Академический Документы

Профессиональный Документы

Культура Документы

Formulation of Insulin Self Nanoemulsifying Drug Delivery System and Its in Vitro-In Vivo Study

Загружено:

Lilia AndromedaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Formulation of Insulin Self Nanoemulsifying Drug Delivery System and Its in Vitro-In Vivo Study

Загружено:

Lilia AndromedaАвторское право:

Доступные форматы

Indonesian J. Pharm. Vol. 29 No.

3 : 157 – 166

ISSN-p : 2338-9427

DOI: 10.14499/indonesianjpharm29iss3pp157

Research Article

Formulation of Insulin Self Nanoemulsifying Drug

Delivery System and Its In Vitro-In Vivo Study

Lina winarti12*, Suwaldi3, Ronny Martien3, Lukman Hakim4

1Postgraduate Programme, ABSTRACT

Faculty of Pharmacy, Particulate delivery system can be used for improving the

Universitas Gadjah Mada, efficacy of protein and peptide drug. In addition to a polymer-

Yogyakarta 55281, based particulate delivery system, self-nanoemulsifying drug

Indonesia; delivery system (SNEDDS), a lipid-based delivery system, is

2Department of

currently developed for either less water-soluble or soluble drugs.

Pharmaceutics, Faculty of This study aims to design SNEDDS for oral insulin administration

Pharmacy, University of

and its in vitro-in vivo study. The SNEDDS template was designed

Jember, Jember 68121,

using D-optimal mixture design and was analyzed using software

Indonesia;

3Dept of Pharmaceutical

Design Expert 7.1.5. The obtained optimum template was loaded

with insulin and evaluated for its transmittance percentage,

Technology Faculty of

Pharmacy, Universitas emulsification time, particle size, zeta potential, stability, the

Gadjah Mada, Yogyakarta amount of insulin in vitro diffused across rat intestine, and insulin

55281, Indonesia. serum concentration after oral administration. The study results

4Dept of Pharmacology and revealed that the optimum template of SNEDDS formula consisted

Clinical Pharmacy, Faculty of of 10% (w/w) Miglyol 812N, 65% (w/w) Tween 80, and 25% (w/w)

Pharmacy, Universitas propylene glycol. These optimum template then was loaded with

Gadjah Mada, Yogyakarta insulin and characterized. SNEDDS insulin has particle size of

55281, Indonesia. 12.0±1.7 nm, zeta potential of +0.16mV, transmittance of >90%,

and emulsification time of < 60 seconds. The stability study

Submitted: 02-04-2018 showed that SNEDDS insulin was stable from both precipitation

Revised: 14-05-2018 and phase separation. The amount of insulin transported from

Accepted: 12-06-2018 SNEDDS formula in vitro was 32.45±2.03% and non-SNEDDS

formula was 10.44±5.04%. In vivo study of SNEDDS insulin

*Corresponding author produced a significantly increased Cmax, AUC, and F value than

Lina Winarni insulin non SNEDDS (p < 0.05). In brief, SNEDDS formulation in

this study is a promising approach to increase the effectiveness of

Email: oral insulin. Insulin is better given orally in SNEDDS formulation

lina.winarti@unej.ac.id than in non SNEDDS formulation.

Keywords: SNEDDS, insulin, D-optimal mixture design, in vitro diffusion

study, in vivo study

INTRODUCTION 2009; Nair et al., 2017; Kunasekaran and

Oral insulin has not been commercially Krishnamoorthy, 2015), microemulsion

available due to the low bioavailability of insulin (Sharma et al., 2010), self-nanoemulsifying drug

in the gastrointestinal tract (Sadrzadeh et al., delivery system (SNEDDS) (Ma et al., 2006; Li et

2007). The enzymatic degradation in the al., 2012; Zhang et al., 2012; Sakloetsakun et al.,

gastrointestinal tract and low permeability of 2013; Rao et al., 2008; Rachmawati et al., 2010),

intestinal membrane result in the low liposome (Wu et al., 2011), and mixed with an

bioavailability of per-oral insulin (Almaeda and aqueous extract obtained from Desmodium

Souto, 2007). Gangeticum roots (Kurian et al., 2010). Among

The approach for oral protein those preparations, SNEDDS is potential to be

formulation is the use of specific excipients such developed as a protein delivery system.

as absorption enhancers, enzyme inhibitors, SNEDDS is a homogenous complex system

mucoadhesive polymers, and other formulations which consists of oil, surfactant, co-surfactant,

enabling protein protection against extreme and co-solvent (Patel et al., 2013). The system is

environment in the gastrointestinal (Park et al., also named as emulsion pre-concentrate. By

2011) like encapsulation of various delivery light agitation in aqueous media leads to the

system including nanoparticles (Sonaje et al., formation of translucent emulsion (Mishra et al.,

Volume 29 Issue 3 (2018) 157

Formulation of Insulin SNEDDS

2014). In some studies, SNEDDS is proven to this study aims to develop optimum SNEDDS

be superior rather than the lipid solution due to template for potential oral insulin delivery.

the surfactant availability in its formulation; it is

homogenous, the drug absorption is more MATERIAL AND METHODS

consistent, it protects drugs against This study used Bovine Insulin from

gastrointestinal environment, the bioavailability Beijing Top Science Biotechnology Co., Ltd.,

gets increased, and the efficiency of absorption Miglyol 812N from CREMER OLEO GmbH &

becomes higher (Kaur and Harikumar, 2013). Co.KG, Tween 80, Span 20, Span 85 from Sigma

SNEDDS has been applied to deliver Aldrich, Chremophor EL 40 was a gift from

hydrophobic drugs such as coenzyme Q10 Shanghai Terppon China, propylene glycol from

(Khattab et al., 2016), halofantrine (Michaelsen et Bratachem Indonesia, glycerol from Merck,

al., 2013), simvastatin (Thomas et al., 2013), Bradford reagen kit from BioRad, Female Wistar

vitamin E-rutin (Khan et al., 2015), and rats obtained from Pharmacology and Pharmacy

cyclosporine A (Jain et al., 2015). Some studies Clinic Laboratory of Pharmacy Faculty

reveal that SNEDDS is also used for protein and University of Gadjah Mada, and ELISA Bovine

peptide drug such as BSA (Rachmawati et al., Insulin Kit from ALPCO USA.

