Академический Документы

Профессиональный Документы

Культура Документы

Hi

Загружено:

sachinsaklani23Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hi

Загружено:

sachinsaklani23Авторское право:

Доступные форматы

04/30/18 DESIGN NO.

_____

SECTION 11401

FOOD SERVICE EQUIPMENT FOR WARMING PANTRY

[Note to Specifier (delete) - This section is intended for all

UPK and 3K Center projects including new building as they

typically only have a warming pantry. Use Section 11400 for all

other projects]

PART 1 - GENERAL

1.01 DESCRIPTION OF WORK

A. Provide all Kitchen/Warming Pantry Work indicated on

the Drawings, specified herein and needed for a

complete and proper installation including, but not

limited to the following:

1. All required and specified equipment delivered to

job site, uncrated, assembled and set in proper

area, ready for final connections.

2. All the necessary drilling, punching and cutting

of walls, floors, slabs, and equipment for all

mechanical and electrical connections.

3. After all equipment is installed and tested, clean

thoroughly and polish same.

B. Smallwares (pans, covers, trays, racks etc.) are to be

supplied with certain pieces of equipment. These

items shall be listed on the Smallwares Schedule and

included as part of the Contract.

C. All products/appliances that use potable water for

human consumption must be certified as “lead free” as

defined in the Reduction of Lead in Drinking Water Act

of 2011 (not more than a weighted average of .25%

lead). Regardless of model numbers indicated herein,

provide equivalent models that are “lead free” as

defined in the act. All solder and flux used during

installation of piping associated with the potable

water system designed for human consumption must also

meet the lead-free requirements of the act

1.02 RELATED WORK

A. Provide the following related work specified elsewhere:

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 1

04/30/18 DESIGN NO._____

1. Electrical service and connections to equipment,

overload protection, wiring between starters when

starters and controls are not integral with the

equipment. Deliver the following items to the

Electrical Subcontractor for installation and

connection to power wiring: Receptacles.

2. Plumbing work and connections, including fittings

which are not an integral part of the equipment,

except as otherwise specified in this Section.

Plumbing trim shall be delivered to Plumbing

Subcontractor for installation and connection to

piping.

3. Wall supports or blocking required for mounting of

wall hung equipment.

4. Concrete, masonry, floor slab depressions and

miscellaneous metals, except as otherwise

specified in this Section.

5. Acid wash and seal the quarry tile floor in

accordance to Section 09310: Ceramic Tile prior to

the installation of any of the equipment.

B. Related Sections include the following:

1. Division 3 Section Cast-in-Place Concrete for the

following: equipment bases, requirements for slab

depressions, etc.

2. Division 9 Section Ceramic Tile for washing and

sealing the quarry tile floor finishes.

3. Division 15 Sections for supply and exhaust fans;

exhaust ductwork; service roughing-ins; drain

traps; atmospheric vents; valves, pipes, and

fittings; and other materials required to complete

kitchen equipment installation including final

connections.

4. Division 16 Sections wiring, disconnect switches,

and other electrical materials required to

complete kitchen equipment installation including

final connections.

1.03 REFERENCES

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 2

04/30/18 DESIGN NO._____

A. New York City Construction Codes, latest edition and

Rules and Regulations of NYC Department of Buildings.

1.04 SUBMITTALS

A. Refer to Division 1 for the submittals general

requirements. The following paragraphs supplement the

requirements of Division 1.

B. Product Data

1. Submit Drawings showing the arrangement of the

equipment, mechanical and electrical services

required and consisting of the following:

Note: Reproduction or enlargement of Contract

Drawings is not acceptable.

a. Drawings showing layout with item numbers

keyed to the Equipment Schedule, service

roughing-in details, accurate dimensions, all

utility connections, drains, depressions,

exhaust openings and partitions, produced in

1/4"=1'-0" scale if CAD drawn, 1/2"=1'-0"

scale if hand drawn. Dimensions shall be

taken from finished walls and columns and

shall include all electrical and plumbing

floor "stub-up", "out of wall" and "branch to

connection (BTC)" notations for use in the

field. Dimensions shall include height of

all connections above finished floor.

b. Schedule of Equipment and Connections: A

schedule similar to that shown on the

Contract Drawings indicating Item Number,

Quantity, Description, Rough-In Data, MEA

Number and Remarks or Approved Agency

Certification listed and/or label.

c. Wiring Diagrams: Details of wiring for power,

signal, and control systems and differentiate

between manufacturer-installed and field-

installed wiring.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 3

04/30/18 DESIGN NO._____

d. Piping Diagrams: Details of piping systems

and differentiate between manufacturer-

installed and field-installed piping.

2. Submit bound and covered booklets containing

manufacturers' standard specification sheets and

installation instructions for each item, all as a

package. Partial submission will not be accepted.

The specification sheets shall include catalog

cut, size, details as to the construction, utility

service connections for water, drainage and power,

include roughing-in dimensions and an illustration

or photograph. A corresponding cover sheet shall

precede each specification sheet. Each cover

sheet shall include the item description, item

number keyed to the plans, manufacturer's name and

model number(s), required utility loads,

connection sizes, options, accessories and

components.

Cover sheets for custom fabricated equipment shall

include the item description, item number keyed to

the plans, required utility loads, connection

sizes, options, accessories and components.

C. Shop Drawings

1. Typical details for all fabricated equipment shall

include fully detailed plans, elevations,

sections, roughing-in dimensions, fabrication

details, all (utility, etc.) service requirements,

and attachments to other work and shall be drawn

in 3/4"=1'-0" scale. Isometric details of Custom

Fabricated Equipment will not be acceptable unless

they are similar to ones already found on the

Drawings.

D. Coordination Drawings

1. Indicate locations of equipment and connections to

utilities. Key equipment using same designations

as indicated on Contract Drawings. Include plans

and elevations; details of support for equipment,

details of concrete and/or masonry bases, details

of floor depressions etc., and utility service

characteristics. Indicate field measurements on

Coordination Drawings.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 4

04/30/18 DESIGN NO._____

2. Coordination Drawing Scale: 1/4”=1’-0”.

E. Submit, for approval, any color or finish proposed to

be used, except where the color or finish is

specifically detailed in the Specifications and/or

Drawings.

F. Certifications

1. Certification and listing by an Approved

Agency in accordance with NYC Dept. of Buildings

rules, indicating that the materials and

assemblies as regulated by the NYC Building Code

are acceptable for the intended use. When test

methods are stipulated in the NYC Building Code,

the tests utilized shall be stated in the

Certification. Prior MEA approvals are acceptable

for materials and assemblies conforming to current

Code requirements.

2. Provide manufacturer’s certification that all

appliances that use potable water for human

consumption (such as the coffee maker, ice makers)

provided meet the requirements of the Reduction of

Lead in Drinking Water Act effective Jan 4, 2014.

G. Operation and Maintenance Data: For kitchen equipment

to include in emergency and normal operation,

maintenance manuals: Four (4) complete printed copies

shall be furnished to the Authority. Submit the

manufacturer written warranty with the maintenance

manual. This information shall be submitted in the

following manner for initial review:

1. A covered bound booklet containing Manufacturer's

current printed Installation/Operation/Maintenance

/Warranty/Emergency/Parts manuals including spare

part lists (include all accessories, components,

faucets, etc.). Each manual shall be clearly

labeled with their respective item number

designation as specified.

2. Booklet shall include a Table of Contents listing

each equipment item included within the booklet,

complete with corresponding item number keyed to

the Equipment Schedule, quantity, description

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 5

04/30/18 DESIGN NO._____

(product data, shop drawing) wiring diagram, and

serial numbers.

Booklet shall also include a list of factory

authorized service agencies including their

addresses and telephone numbers. This listing

shall include the local factory authorized service

agency for all equipment included within the

booklet, whom the Authority and/or New York City

Department of Education Office of School Food (OSF)

may call for service during the guarantee period.

