experience in solving the mining world’s most demanding 1” 12” 144” >2500 Dimpled SBR, MSHA

lagging applications.

Overall Tile Size 0.30” x 1” x 1”

Combi-Lagg® revolutionized the lagging industry with its Total Ceramic Surface Area 43.8%

embedded tile design. Our continued research, involving Raised Dimples Per Linear Foot 1300

Dimple Size Oval (0.0197” sq)

the mechanics of how and why ceramic lagging drives Friction Value .4 to .6 Depending on Application

a belt, has ensured that Combi-Lagg® Ceramic Lagging Factory Prepared Bonding Surface yes

outlasts and provides more grip than any other ceramic

lagging on the market. R2000LS SBR MSHA Grade (#IC-182/4)

Durometer 60+/-5 Shore A 60+/-5 Shore A

COMBI-LAGG ADVANTAGES:

Elongation 525% 500%

Higher Friction Values Easy Installation

Tensile Strength 3800 2000

Improved Belt Tracking Less Pulley Wear

Sheds Water and Dirt Minimize Downtime

The quality of the rubber and ceramic materials used in

our Combi-Lagg® Ceramic Lagging is what sets it apart.

Combi-Lagg® uses our R2000LS SBR premium rubber

compound which ensures that the ceramic tiles have

the maximum flexibility and support. Our proprietary tile

bonding chemistry also ensures that tile loss is eliminated.

All Richwood products are backed by our

3-year Manufacturer’s Warranty

(304) 525-5436 | (800) 237-6951

richwood.com

Вам также может понравиться

- Manual Grand CherokeeДокумент336 страницManual Grand CherokeeManuel Padilla Ramirez100% (1)

- SigmaprimeДокумент8 страницSigmaprimeHaresh BhavnaniОценок пока нет

- Essential Rubber Formulary: Formulas for PractitionersОт EverandEssential Rubber Formulary: Formulas for PractitionersРейтинг: 3 из 5 звезд3/5 (1)

- Rev1 Sew Gear MotorДокумент248 страницRev1 Sew Gear MotorWirote DewilaiОценок пока нет

- Rev1 Sew Gear MotorДокумент248 страницRev1 Sew Gear MotorWirote DewilaiОценок пока нет

- Armed Struggle in Africa (1969)Документ167 страницArmed Struggle in Africa (1969)Dr.VolandОценок пока нет

- HDPE Geomembrane - AlvatechДокумент10 страницHDPE Geomembrane - AlvatechshgsuhermanОценок пока нет

- Heavy Duty Pillow BlocksДокумент323 страницыHeavy Duty Pillow BlocksRafael JonathОценок пока нет

- A DETAILED LESSON PLAN IN TLE DraftingДокумент16 страницA DETAILED LESSON PLAN IN TLE DraftingJude PellerinОценок пока нет

- Cem-FIL GRC Technical DataДокумент91 страницаCem-FIL GRC Technical Datacbler100% (1)

- Sharp MX2310U Technical Handy ManualДокумент64 страницыSharp MX2310U Technical Handy ManualUserОценок пока нет

- Arcoplate TecnologiaPresentationДокумент75 страницArcoplate TecnologiaPresentationrinaldo KurniawanОценок пока нет

- The Judicial Affidavit RuleДокумент20 страницThe Judicial Affidavit RuleMhay ReyesОценок пока нет

- Data Science Machine LearningДокумент15 страницData Science Machine LearningmagrinraphaelОценок пока нет

- Manual SumitomoДокумент4 страницыManual SumitomoJorge A Vilal50% (2)

- GYPROCK 547 Residential - Installation - Guide 201111 PDFДокумент56 страницGYPROCK 547 Residential - Installation - Guide 201111 PDFduckeОценок пока нет

- Martillo Komac KB1500 Parts ManualДокумент12 страницMartillo Komac KB1500 Parts ManualJOHN FRADER ARRUBLA LOPEZ100% (1)

- TG Comply With WP Hygiene Proc 270812 PDFДокумент224 страницыTG Comply With WP Hygiene Proc 270812 PDFEmelita MendezОценок пока нет