2002; Winarti et al., 2016a; Winarti et al., 2016b),

β-lactamase (Rao et al., 2008), Insulin (Ma et al., Compatibility study of oils-surfactants-

2006; Li et al., 2012; Zhang et al., 2012, co-surfactant mixture

Sakloetsakun et al., 2013). Various oil components consist of Miglyol

SNEDDS insulin prepared by previous 812N, Span 85, and oleic acid, surfactants

researchers (Li et al., 2012; Zhang et al., 2012) (Tween 80, Tween 20, and Cremophor EL 40),

using phospholipid to produce insulin and co-surfactants (Span 20, and propylene

phospholipid complex. The resulted insulin- glycol) used for SNEDDS component. The

phospholipid complex improved the insulin compatibility of oil: surfactants: co-surfactants

solubility in oil. Other reseracher prepared (1:1:1, 1:2:1, 1:3:1, 1:4:1, 1:5:1, 1:6:1, 1:7:1, 1:8:1,

SNEDDS for mucus permeating by initially 2:1:1, 2:2:1, 2:3:1, 2:4:1, 2:5:1, 2:6:1, 2:7:1, 2:8:1,

processing the insulin through hidrophobic ion 3:1:1, 3:2:1, 3:3:1, 3:4:1, 3:5:1, 3:6:1, 3:7:1, 3:8:1)

pair of insulin/dimyristoyl phosphatidylglycerol was visually observed for three days. The

method to improve the insulin solubility in the mixtures of the components with the largest

system and prevent from burst release miscibility area and with the highest emulsion

(Karamanidou et al., 2015). This formulation of transparency produced at a short emulsification

SNEDDS insulin resulted in higher in vitro and time were used to construct the ternary phase

in vivo permeability. diagram and to optimize the composition of

In this study, insulin was dissolved in SNEDDS templates.

glycerol and incorporated in optimum Construction of pseudoternary phase

SNEDDS template optimized using D-optimal diagram

mixture design. The optimum SNEDDS Based on the compatibility study, the

template loaded insulin was characterized mixtures of the components that fulfilled the

and evaluated for in vitro diffussion study and in evaluation criteria were used to construct the

vivo study. The study using rat was approved by pseudoternary phase diagram.

the Ethics Commission of Integrated Reserach

and Testing Laboratory, Universitas Gadjah Optimization of SNEDDS template with

Mada no. 00077/04/LPPT/X/2016. D-optimal

The approach applied in this research is The optimization using D-optimal

said to be able to succeed the generation of mixture design was performed on three

effective insulin delivery system. In addition, this independent variables which are oil (Myglyol 81)

study suggests interesting possibilities for other 10-25%, surfactant (Tween 80) 50-80%, and co-

proteins formulated by SNEDDS. Studies using surfactant (propylene glycol) 10-25%, and it was

insulin as active ingredient that apply this also on two dependent variables which are %

approach have not been established. Therefore, transmittance (Y1) and emulsification time (Y2).

158 Volume 29 Issue 3 (2018)

Lina winarti

Optimum formula verification speed of ±100 bubbles per minute to keep the

The optimum formula verification was membrane function. Sampling technique was

done to determine the suitability of the predicted performed by taking 1 mL solution of the serosal

value with the value of the observation (actual at the 0th, 15th, 30th, 45th , 60th, 90th, 120th, 180th,

value). 240th, and 300th minute. To keep the sinking

condition, the solution was changed to 1 mL of

Preparation of insulin SNEDDS serosal media. The sample obtained was

Insulin was dissolved in glycerin and was centrifuged at a speed of 3.000rpm for 5min to

stirred in the mixture of surfactant (Tween 80), eliminate intestinal debris. The content

co-surfactant (propylene glycol) and Myglyol detection was performed with visible

812N. Each gram of SNEDDS template was spectrophotometer through validated micro

added with 100μL of glycerin containing insulin. Bradford Assay. This method was carried out by

reacted 160µL sample solution with 40µL

Determination of emulsion droplet size

Bradford Reagent, then allowed to stand for at

and zeta potential

SNEDDS Insulin was added with least 5min, and no more than 1h. Absorbance

distilled water (1:1000) in a test tube. The was measured at maximum wavelengths against

particle size was measured and the polydispersity blanks.

index (PDI) of the formulated nanoemulsion

In vivo pharmacokinetic study

was analyzed using DelsaTM Nano Beckman Experimental animal

Coulter. The experimental animal used in the in

vivo test was treated based on the approved

Evaluation of emulsification time

SNEDDS insulin of 250.0µL was quickly procedure by the Ethics Commission of LPPT

UGM no. 00077/04/LPPT/X/2016. The

dripped into a baker glass using 250.0mL

distilled water, simulated gastric fluid PH 1.2 and animals used are healthy 1.5–2-month-old

female Wistar rats (150-250g). The rats were

phosphate buffer pH 6.8 at 37±0.5ºC. The

kept in light cage for 12h and in dark cage for 12

medium was stirred at a speed of 100rpm

(Weerapol et al., 2014). The time to form h, and were given standard diet and sufficient

nanoemulsion was recorded as emulsification water access (ad libitum).

time.

Induction of diabetes

Transmittance percentage

The induction of diabetes in rats were

SNEDDS insulin of 100µL was added to performed through the injection of

a vial containing 10mL and 100mL double Intraperitoneal Streptozotocin (48mg/kg) in

distilled water, Simulated Gastric Fluids pH 1.2, 10mM citrate buffer (pH 4.5) of rats fasted for

and phosphate buffer pH 6.8 at the room 14h with water access (ad libitum). The rats for

temperature, stirred for a minute and measured the following test were selected based on the

for its transmittance using SpectroVis at λ 650 glucose level >250mg/dL after five days of

nm (Reddy and Sowjanya, 2015). streptozotocin induction.

Procedure of in vitro difussion study Treatment of experimental animals

(Ussing Chamber) The study for blood insulin profile was

The diffusion study was conducted using conducted by randomly dividing 28 rats into

Ussing Chamber and intestine of male Wistar seven groups; each group consists of 4 rats. The

rats put on a chip chamber. SNEDDS insulin experimental groups of the study are: Grup I

(1mL) was dispersed in AIF (Artificial Intestinal was given 5.0mL/200g blank SNEDDS (oral);

Fluids) at pH 6.8 and put into the mucosal Grup II was given 43.39IU/KgBW SNEDDS

compartment. The non-SNEDDS insulin was Insulin (1mL oral); Grup III was given

used as the comparator. Phosphate buffer saline 108.47IU/KgBW SNEDDS insulin (2.5mL

pH 7.4 was added into serosal compartment. oral); Grup IV was given 216.94IU/KgBW

The Ussing chamber was set on the water bath SNEDDS insulin (5mL oral), Grup V was given

at 37±0.5ºC. The oxygen was distributed at the 5.0 mL/200gr PBS pH 7.4 (oral); Grup VI was

Volume 29 Issue 3 (2018) 159

Formulation of Insulin SNEDDS

given 200 IU/KgBW non-SNEDDS insulin which SNEDDS templates can form

(oral), and Grup VII was given 10 IU/KgBW nanoemulsion when added to water. The

subcutaneous insulin. diagram consists of Miglyol 812N: Tween 80:

propylene glycol (Figure 1). Red squares showed

Sample Analysis the nanoemulsion.