Such service shall include parts, labor, traveling

time and other expenses. Such services shall not

be at the expense of the Authority. Coordinate

with Division 1 Section on guarantees, warranties,

bonds and maintenance contracts.

H. Submit a detailed inventory of all Smallwares provided

by the Kitchen Equipment Subcontractor.

I. Submit, for approval, any color or finish proposed to

be used, except where the color or finish is

specifically detailed in the Specifications and/or

Drawings.

J. The General Contractor and Kitchen Equipment

Subcontractor shall provide each a schedule of testing

and coordinate reporting of the results.

1.05 QUALITY ASSURANCE

A. Manufacturer Qualifications: Firms engaged in

manufacture of food service equipment of types,

capacities, and sizes specified, whose products have

been in satisfactory service not less than 5 years.

B. Installer Qualifications: Kitchen Equipment

Subcontractor with at least five (5) years

installation experience with projects of a scope and

size similar to that required for this Project.

C. Codes and Standards: comply with the following:

1. American Society of Testing and Materials (ASTM).

2. National Electrical Manufacturers Association

(NEMA).

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 6

04/30/18 DESIGN NO._____

3. National Associations of Food Equipment

Manufacturers (NAFEM).

4. Underwriters Laboratories, Inc. (UL):

a. UL Certification: Provide electric equipment

and components that are evaluated by UL for

fire, electric shock, and casualty hazards

according to applicable safety standards and

that are UL certified for compliance and

labeled for intended use.

b. UL Labels: on electrical components and

assemblies, provide either UL labeled

products or, where no labeling service is

available, “recognized markings” to indicate

listing in the UL “recognized component

index”.

5. International Mechanical Code (IMC).

6. National Sanitation Foundation (NSF) Standards:

Provide equipment that bears NSF Certification

Mark or UL Classification Mark certifying

compliance with applicable NSF/ANSI standards.

7. ANSI Standards: For electric powered appliances

and for plumbing fittings including vacuum

breakers and air gaps.

8. NFPA Codes:

NFPA 70- National Electrical Code.

9. Health Code: in accordance with NYC Health

Department applicable regulations and all New York

State Safety and Health Laws.

10. ASHRAE Compliance: mechanical refrigeration systems

complying with the American Society of Heating,

Refrigerating and Air-Conditioning Engineers ASHRAE

15: Safety Code for Mechanical Refrigeration.

11. SMACNA Standard: Fabricate food service equipment

to comply with the Sheet Metal and Air Conditioning

Contractors National Association's (SMACNA)

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 7

04/30/18 DESIGN NO._____

"Kitchen Equipment Fabrication Guidelines," unless

otherwise indicated.

12. All the Federal, New York City and State Codes and

Regulations.

13. All equipment, accessories, and methods of

installation shall be in accordance with OSHA

(Occupational Safety and Health Administration)

requirements.

14. Reduction of Lead in Drinking Water Act: Beginning

on January 4, 2014, a federal law known as

“Reduction of Lead in Drinking Water Act” took

effect. This law requires that products must

conform to” lead free” criteria level whenever

products are employed for delivery of potable

water for human consumption.

a. The law makes it unlawful for any person,

including a contractor, to introduce into

commerce any pipe, pipe fitting, plumbing

fixture, faucet that is not lead free.

1) “Lead free” content is intended to mean

not more than 0.2% lead when applied in

connection to solder and flux and not

more than 0.25 percent of the weighted

average of lead when used with respect

to the wetted surfaces of pipes, pipe

fittings, plumbing fixtures and faucets.

2) The section of the federal act that

applies to solder and flux, 0.2% lead

content, went into effect back in August

of 1998; and for the most part soldering

product being sold in today’s market

complies with the law.

3) The requirement for .25% weighted

average of lead when applied to the

wetted surfaces of pipes, pipe fittings,

plumbing fixtures and faucet is the new

section of the law that requires special

attention from a contractor.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 8

04/30/18 DESIGN NO._____

b. To ensure compliance with “Reduction of Lead

in Drinking Water Act”, a procedure for

determining lead content was developed. The

calculation procedure works as follows:

1) “For each wetted component, the

percentage of lead in the component

shall be multiplied by the ratio of the

wetted surface area of that component to

the total wetted surface area of the

entire product to arrive at the weighted

percentage of lead of the component. The

weighted percentage of lead of each

wetted component shall be added

together, and the sum of these weighted

percentages shall constitute the

weighted average lead content of the

product. The lead content of the

material used to produce wetted

components shall be used to determine

compliance with paragraph (1)(B)

[Paragraph 1B Describes 0.25%

Requirement For 0.25 % Lead Content]”

2) As an alternative to implementing the

lead content calculation, the contractor

may choose to demonstrate compliance

with the act by requiring from

manufacturer documentation certifying

that products are lead free based on

either calculation or tests or third

party certification.

15. Balance of codes and standards shall be as set

forth elsewhere in these overall technical

Specifications.

D. Refrigeration System (s) shall utilize refrigerants only

approved by the Federal Government EPA (Clean Air Act

Amendments of 1990) and the Montreal Protocol. All

refrigerant shall be environmental friendly (CFC and

HCFC free). For systems containing 0.5 lbs or more of

refrigerant only HFC refrigerants are acceptable.

1.06 DELIVERY, STORAGE, AND HANDLING

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 9

04/30/18 DESIGN NO._____

A. Deliver food service equipment as factory-assembled

units with protective crating and covering.

B. Store food service equipment in original containers,

and in location to provide adequate protection while

not interfering with other construction operations.

C. Handle food service equipment carefully to avoid damage

to components, enclosures, and finish. Do not install

damaged food service equipment; replace and return

damaged components to equipment manufacturer.

1.07 REQUIREMENTS AND RESTRICTIONS

A. Electrical

1. Provide electrical plugs and cords. Electrical

shall make all the connections to all the outlets.

2. Provide all motors with thermal overload

protection and magnetic starters with reset

buttons. Provide disconnect switches and all

other items and accessories.

3. Verify all services relative to electrical current

availability. Notify immediately the respective

trade of any changes in location of utility

connections.

4. All electrical connections and raceways on

equipment in wet areas shall be waterproof liquid-

type flexible conduit.

5. Lighting fixtures integral with equipment shall be

fitted with approved shatter shields.

6. In case of surface mounted switches, waterproof

hubs shall be used.

7. Electrically heated equipment shall be internally

wired with fire-retardant insulated wire to a

thermostatic control, on-off switch, and a red

neon light indicator in a terminal box with

removal access panel.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 10

04/30/18 DESIGN NO._____

8. Where rigid steel conduit is provided, it shall be

zinc-coated where unexposed, and chrome-plated

where exposed.

9. Provide Ground Fault Circuit Interrupter (GFCI)

receptacles. All receptacles shall be as

specified and provided with stainless steel

faceplate.

B. Plumbing

1. Exposed plumbing, piping, fittings and valves

shall be chrome plated. Provide copper or brass

where not exposed. Provide threaded fittings (no

slip joints).

2. Provide vacuum breakers where required by

governing regulations, including but not limited

to locations where water outlets are equipped for

hose attachment and all other required items and

accessories.

C. All drawers, cabinets, and doors shall be equipped with

locks, keyed alike unless otherwise directed.

D. Review the electrical, plumbing, and ventilating

Drawings to determine the proper electrical, plumbing

and ventilating characteristics of the equipment

specified. If a product other than that specified in

the Equipment Schedule is submitted for approval,

include electric power, plumbing and ventilating

requirement data. Where proposed equipment exceeds

the power requirement of the specified equipment, pay

any additional cost due to necessary increase in

branch circuit and feeder sizes, circuit breaker

sizes, etc., provided under Electrical Work. Pay also

any additional cost due to necessary changes to the

mechanical work (Plumbing and HVAC).

