Академический Документы

Профессиональный Документы

Культура Документы

Detección de Fisuras Utilizando Radiografía Industrial en Alas de Avión

Загружено:

luisИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Detección de Fisuras Utilizando Radiografía Industrial en Alas de Avión

Загружено:

luisАвторское право:

Доступные форматы

DOI: 10.1784/insi.2011.53.10.

552 AEROSPACE RADIOGRAPHY

Crack detection using image processing techniques for

radiographic inspection of aircraft wing spar

Submitted 19.07.11

B Stephen Wong, Xin Wang, Chen Ming Koh, Chen Guan Tui, ChingSeong Tan and Jian Xu Accepted 19.09.11

Radiographic inspection is one of the most important developing films, it also allows images to be stored digitally. To

non-destructive inspection methods for aircraft wing spar fully utilise the benefits of digital radiography and further improve

inspection. Traditionally, radiographic inspection is time the inspection process, an automatic crack detection software is

and manpower consuming. In addition, human inspection required to aid inspectors to quickly recognise crack features from

of cracks and damage based on film radiography is very digital radiographs.

subjective, inconsistent and sometimes biased. To improve In our previous work[11], we identified suitable digital X-ray

the speed and efficiency of radiographic inspection, digital detectors to meet the high sensitivity required to inspect the aircraft

X-ray systems are gaining popularity over traditional wing. Different sensors were evaluated by using a set-up of a wire

film-based X-ray. Digital radiography has emerged as a IQI penetrameter, aluminium specimens with 6 mm thickness and

leading technology for aircraft inspection. Therefore, it is a 2T-hole penetrameter. We recommended amorphous silicon flat

desirable to develop a computer-aided system to assist in panels to be the most suitable detector for the aircraft inspection

the interpretation of digital radiographic images to increase applications. We also developed a crack detection algorithm using

the objectivity, accuracy and efficiency of radiographic region of interest (ROI) minimisation and improved Canny edge

interpretation. In this paper, a crack detection algorithm detection techniques for aircraft wing inspection[12]. However,

using region of interest (ROI) minimisation, thresholding the algorithm has limited accuracy when tested on aircraft wing

and edge detection techniques is developed for radiographic spar images that are noisy or cluttered with many features. In this

inspection of an aircraft wing spar. paper, an improved algorithm is developed for aircraft wing spar

radiographic inspection.

1. Introduction 2. Robot guided X-ray system for aircraft

The use of non-destructive testing (NDT) in the inspection wing inspection

of aircraft parts and components is crucial in determining the A robot guided digital X-ray imaging system, as shown in Figure

structural integrity of aircraft. Commonly used NDT methods 1, is developed for automatic aircraft wing inspection. The

in aerospace are visual inspection, liquid penetrant inspection, manipulator system automatically moves an X-ray tube and a

magnetic particle inspection, eddy current inspection, ultrasonic digital sensor along the wing of the aircraft. Digital radiographs are

inspection, radiographic inspection and leak testing[1]. Some taken as the system moves and the whole wing area can be built up

advanced NDT techniques such as acousto-ultrasonic techniques, gradually. The movement is programmed from a database drawing

ultrasonic phased array and magnetic sensors can also be applied in of the aircraft wing.

aircraft inspection[2-7].

Defects on the aircraft wing are usually non-visible. Traditional

radiography is one of the effective NDT techniques used for the

detection of cracks and damage in aircraft structures[8]. To improve

the speed and efficiency of radiographic inspection, digital X-ray

systems are gaining popularity over traditional film-based X-ray.

Digital radiography makes use of digital X-ray sensors to convert

the X-rays into visible images. Digital radiography has emerged

as a leading technology for aircraft crack inspection. It offers

many advantages over conventional film-based radiography[9,10].

Digital radiography can not only save the time spent on chemically

B Stephen Wong and Chen Ming Koh are with the School of Mechanical

and Aerospace Engineering, Nanyang Technological University (NTU),

Singapore.