- Pavement Construction PDFДокумент83 страницыPavement Construction PDFadhirajn4073100% (1)

- FRP GratingДокумент20 страницFRP Gratingmike maxwellОценок пока нет

- Dodge MagnaGear Speed Reducers Size G525, Size G700, Size G920Документ32 страницыDodge MagnaGear Speed Reducers Size G525, Size G700, Size G920Jorge A VilalОценок пока нет

- Bearing Housings and Components, CBCДокумент202 страницыBearing Housings and Components, CBCAnonymous opOWUIОценок пока нет

- Bearing Housings and Components, CBCДокумент202 страницыBearing Housings and Components, CBCAnonymous opOWUIОценок пока нет

- Self-Compacting Concrete: Prepared By. Gurpreet Singh ME (Structures)Документ17 страницSelf-Compacting Concrete: Prepared By. Gurpreet Singh ME (Structures)Binny SidhuОценок пока нет

- FALK 131-110 CatalogДокумент118 страницFALK 131-110 CatalogJorge A VilalОценок пока нет

- CarboDur Structural Strengthening SystemsДокумент4 страницыCarboDur Structural Strengthening Systemsmtor_scribdОценок пока нет

- SikaGrind For Vertical Roller Mills PDFДокумент8 страницSikaGrind For Vertical Roller Mills PDFEduardo RojasОценок пока нет

- Catalogo SewДокумент740 страницCatalogo SewAlejandro Tapia100% (1)

- FRP 1543494499564 - Grating Brochure - 2018Документ6 страницFRP 1543494499564 - Grating Brochure - 2018Ganesh KumarОценок пока нет

- ScreedMax Pro S30 TDS and MSDS PDFДокумент16 страницScreedMax Pro S30 TDS and MSDS PDFfuaunОценок пока нет

- Fabrication of Large GRP Storage TanksДокумент60 страницFabrication of Large GRP Storage TanksjoekaledaОценок пока нет

- REMAGRIP REMASLEEVE Pulley Laggings and Belt Idler SleevesДокумент16 страницREMAGRIP REMASLEEVE Pulley Laggings and Belt Idler SleevesBaihaki StОценок пока нет

- Viscochape DUBAI NOV 2019Документ58 страницViscochape DUBAI NOV 2019Christos LeptokaridisОценок пока нет

- Sika Grind SlagДокумент4 страницыSika Grind SlagMohamed AamerОценок пока нет

- Industrial Wear Protection Solution: ApplicationДокумент1 страницаIndustrial Wear Protection Solution: ApplicationMehmet TürkerОценок пока нет

- CR70C Gaskets PDFДокумент2 страницыCR70C Gaskets PDFipraoОценок пока нет

- Sika® Carbodur® Rods: Carbon Fiber Rods For Structural StrengtheningДокумент2 страницыSika® Carbodur® Rods: Carbon Fiber Rods For Structural StrengtheningGonzalo OviedoОценок пока нет

- Mirka Marinesolutions-Surfacefinishing Brochure en 01-2020 HighresДокумент20 страницMirka Marinesolutions-Surfacefinishing Brochure en 01-2020 HighresPatrick MeloОценок пока нет

- Sika Carbodur RodsДокумент3 страницыSika Carbodur RodsIndra KusumaОценок пока нет

- SikaFast 3000Документ4 страницыSikaFast 3000robox514Оценок пока нет

- Sika-Wrap Struct StrengthДокумент7 страницSika-Wrap Struct StrengthMiky CastenОценок пока нет

- Ceralag-01: Ceramic Lagging SheetingДокумент2 страницыCeralag-01: Ceramic Lagging SheetingARUN KUMAR DASОценок пока нет

- Reduce Your Casting Costs, and Improve Your Environment, Casting Productivity, and QualityДокумент8 страницReduce Your Casting Costs, and Improve Your Environment, Casting Productivity, and QualityAjay WanveОценок пока нет

- Sikawrap® Hex-230 C: Product Data SheetДокумент4 страницыSikawrap® Hex-230 C: Product Data SheetArindam SarkarОценок пока нет