E. Basis-of-Design Product: The design for the food

service equipment is based on the product listed on

the Equipment Schedule. Drawings indicate sizes,

profiles, dimensions, and other characteristics that

are based on the product specified on the Equipment

Schedule. Subject to compliance with requirements,

provide either the named product or a comparable

product by the other manufacturer models specified.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 11

04/30/18 DESIGN NO._____

Where proposed equipment differs from the listed

equipment, Kitchen Equipment Subcontractor shall pay

all the additional cost necessary to make the changes

with regard to sizes, locations, utilities and all

other required details. Deviations shall be

substituted for approval provided basic requirements

are met and no major rearrangement of service to the

equipment is required to affect the proposed

alteration. These deviations shall be made without

expense to and approved by the Authority.

F. Verify dimensions of equipment installation areas by

field measurements before ordering equipment and shop

fabrication of items. Verify actual dimensions of

construction contiguous with foodservice equipment by

field measurements before fabrication. Indicate field

measurements on Shop and Coordination Drawings.

Coordinate to ensure that actual dimensions correspond

to established dimensions. Assume complete

responsibility for accuracy.

G. All equipment shall be provided with brass or non-

ferrous plates or tags. Tags or plates content: model

and serial numbers. Minimum letter and numeral sizes

shall be 1/4” high. Locate equipment tags or plates

where accessible and visible. The location of the tags

or plates shall be included in the submittal.

1.08 COORDINATION

A. Coordinate equipment layout and installation with other

work, including lighting fixtures and mechanical

equipment.

B. Coordinate location and requirements of utility service

connections.

C. Coordinate size, location, and requirements of the

following: Overhead equipment supports; equipment

bases; floor depressions; insulated floors; floor areas

with positive slopes to drains; floor sinks and drains

serving foodservice equipment; duct and equipment

supports, and penetrations and all other items and

accessories.

1.09 QUALITY CONTROL

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 12

04/30/18 DESIGN NO._____

A. It is the intention of the Project Architect that the

equipment provided herein shall harmonize in color and

finish even though provided by various manufacturers.

Colors and finishes will be selected by the Project

Architect.

1.10 WARRANTY/GUARANTEE

A. All equipment other than the following listed in this

Article shall be guaranteed for a period of one year

from the date of substantial completion

B. Epoxy Coated Dunnage Racks and Wire Shelving: Ten years

minimum warranty against rust and corrosion from the

date of substantial completion.

C. If, at any time within this warranty period, any

equipment that is found to be faulty due to poor

workmanship, inferior or defective materials, replace

said pieces or correct each defective part at no cost

to the Authority and/or the NYC Department of

Education.

PART 2 - PRODUCTS

2.01 LIST OF EQUIPMENT

1. Sink

a. Pot Sink (2 compartments)

3. Sink Agitator - Washer

4. Shelving & Dunnage

a. Wire Shelving (Storage Room)

b. Dunnage Racks - Steel Wire (Dry Area)

5. Tables

a. Work/prep Tables

6. High Pressure Spray Cleaner Power Washer (Hose Reel)

7. Milk Chest

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 13

04/30/18 DESIGN NO._____

8. Mobile Pan Rack

9. Hot Cabinet, Electrically Heated, Mobile

10. Smallwares

a. Stainless Steel Pans

b. Stainless Steel Pans Covers

c. Stainless Steel Perforated Pans

d. Sheet Pans 18" x 26"

11. Miscellaneous Equipment

a. Corner Guards

12. Paper Towel Dispenser next to hand sink.

13. Utility carts

2.02 MATERIALS

A. Metals

1. Stainless-Steel: ASTM A240, type as indicated

(Type 304 or 316). Finishes: concealed surfaces:

No. 2; exposed surfaces: No. 3 or 4

2. Carbon-Steel: ASTM A1008, cold-rolled sheets;

commercial quality; with oiled, exposed matte or

powder-coat painted finish.

3. Galvanized Steel: ASTM A653, G90 coating

designation; commercial-quality, cold-rolled steel

that is zinc coated by the hot-dip process and

chemically treated.

4. Zinc-Coated Steel Shapes: ASTM A36, zinc coated

according to ASTM A123.

5. Steel Structural Members: Hot rolled or cold

formed, carbon steel unless stainless steel is

indicated.

6. Galvanized finish: ASTM A123 hot dipped zinc

coating.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 14

04/30/18 DESIGN NO._____

7. Aluminum: ASTM B209/B221 sheet, plate and

extrusion alloy, temper and finish as determined

by manufacturer, except 0.40 mil natural anodized

finish on exposed work unless another finish is

specified.

B. Elastomeric Joint Sealant: ASTM C920; silicone or

urethane. Type S (single component), Grade NS

(nonsag), Class 25, Use NT (nontraffic) related to

exposure, and Use M, G, A, or O as applicable to joint

substrates indicated.

1. Public Health and Safety Requirements:

a. Sealant is certified for compliance with NSF

standards for end-use application indicated.

b. Washed and cured sealant complies with the

FDA's regulations for use in areas that come

in contact with food.

2. Cylindrical Sealant Backing: ASTM C1330, Type C,

closed-cell polyethylene, in diameter larger than

joint width.

C. Gaskets: NSF certified for end-use application

indicated; of resilient rubber, neoprene, or PVC that is

nontoxic, stable, odorless, nonabsorbent, and unaffected

by exposure to foods and cleaning compounds and passes

testing according to UL 710.

2.03 FABRICATION

A. Acoustical Isolation

1. Sound deaden underside of metal work surfaces,

including sinks, work tops, tables, drainboards,

back counter and similar units with a coating of a

NSF approved sound deadening material with an

aluminum finish. Sound deadening shall be applied

to fixtures after tops have been completely

fabricated.

2. Hold coating back 3" from sanitary edges which are

open for cleaning.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 15

04/30/18 DESIGN NO._____

B. Structural Framing: minimum 1" pipe size or tube

members, with mitered and welded joints and gusset

plates ground smooth or 1½" x 1½" x 1/8" thick stainless

steel angles for exposed framing and 1½" x 1½" x 1/8"

thick galvanized steel angle for concealed framing.

1. Provide 14 gauge stainless steel for exposed

framing and galvanized steel for concealed

framing.

C. Enclosures General

1. Provide enclosures including panels housing and

skirt for service lines, mechanical and electrical

devices and secondary enclosures for equipment

items where indicated and where required for

compliance with governing regulations and NSF

Standards. Otherwise, fabricate and/or manufacture

each item to be as open as possible for ease of

cleaning.

2. Where equipment is exposed to view, provide

enclosure for service lines, operating components,

and mechanical and electrical devices.

3. Enclosure joints shall be sealed to prevent vermin

infestation.

D. Cap exposed fastener threads, including those inside

cabinets, with stainless-steel lock washers and

stainless-steel nuts.

E. Remove burrs from sheared edges of metal work, ease the

corners and smooth to eliminate cutting hazard.

F. Welding shall be done with rod of same material and

full penetration in the entire length of the joint.

Welds shall be flat without buckles, voids or

imperfections. All welds shall be ground flush with

adjacent surfaces, conditioned to eliminate dangerous

surfaces. All shear cuts or bends that tend to open

the surface of the metal shall be rewelded, ground and

polished. All edges are to be ground and filed to

eliminate sharp or rough edges.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 16

04/30/18 DESIGN NO._____

G. Edges and Backsplashes: Provide equipment edges and

backsplashes indicated complying with referenced

SMACNA standard, unless otherwise indicated.

H. Legs: 15/8” O.D. #16 gauge type 304 stainless steel

tubing. Legs shall be fitted at top with fully

enclosed stainless steel sanitary gussets welded to

underside of tables, to reinforcing channels, and/or

underside of sinks and at bottom with stainless steel

adjustable flanges or bullet feet. Refer to the

Drawings Details. The number of legs to be provided

shall be four (4) for table length less than 72" and

six (6) for table length ranging from 72" to 120".

I. Feet shall be stainless steel adjustable bullet or

flanged fully enclosed tightly fitting the leg.