Xin Wang* is with the Faculty of Engineering and Science, Universiti Tunku

Abdul Rahman (UTAR), Malaysia. Figure 1. Robot guided scanning manipulator

Chen Guan Tui is with the Republic of Singapore Air Force (RSAF), Figure 2 is the aircraft wing spar radiograph. In this radiograph,

Singapore. line cracks and fatigue cracks created on specimens are taken with

ChingSeong Tan is with the Multimedia University (MMU), Malaysia. a wing spar image, with the cracks circled in yellow. Even though

the cracks are visible to the human eye, it takes close and careful

Jian Xu is with the Singapore Institute of Manufacturing Technology observations to detect them. Moreover, there are numerous rivet

(SIMTech), Singapore.

holes in each radiograph and these areas are the high-risk regions

*Corresponding author. Email: wangx@utar.edu.my for fatigue cracks, which require more attention. Having numerous

552 Insight Vol 53 No 10 October 2011

Figure 2. Typical aircraft wing spar radiograph

rivet holes that inspectors are required to scrutinise closely puts

them under intense stress and hinders their efficiency. With a good

crack detection algorithm that focuses around the rivet holes,

inspectors will be able to make quick and accurate conclusions on

the aircraft wing spar radiographs.

3. Crack detection algorithm

Firstly, we tested the algorithm developed by Wang et al[12] using

some aircraft wing spar images. The presence of noise is either

mistaken as cracks, or drowns out the crack features from the

algorithm (Figure 3), thus some improvement is needed to increase

the accuracy of the algorithm. In addition to the algorithm, which

recognises cracks through grey-level gradients and the dimensions Figure 3. Detection results using Wang et al method

of the features detected, other parameters need to be considered to

make crack detection more accurate.

Suggested improvements include the removal of rivet holes

from the region of interest, as well as using thresholds instead of

edge detection to find rivet holes.

3.1 Improvement on region of interest (ROI) generation

As seen in the test on image No 2, as shown in Figure 3, there

is a wrong detection marked within the rivet holes. However, the

likeliness of a crack occurring on a rivet is very low, thus the need

to detect cracks within the rivet area is questionable. The edge of a

rivet hole is also sometimes mistaken as a crack, as seen from image

No 2. It is evident that the rivet itself is causing some problems

for the accuracy of detection. In the test on image No 4, the crack

detected in the ROI is grouped as a single object with the rivet

hole itself, thus being excluded after shape recognition processes.

This further compounds the problem of having the rivet hole’s area

included in the ROI as it clearly interferes with the crack.

To solve the problem of the rivet hole interfering with crack

recognition, the rivet hole is removed from the ROI, leaving only

the area around the rivet.

Figure 4 shows the ROI obtained when the new algorithm is Figure 4. (a) Binary image of holes in test image No 1; (b)

used on test image No 1. Figure 4(a) is the binary image of the expanded mask area; (c) slightly expanded mask area; (d) final

holes detected, Figure 4(b) is the enlarged masking area and Figure ROI

4(c) is the slightly increased masking area to cover the edges of

the holes. The final ROI is obtained by subtracting the result of image edge matrix. The result of this final operation on test image

the second from the first, and the result can be seen in Figure 4(d). No 1 is shown in Figure 5(a). Figure 5(b) shows the final crack

After obtaining the ROI, the edge information within the ROI is detected on test image No 1 when the new algorithm is included,

obtained using element-by-element multiplication with the full where all cracks are detected instead of four out of five previously.

Insight Vol 53 No 10 October 2011 553

crack from the specimen is not detected. The edge of the specimen

hole is, however, in the ROI of the true rivet hole, and is mistaken

as a crack. Image No 3 in Figure 3 is the same as image No 2 but

has a different implanted crack and therefore has a similar source

of error.