The blood sample (0.5mL) was obtained

from the eye orbital sinus at the 0th, 15th, 30th, Optimization of SNEDDS template with

45th, 60th, 90th, 120th, 240th, 480th, and 600th minute. D-optimal

The serum insulin concentration (25µL) was Response of % transmittance

measured using Bovine Insulin ELISA Kit. The % transmittance is one of SNEDDS

characteristics that needs to be evaluated for its

Statistical Analysis use to predict the size of emulsion droplets

The differences of each treatment group (Nasr et al., 2016). The equation for %

were statistically analyzed with p<0.05 indicating transmittance using D-optimal Design (pseudo

significantly different. components) is as follow:

Y1= -8.43*A+9.8*B+8.89*C+28.79*A*B+2.07

RESULTS AND DISCUSSION *A*C+2.67*B*C…………………………(1)

Development of SNEDDS templates

The component screened for SNEDDS Remarks: Y1= √ transmittance; A= Miglyol

templates shows that Miglyol 812N: Tween 80: 812N composition; B= Surfactant (Tween 80)

propylene glycol produced the mixtures fulfilling composition; C= Co-surfactant (propylene

the designed criteria. Oleic acid and Span 85 glycol) composition

tend to form less transparent emulsion than

Miglyol 812N. Mygliol 812 is medium chain Based on the equation 1, oil reduced the

triglyceride with the HLB value 15.36 % transmittance due to the improving amount

(Kawakami et al., 2002), while the HLB of of oil composition leading to the increased

Span 85 is 1.8 and HLB of oleic acid is 1.0. It droplet size. It results in the decreased value of

% transmittance (Desmukh and Kulkarni, 2014).

was reported that lipid with higher polarity is

In contrast, surfactants increase the value of %

easier to form nano-emulsion (Hong et al.,

transmittance as they will be absorbed on the oil

2006). Oil that has long hydrocarbon chain surface so fast that the oil changes into small-

like oleic acid and Span 85 (C18) is difficult to sized droplets in continuous phase. Co-

form nano-emulsion; Miglyol 812N has such surfactants support surfactants to reduce the

medium-long hydrocarbon chain that is surface tension into negative value and to

emulsified easily (Anton and Vandamme, modulate the drop size to nanometer by

2009; Sadurní et al., 2005). Span 85 is a sorbitan decreasing the interfacial bending stress and

trioleate, a long hydrocarbon chain, resulting increasing the flexibility of an interfacial film

in higher viscosity (200-300mpas) than (Nasr et al., 2016). Consequently, due to the

Miglyol 812 has (27-33mpas) and oleic acid synergic function, the increased amount of co-

(25.6mpas); Span 85 has less spontaneous nano- surfactants results in the increased value of %

emulsifying and tends to from bigger-sized transmittance.

droplets. The oil-surfactant interaction has the

Tween 80 is able to form nano-emulsion biggest influence on % transmittance for the

with Miglyol 812 due to its higher HLB viscosity of oil-surfactant combination lower

value than of Cremophor EL 40; although than of surfactant; it results in easier penetration

HLB of Tween 80 is lower than of Tween 20, of water in the nano-emulsion formation

it can form better nano-emulsion than Tween 20 process (Ittiqo et al., 2016).

(Chinwong et al., 2012; Macedo et al., 2006).

Response of emulsification time

Phase Diagram of SNEDDS Formulation Emulsification time is essential parameter

Pseudoternary phase diagram was in evaluating the efficiency of self nanoemulsion

constructed to estimate the concentration in formation (Basalious et al., 2010; Costa et al., 2012).

160 Volume 29 Issue 3 (2018)

Lina winarti

Figure 1. Pseudoternary phase diagram of SNEDDS Figure 2. Overlay plot of % transmitan and

template consist of Miglyol 812N:Tween emulsification time

80:Propylene glycol

Figure 3. Amount of insulin transported across rat gut in vitro for 5h (average±sd) (a) insulin

SNEDDS, (b) insulin non SNEDDS

Figure 4. Profile of serum insulin concentration (Average±SEM, n=4)

Volume 29 Issue 3 (2018) 161

Formulation of Insulin SNEDDS

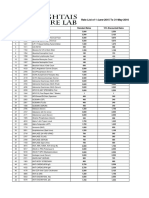

Table I. Pharmacokinetic parameters after oral administration

Cmax Tmax AUC0-10

Treatment F

(ng/mL) (min) (min.ng.mL-1)

Insulin non SNEDDS 200IU/Kg BB 0.52±0.51 15-60 27.34±10.00 0.004±0.003

Insulin SNEDDS 43.39IU/Kg BB 0.82±0.19 45-60 85.86±16.10 0.062±0.024

Insulin SNEDDS 108.47IU/Kg BB 0.77±0.17 240 293.23±42.76 0.084±0.027

Insulin SNEDDS 216.94 IU/Kg BB 1.31±0.19 240 506.75±32.75 0.073±0.008

Insulin Sub Cutane 10IU/Kg BB 4.21±0.57 15 324.60±26.33 1

The obtained equation of D-optimal Design one-minute emulsification time, and it has

(pseudo components) for response of transparent or clear bluish appearance (Kaur et

emulsification time is as follow: al., 2003).

Y2 = -0.029*A+0.036*B+0.15*C…………...(2)

The % transmittance

Remarks: Y2= 1/Emulsification time; A= Miglyol The % transmittance of SNEDDS

812N composition; B= Surfactant (Tween 80) insulin (>90%) indicates transparency formula

composition; C= Co-surfactant (propylene or ability to form nano-emulsion in the used

glycol) media.

Oil increase the emulsification time

while both surfactant and co-surfactant Diffusion test with ussing chamber

decreases the emulsification time. Oil prolong Validation process to determines the level

of insulin transported during diffusion study has

the emulsification time due to different phase

been successfully carried out according to ICH

of oil and water that results in high surface

Guideline Q2 (R1). Validation parameters

tension prohibiting the water penetration in include selectivity, linearity, LOD, LOQ,

forming nano-emulsion spontaneously (Ruan accuracy, and precision. Microbradford assay

et al., 2010). used in this study was selective, linear, accurate

The optimization result shows the and precise. LOD and LOQ were obtained

optimal ratio of Miglyol 812: Tween 80: 0.49μg/mL and 1.64μg/mL. The result of

propylene glycol is 10:65:25 (%w/w) with the diffusion test with Ussing Chamber shows that

desirability of 0.97. Figure 2 shows mixed the amount of transported insulin of SNEDDS

overlay plots resulted by two responses. preparation (32.45±2.03%) is significantly

different (p=0.001) from non-SNEDDS insulin

Verification of optimal formula

(10.44±5.04%) (Figure 3). The test result reveals

The verification result showed no

that SNEDDS significantly influences the

significant difference between the prediction

increase of flux and amount of in vitro

value and observation value of Y1 and Y2

transported insulin.

with p>0.05 therefore that the prediction value

experimentally fits with the observation value.