Provide 1" up and down adjustment from the central

position without exposing any threads. Adjustments are

to be easily made by hand without the use of tools.

Where flanged feet are specified, provide stainless

steel flanged feet, which can be securely fastened to

floor with stainless steel bolts. Where mobile

equipments are specified, provide caster instead of

feet.

J. Casters shall be heavy duty, ball bearing, swivel type

with non-marking rubber tread; 5" diameter wheel;

polyurethane tires unless otherwise specified. Provide

casters with locking type brakes when casters with

brakes are specified. Unless equipment item is

equipped with another form of all-around protective

bumper, provide circular rotating bumper above each

caster.

K. Wall-Mounted Shelves: 12" wide, 16-gauge stainless

steel, solid or louvered. All corners shall be coved,

welded, ground smooth and polished. Louvered or

Slotted: 2” x 8” slots with rounded ends, spaced 4” on

center Refer to the Drawings Details. The working

surface of the bottom overshelf shall be 54" above the

finished floor unless otherwise shown on the Drawings.

1. Secure each bracket to wall with stainless steel

bolts anchored securely by means of toggle devices

or expansion shields, whichever is best suited to

wall construction. Maximum wall bracket spacing

shall be 48" between brackets.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 17

04/30/18 DESIGN NO._____

2. Shelves shall be set 3" away from wall and be

bolted to brackets with countersunk stainless

steel bolts, lockwashers and C.P. brass cap nuts.

3. Enclose ends of shelves full width of shelf

bottom, fully welded, ground and polished.

L. Sinks

1. Fabrication: 14-gauge stainless steel fully welded

one-piece construction, sound deadened; double

wall partitions between compartments with radius

rounded tops that are welded integral with sink

body. Front and ends shall be extended 3",

measured at sink edge and rolled on a diameter of

1½", 180o. All bottom corners shall be fully coved

and sloped to assure drainage to the waste outlet.

2. Wastes: 2" chrome plated cast brass or bronze,

twist or rotary-handle waste assembly with

stainless-steel strainer plate and chrome plated

brass connected overflow; overflow fitting: 1¼"

stainless steel strainer on the sink interior at

the rear and connected to the waste outlet.

3. Drainboards welded integrally to sink to form one-

piece construction; same material and finish as

sink; pitched to sink.

Drainboards Underbracing: 1" x 4" x 1" channels of

14 gauge stainless steel. Bracing shall be welded

to the underside of fixtures in a manner suitable

to seal out vermin and also to create a noise

deadening top surface. All channels shall extend

the full length and depth of fixtures and shall be

so positioned that no dimension exceeds 30" in any

direction.

4. Legs: 15/8" OD, 16-gauge stainless steel with

stainless-steel gusset and adjustable bullet feet.

Worktables with sinks, pot sinks and preparation

sinks shall be provided with flanged feet anchored

to the floor.

5. Back Splash: Sinks and drain boards adjacent to

walls or adjoining equipment shall have 10" high

splashbacks, level and continuous, not following

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 18

04/30/18 DESIGN NO._____

the pitch of drain boards. Openings for hot and

cold faucets shall be cut into the splashback.

6. Cross Bracing: 1¼" OD, minimum 16-ga stainless

steel.

7. Sinks set into counter or table tops shall be

constructed of same gauge and material as

specified for counter top as follows:

a. Top perimeter of each sink shall be

integrally welded to edge of opening in table

or counter top. Table or counter top shall

be die-punched to receive faucets.

b. Sinks shall have vertical and horizontal

corners rounded on a 1" radius, with bottoms

pitched to a 2" waste outlet. Sinks shall be

finished the same as table or counter tops.

8. Water inlets shall be located in all instances

above the positive water level to prevent

siphoning of liquids into the water system.

9. Faucets: Polished chrome plated cast brass body 8”

c/c adjustable faucet with swing spout or nozzle,

separate lever type hot and cold water handles

indexed to indicate type of water it will supply;

as manufactured by T&S Brass and Bronze Works,

Inc; Zurn Industries, Inc., Commercial Brass

Operation; Fisher Manufacturing Company or

Component Hardware Group, Inc (CHG)

M. Stainless Steel Table: Fabricate with reinforced tops,

legs, and reinforced undershelves or cross bracing.

Refer to the Drawings Details.

1. Top shall be constructed of 14-gauge, type 304

stainless steel. All tops shall be inverted “V”

marine edge or box marine edge on all exposed

sides. Where tables are placed against building

walls and abutted with equipment over 34" high,

they shall be turned up in back 6", returned 1"

diagonally with all exposed ends welded closed.

Corners shall be rounded or "bull-nose". Top

shall be reinforced 1½" x 1½" x 1/8" galvanized

iron angle framework reinforcing, full perimeter

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 19

04/30/18 DESIGN NO._____

of underside of top, with cross angles every 30"

or less and sound deadened. Reinforcing shall be

secured to the underside of the top with stud

welds, lockwashers, and speed nuts in a vermin-

proof manner. Underbracing shall be provided and

shall be 1" x 4" x 1" channels of 14 gauge

stainless steel. Bracing shall be welded to the

underside of fixtures in a manner suitable to seal

out vermin and also to create a noise deadening top

surface. All channels shall extend the full length

and depth of fixtures and shall be so positioned

that no dimension exceeds 30" in any direction.

2. Legs: 15/8" OD, 16 gauge stainless steel tubing

welded into fully enclosed stainless steel

sanitary gussets with stainless steel adjustable

bullet or flanged feet.

3. Undershelves: 16-gauge stainless steel welded to

legs 10" off finished floor.

4. Cross Bracing: 1¼" OD, minimum 16-ga stainless

steel.

N. Sink Drain Tray: To fit within sink opening; perforated

with 3/8" holes at 2" o.c.; and with turned down edges

and two recessed handles. Refer to the Drawing Detail.

O. Corner Guards: Protective vertical corner guards on all

wall ends, corners and columns. Corner guards shall be

constructed of #16 gauge polished stainless steel with

rounded corner edges. Refer to the Drawings Details.

Secure to wall and seal all exposed edges to walls,

columns, etc. with an approved silicone sealant.

2.04 HANDLES, BRACKETS, LOCKING DEVICES AND HARDWARE

A. Wherever equipment is provided with handles, knobs,

hinges, brackets, or other miscellaneous hardware, all

shall be either satin finish chrome plated or stainless

steel. All pull handles shall be of the full-grip

type.

B. All sliding and hinged doors in cabinets shall be

provided with extra heavy-duty security type locking

devices of cylinder type, chrome plated.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 20

04/30/18 DESIGN NO._____

C. All stainless steel hinged doors shall be provided with

stainless steel lift-off type hinges and adjustable

tension type catches. Each shall be fully mortised

into doors and corresponding mullions to create a

flush, clean appearance.

2.05 SHOP PAINT AND COATING

A. Provide the types of painting and coating materials

which after drying or curing are suitable for use in

conjunction with food service, and which are durable,

non-toxic, not dusting, non-flaking, mildew resistant

and comply with Government Regulations for food

service.

B. Primer Coating for Metal: Type suitable for baking.

C. Enamel for Metal: Synthetic type suitable for baking.

D. Galvanized iron shall be cleaned, degreased, and coated

with 2 coats as specified in Section 09900: Painting,

with paint material suitable for intended use.

Adequate drying period shall be allowed between

application of first and second coat.

2.06 SHOP JOINTS

A. Shop joints shall be butt welded with joints ground

smooth, presenting a uniform one-piece construction.

Butt joints made by spot welding or riveting straps

under seams filled with solder and then ground will

not be acceptable

PART 3 - EXECUTION

3.01 INSPECTION

A. Prior to all work, examine all areas prepared by others

to receive Work of this Section. Notify other trades

of unsatisfactory locations and dimensions of their

work, and of unsatisfactory conditions for proper

installation of the Food Service Equipment.