Figure 5. (a) Edges detected within new ROI of test image No 1;

(b) final detection with new algorithm

3.2 Hole detection by thresholding

In image No 1 of Figure 3, one of the cracks is not detected. On

closer inspection this is because the undetected crack is recognised

as a single object together with the hole. This results in the crack

being filtered out together with the hole as they did not have a shape

that resembled a crack. Figure 6 shows how the edge detected crack

and hole are joined as one entity.

Figure 8. Edge detected possible holes in test image No 2

In image No 4 of Figure 3, the algorithm fails entirely because

the rivet hole is not detected. Failure to detect rivet holes results in

the failure to set a ROI, thus nothing will be detected. The reason

for failing to detect rivet holes is the same as the reason specimen

holes could not be detected in image No 2 and No 3, and that is

because the edge detected rivet hole is not complete to form an

enclosed object.

The tests conducted on image No 2, No 3 and No 4 showed

that Wang’s algorithm has problems detecting rivet holes when

edge detection could not form an enclosed object on the holes. This

Figure 6. ROI of image No 1 in Figure 3 shows crack and hole means that even the slightest failure of edge detection in detecting

grouped as the same object

a small part of the hole will lead to the entire hole being neglected,

Figure 7 shows the result of image No 2 in Figure 3. There are thus missing any possible cracks around such holes.

four wrong detections which are marked by yellow circles, with The authors therefore propose an alternative method of detecting

three of them on the rivet hole and identifying the rivet as a crack. the rivet holes which is less punishing on imperfect accuracy, and

Another wrong detection marks the edge of a specimen hole as a that is by thresholding instead of by edge detection. Thresholding

crack. The white lines are IQI wires which were added and meant is the simplest method of image segmentation. From a greyscale

to simulate cracks, so their detection is considered acceptable. The image, thresholding can be used to create binary images[13]. In

dark coloured hole, which is the specimen hole, is not detected. image thresholding, a range of grey level is selected and only pixels

Figure 8 shows the possible hole features after edge detection. It that satisfy the grey levels are selected. Therefore, this method is

can be seen that the dark specimen hole is not fully detected by very useful in images where the relevant objects have a distinct

the Canny edge function. As a result, the hole is not an enclosed difference in grey levels to the background.

object and cannot be filled to form a masking area. As a result, a The new algorithm requires a threshold value to be explicitly

defined first, 110 for the case shown. If the rivet holes are bright

pixels, they will be selected by picking pixels in the original image

that are more than the threshold. If the hole pixels are dark, then

they will be selected by calling for pixels less than the threshold.

The rest of the algorithm is similar to Wang’s algorithm, which

performs recognition of the rivet holes by their area and eccentricity.

Figure 9(a) shows the effect of using thresholding to find rivet

holes in test image No 4. The holes can be found, but together with

some IQI wires that are meant to simulate cracks. The algorithm is

able to make detections in the end, as shown in Figure 9(b).

The flow chart of the new algorithm is shown in Figure 10 and

the detection results using the new algorithm are shown in Figure 11.

4. Experimental results

The new algorithm was tested on eight images, as shown in Figure

12.

Table 1 shows the detection results using the original algorithm.

Out of a total of 18 cracks in the tested images, 14 cracks were

detected with four wrong detections. Table 2 shows the detection

results using the new algorithm. In general, the new algorithm

is able to detect slightly more cracks with no wrong detections.

Figure 7. Detected cracks in image No 2 Out of a total of 18 cracks in the tested images, 16 cracks were

554 Insight Vol 53 No 10 October 2011

Figure 9. (a) Result of thresholding on test image No 4; (b) final

detection on test image No 4 with new algorithm

Figure 11. Detection results using new algorithm

Table 2. Results of image test with new algorithms incorporated

Image Number of Correctly Non- Cracks Minimum

No cracks detected cracks detected detectable

cracks detected as non- crack length

Figure 10. Flow chart of new algorithm as cracks cracks (pixels)