Analysis of blood insulin level

Particle size and zeta potential The method used to determine insulin

The analysis result of particle size levels in serum is Sandwich ELISA. Color

indicated that the droplet size of insulin nano- intensity after the addition of TMB substrate (3,

emulsion is 12.0±1.7nm with narrow 3', 5, 5'-tetramethylbenzidine) and stop solution

distribution size (polydispersity index = 0.243) measured using ELISA reader at the wavelength

and the zeta potential is +0.16mV. of 450 nm. Before use, ELISA kit was verified

to know its linearity, accuracy, precision, and

Visual observation of emulsification time suitability with the internal quality controls. The

Emulsification time of SNEDDS insulin verification results show that the standard curve

occurs fast in three media, with emulsification is linear (R2 = 0.9998), accurate, precise, and in

time <60s, it belongs to grade A for less than accordance with internal controls.

162 Volume 29 Issue 3 (2018)

Lina winarti

Protein activity depent on the intergrity of pH changes of gastrointestinal tract leading to

three dimensional structure. ELISA results show unpredictable speed of insulin absorption.

that SNEEDS are able to preserve biological Subcutaneous insulin was used as positive

activity of entrapped Insulin. After oral control of blood insulin level. Cmax of this

administration, SNEDDS formulation can insulin is reached fast, in 15min, with

increase in AUC, C max, and an F value of 4.21±0.57ng/mL of level. The Cmax of

insulin (Figure 4). These caused by some factors SNEDDS insulin of the highest dosage remains

including lymphatic transport, high surfactant smaller than of subcutaneous insulin; this occurs

content, and paracellular transport of tight due to bigger insulin hindrance to enter blood

junction (Georgakopoulos et al., 1992). The lipid through oral route. The protein given

given orally will be digested and absorbed in subcutaneously will move slowly from tissues to

intestinal lymphatic. SNEDDS insulin forms capillary, and it generally reach the bloodstream

nano-sized droplet system that will experience through lymphatic vessels; the protein given

intestinal uptake through lymphoid follicles and orally must be resistant to the extreme pH

Peyer’s patches GALT and be transported to environment and protease that can destroy

spleen either directly or through macrophage protein, and it must be able to penetrate the

phagocytosis effect (Reddy and Murthy, 2002). intestinal epithelial membrane to enter the

Insulin also transported to intestinal lymphatic bloodstream.

due to its big-sized molecule and resistance to The result of Pharmacokinetic test reveals

portal circulation absorption (Reddy and that insulin is better given in SNEDDS

Murthy, 2002). preparation than in non-SNEDDS preparation;

Insulin absorption can be reached using this explains that it is highly possible to enhance

enhancer (Muranishi, 1990) and lipid based vehicles the amount of absorbed insulin using SNEDDS

(Porter and Charman, 2001). Long chain lipid preparation.

will tend to be transported to spleen rather than

to portal circulation. The oil used in SNEDDS CONCLUSION

system is Miglyol 812N, medium chain The resulted design of SNEDDS

triglycerides that will be transported to intestinal templates reveals that the optimal SNEDDS

lymphatic due to its combination with Tween 80 template after being loaded with insulin provides

consisting of oleic acid, long chain fat (C18). nano-emulsion characteristic resulting in bigger

Tween 80 is an enhancer that increases the amount of in vitro diffused and in vivo absorbed

permeability of cell membrane. Tween 80 also insulin than of non-SNEDDS insulin. This

has reversible effects in opening tight junction enables the designed SNEDDS formula to be

through interaction with polar parts of lipid used in per-oral insulin delivery.

bilayers (Selvam et al., 2013).

The fastest Cmax reached by Insulin ACKNOWLEDGEMENT

SNEDDS 1mL than Insulin SNEDDS 2.5 mL The writer thanks to Ministry of

adn 5mL (Figure 4). These can be seen from Research, Technology and Directorate of

Insulin SNEDDS given orally as much as 2.5 mL Higher Education of The Republic Indonesia

and 5mL reached Cmax after 240 minutes while for the financial aid and Faculty of Pharmacy,

Insulin SNEDDS 1mL reached Cmax after 45- Universitas Gadjah Mada for the laboratory

60min. These caused by delayed gastric support.

emptying time (Cooke, 1975) and the slow

dispersing process of SNEDDS into REFERENCES

nanoemulsion in limited gastric media (Porter Almeida AJ., Souto E., 2007. Solid lipid

and Charman, 2001; Pouton, 2000). Fat has a nanoparticles as a drug delivery system

long residence time in the stomach (Cooke, for peptides and proteins. Adv. Drug Deliv.

1975) which delayed gastric emptying time Rev., 59: 478–490.

leading to delayed absorption. Anton N., Vandamme TF., 2009. The

Compared with non-SNEDDS insulin, universality of low-energy nano-

the SNEDDS insulin is absorbed more. This emulsification. Int. J. Pharm., 377: 142–

occurs as non-SNEDDS insulin is unstable to 147.

Volume 29 Issue 3 (2018) 163

Formulation of Insulin SNEDDS

Basalious EB., Shawky N., Badr-Eldin SM., on oral bioavailability and nephrotoxicity.

2010. SNEDDS containing bioenhancers RSC Adv., 5:49633-42.

for improvement of dissolution and oral Karamanidou T., Karidi K., Bourganis V.,

absorption of lacidipine. I: development Kontonikola K., Kammona O.,

and optimization. Int. J. Pharm., 391: 203– Kiparissides C., 2015. Effective

211. incorporation of insulin in mucus

Chinwong S., Chinwong D., Mangklabruks A., permeating self-nanoemulsifying drug

2012. 'The Effect of Daily Consumption delivery systems. Eur. J. Pharm. Biopharm.,

of Virgin Coconut Oil on Plasma 97(Pt A):223-9.

Lipoproteins Levels in Healthy Thai Kaur G., Harikumar .L., 2013. Formulation

Volunteers' Geneva Health Forum. Development Of Self Nanoemulsifying

(http://ghf.globalhealthforum.net/2012 Drug Delivery Systems (SNEDDS) Of

/01/06/the-effect-of-daily-consump- Celecoxib For Improvement Of Oral

tion-of-virgin-coconut-oil-on-plasma- Bioavailability. Pharmacophore., 4: 120–133.

lipoproteins-levels-in-healthy-thai-volun- Kawakami K., Yoshikawa T., Moroto Y.,

teers/#.U3MY4nYzeeo accessed 14 May Kanaoka E., Takahashi K., Nishihara Y.,

2014). Masuda K., 2002. Microemulsion

Cooke AR., 1975. Control of gastric emptying formulation for enhanced absorption of

and motility. Gastro-enterology., 68:804-16. poorly soluble drugs.I. Prescription

Costa JA., Lucas EF., Queirós YGC., Mansur design. J. Control. Release., 81:65-74.

CRE., 2012. Evaluation of Khan AW., Kotta S., Ansari SH., Sharma RK.,

nanoemulsions in the cleaning of Ali J., 2015. Self-nanoemulsifying drug

polymeric resins. Colloids Surf. A: delivery system (SNEDDS) of the poorly

Physicochem. Eng. Asp., 415: 112–118. water-soluble grapefruit flavonoid

Desmukh A., Kulkarni S., 2014. Solid self- Naringenin:design, characterization, in

microemulsifying drug delivery system of vitro and in vivo evaluation. Drug. Deliv.,

ritonavir. Drug. Dev. Ind .Pharm., 40:477- 22(4):552-61.