B. Do not proceed with fabrication and installation until

unsatisfactory dimensions and conditions have been

corrected.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 21

04/30/18 DESIGN NO._____

3.02 GENERAL

A. Silver paint and/or silver silicone shall not be used

to hide burns or imperfections.

B. Solder shall not be used to fill in pits or crevices in

stainless steel or to fill in the corners of same.

C. Finished Ends and Backs: Equipment, fixtures, splashes,

shelves, and all other items and accessories shall

have finished closed ends and backs of the same

material and finish when exposed to view. Finished

backs shall be made removable with concealed

fastenings when enclosing area contains electrical or

mechanical services or any other maintenance or repair

requirements.

D. General Contractor shall leave openings for the entry

of all equipment including unusually large size that

would not normally pass through finished openings or

door bucks and close the openings thereafter.

3.03 INSTALLATION

A. The installation and erection shall be performed under

the supervision of the Kitchen Equipment Subcontractor

and Manufacturer in strict accordance with the

specifications, manufacturer's written instructions,

and all the Drawings.

B. Do not set food service equipment in place until after

Quarry Tile floor has been acid washed and sealed.

C. Complete equipment assembly where field assembly is

required.

1. Provide closed butt and contact joints that do not

require filler.

2. Grind field welds on stainless-steel equipment

smooth, and polish to match adjacent finish.

D. Install equipment with access and maintenance

clearances that comply with manufacturer's written

installation instructions and requirements of

authorities having jurisdiction.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 22

04/30/18 DESIGN NO._____

E. Cover and protect the exposed surfaces of all the

equipment in a manner that shall preclude injury to

the finish by absorption of oil, grease, chemicals,

etc., contact from tools and machinery, and from all

other causes which may be incidental to operations

performed in the area.

F. Install joint sealant in joints between equipment and

abutting surfaces with continuous joint backing,

unless otherwise indicated. Produce airtight,

watertight, vermin-proof, sanitary joints.

1. Where stainless steel equipment abuts other

stainless steel equipment, silver silicone may be

used.

2. If joints exceed a 3/8" gap but not more than 3",

Provide stainless steel trim strips to seal and

then apply silicone.

G. All methods of installing, mounting and securing

equipment provided hereunder shall comply with

applicable NSF standards.

H. Fixtures intended to be 3" or more away from wall shall

not be trimmed or sealed.

I. Repair adjacent surfaces damaged by improper

installation to the satisfaction of the Authority.

J. Set each item of nonmobile and nonportable equipment

securely in place, level and adjust to correct height.

Anchor to supporting structure where indicated and

where required for sustained operation and use without

shifting or dislocation. Conceal anchorages where

possible. Adjust counter tops and other work surfaces

to level tolerance of 1/16" maximum offset, and

maximum variation from level or indicated slope of

1/16" per foot. Where indicated, or required for

safety of equipment operator, anchor equipment to

floor or wall. Where equipment is indicated to be

anchored to floor, provide legs with S/S adjustable

bullet or flanged feet as specified.

Flanged feet shall be anchored to the floor using

stainless steel bolts and anchors bolts or anchors.

Predrill floor for installation of bolts or anchors.

Waterproofing of the floor shall be maintained.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 23

04/30/18 DESIGN NO._____

K. Cut-Outs: Provide cut-outs in food service equipment

where required to run plumbing, electric or gas lines

through equipment for final connections. All such

penetrations shall be fitted with rubber grommets to

protect these service lines.

L. Install all equipment level and plumb, according to

manufacturer's written instructions and requirements

of authorities having jurisdiction. The installation

location must allow adequate clearances for servicing

and proper operation.

M. All wall mounted fixtures and ceiling penetrations must

be sealed to tile wall and metal panel unit with an

approved silicone sealant.

N. Liquid soap and Single-fold paper towel dispensers must

be installed above all hand sinks (Kitchen Lavatories)

to meet DOH code.

O. General Contractor, Mechanical Subcontractor, Plumbing

Subcontractor and Electrical Subcontractor to insure

all equipment runs above finished ceiling do not

interfere with any ceiling hung equipment specified

and shown on the Drawings.

P. Provide a continuous coved bead of clear silicone

caulking to seal joints of all fixed equipment setting

directly against wall surfaces, such as, at

backsplashes on work tables, pot sinks, and all other

items and accessories.

3.04 PENETRATIONS

A. Where utility lines and all other items and accessories

pass through slabs or fire rated walls, the openings

or sleeves through which these lines pass shall be

sealed in an approved manner with an approved Fire

Safety Material.

B. The sealing of such openings shall be made using self

expanding fire retardant foam sealant as specified in

Section 07270: Firestopping.

C. Utility Penetration: Each trade to provide penetration

to accommodate their respective work. Provide sleeves

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 24

04/30/18 DESIGN NO._____

and stainless steel escutcheon plates for each trade

to dress off utility penetrations. Each trade shall be

responsible for cutting the hole, provide the sleeve

and sealing of respective penetrations. Penetrations

should be fire stopped when passing through fire rated

construction.

3.05 ASSISTANCE AND INSPECTION

A. Provide assistance to the various trades in locating

sleeves and conduits through which the utility lines

are to be drawn and make necessary field inspections

to check the location of sleeves and conduits and

other conditions affecting the Food Service Equipment

relative to the space on which each piece of equipment

is to be located or its utility connections.

B. Field inspections for this purpose shall be made before

finished floors are laid in order to make any

necessary relocation of utility sleeves or conduits.

3.06 FIELD QUALITY CONTROL AND TESTING

A. Do not start-up the Food Service Equipment until

service lines have been tested, balanced, and adjusted

for pressure, voltage, and all other items,

accessories and considerations; and until water lines

have been cleaned and treated for sanitation. Before

testing, lubricate each equipment in accordance with

manufacturer's recommendations. Test each item of

operational equipment to demonstrate that it is

operating properly, and that controls and safety

devices are functioning.

Before demonstration of the equipment to the operating

personnel, test through authorized service agencies,

all mechanical and electrical equipment provided

hereunder for operating efficiency and for conformance

to all requirements herein specified.

Repair or replace equipment which is found to be

defective including units which are below capacity or

operating with excessive noise or vibration.

B. Equipment shall be tested under operating conditions;

where possible, all safety devices shall be tested

under simulated emergency conditions.

C. Such testing shall include, but not be limited to:

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 25

04/30/18 DESIGN NO._____

1. All valves, regulators, gauges, safety devices and

sensors.

2. Calibration of all thermostats, thermometers, heat

switches and temperature sensing controls.

3. All heating devices for hot spots and heating

patterns.

D. Provide necessary technicians, materials, and equipment

required to conduct these tests.

E. Remove malfunctioning units, replace with new units,

and retest as required and specified above.

3.07 DEMONSTRATING AND OPERATING INSTRUCTIONS

A. After all equipment has been tested and found to be in

perfect working order, and before final acceptance of

the installation, demonstrate and instruct the

operating personnel in the use and maintenance of all

equipment provided.

B. Provide services of, and manufacturer's technical

representative where required, to instruct the

designated personnel of the Authority and NYC

Department of Education, Office of School Food (OSF)

in operation and maintenance of Food Service

Equipment. Schedule training with indicated

personnel, provide at least 10 days notice to the

Authority of training date.

As a part of the operating instructions, review data in

the operating and maintenance manuals, including

maintenance, emergency and cleaning procedures, and

procedures for obtaining technical assistance.

Demonstrate all phases of operation including start-up

and shutdown of all the equipment.

3.08 CLEANING AND PROTECTING

A. When all the work by this Contract, together with the

work of other trades has been completed, clean each

and every item of equipment so that all traces of

grease, stains, protective coatings, abrasive dusts,

markings, scratches, and other foreign matter are

completely removed. The cleaning process shall be one

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 26

04/30/18 DESIGN NO._____

which shall eliminate any further cleaning on the part

of the Authority with the exception of that which

would ordinarily be undertaken daily to maintain

accepted standards of sanitation and appearance.