1 1 1 0 0 25

detected without a wrong detection. The new algorithm improves 2 2 2 0 0 11

the accuracy of aircraft wing spar inspection. 88.9% of cracks

are detected using the new algorithm, while 77.8% of cracks are 3 4 4 0 0 8

detected using the old algorithm. 4 1 1 0 0 28

Table 1. Results of image test using original algorithm 5 5 5 0 0 22

6 2 1 0 1 25

Image Number Correctly Non- Cracks Minimum

No of cracks detected cracks detected detectable 7 2 1 0 1 21

cracks detected as non- crack length 8 1 1 0 0 18

as cracks cracks (pixels)

Total 18 16 0 2

1 1 1 0 0 25

2 2 2 0 0 11

3 4 4 0 0 8

5. Conclusion

4 1 1 0 0 28 The development of automated crack detection software has a

huge importance in improving the efficiency and accuracy of

5 5 4 0 1 22

radiographic inspection. Currently, the developed algorithm

6 2 1 4 1 25 can perform well in the localised images tested. However, good

7 2 1 0 1 21 performance of current algorithm requires manual tweaking of

8 1 0 0 1 NA certain parameters, thus it still lacks complete automation. The

crack detection software is a function of the radiographs and cracks

Total 18 14 4 4 it would encounter. The recommendations for future developments

Insight Vol 53 No 10 October 2011 555

also depend hugely on the accuracy of maintaining conditions in

X-ray shoots. Therefore, further developments will be dependent

greatly on changes in the quality of digital radiographs, as well as

a good number of wing radiographs with cracks present to base

future development on.

Acknowledgements

The authors gratefully acknowledge the support from Nanyang

Technological University, Republic of Singapore Air Force and

Singapore Technology Aerospace.

References

1. R Prasad and N S L Ganesh, ‘Defect analysis in aerospace

systems using non-destructive testing’, Proc National

Seminar on Non-Destructive Evaluation, Hyderabad,

December 2006.

2. N Guo and P Cawley, ‘Lamb wave propagation in composite

laminates and its relationship with acousto-ultrsonics’,

NDT&E International, 26 (2), pp 75-84, 1993.

3. L P Scudder, D A Hutchins and N Guo, ‘Laser-generated

ultrasonic guided wave in fibre-reinforced plates – theory and

experiment’, IEEE Transactions on Ultrasonics, Ferroelectrics

and Frequency Control, 43 (5), pp 870-880, 1996.

4. D J Roth, R P Tokars, R E Martin, R W Rauser, J C Aldrin and

E J Schumacher, ‘Ultrasonic phased array inspection

simulations of welded components at NASA’, Materials

Evaluation, Vol 67, No 1, January 2009.

5. S Mahaut, S Chatillon, E Kerbrat, J Porré, P Calmon and

O Roy, ‘New features for phased array techniques inspections:

simulation and experiments’, 16th World Conference on Non-

Destructive Testing, Montréal, 2004.

6. B Lebrun, Y Jayet and J C Baboux, ‘Pulsed eddy current

application to the detection of deep cracks’, Materials

Evaluation, Vol 53, No 11, pp 1296-1300, 1995.

7. W F Avrin, ‘Eddy current measurements with magnetoresistive

sensors: third-layer flaw detection in a wingsplice structure

25 mm thick’, Proceedings of SPIE, Vol 3994, pp 29-36,

2000.

8. R D Bowman, B A Bennett and M E Stevenson, ‘Radiographic

inspection in failure investigations’, Journal of Failure Analysis

and Prevention, 3 (3), pp 73-77, 2003.

9. R Halmshaw, Industrial Radiology: Theory and Practice,

Second Edition, Chapman and Hall, UK, 1995.

10. U Ewert, U Zscherpel and K Bavendiek, ‘Replacement of film

radiography by digital techniques and enhancement of image

quality’, Online NDT Journal, Vol 12, No 6, 2007.

11. X Wang, B Stephen Wong, C G Tui, K P Khoo and F Foo,

‘Real-time radiographic non-destructive inspection for aircraft

maintenance’, 17th World Conference on Non-Destructive

Testing, Shanghai, China, 25-28 October 2008.