- 04c - Asphalt Reinforcement (Sami Grid)Документ4 страницы04c - Asphalt Reinforcement (Sami Grid)Andhika PribadiОценок пока нет

- Flooring: Sikafloor®-3240 A Versatile Flooring ProductДокумент4 страницыFlooring: Sikafloor®-3240 A Versatile Flooring ProductGeorge EnescuОценок пока нет

- MA105 Bridgemaster Datasheet (Issue 9)Документ2 страницыMA105 Bridgemaster Datasheet (Issue 9)aОценок пока нет

- Rubber Disc: Features & BenefitsДокумент2 страницыRubber Disc: Features & BenefitsDiego AndradeОценок пока нет

- O E +Manufacturing+Pte+Ltd+T35+Promo+PDF PDFДокумент4 страницыO E +Manufacturing+Pte+Ltd+T35+Promo+PDF PDFJayaprakashОценок пока нет

- PPG PMC Sigmaprime Brochure A4 Feb2016 Glob en LRSPДокумент8 страницPPG PMC Sigmaprime Brochure A4 Feb2016 Glob en LRSPImam SitumeangОценок пока нет

- 50 Years Manufacturing ExcellenceДокумент6 страниц50 Years Manufacturing ExcellenceRaj hegdeОценок пока нет

- GRP Moulded Grating Specification GuideДокумент15 страницGRP Moulded Grating Specification GuideSubhadip RoyОценок пока нет

- SikaEmeriCreteTopping PdsДокумент2 страницыSikaEmeriCreteTopping Pdsfvtolosa2022a11Оценок пока нет

- 1ZSE 2750-117 enДокумент4 страницы1ZSE 2750-117 enThiagoPinheiroОценок пока нет

- Ceramic PPT 2Документ37 страницCeramic PPT 2Eduardo ampuero oviedoОценок пока нет

- Bedford Grating CatalogДокумент52 страницыBedford Grating Catalogartdanielz09Оценок пока нет

- Datasheet Dramix RC 6535 BNДокумент1 страницаDatasheet Dramix RC 6535 BNSahil GandhiОценок пока нет

- The Complete Façade Solution: Adhesives and Weather SealingДокумент24 страницыThe Complete Façade Solution: Adhesives and Weather Sealinga7mosОценок пока нет

- Anti Crak Brochure ScreenДокумент7 страницAnti Crak Brochure ScreenPablo Quinteros PizarroОценок пока нет

- Mechanical Seals PDFДокумент14 страницMechanical Seals PDFZeeshan SajidОценок пока нет

- GRP Web Technical ContentДокумент4 страницыGRP Web Technical ContentJai-Hong ChungОценок пока нет

- BluGeo GRP Ground SystemsДокумент22 страницыBluGeo GRP Ground SystemsaparsapaОценок пока нет

- Remalox HD 35 Optimum Impact and Wear ProtectionДокумент2 страницыRemalox HD 35 Optimum Impact and Wear ProtectionCamilo MesaRОценок пока нет

- Launch FRPДокумент6 страницLaunch FRPRana MahatoОценок пока нет

- Final Acrylic Brochure LRДокумент7 страницFinal Acrylic Brochure LRThuy NguyenОценок пока нет

- GripperSlings WEBДокумент8 страницGripperSlings WEBbman0051401Оценок пока нет

- Sikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningДокумент2 страницыSikawrap®-900 C: Carbon Fibre Fabric For Structural StrengtheningRoberto Jimenez PerezОценок пока нет

- Evergrip GRP Moulded Grating SpecificationДокумент15 страницEvergrip GRP Moulded Grating SpecificationTarun SharmaОценок пока нет

- Sales@specialistconstructionsupplies - Online Freephone: 0800 047 6775Документ21 страницаSales@specialistconstructionsupplies - Online Freephone: 0800 047 6775AlaaGaballaОценок пока нет

- Brick V AACДокумент1 страницаBrick V AACbopayyaОценок пока нет

- CorroCube™ CorroTile™ Corporate Brochure - RE0416C PDFДокумент6 страницCorroCube™ CorroTile™ Corporate Brochure - RE0416C PDFHKM IngenierosОценок пока нет