B. At the end of each work day, remove all debris, empty

cartons, crates, and all other items and accessories,

from the work areas to a location on the premises

designated by the Authority for that purpose, and

leave work areas clean and orderly, ready for the

following day's work.

C. After completing installation of equipment, repair

damaged finishes. Clean and adjust equipment as

required to produce ready-for-use condition. Protect

equipment from damage during remainder of the

construction period.

3.09 SPECIAL NOTES

A. Equipment listed under "Schedule of Kitchen Equipment"

shall match in every respect all mechanical and

electrical requirements indicated on the Drawings.

B. Dimensions given herein are approximate only, and in

all cases where equipment is intended to occupy fixed

locations and spaces, the physical conditions of the

building are to control the absolute sizes.

PART 4 - EQUIPMENT

4.01 GENERAL

A. The basis-of-design for the food service equipment is

based on the product listed on the Equipment Schedule.

Any proposed substitution from the basis-of-design

shall meet specified requirements in each and every

respect and shall be by a manufacturer and product

listed herein.

B. The approval of a product substitution that is not

listed herein shall be in accordance with the

following:

1. Submit requests for substitution in accordance

with Section G01630 - Product Substitutions.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 27

04/30/18 DESIGN NO._____

2. If the technical data is determined to meet the

requirements of the specifications, it is required

that the below listed pieces of equipment that can

be delivered and plugged in undergo a 90-day test

period at a school selected by the NYC Department

of Education, Office of School Food (OSF).

a. The following items require such a test

period: Wire Shelving, Dunnage Racks, High

Pressure Power Washer, Milk Chest, Mobile Pan

Rack, Mobile Pot Rack, Mobile Heated Cabinet,

Smallwares and all other items and

accessories that do not necessitate any labor

except delivery and installation at the

designated area.

b. At the test facility, the proposed vendor is

responsible for the following services:

Delivery and uncrating of proposed item,

removal, crating and protected storage of

existing item, setting in place and leveling

of proposed item, removal of proposed item at

end of test period, reinstallation of

original item at completion of project, and

all other expenses. Such services shall be at

no cost to the Authority and/or NYC

Department of Education, Office of School

Food (OSF).

3. No Equipment shall be installed at the Project

Site until completion of the testing period and

approval of such by the Authority. The decision

for approval or rejection of a product option or

substitution shall rest solely with the Authority

and the NYC Department of Education, Office of

School Food (OSF). The other types of Equipment

not listed above to undergo the test period will

be evaluated on a case-by-case basis within the

sole discretion of the Authority.

4.02 SINKS

C. Pot Sink (2 Compartment Sink)

1. Length, height, width, overshelf and drainboards

shall be indicated on the Equipment Schedule;

location shown on the Drawings. Compartments

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 28

04/30/18 DESIGN NO._____

shall not be less than 27" long x 20" wide.

Compartments shall not be more than 12" deep. Sink

shall comply with general requirements of the

Fabrication Article. Refer to the Drawings

Details.

2. The wash and rinse compartment may be manifolded

to one (1) floor sink.

3. First Compartment (27" long x 20" wide x 12" deep)

shall be equipped with a sink agitator.

4. Plumbing Trim: two (2) 2" indirect wastes to be

piped to floor sink and one (1) swivel spout

faucet.

4.03 SINK AGITATOR - WASHER

A. Sink Agitator-Washing: Commercial fabrication heavy-

duty Hydro-Surge Washer designed for easy installation

into the side of the 27” compartment (wash/soak) 12"

depth pot sink where shown on the Drawings Details.

All bearing shall be permanently sealed. Unit shall

require no lubrication. No plumbing connection

required.

B. Circulates water at 500 gallons per minute with a motor

speed of 1725 R.P.M. Pump housing and removable intake

screen shall be stainless steel. Impeller shall be

composed of non-corrosive nickel-steel alloy. Motor

shall be equipped with an automatic overload protector

to help prevent burnout. Power-on shall be activated

by a toggle switch located on the motor easily

accessible to the operator. Unit is Underwriters

Laboratories, Inc. LISTED.

C. Electrical: 120 Volt, 60HZ, single phase, 1/3

horsepower, direct-connected pump motor and impeller.

Unit shall be supplied with a 15 amp, 6 ft, 120 volt

cord, NEMA 5-15P.

Manufacturer: Subject to compliance with specifications:

Wells Manufacturing Co. Model PW-106

4.04 SHELVING & DUNNAGE RACKS

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 29

04/30/18 DESIGN NO._____

A. Wire Shelving (Storage Room): Wire chrome or zinc

shelves and plated posts with casters, brakes and

bumpers. Shelves shall be 48" long maximum and 24"

wide, four (4) tiers high with overall height not to

exceed 69". Bottom shelf shall be no more than 2" up

from caster. Length and width of each unit as

indicated on Equipment Schedule. Heavy duty casters

shall be 5" polyurethane with a load rating of not

less than 300 lbs, two with brakes. Include donut or

revolving bumpers. Provide quantity shown on the

Drawings. Size and quantity of units shall conform to

field conditions.

Manufacturer: Subject to compliance with specifications:

Advance Tabco Model #EC-24XX, EC-26, ECPC-64

AMCO Corporation Model #A24xxZP, PC64ZP, AC2S, AC2B

Cari-All Inc ADAPTA PLUS Model #Z24xxR, P60, 5C(B)

Eagle Foodservice Equipment Model #24xxZ, CP63-Z, CSS(B)5P

InterMetro Industries Corp. Model No. N5xxEBR

LPI Shelving (SPG) Model #MA24XXC, MG064NFC, DB5, IMPCAS5

Nexel Industries Inc. Model #24XX6EP, CA5SB

B. Dunnage Racks - Wire, nickel/chrome or zinc plating;

maximum 36" long and 24" wide. The nickel/chrome

plating shall be finished with a baked on clear

coating. The racks shall be for dry storage area

only; not to be installed or utilized in can wash room

or wet area. Length and width of each unit as

indicated on Equipment Schedule.

Racks shall be fabricated of basic carbon steel rod

Electro-zinc plated all welded construction. Legs

shall be welded to all three-frame members and holding

the rack surface at 12" above ground level and shall be

formed to allow nesting of common sizes. NSF approved

Quantity and size as shown on the Drawings. Size and

quantity of units shall conform to field conditions.

Weight capacity 1,400 lbs.

Manufacturer: Subject to compliance with specifications:

AMCO Corporation Model #PW24xxZP

United Steel and Wire Co. Model #D24XXC

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 30

04/30/18 DESIGN NO._____

4.05 TABLES

A. Work/Prep Tables

1. Length as indicated on the Equipment Schedule;

location shown on the Drawings. . Height to work

surface shall be 34" and width shall be 30".

2. Table shall be constructed with stainless steel

tops, and provided with drawer, backsplash,

stainless steel legs and adjustable bullet feet,

undershelf and overshelf or wall shelf. Table

shall comply with general requirements of the

Fabrication Article.

3. Provide each Work Table with stainless steel

housing(s) for convenience outlet(s). Mount

housing(s) for outlet(s) as shown on Details.

4.06 HIGH PRESSURE SPRAY CLEANER POWER WASHER (HOSE REEL)

A. Provide high pressure spray cleaner, mobile power

washer rated at 600 psi, with soap and sanitizer

gravity fed (solenoid) chemical injection method, 115

volt, 75 foot stainless steel manual hose reel with 75

feet high pressure steel braided hose with quick

disconnects, a 36" spray gun with wand and nozzle and

quick disconnects. Unit shall be fully certified and

listed as a pressure washer for commercial indoor use.

B. Construction: Stainless steel cart, cover, handle,

structure and hardware; full locking commercial front

casters; float tank with 1" air gap to prevent back

flow; commercial electric motor with manual reset

thermal overload protection; 35 foot power cord with

GFCI and plug; 6’ water inlet hose, with 3/4" garden

hose thread; triplex plunger pump. All fluid handling

components shall be stainless; 5/16" or 3/8” heavy

duty, non-kinking spray hose, non-marking with flex

guards and 1/4" brass quick-disconnect sockets at each

end; ergonomic spray gun with stainless wand, heat

insulating grip, and adjustable nozzle for low/high

pressure and stream/spray.