12. X Wang, B S Wong, C S Tan and C G Tui, ‘Automated crack

detection for digital radiography aircraft wing skin inspection’,

Research in Nondestructive Evaluation, pp 105-127, 2011.

13. L G Shapiro and G C Stockman, Computer Vision, Prentice

Figure 12. Test new algorithm Hall, 2002.

556 Insight Vol 53 No 10 October 2011

Вам также может понравиться

- Automatic X-Ray Crack Inspection For Aircraft Wing Fastener HolesДокумент8 страницAutomatic X-Ray Crack Inspection For Aircraft Wing Fastener HolesRamakrishnan AmbiSubbiahОценок пока нет

- Aerospace NDT With Advanced Laser Shearography - 534Документ6 страницAerospace NDT With Advanced Laser Shearography - 534hardrock99Оценок пока нет

- Drone Detection Through Live Camera Using YOLOv3Документ8 страницDrone Detection Through Live Camera Using YOLOv3Ayapilla Sri hari PranavОценок пока нет

- Aerospace Applications of Radiographic Testing: HapterДокумент26 страницAerospace Applications of Radiographic Testing: HapterErick OlavarriaОценок пока нет

- IR Seeker Simulator and IR Scene Generation To Evaluate IR Decoy EffectivenessДокумент12 страницIR Seeker Simulator and IR Scene Generation To Evaluate IR Decoy EffectivenessAhmed HamoudaОценок пока нет

- Phasor XS Flange Face PaperДокумент32 страницыPhasor XS Flange Face PapervrapciudorianОценок пока нет

- Application Notes: Nondestructive Bond Testing For Aircraft CompositesДокумент5 страницApplication Notes: Nondestructive Bond Testing For Aircraft CompositesPDDELUCAОценок пока нет

- YOLO and Mask R-CNN For Vehicle Number Plate IdentificationДокумент10 страницYOLO and Mask R-CNN For Vehicle Number Plate IdentificationIJRASETPublicationsОценок пока нет

- Detecting Defects On Curved EdgesДокумент8 страницDetecting Defects On Curved Edgesmike mikeОценок пока нет

- Aise 28 Aise200026Документ10 страницAise 28 Aise200026bd25qvn6c5Оценок пока нет

- Manikandan 2007Документ5 страницManikandan 2007Aryan SinghОценок пока нет

- Automation in Construction: Mathieu Lepot, Nikola Stani Ć, François H.L.R. ClemensДокумент11 страницAutomation in Construction: Mathieu Lepot, Nikola Stani Ć, François H.L.R. ClemenssulastriОценок пока нет

- Nondestructive Bond Testing For Aircraft Composites-OlympusДокумент6 страницNondestructive Bond Testing For Aircraft Composites-OlympusAhmad DanielОценок пока нет

- Cui 2021Документ8 страницCui 2021mvssrajuОценок пока нет

- Robotics Assistance in Aircraft InspectorДокумент22 страницыRobotics Assistance in Aircraft InspectorUmesh KokaneОценок пока нет

- IEEE Conf 2018 TrackNet - A - Deep - Learning - Based - Fault - Detection - For - Railway - Track - InspectionДокумент5 страницIEEE Conf 2018 TrackNet - A - Deep - Learning - Based - Fault - Detection - For - Railway - Track - InspectionkaruldeepaОценок пока нет

- An Aircraft Detection Framework Based On ReinforceДокумент19 страницAn Aircraft Detection Framework Based On ReinforceTheanmozhi SОценок пока нет

- Anomaly Detection For Industrial Surface Inspection Application in Maintenance of Aircraft ComponentsДокумент6 страницAnomaly Detection For Industrial Surface Inspection Application in Maintenance of Aircraft Components이재헌 서울 대학원 융합기계공학과 장학조교Оценок пока нет