87. Khattab A., Hassanin L., Zaki N., 2016. Self-

Georgakopoulos E., Farah N., Vergnault G., Nanoemulsifying drug delivery system of

1992. Oral anhydrous non-ionic Coenzyme (Q10) with improved

nanoemulsions administered in soft gel dissolution, bioavailability, and protective

capsules. Bulletin Technology Gattefosse., 11- efficiency on liver fibrosis. AAPSJ.,

19. 18:180-6.

Hong JY., Kim JK., Song YK., Park JS., Kim Kunasekaran V., Krishnamoorthy K., 2015.

CK., 2006. A new self-emulsifying Experimental design for the optimization

formulation of itraconazole with of nanoscale solid lipid particles

improved dissolution and oral containing rasagiline mesylate. J.Young.

absorption. J.Control. Release., 110:332- Pharm., 7(4):285-95.

338. Kurian G., Seetharaman A., Subramanian N.,

Ittiqo DH., Pramono S., Martien R., 2016, Paddikkala J., 2010. A novel approach for

Optimization of the formula SNEDDS oral delivery of insulin via Desmodium

purified extract combination of Curcuma gangeticum Aqueous Root Extract. J.

xanthorrhiza and Andrographis Young Pharm., 2:156-61.

paniculata (Burm.f.) Nees using Miglyol Li P., Tan A., Prestidge CA., Nielsen HM.,

812N as an oil phase and absorption Müllertz A., 2014. Self-nanoemulsifying

study in vitro. Thesis, Universitas Gadjah drug delivery systems for oral insulin

Mada, Indonesia. delivery: In vitro and in vivo evaluations of

Jain S., Kambam S., Thanki K., Jain AK., 2015. enteric coating and drug loading. Int. J.

Cyclosphorine A loaded self- Pharm., 477: 390–398.

nanoemulsifying drug delivery system Ma H., Liu Z., Zheng C., 2006. In vitro and in vivo

(SNEDDS):implication of a functional evaluation of a novel oral insulin

excipient based co-encapsulation strategy

164 Volume 29 Issue 3 (2018)

Lina winarti

formulation. Acta Pharmacol. Sin,. 27: self-emulsifying and self-

1382–1388. microemulsifying drug delivery systems.

Macedo JPF., Fernandes LL., Formiga FR., Reis European J. Pahrm. Sci., 11:S93-S98.

MF., Nagashima T., Soares LAL., Egito Rachmawati H., Rasaputri D., Susilowidodo R.,

EST., 2006. Microemultocrit Technique: Darijanto S., Sumirtapura Y., 2010. The

A valuable tool for determination of influence of oils and surfactants on the

critical HLB value of emulsions. AAPS formation of self-nanoemul sifying drug

Pharm. Sc. Tech., 7:E1-E7. delivery systems (SNEDDS) containing

Michaelsen MH., Wasan KM., Sivak O., therapeutic protein. Materials Science and

Müllertz A., Rades T., 2016. The Effect of Technology. Institute Teknologi

Digestion and Drug Load on Bandung.digilib.batan.go.id, accessed 12

Halofantrine Absorption from Self- December 2014).

nanoemulsifying Drug Delivery System Rao SVR., Agarwal P., Shao J., 2008. Self-

(SNEDDS). AAPSJ., 15:219-27. nanoemulsifying drug delivery systems

Mishra A., Panola R., Rana AC., 2014. (SNEDDS) for oral delivery of protein

Microemulsions:As drug delivery system. drugs. I. Formulation design. Int. J.

JSIR., 3(4):467-474. Pharm., 362: 10–15.

Mudi, DM., Murray K., Hoad CL., Pritchard Reddy LH., Murthy RS., 2002. Lympatic

SE., Garnett MC., Amidon GL., transport orally administered drugs. Indian

Gowland PA., Spiller RC., Amidon GE., J. Exp. Biol., 40:1097-1109.

Marciani L., 2014. Quantification of Reddy S., Sowjanya N., 2015. Formulation and

Gastrointestinal liquid volumes and in vitro characterization of solid self-

distribution following a 240 mL dose of nanoemulsifying drug delivery system (s-

water in the fasted state. Mol. Pharm., SNEDDS) of simvastatin. J. Pharm. Sci.

11:3039-47. Res., 7:40-48.

Muranishi S., 1990. Absorption enhancers. Crit. Ruan J., Liu J., Zhu D., Gong T., Yang F., Hao

Rev. Ther. Drug Carrier Syst., 7:1-33. X., Zhang Z., 2010. Preparation and

Nair AB., Al-ghannam AA., Al-Dhubiab BE., evaluation of self-nanoemulsified drug

Hasan AA., 2017. Mucoadhesive film delivery systems (SNEDDSs) of matrine

embedded with Acyclovir loaded based on drug-phospholipid complex

biopolymeric nanoparticles:in vitro technique. Int. J. Pharm., 386:282-90.

studies. J. Young. Pharm., 9(1):100-5. Sadrzadeh N., Glembourtt M., Stevenson C.,

Nasr A., Gardouh A., Ghorab M., 2016. Novel 2007. Peptide drug delivery strategies for

solid self-nanoemulsifying drug delivery the treatment of diabetes. J. Pharm. Sci.,

system (S-SNEDDS) for oral delivery of 96:1925-54.

olmesartan Sadurní N., Solans C., Azemar N., García-Celma

medoxomil:design,formulation, M.J., 2005. Studies on the formation of

pharmacokinetic and bioavailability O/W nano-emulsions, by low-energy

evaluation. Pharmaceutics., 8(20):1-29. emulsification methods, suitable for

Park K., Kwon IC., Park K., 2011. Oral protein pharmaceutical applications. Eur. J.

delivery: Current status and future Pharm. Sci: Official Journal of the European

prospect. React. Funct. Polym., 71: 280–287. Federation for Pharmaceutical Sciences., 26:

Patel H., Santwani P., Patel P., Akshay K., Ranch 438–445.

K., Shah D., 2013. A review on solid self- Sakloetsakun D., Dünnhaupt S., Barthelmes J.,

emulsification - tecniques, dosage forms Perera G., Bernkop-Schnürch A., 2013.

development and pharmaceutical Combining two technologies:

applications. JBPR., 2(4):52-56. Multifunctional polymers and self-

Porter CJH., Charman WN., 2001. Transport nanoemulsifying drug delivery system

and absorption of drugs via the lymphatic (SNEDDS) for oral insulin

system. Adv. Drug Deliv Rev., 50:1-2. administration. Int. J. Biol. Macromol., 61:

Pouton CW., 2000. Lipid formulation for oral 363–372.

administration of drugs:non-emulsifying,

Volume 29 Issue 3 (2018) 165

Formulation of Insulin SNEDDS

Selvam RP., Kulkarni PK., Dixit M., 2013. molecular structure of mixed surfactants.