- Fibertrench - Rev - 1 1Документ2 страницыFibertrench - Rev - 1 1Nidhi Amit GoyalОценок пока нет

- Sikagrout® - 200 PDFДокумент2 страницыSikagrout® - 200 PDFMohamed SalahОценок пока нет

- Glass Fibre Reinforced ConcreteДокумент10 страницGlass Fibre Reinforced ConcreteHimanshu Sekhar PandaОценок пока нет

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965От EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Оценок пока нет

- Advances in Ceramic Armor XОт EverandAdvances in Ceramic Armor XJerry C. LaSalviaОценок пока нет

- Advances in Ceramic Armor XIОт EverandAdvances in Ceramic Armor XIJerry C. LaSalviaОценок пока нет

- MPTA B8i 2011 R2016 Final April 2018 PDFДокумент9 страницMPTA B8i 2011 R2016 Final April 2018 PDFJorge A VilalОценок пока нет

- MPTA B2c 2017 Sheave - Pulley Balancing Final April 2018 PDFДокумент9 страницMPTA B2c 2017 Sheave - Pulley Balancing Final April 2018 PDFJorge A VilalОценок пока нет

- Pulley Lagging Combi LaggДокумент1 страницаPulley Lagging Combi LaggJorge A VilalОценок пока нет

- Stuewe 201708 Catalogue Type-HydДокумент8 страницStuewe 201708 Catalogue Type-HydJorge A VilalОценок пока нет

- Stuewe 201708 Catalogue Type-HsdДокумент25 страницStuewe 201708 Catalogue Type-HsdJorge A VilalОценок пока нет

- Split Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard seals-FSNL 526 + C 2226 K + H 3126 L PDFДокумент2 страницыSplit Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard seals-FSNL 526 + C 2226 K + H 3126 L PDFJorge A VilalОценок пока нет

- Stuewe 201708 Catalogue Type-HydДокумент8 страницStuewe 201708 Catalogue Type-HydJorge A VilalОценок пока нет

- 118TS615 Single Row TS Bearing - American Roller BearingДокумент2 страницы118TS615 Single Row TS Bearing - American Roller BearingJorge A VilalОценок пока нет

- THD take-up housings for spherical roller bearings on an adapter sleeve and a plain shaftДокумент2 страницыTHD take-up housings for spherical roller bearings on an adapter sleeve and a plain shaftJorge A VilalОценок пока нет

- D SeriesДокумент20 страницD SeriesJorge A VilalОценок пока нет

- BSD 2562 CGA: Product DetailДокумент1 страницаBSD 2562 CGA: Product DetailJorge A VilalОценок пока нет

- NTN 5301eДокумент24 страницыNTN 5301eDhanielОценок пока нет

- M371 110 Falk Quadrive Shaft Mounted Gear Drive CatalogДокумент56 страницM371 110 Falk Quadrive Shaft Mounted Gear Drive CatalogJorge A VilalОценок пока нет

- Reodamientos Esfericos NSKSphericalWeb PDFДокумент28 страницReodamientos Esfericos NSKSphericalWeb PDFJorge A VilalОценок пока нет

- Manual de Operacion y Mantenimiento HSM-Shaft Manual (Ing) PDFДокумент16 страницManual de Operacion y Mantenimiento HSM-Shaft Manual (Ing) PDFJorge A VilalОценок пока нет

- Benzlers Reducotr Seriescmetric PDFДокумент124 страницыBenzlers Reducotr Seriescmetric PDFJorge A VilalОценок пока нет

- NHL - MNHL: Installation, Operation and Maintenance ManualДокумент20 страницNHL - MNHL: Installation, Operation and Maintenance ManualJorge A VilalОценок пока нет

- Andritz S3 MaatschetsenДокумент13 страницAndritz S3 MaatschetsenJorge A VilalОценок пока нет

- Manual de Operacion y Mantenimiento HSM-Shaft Manual (Ing) PDFДокумент16 страницManual de Operacion y Mantenimiento HSM-Shaft Manual (Ing) PDFJorge A VilalОценок пока нет