- Weld Defect Detection in Industrial Radiography Based On Image SegmentationДокумент7 страницWeld Defect Detection in Industrial Radiography Based On Image Segmentationivan brittoОценок пока нет

- 7edc PDFДокумент10 страниц7edc PDFAnkush RatnaparkheОценок пока нет

- Automated Detection of Welding Defects in Pipelines From 2017 NDT E InternДокумент7 страницAutomated Detection of Welding Defects in Pipelines From 2017 NDT E InternAndres CasteloОценок пока нет

- Vision-Based Unmanned Aerial Vehicle Detection and Tracking For Sense and Avoid SystemsДокумент6 страницVision-Based Unmanned Aerial Vehicle Detection and Tracking For Sense and Avoid SystemsKaran ShettyОценок пока нет

- Crack FetectionДокумент12 страницCrack FetectionSurya Patria CraneОценок пока нет

- Nguyen Lee2014 Article Laser Vision BasedQualityInspeДокумент9 страницNguyen Lee2014 Article Laser Vision BasedQualityInspeShadi AtriОценок пока нет

- Identitas JurnalДокумент15 страницIdentitas JurnalihsanОценок пока нет

- DroneДокумент102 страницыDronePrashanth RajannaОценок пока нет

- Jahanshahi 2011 - Adaptive Vision-Based Crack DetectionДокумент10 страницJahanshahi 2011 - Adaptive Vision-Based Crack DetectionAntonОценок пока нет

- Sensors: A Multi-Step CNN-Based Estimation of Aircraft Landing Gear AnglesДокумент17 страницSensors: A Multi-Step CNN-Based Estimation of Aircraft Landing Gear AnglesKrasakKrusuk Si MaulОценок пока нет

- The Assessment Method For Multi-Azimuth and Multi-Frequency Dynamic Integrated Stealth Performance of AircraftДокумент27 страницThe Assessment Method For Multi-Azimuth and Multi-Frequency Dynamic Integrated Stealth Performance of AircraftMichael MarciniakОценок пока нет

- Automatic Crack Detection and Measurement Based On Image AnaДокумент8 страницAutomatic Crack Detection and Measurement Based On Image Anab3d.dharoharОценок пока нет

- Finger Print Matching Based On Miniature and Phog Feature ExtractionДокумент5 страницFinger Print Matching Based On Miniature and Phog Feature ExtractionIJRASETPublicationsОценок пока нет

- Defect Inspection in Tire Radiographic Image Using Concise Semantic SegmentationДокумент14 страницDefect Inspection in Tire Radiographic Image Using Concise Semantic Segmentationsudhir kumarОценок пока нет

- Automated New License Plate Recognition in EgyptДокумент8 страницAutomated New License Plate Recognition in EgyptAhmed GalalОценок пока нет

- Ultrasonic Sampling Phased Array Testing As A Replacement For X-Ray Testing of Weld Joints in Ship ConstructionДокумент4 страницыUltrasonic Sampling Phased Array Testing As A Replacement For X-Ray Testing of Weld Joints in Ship ConstructionRiza KhanОценок пока нет

- Line Scratch Detection and Removal in Films: Aditya P. Mukkawar, Swati D. Gaikwad, Asst Prof. Prajakta DeshmaneДокумент4 страницыLine Scratch Detection and Removal in Films: Aditya P. Mukkawar, Swati D. Gaikwad, Asst Prof. Prajakta DeshmaneerpublicationОценок пока нет

- Fasteners in The Aerospace Industry: Automated Systems in Fastener TechnologyДокумент14 страницFasteners in The Aerospace Industry: Automated Systems in Fastener Technologyudaykumar8995Оценок пока нет

- An Automated Method For Computer Vision Analysis of Cannon-Launched Artillery VideoДокумент12 страницAn Automated Method For Computer Vision Analysis of Cannon-Launched Artillery VideoyararaОценок пока нет

- Building Crack Detection Using Deep Learning TechniquesДокумент11 страницBuilding Crack Detection Using Deep Learning TechniquesIJRASETPublicationsОценок пока нет