Preparation and evaluation of self- AAPS Pharm. Sci. Tech., 15;435-443.

nanoemulsifying formulation of Winarti L., Suwaldi, Martien R., Hakim L.,

efavirenz. IJPER., 47:47-54. 2016a. An experimental design of

Sharma, G., Wilson, K., van der Walle, C.F., SNEDDS template loaded with bovine

Sattar, N., Petrie, J.R., dan Ravi Kumar, serum albumin and optimization using D-

M.N.V., 2010. Microemulsions for oral optimal. IJPCR., 8:425-432.

delivery of insulin: Design, development Winarti L., Suwaldi, Martien R., Hakim L.,

and evaluation in streptozotocin induced 2016b. Formulation of self-

diabetic rats. Eur. J. Pharm. Biopharm., 76: nanoemulsifying drug delivery system of

159–169. bovine serum albumin using HLB

Sonaje K., Lin Y., Juang J., Wey S., Chen C., (hydrophilic-lypophilic balance)

Sung H., 2009. In vivo evaluation of approach. Indonesian J. Pharm., 27:117-127.

safety and efficacy of self-assembled Wu W., Niu M., Lu Y., Hovgaard L., 2011.

nanoparticles for oral insulin delivery. Liposomes containing glycocholate as

Biomaterials., 30:2329-39. potential oral insulin delivery systems:

Thomas N., Holm R., Garmer M., Karlsson JJ., preparation, in vitro characterization, and

Müllertz A., Rades T., 2013. improved protection against enzymatic

Supersaturated self-nanoemulsifying drug degradation. Int. J. Nanomedicine., 6:1155-

delivery systems (Super-SNEDDS) 66.

enhance the bioavailability of the poorly Zhang Q., He N., Zhang L., Zhu F., Chen Q.,

water-soluble drug simvastatin in dogs. Qin Y., Zhang Z., Zhang Q., Wang S., He

AAPSJ., 15:219-227. Q., 2012. The In vitro and In Vivo Study on

Weerapol Y., Limmatvapirat S., Sriamornsak P., SNEDDS Based on Insulin-

2014. Self-nanoemulsifying drug delivery Phospholipid Complex. J. Biomed.

system of nifedipine: impact of Nanotechnol., 8:90-7.

hydrophilic-lypophilic balance and

166 Volume 29 Issue 3 (2018)

Вам также может понравиться

- Research ArticleДокумент11 страницResearch ArticleLilia AndromedaОценок пока нет

- 1654 3867 1 PBДокумент7 страниц1654 3867 1 PBLina WinartiОценок пока нет

- Areviewon Self Emulsifying Drug Delivery SystemДокумент6 страницAreviewon Self Emulsifying Drug Delivery SystemAhmed RedaОценок пока нет

- Formulation and Evaluation of Niosomal in Situ GelДокумент14 страницFormulation and Evaluation of Niosomal in Situ GelrandatagОценок пока нет

- MY Rsearch Publication 1Документ14 страницMY Rsearch Publication 1Samuel UzonduОценок пока нет

- Ece 6Документ11 страницEce 6Ellie satrianiОценок пока нет

- Snedds, Loratazin, 2014 PDFДокумент7 страницSnedds, Loratazin, 2014 PDFPradipta MondalОценок пока нет

- (216 235) V10N5CTДокумент20 страниц(216 235) V10N5CTgritty gallantОценок пока нет

- Saudi Pharmaceutical JournalДокумент8 страницSaudi Pharmaceutical Journalrefilda suhailiОценок пока нет

- Tungadi - 2018 - Transdermal Delivery of Snakehead Fish (Ophiocephalus Striatus) Nanoemulgel Containing Hydrophobic Powder For Burn WoundДокумент12 страницTungadi - 2018 - Transdermal Delivery of Snakehead Fish (Ophiocephalus Striatus) Nanoemulgel Containing Hydrophobic Powder For Burn Woundsibon M amrilОценок пока нет

- Development of Curcumin Based Ophthalmic FormulationДокумент9 страницDevelopment of Curcumin Based Ophthalmic FormulationBagus Prasetya WirawanОценок пока нет

- 4.2. Nanotechnology: J. Zhao, Et Al. International Journal of Pharmaceutics 570 (2019) 118642Документ9 страниц4.2. Nanotechnology: J. Zhao, Et Al. International Journal of Pharmaceutics 570 (2019) 118642Wulan AdiariОценок пока нет

- Available Online Through: ISSN: 0975-766XДокумент20 страницAvailable Online Through: ISSN: 0975-766XnurulОценок пока нет

- Naggar StarchДокумент12 страницNaggar StarchBruno Adriel ZamoraОценок пока нет

- Design and Development of Controlled Porosity Osmotic Pump Tablets of Zidovudine Using Sodium Chloride As Osmogen For The Treatment of Aids JPR 19Документ8 страницDesign and Development of Controlled Porosity Osmotic Pump Tablets of Zidovudine Using Sodium Chloride As Osmogen For The Treatment of Aids JPR 19gritty gallantОценок пока нет

- Spray Dried Solid Dispersion of Repaglinide Using Hypromellose Acetate Succinate: in Vitro and in Vivo CharacterizationДокумент36 страницSpray Dried Solid Dispersion of Repaglinide Using Hypromellose Acetate Succinate: in Vitro and in Vivo CharacterizationWarenda May LatifahОценок пока нет

- 3.nasal GelДокумент9 страниц3.nasal GelBaru Chandrasekhar RaoОценок пока нет

- 5154-Article Text-15276-1-10-20220107Документ7 страниц5154-Article Text-15276-1-10-20220107jimi jamalОценок пока нет

- Pnfs 24 225Документ10 страницPnfs 24 225Hector LeónОценок пока нет

- Research Article: Development and Evaluation of Microemulsions For Transdermal Delivery of InsulinДокумент7 страницResearch Article: Development and Evaluation of Microemulsions For Transdermal Delivery of InsulinFeslyAnugerahAriestaPayungОценок пока нет

- Medicina 55 00210 PDFДокумент13 страницMedicina 55 00210 PDFRizqi AmaliaОценок пока нет

- Formulation and In-Vitro Evaluation of Glibenclamide Dry Emulsion in Vegetarian CapsulesДокумент5 страницFormulation and In-Vitro Evaluation of Glibenclamide Dry Emulsion in Vegetarian CapsulesBaru Chandrasekhar RaoОценок пока нет

- Journal of Drug Delivery Science and Technology: SciencedirectДокумент7 страницJournal of Drug Delivery Science and Technology: Sciencedirectarif fikriОценок пока нет

- Formulation and Evaluation of Levodropropizine LozengesДокумент14 страницFormulation and Evaluation of Levodropropizine LozengesFitria MokodompitОценок пока нет