- Indian companies involved in trade dispute caseДокумент15 страницIndian companies involved in trade dispute caseakshay daymaОценок пока нет

- Fiber Optics Splicing Procedures: Your Source To Fiber Optics, Industrial Datacomm & Fieldbus Products-Solutions-ServicesДокумент7 страницFiber Optics Splicing Procedures: Your Source To Fiber Optics, Industrial Datacomm & Fieldbus Products-Solutions-ServicesHafis Aikal AmranОценок пока нет

- The Importance of Personal Protective Equipment in Pesticide App 2018Документ4 страницыThe Importance of Personal Protective Equipment in Pesticide App 2018Anees MalikОценок пока нет

- Costs-Concepts and ClassificationsДокумент12 страницCosts-Concepts and ClassificationsLune NoireОценок пока нет

- G C Reddy ProfileДокумент3 страницыG C Reddy ProfileG.C.ReddyОценок пока нет

- TT100 Viscometer: For Inline Systems ApplicationsДокумент2 страницыTT100 Viscometer: For Inline Systems ApplicationsPablo Antu Manque RodriguezОценок пока нет

- IPR GUIDE COVERS PATENTS, TRADEMARKS AND MOREДокумент22 страницыIPR GUIDE COVERS PATENTS, TRADEMARKS AND MOREShaheen TajОценок пока нет

- Project Proposal: Retail Environment Design To Create Brand ExperienceДокумент3 страницыProject Proposal: Retail Environment Design To Create Brand ExperienceMithin R KumarОценок пока нет

- What is Software Development Life Cycle (SDLC)? Key Phases and ActivitiesДокумент11 страницWhat is Software Development Life Cycle (SDLC)? Key Phases and ActivitiessachinОценок пока нет

- OTA710C User ManualДокумент32 страницыOTA710C User ManualEver Daniel Barreto Rojas100% (2)

- Cough: by Dr. Meghana Patil (Intern Batch 2016)Документ24 страницыCough: by Dr. Meghana Patil (Intern Batch 2016)Meghana PatilОценок пока нет

- Parents Day Script - PDF - Schools - LeisureДокумент17 страницParents Day Script - PDF - Schools - LeisureNAIDU SHAKEENAОценок пока нет

- English Speech Save Our Earth Save Our RainforestДокумент3 страницыEnglish Speech Save Our Earth Save Our RainforestYeremia Billy100% (1)

- QPMC Rate CardsДокумент9 страницQPMC Rate CardsTarek TarekОценок пока нет

- Patient Safety IngДокумент6 страницPatient Safety IngUlfani DewiОценок пока нет

- TT1 2lecture SpinningДокумент29 страницTT1 2lecture SpinninghaiОценок пока нет

- Chapter 4-Ohm's LawДокумент12 страницChapter 4-Ohm's LawErin LoveОценок пока нет

- Loctite 270™: Technical Data SheetДокумент4 страницыLoctite 270™: Technical Data SheetM Jobayer AzadОценок пока нет

- IEEE Registration StuffДокумент11 страницIEEE Registration StuffsegeluluОценок пока нет

- Guidelines For Planning Conjunctive Use of SUR Face and Ground Waters in Irrigation ProjectsДокумент34 страницыGuidelines For Planning Conjunctive Use of SUR Face and Ground Waters in Irrigation Projectshram_phdОценок пока нет

- Group 2 - Assignment 2 - A Case Study of Telecom SectorДокумент13 страницGroup 2 - Assignment 2 - A Case Study of Telecom Sectorfajarina ambarasariОценок пока нет

- Chapter-5-Entrepreneurial-Marketing Inoceno de Ocampo EvangelistaДокумент63 страницыChapter-5-Entrepreneurial-Marketing Inoceno de Ocampo EvangelistaMelgrey InocenoОценок пока нет

- 1 s2.0 S0313592622001369 MainДокумент14 страниц1 s2.0 S0313592622001369 MainNGOC VO LE THANHОценок пока нет