- Detecting Gear Surface Defects Using Background-WeДокумент13 страницDetecting Gear Surface Defects Using Background-Weshubham d lakheОценок пока нет

- Detecting Gear Surface Defects Using Background-Weakening Method and Convolutional Neural NetworkДокумент14 страницDetecting Gear Surface Defects Using Background-Weakening Method and Convolutional Neural NetworkMayur KolpeОценок пока нет

- Onboard Detection and Localization of Drones Using Depth MapsДокумент11 страницOnboard Detection and Localization of Drones Using Depth MapskumamennaОценок пока нет

- PDF - Object Detection and Person Tracking Using UavДокумент11 страницPDF - Object Detection and Person Tracking Using UavVj KumarОценок пока нет

- Detection of Corrosion Damage in AircraftДокумент17 страницDetection of Corrosion Damage in AircraftLibin LalОценок пока нет

- Aplicaciones MilitaresДокумент4 страницыAplicaciones MilitaresMabel NúñezОценок пока нет

- An Automated Radiographic NDT System For Weld Inspection - Part I - Weld Extraction PDFДокумент6 страницAn Automated Radiographic NDT System For Weld Inspection - Part I - Weld Extraction PDFaliОценок пока нет

- Rotation-Invariant Infrared Aerial Target Identification Based On SRCДокумент9 страницRotation-Invariant Infrared Aerial Target Identification Based On SRCapplebao1022Оценок пока нет

- ABECIS: An Automated Building Exterior Crack Inspection System Using UAVs, Open-Source Deep Learning and PhotogrammetryДокумент8 страницABECIS: An Automated Building Exterior Crack Inspection System Using UAVs, Open-Source Deep Learning and PhotogrammetryPaing Thet KoОценок пока нет

- Review 3 ReportДокумент17 страницReview 3 ReportSadanala KarthikОценок пока нет

- RESEARCHДокумент5 страницRESEARCHPRAYUSHI KHANDELWALОценок пока нет

- DissertationДокумент120 страницDissertationEmpresaSTIОценок пока нет

- Free As A Bird Event-Based Dynamic Sense-And-Avoid For Ornithopter Robot FlightДокумент8 страницFree As A Bird Event-Based Dynamic Sense-And-Avoid For Ornithopter Robot FlightNisha KamarajОценок пока нет

- ICCRE2021 Drone Tracking With Shadow and Reflection RemovalДокумент7 страницICCRE2021 Drone Tracking With Shadow and Reflection Removaljzhong_7Оценок пока нет

- Obstacle Detection and Collision Avoidance For A UAV With Complementary Low-Cost SensorsДокумент11 страницObstacle Detection and Collision Avoidance For A UAV With Complementary Low-Cost SensorssreekuttymsОценок пока нет

- (A9) Outdoor Autonomous Landing On A Moving Platform For Quadrotors Using An Omnidirecional Camera PDFДокумент10 страниц(A9) Outdoor Autonomous Landing On A Moving Platform For Quadrotors Using An Omnidirecional Camera PDFGiovanni GozziniОценок пока нет

- Image Processing For Radiographic Films of Weld InspectionДокумент7 страницImage Processing For Radiographic Films of Weld InspectionMahmoud AbdullahОценок пока нет

- NDT Phased Array Ultrasonic TestingДокумент54 страницыNDT Phased Array Ultrasonic TestingDeepak100% (2)

- Ultrasonics Corrosion PittingДокумент11 страницUltrasonics Corrosion PittingAsyraf NordinОценок пока нет

- Research Article: Defect Detection in Tire X-Ray Images Using Weighted Texture DissimilarityДокумент13 страницResearch Article: Defect Detection in Tire X-Ray Images Using Weighted Texture DissimilarityChistiMonuОценок пока нет

- Industrial X-Ray Computed TomographyОт EverandIndustrial X-Ray Computed TomographySimone CarmignatoОценок пока нет