- Self-Nanoemulsifying Drug Delivery System (SNEDDS) of Amomum Compactum Essential Oil: Design, Formulation, and CharacterizationДокумент9 страницSelf-Nanoemulsifying Drug Delivery System (SNEDDS) of Amomum Compactum Essential Oil: Design, Formulation, and CharacterizationFebye ElizaОценок пока нет

- Formulation and Characterization of Floating Microballoons of Nizatidine For Effective Treatment of Gastric Ulcers in Murine ModelДокумент6 страницFormulation and Characterization of Floating Microballoons of Nizatidine For Effective Treatment of Gastric Ulcers in Murine ModelFitria MayangsariОценок пока нет

- Comparison of Solvent Evaporation and Ultrasonicassisted Production Methods in The Development of Nimesulide Nanosponges and Their CharacterizationДокумент7 страницComparison of Solvent Evaporation and Ultrasonicassisted Production Methods in The Development of Nimesulide Nanosponges and Their Characterizationafrink846Оценок пока нет

- 131 138 PDFДокумент8 страниц131 138 PDFRizQi FatmiyahОценок пока нет

- 595-Article Text-2709-1-10-20201004Документ7 страниц595-Article Text-2709-1-10-20201004Ellie satrianiОценок пока нет

- 2.study of Quality and Stability of Ursodeoxycholic Acid Formulations ForДокумент7 страниц2.study of Quality and Stability of Ursodeoxycholic Acid Formulations ForhasanahОценок пока нет

- The Effect of Eugenol and ChitДокумент15 страницThe Effect of Eugenol and Chitfahrullah unhasОценок пока нет

- Bioavalibility Enhancement of Resveratrol Using Self Nanoemulsifying Drug Delivery System Developed Applying Central Composite DesignДокумент13 страницBioavalibility Enhancement of Resveratrol Using Self Nanoemulsifying Drug Delivery System Developed Applying Central Composite DesignLina WinartiОценок пока нет

- Formulation and Evaluation of Floating Tablet of Metoprolol SuccinateДокумент13 страницFormulation and Evaluation of Floating Tablet of Metoprolol SuccinateEditor IJTSRDОценок пока нет

- Formulation Optimization of A Palm-Based Nanoemulsion System Containing LevodopaДокумент16 страницFormulation Optimization of A Palm-Based Nanoemulsion System Containing LevodopaAnton MelcherОценок пока нет

- Formulation and Evaluation of Enteric CoatedДокумент13 страницFormulation and Evaluation of Enteric Coatedvanvu buiОценок пока нет

- Obat OralДокумент10 страницObat Oralmaisaptr06Оценок пока нет

- Saudi Pharmaceutical JournalДокумент10 страницSaudi Pharmaceutical JournalDiky ArdianОценок пока нет

- International Journal of Pharma and Bio Sciences Issn 0975-6299Документ13 страницInternational Journal of Pharma and Bio Sciences Issn 0975-6299Nadya PrafitaОценок пока нет

- Pilocarpine Hydrochloride-Loaded NiosomesДокумент14 страницPilocarpine Hydrochloride-Loaded NiosomesĐủ PhạmОценок пока нет

- Formulation and Evaluation of Solid Self Micro Emulsifying Drug Delivery System Using Aerosil 200 As Solid CarrierДокумент6 страницFormulation and Evaluation of Solid Self Micro Emulsifying Drug Delivery System Using Aerosil 200 As Solid CarriermorganvilleОценок пока нет

- RajendraДокумент11 страницRajendraL4M OFFICIALОценок пока нет

- Evaluation of Self-Nanoemulsifying Drug Delivery Systems (SNEDDS) For Poorly Water-Soluble Talinolol: Preparation, in Vitro and in Vivo AssessmentДокумент13 страницEvaluation of Self-Nanoemulsifying Drug Delivery Systems (SNEDDS) For Poorly Water-Soluble Talinolol: Preparation, in Vitro and in Vivo AssessmentBeatriz PatricioОценок пока нет

- Abstract Cluster Healtcare and Pharmacy1Документ1 страницаAbstract Cluster Healtcare and Pharmacy1faradillasuciОценок пока нет

- Microencapsulation of An Essential Oil (Cinnamon Oil) by Spray Drying: Effects of Wall Materials and Storage Conditions On Microcapsule PropertiesДокумент15 страницMicroencapsulation of An Essential Oil (Cinnamon Oil) by Spray Drying: Effects of Wall Materials and Storage Conditions On Microcapsule PropertiesadОценок пока нет

- JurnalДокумент9 страницJurnalYanuar Ahsan OfficialОценок пока нет

- 109-Article Text-182-1-10-20181220Документ5 страниц109-Article Text-182-1-10-20181220SadishkumarОценок пока нет

- 51 Vol. 5 Issue 5 May 2014IJPSR RA 3450 Paper 51Документ12 страниц51 Vol. 5 Issue 5 May 2014IJPSR RA 3450 Paper 51yurlinzha ChyntiaTandipareОценок пока нет

- Development and Evaluation of Nanoemulsion of RepaglinideДокумент8 страницDevelopment and Evaluation of Nanoemulsion of Repaglinidevikrantkadam12Оценок пока нет

- Development and Optimization of Gastroretentive Mucoadhesive Microspheres of Gabapentin by Box Behnken DesignДокумент12 страницDevelopment and Optimization of Gastroretentive Mucoadhesive Microspheres of Gabapentin by Box Behnken DesignJhasketan PandeОценок пока нет

- 04 12762Документ9 страниц04 12762Umang VariaОценок пока нет

- Liposomal Delivery of Black Seed OilДокумент10 страницLiposomal Delivery of Black Seed OilShalin CОценок пока нет

- Oral Delivery of Indinavir Using mPEG PCL Nanoparticles Preparation Optimization Cellular Uptake Transport and Pharmacokinetic EvaluationДокумент12 страницOral Delivery of Indinavir Using mPEG PCL Nanoparticles Preparation Optimization Cellular Uptake Transport and Pharmacokinetic Evaluationshyam pangaОценок пока нет

- Research Article: Qiuyu Wei, Qiuxuan Yang, Qilong Wang, Congyong Sun, Yuan Zhu, Ya Niu, Jiangnan Yu, and Ximing XuДокумент9 страницResearch Article: Qiuyu Wei, Qiuxuan Yang, Qilong Wang, Congyong Sun, Yuan Zhu, Ya Niu, Jiangnan Yu, and Ximing XuHector LeónОценок пока нет

- Vol 2 - Cont. J. Pharm SciДокумент48 страницVol 2 - Cont. J. Pharm Sciwilolud9822Оценок пока нет

- Prosiding Icpaps 2017Документ98 страницProsiding Icpaps 2017ElfiaNeswitaОценок пока нет

- 8463-Article Text-35730-1-10-20230803Документ8 страниц8463-Article Text-35730-1-10-20230803satrianisyarmafasih19Оценок пока нет