C. Features: In-line water filter; adjustable unloader

valve, pressure relief valve and thermal relief valve.

Adjustable soap and sanitizer selectors with flush

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 31

04/30/18 DESIGN NO._____

feature; pressure gauge, 2000 psi, liquid filled.

Discharge shall occur at 160°F.

1. Solenoid Valve.

2. Manual Hose Reel: Stainless steel reel for

installation at the machine. Provide 50 feet of

hose.

3. Floor Cleaner Attachment: Floor cleaning

attachments cleans a 12" wide path with protective

hood to eliminate over spray; turbo rotating arms

with dual nozzles; low pressure SOAP and High

pressure RINSE.

D. The power washer station shall consist of:

T&S Model # B-0707 or Fisher Model #82295 faucet with

vacuum breaker and 3/4” garden hose thread

Electrical: GFCI receptacles to match the specified

power of the machine. Locate receptacles on the wall

next to the faucet.

Manufacturer: Subject to compliance with specifications:

Sage Sanitizing Systems Model SM-060107R

Spray Master Technologies Model SMT-600PEW

E. Milk Chest: Refrigerated Milk Storage Cabinet

(Commercial Type for Racked Container Storage).

1. The cabinet shall be provided with easily readable

thermometer mounted integral to cabinet walls.

2. The cabinet shall be mechanically refrigerated

with hermetically sealed condensing unit and

cooling coil or plate coil cooling unit.

3. Both exterior shell and inner lining shall be of

stainless steel construction. The cabinet shall

be supported on an angle frame base with channels

or gussets for caster supports. The interior

bottom shall slope 1" toward cabinet back to

prevent carton from tipping during self-service.

Opening shall be provided in the back for

ventilation and for access to the refrigeration

unit.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 32

04/30/18 DESIGN NO._____

4. The cabinet shall be equipped with a top "Upper

Door" and "Drop Down" front door full width of the

cabinet. Door shall be provided with bumper

guards and a locking mechanism with two brass

master keys and tags. All cabinets shall be keyed

alike. Provide keys with C.P. brass ring and tag,

stamped "NYC DOE" and "PIC" for Pupils Serving

unit.

5. Condensing Unit: Fully hermetically sealed, air-

cooled type: self-contained with cabinet.

6. Cooling Unit: Cooling coils or plates. Cooling

coils shall be secured to cabinet.

7. Electric Requirements: 1/3 H.P., 120 volts, single

phase, 60 HZ. Six feet min. of 3 wire cord and

ground plug to match receptacle.

8 Two swivel and two rigid casters with ball-bearing

wheels with polyurethane tires (and ball-bearing

swivel).

9. The height of the cabinet front with door open

shall not exceed 27" from floor to facilitate

self-service by small students.

10. Provide flexible drain hose with length to extend

distance to floor drain.

11. Provide the following additional options: wrap

around and corner bumpers and bumper guards on the

inside and outside of the doors at the corners and

next to the lock. If the manufacturer does not

install the bumpers on the unit, contractor shall

supply and install all the required bumpers and

bumper guards as specified.

Manufacturer: Subject to compliance with specifications:

Beverage-Air SMF49Y-1-S (SS)

NOR-LAKE AR122SSS/0

True Food Service Equipment, Inc. TMC-49-SSS

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 33

04/30/18 DESIGN NO._____

4.07 RACKS

A. Mobile Pan Rack:

1. The unit shall be constructed of aluminum alloy

and mounted on 5" dia. swivel double-ball bearing

casters, two with brakes, and removable

polyurethane tires. Unit shall accommodate

eighteen (18) full size sheet pans (18” x 26”).

Provide with standard finish, equipment, the

additional specified requirements and the

following accessories: corner or perimeter

bumpers.

2. Provide Smallwares as specified in the Smallwares

Schedule.

Manufacturer: Subject to compliance with specifications:

CHANNEL Manufacturing, Inc. Model 401A/011/024

Cres Cor Model 207-1820

InterMetro Industries Model RF78N-A33RD

Kel Max Equipment Model APR1818-3/B

New Age Industrial Corp., Inc. Model 1331-CL-PB

Wilder Model 407-3-A18NF

4.08 HOT CABINET (ELECTRIC) - MOBILE

A. The mobile heated cabinet shall be indicated in the

Equipment Schedule complete with thermostatically

controlled heating unit and 5" dia. swivel casters

with non-marking polyurethane tires (two wheels fitted

with locking devices). Provide with wrap-around,

corner or full perimeter bumpers. Unit shall

accommodate eighteen (18) full size sheet pans (18” x

26”) on 3” centers min. spacing aluminum angle slides.

Provide additional slides if required.

B. The entire body of the cabinet, including door, shall

be fabricated of aluminum, and insulated with high-

density fiberglass. No lock required

C. Unit shall be equipped with thermostatically controlled

heater with switch, pilot light, and 3 wire heavy duty

line cord with non-twist lock connector and grounding

type plug to match receptacle. Cavity of unit shall

not be obstructed with crossbar.

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 34

04/30/18 DESIGN NO._____

D. Provide with side handle

E. Digital or Analog Thermometer: Mounted in the unit with

the sensing bulb stationary inside the cabinet for

more consistent readings during frequent cabinet

opening.

F. Provide Smallwares as specified in the Smallwares

Schedule.

G. Electrical Requirements: 120V, 60Hz, 1 ph, (Receptacle).

Manufacturer: Subject to compliance with specifications:

Carter Hoffmann Corp Model PH-1825

Cres Cor Model H-135-UA-17-NY

Food Warming Equipment Company, Inc/FWE Model TS-1826-18-SCA

Skydyne/SkyTherm Model 641-HTE-SA-3018DD-PH-TL-PB

Wittco Foodservice Equipment Model 1826-15-SCHNY

Winston Industries, LLC. Model HL4522-AL-SCA

Winston Industries shall include bumper guard and

transport options

4.09 SMALLWARES

A. Stainless Steel Solid Pans: Pan Size shall be full,

half, third, quarter or sixth. Pan shall be made of

22-gauge 18-8, Type 304 stainless steel. Anti–jam

design for easy stacking. Pan shall be permanently

marked with item number, steel type and gauge, and

capacity. Pan shall be NSF-listed. Quantities to be

provided as specified in the Smallwares Schedule.

Manufacturer: Subject to compliance with specifications,

Polar Ware

Volrath

Carlisle FoodService Products

Carlisle FoodService Products shall provide the half,

third, quarter or sixth size pan only not the full.

The Edge manufactured by Polar Ware shall be 22-gauge,

type 300-series stainless steel. Pan shall be NSF

listed and have a minimum of 1/2" Grip-N-Lift edge

along top flange for easy removal and increased

strength. Top outside corners of pan shall be flat and

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 35

04/30/18 DESIGN NO._____

free of additional geometry for easy cleaning. Pan

shall have anti-jam lugs in corners of 4" deep pans to

resist jamming and facilitate easy separation. Reversed

form edge shall be polished and flattened to provide

consistent contact to the well opening. Solid Pan Size

shall be full, half, third, quarter or sixth.

Perforated pan size shall be full size. Quantities to

be provided as specified in the Smallwares Schedule.

Item number, size, and capacity must be visible on pan.

Polar Ware Item Number: IE11X, IE12X, IE13X, IE14X,

IE16X and IE11XP.

B. Stainless Steel Pan Covers: Pan Cover shall be the dome

type without spoon or ladle slot. Full size pan cover:

satin finished 18-8, Type 304 stainless steel; cool

touch handles shall stay comfortable to 220°F. Dome

1

shall be 2 /4” min. Solid covers shall be NSF-listed,

and permanently marked with item number. Quantities

to be provided as specified in the Smallwares

Schedule.