- DSE4610 DSE4620 Operators ManualДокумент86 страницDSE4610 DSE4620 Operators ManualJorge Carrasco100% (6)

- Exercise On Coordination and ResponseДокумент8 страницExercise On Coordination and ResponseNorliyana AliОценок пока нет

- UX-driven Heuristics For Every Designer: OutlineДокумент7 страницUX-driven Heuristics For Every Designer: OutlinemuhammadsabirinhadisОценок пока нет

- PA SystemДокумент4 страницыPA SystemSnehal DambhareОценок пока нет

- Monorail Hoist SystemДокумент17 страницMonorail Hoist SystemypatelsОценок пока нет

- TOS 1st QuarterДокумент6 страницTOS 1st QuarterQuerisa Ingrid MortelОценок пока нет

- SalivaДокумент42 страницыSalivaAtharva KambleОценок пока нет

- RenewalPremium 1123186Документ1 страницаRenewalPremium 1123186Suhas Renu85Оценок пока нет

- Department of Education: Republic of The PhilippinesДокумент6 страницDepartment of Education: Republic of The PhilippinesLalaine QuitoОценок пока нет

- SolutionsManual NewДокумент123 страницыSolutionsManual NewManoj SinghОценок пока нет

- Test Report For Feeder Protection RelayДокумент3 страницыTest Report For Feeder Protection RelayHari haranОценок пока нет

- Report Liquid Detergent BreezeДокумент12 страницReport Liquid Detergent BreezeDhiyyah Mardhiyyah100% (1)

- ECE3073 P4 Bus Interfacing Answers PDFДокумент3 страницыECE3073 P4 Bus Interfacing Answers PDFkewancamОценок пока нет

- DEP 33641012 Electrical Supply and Generation - Design and OperationДокумент51 страницаDEP 33641012 Electrical Supply and Generation - Design and Operationpeter wiltjerОценок пока нет

- Creating A Pathway For Every Student: Holyoke High School Redesign Strategic PlanДокумент29 страницCreating A Pathway For Every Student: Holyoke High School Redesign Strategic PlanMike PlaisanceОценок пока нет

- BronchiolitisДокумент5 страницBronchiolitisreshianeОценок пока нет

- Ponce vs. Court of AppealsДокумент7 страницPonce vs. Court of AppealsMp CasОценок пока нет

- ExamДокумент12 страницExamAidar MukushevОценок пока нет

- Downloaded From Manuals Search EngineДокумент14 страницDownloaded From Manuals Search EngineAl AlОценок пока нет

- Fulltext PDFДокумент454 страницыFulltext PDFVirmantas JuoceviciusОценок пока нет

- LoratadinaДокумент3 страницыLoratadinapapaindoОценок пока нет

- AAR Safety Fact SheetДокумент2 страницыAAR Safety Fact Sheetrogelio mezaОценок пока нет

- D2 1 PDFДокумент148 страницD2 1 PDFsubas khanalОценок пока нет

- GSM Sniffing - Telegraph+Документ9 страницGSM Sniffing - Telegraph+Sridhar PОценок пока нет

- How To Install Mesa (OpenGL) On Linux Mint - 6 StepsДокумент2 страницыHow To Install Mesa (OpenGL) On Linux Mint - 6 Stepsankitfrnd45Оценок пока нет

- NPN Silicon: Semiconductor Technical DataДокумент8 страницNPN Silicon: Semiconductor Technical DataMinh Hà QuangОценок пока нет

- Electricity MagnetismДокумент19 страницElectricity MagnetismGray Amiel VilarОценок пока нет

- Serie10 ElecДокумент75 страницSerie10 Elecmealier severineОценок пока нет

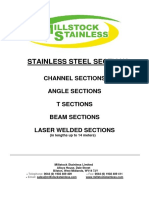

- Steel Sections PDFДокумент36 страницSteel Sections PDFTonderai RusereОценок пока нет