- 2039 PDF PDFДокумент11 страниц2039 PDF PDFnicko.arya.dharmaОценок пока нет

- JHP-4-102Formulation and Evaluation of Orally Disintegrating Tablet of Ondansetron Using Natural SuperdisintegrantДокумент8 страницJHP-4-102Formulation and Evaluation of Orally Disintegrating Tablet of Ondansetron Using Natural SuperdisintegrantIrfan SetiyawanОценок пока нет

- Polysaccharide Hydrogels for Drug Delivery and Regenerative MedicineОт EverandPolysaccharide Hydrogels for Drug Delivery and Regenerative MedicineTapan Kumar GiriОценок пока нет

- (18469558 - Acta Pharmaceutica) Effect of Core and Surface Cross-Linking On The Entrapment of Metronidazole in Pectin BeadsДокумент11 страниц(18469558 - Acta Pharmaceutica) Effect of Core and Surface Cross-Linking On The Entrapment of Metronidazole in Pectin BeadsLilia AndromedaОценок пока нет

- A Review - Self Nanoemulsifying Drug Delivery System (Snedds)Документ13 страницA Review - Self Nanoemulsifying Drug Delivery System (Snedds)Lilia AndromedaОценок пока нет

- European Journal of PharmacologyДокумент15 страницEuropean Journal of PharmacologyLilia AndromedaОценок пока нет

- Basics of Pharmaceutical Emulsions: A Review: African Journal of Pharmacy and Pharmacology December 2011Документ12 страницBasics of Pharmaceutical Emulsions: A Review: African Journal of Pharmacy and Pharmacology December 2011Lilia AndromedaОценок пока нет

- Physico-Chemical Properties of The Drug Affecting BioavailabilityДокумент32 страницыPhysico-Chemical Properties of The Drug Affecting BioavailabilityLilia AndromedaОценок пока нет

- 814 1584 1 PBДокумент11 страниц814 1584 1 PBLilia AndromedaОценок пока нет

- Interaksi Eksipien 2Документ16 страницInteraksi Eksipien 2Lilia AndromedaОценок пока нет

- Research Article: Formula Optimization of Orally Disintegrating Tablet Containing Meloxicam NanoparticlesДокумент12 страницResearch Article: Formula Optimization of Orally Disintegrating Tablet Containing Meloxicam NanoparticlesLilia AndromedaОценок пока нет

- List INN 08february2012 PDFДокумент128 страницList INN 08february2012 PDFMarisaОценок пока нет

- Hipertensiunea Arteriala - Cauze Si TratamenteДокумент25 страницHipertensiunea Arteriala - Cauze Si TratamenteClaudia MurguОценок пока нет

- Manual Placa Mae Ga 945gcmx-s2 6.6Документ72 страницыManual Placa Mae Ga 945gcmx-s2 6.6luisb3toОценок пока нет

- Mathematics Specialist Unit 3A: VectorsДокумент4 страницыMathematics Specialist Unit 3A: VectorsMahir MahmoodОценок пока нет

- Flares & VentsДокумент29 страницFlares & VentsSonu Kaka KakaОценок пока нет

- Ferrozine Rapid Liquid Method Method 8147 0.009 To 1.400 MG/L Fe Pour-Thru CellДокумент6 страницFerrozine Rapid Liquid Method Method 8147 0.009 To 1.400 MG/L Fe Pour-Thru CellCarlos Andres MedinaОценок пока нет

- Darmoatmodjo 2023Документ7 страницDarmoatmodjo 2023mayaОценок пока нет

- The Girl Who CanДокумент4 страницыThe Girl Who CanMadhu50% (2)

- Gurps Fallout HandgunsДокумент1 страницаGurps Fallout HandgunsAndrew Scott100% (1)

- ME4542/ME4542-G: N and P-Channel 30-V (D-S) MOSFETДокумент7 страницME4542/ME4542-G: N and P-Channel 30-V (D-S) MOSFETfelipe ayalaОценок пока нет

- MEAMTA2-Assignment 2Документ5 страницMEAMTA2-Assignment 2pfukanisibuyi7Оценок пока нет

- PGC Inquiries Chapter 7 Grid ProtectionДокумент7 страницPGC Inquiries Chapter 7 Grid ProtectionhansamvОценок пока нет

- Markov Interest Rate Models - Hagan and WoodwardДокумент28 страницMarkov Interest Rate Models - Hagan and WoodwardlucaliberaceОценок пока нет

- CT GenerationsДокумент3 страницыCT GenerationssanyengereОценок пока нет

- Animal Whisperer PDFДокумент4 страницыAnimal Whisperer PDFKevinPriestmanОценок пока нет

- Y10-lab-4-Gas LawДокумент10 страницY10-lab-4-Gas LawEusebio Torres TatayОценок пока нет

- Rate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesДокумент25 страницRate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesMirza BabarОценок пока нет

- Acid Alkaline Food ChartДокумент3 страницыAcid Alkaline Food Chartgime2013Оценок пока нет

- 6.m.tech-Ece-Vlsi, Vlsi Systems, Vlsi System Design (Vlsi, Vlsis, Vlsisd) r17 Course Structure & SyllabiДокумент35 страниц6.m.tech-Ece-Vlsi, Vlsi Systems, Vlsi System Design (Vlsi, Vlsis, Vlsisd) r17 Course Structure & SyllabiravibabukancharlaОценок пока нет

- Häggloader 10HR-B: Atlas CopcoДокумент2 страницыHäggloader 10HR-B: Atlas CopcoHayam BaşaranОценок пока нет

- Pharma Iii To Viii PDFДокумент57 страницPharma Iii To Viii PDFRaja PrabhuОценок пока нет

- Gayatri Mantras of Several GodДокумент10 страницGayatri Mantras of Several GodAnup KashyapОценок пока нет

- Examination Speaking Assignments Term III - 2021Документ2 страницыExamination Speaking Assignments Term III - 2021Khrystyna ShkilniukОценок пока нет

- Hypochondriasis and Health Anxiety - A Guide For Clinicians (PDFDrive)Документ289 страницHypochondriasis and Health Anxiety - A Guide For Clinicians (PDFDrive)Fernanda SilvaОценок пока нет

- Material Control Procedure - TemplateДокумент5 страницMaterial Control Procedure - TemplateHernandito Rahmat KusumaОценок пока нет

- Ford6000cd Rear ConnectorДокумент2 страницыFord6000cd Rear ConnectorAnonymous WcYW9AeОценок пока нет

- Preventive Pump SetДокумент67 страницPreventive Pump Setwtpstp sardОценок пока нет

- Action Plan Gulayan Sa PaaralanДокумент2 страницыAction Plan Gulayan Sa PaaralanAntonio ArienzaОценок пока нет

- Wolfi Landstreicher - Willful Disobedience - Number 3Документ32 страницыWolfi Landstreicher - Willful Disobedience - Number 3populaererОценок пока нет

- Grade 7 Information Writing: The Bulldog: A Dog Like No OtherДокумент5 страницGrade 7 Information Writing: The Bulldog: A Dog Like No Otherapi-202727113Оценок пока нет