Manufacturer: Subject to compliance with specifications,

Polar Ware

Volrath

C. Stainless Steel Perforated Pans: Perforated pan size

shall be full size. Pan shall be made of 22-gauge 18-

8, Type 304 stainless steel. Pan shall be permanently

marked with item number, steel gauge and capacity.

Pan shall be NSF-listed. Quantities to be provided as

specified in the Smallwares Schedule.

Manufacturer: Subject to compliance with specifications:

Polar Ware

Volrath

Carlisle FoodService Products

D. 18" x 26" Solid Aluminum Pans: Full-size sheet pans;

NSF Listed; extra dent resistant 3004 aluminum alloy;

12 gauge construction; concave bottom; sanitary open

bead. Lincoln Wear-ever Model #5315 or Vollrath model

#68374. Quantities to be provided as specified in the

Smallwares Schedule.

Manufacturer: Subject to compliance with specifications:

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 36

04/30/18 DESIGN NO._____

Lincoln Wear-ever

Vollrath

E. 18" x 26" Perforated Aluminum Pans: Full-size sheet

pans; extra dent resistant 3003 aluminum alloy; concave

bottom, perforated; galvanized bead wire; 18 gauge

construction; natural finish. Lincoln Wear-ever Model

#9002P. Quantities to be provided as specified in the

Smallwares Schedule.

Manufacturer: Subject to compliance with specifications:

Lincoln Wear-ever

4.10 MISCELLANEOUS EQUIPMENT

Corner Guards: Provide as specified in the Fabrication

Article

1 4.11 SMALLWARES SCHEDULE

A B C D E F

Item Description Total # Spec Smallwares Required Per Unit Total of

of Reference Item

Items Required

on Dwg.

Description Number (B x E)

Pot Sink Perforated Pot Sink Heater Insert 1

Milk chest Chrome Wire Baskets 6

Hot Mobile Cabinet Pan – 18" X 26" Solid 18

Angle (Pan) Rack Pan – 18" X 26" Solid 18

4.12 PAPER TOWEL DISPENSER

4

A. Surface-mounted paper towel dispenser shall be

fabricated of stainless steel with exposed surfaces in

satin finish. Stainless steel: 22 gage (min.). Free

of burrs and sharp edges. Tumbler lock to secure

hinged cabinet.

Towel Capacity: 400 single-fold paper towels (minimum).

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 37

04/30/18 DESIGN NO._____

B. Manufacturers: Subject to compliance with

specifications:

Bobrick Washroom Equipment Inc. Model B-263, Bradley

Corporation Model 251-15, ASI 0245-SS, AJW U190, GAMCO

TD-5.

4.13 UTILITY CART

Two tier stainless steel utility cart with heavy duty

welded connections. 4” Swivel casters. Stainless Steel

shelves with hemmed front and retaining lips on three

sides:

Manufacturer: Subject to compliance with specifications,

Volrath model 97140

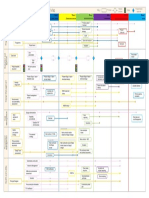

3 PART 5 - EQUIPMENT SCHEDULE

Item Qty Eqp’t CW HW Drain Plug Volts HP Phase Manufacturer Model

No.

P1 Milk X 120 1 Beverage- SMF49Y-1-S

Chest Air (SS)

P2 Mobile X 120 1 Carter Model PH-

Heated Hoffmann 1825

Cabinet Corp

P3 1 Hand Sink 0.5 0.5 1.5

P4 1 Sink X 120 .33 1 Wells Model PW-

Agitator Manuf. Co. 106

P5 1 Pot Sink 2

P6 1 Soap

Dispencer

P7 1 Paper

Towel

Dispencer

P8 Mobile InterMetro Model

pan rack Industries RF78N-A33RD

P9 Mobile Volrath 97140

utility

cart

END OF SECTION

RGB:MM:as

Notes to Specifier (Delete from Specification)

1. Edit quantities as required for equipment specified for this

project. Fill in the total numbers of each piece of

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 38

04/30/18 DESIGN NO._____

equipment shown on the Drawings (shaded column). Update the

field of column F to get the total for each piece.

2. Construction phasing is specified under Division 1.

Coordinate with Architect.

Use electric equipment.

The salvage of existing equipment scheduled to be removed is

to be addressed in the scoping/design phase. The A/E of

Record shall contact the NYC Department of Education Office

of School Food (OSF) in order to determine whether there is

any interest in salvaging the components scheduled to be

removed. Equipment designated to be salvaged shall be

specified by the A/E to be delivered by the Contractor to a

location designated by OSF. The specific equipment to be

salvaged and specific delivery location shall be precisely

detailed in the bid documents.

3. Key the list to Item Numbers shown on the Drawings and

indicate quantities and the specific manufacturers used to

create the Drawings. Indicate all accessories required that

are not included in the Smallwares Specifications.

4. Coordinate with specification section 10810.

* * *

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 39

04/30/18 DESIGN NO._____

LIST OF SUBMITTALS

SUBMITTAL DATE SUBMITTED DATE APPROVED

Product Data:

1. Equipment Drawings Layout

2. Schedule of Equipment and Connections

3. Wiring Diagrams

4. Piping Diagrams

5. Manufacturers Specification Sheets

6. Installation Instructions

Shop Drawings:

1. Fabrication Drawings

Coordination Drawings:

List of Finish Color:

Certifications: _____________

1. Quality assurance listings

And certifications

2. Applicable appliances meet

Reduction in Lead in Drinking

Water Act of 2011

Maintenance Data:

1. Operations Manuals

2. Spare Part lists

3. Warranty

4. List of Factory Authorized Service Agencies

5. Local Service Agency

Smallwares Inventory:

* * *

NYCSCA FOOD SERVICE EQUIPMENT FOR WARMING PANTRY 11401 - 40

Вам также может понравиться

- Sachin SaklaniДокумент1 страницаSachin Saklanisachinsaklani23Оценок пока нет

- Report On Under-Floor Heating Design: Prepared By: Prepared For: Contract Number: DateДокумент11 страницReport On Under-Floor Heating Design: Prepared By: Prepared For: Contract Number: Datesachinsaklani23Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- CLCV - Sachin Saklani - 20210613-1Документ4 страницыCLCV - Sachin Saklani - 20210613-1sachinsaklani23Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Admission Form: Registration Class - Age Chart (In Years) On 1 AprilДокумент2 страницыAdmission Form: Registration Class - Age Chart (In Years) On 1 Aprilsachinsaklani23Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Guide B1 Appendix LTHW SizingДокумент28 страницGuide B1 Appendix LTHW Sizingsachinsaklani23Оценок пока нет

- The Rocket - From East To WestДокумент3 страницыThe Rocket - From East To Westmukaddes12199757Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Speaking sample task - Car and clothing status symbolsДокумент1 страницаSpeaking sample task - Car and clothing status symbolsAnamika DhillonОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Item Rate Boq: Sac Code Basic Price (RS.) Rate of GST (In %)Документ1 страницаItem Rate Boq: Sac Code Basic Price (RS.) Rate of GST (In %)sachinsaklani23Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Section 1: Questions 1 - 8Документ3 страницыSection 1: Questions 1 - 8fagasgОценок пока нет

- A Small Piece of AdviceДокумент1 страницаA Small Piece of Advicesachinsaklani23Оценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Future For 3D Laser Scanning Services in ConstructionДокумент3 страницыFuture For 3D Laser Scanning Services in Constructionsachinsaklani23Оценок пока нет

- Ideal Logic HIU Design GuideДокумент24 страницыIdeal Logic HIU Design Guidesachinsaklani23Оценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Delhi Public School Maruti Kunj Post Mid Term 1 (2020-21)Документ1 страницаDelhi Public School Maruti Kunj Post Mid Term 1 (2020-21)sachinsaklani23Оценок пока нет