Академический Документы

Профессиональный Документы

Культура Документы

Steelplate PDF

Загружено:

Gary NugrohoОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Steelplate PDF

Загружено:

Gary NugrohoАвторское право:

Доступные форматы

Steel Plate

At PT. Gunung Raja Paksi we understand the diverse demand for this form of flat steel

as we produce steel plates from Mild Steel, High-Strength Low Alloy, Pressure Vessel,

Ship Building Plates, and for general purpose uses.

As products with many uses, steel plates have a wide variety of applications. For this

reason, to have the right steel properties for the right applications, a steel plate’s

chemical composition will have to be adjusted to form the desired properties and

material’s characteristics.

With our experience in the processing steel, we are able to cater to our customer’s

requirements with compliances under the ASTM, JIS, BS, DIN and EN standards, and

fulfill majority of size and dimension available.

Standard & Specification : AS 3678, ASTM A-36, BS 4360,

DIN 17100, EN 10025, JIS G 3101,

JIS G 3106.

Standard Size : 1219mm x 2438mm to 3353mm x 12192mm

Annual Capacity : 500.000 MT/Year

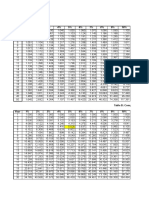

CALCULATED PLATE WEIGHT (FROM THICKNESS & SIZE)

Width x Length 1219 1219 1524 1524 1524 1524 1829 1829 2133 2133 2438 2438 2743 2743 3048 3048 3353 3353

x x x x x x x x x x x x x x x x x x

(in mm) 2438 6096 3048 6096 9144 12192 6096 12192 6096 12192 6096 12192 6096 12192 6096 12192 6096 12192

Width x Length 4’ x 8’ 4’ x 20’ 5’ x 10’ 5’ x 20’ 5’ x 30’ 5’ x 40’ 6’ x 20’ 6’ x 40’ 7’ x 20’ 7’ x 40’ 8’ x 20’ 8’ x 40’ 9’ x 20’ 9’ x 40’ 10’ x 20’ 10’ x 40’ 11’ x 20’ 11’ x 40’

(in ft)

Width x Length

(in inch) 48 x 96 48 x 240 60 x 120 60 x 240 60 x 360 60 x 480 72 x 240 72 x 480 84 x 240 84 x 480 96 x 240 96 x 480 108 x 240 108 x 480 120 x 240 120 x 480 132 x 240 132 x 480

Thickness (mm)

8 187 467 292 583 875 1.167 700 1.400 817 1.633 933 1.867 1.050 2.100 1.167 2.334 1.284 2.567

9 210 525 328 656 985 1.313 788 1.575 919 1.837 1.050 2.100 1.181 2.363 1.313 2.625 1.444 2.888

10 233 583 365 729 1.094 1.459 875 1.750 1.021 2.041 1.167 2.333 1.313 2.625 1.459 2.917 1.605 3.209

12 280 700 438 875 1.313 1.750 1.050 2.101 1.225 2.450 1.400 2.800 1.575 3.150 1.750 3.501 1.925 3.851

12.7 296 741 463 926 1.389 1.852 1.112 2.223 1.296 2.593 1.482 2.963 1.667 3.334 1.852 3.705 2.038 4.076

14 327 817 511 1.021 1.532 2.042 1.225 2.451 1.429 2.858 1.633 3.267 1.838 3.675 2.042 4.084 2.246 4.493

15 350 875 547 1.094 1.641 2.188 1.313 2.626 1.531 3.062 1.750 3.500 1.969 3.938 2.188 4.376 2.407 4.814

16 373 933 583 1.167 1.750 2.334 1.400 2.801 1.633 3.266 1.867 3.733 2.100 4.200 2.334 4.667 2.567 5.134

18 420 1.050 656 1.313 1.969 2.625 1.575 3.151 1.837 3.675 2.100 4.200 2.363 4.725 2.625 5.251 2.888 5.776

19 443 1.108 693 1.386 2.078 2.771 1.663 3.326 1.939 3.879 2.217 4.433 2.494 4.988 2.771 5.543 3.049 6.097

20 467 1.167 729 1.459 2.188 2.917 1.750 3.501 2.041 4.083 2.333 4.667 2.625 5.250 2.917 5.834 3.209 6.418

22 513 1.283 802 1.604 2.407 3.209 1.926 3.851 2.246 4.491 2.567 5.133 2.888 5.776 3.209 6.418 3.530 7.060

24 560 1.400 875 1.750 2.625 3.501 2.101 4.201 2.450 4.899 2.800 5.600 3.150 6.301 3.501 7.001 3.851 7.702

25 583 1.458 912 1.823 2.735 3.646 2.188 4.376 2.552 5.104 2.917 5.833 3.282 6.563 3.646 7.293 4.011 8.023

25.4 593 1.482 926 1.852 2.779 3.705 2.223 4.446 2.593 5.185 2.963 5.927 3.334 6.668 3.705 7.410 4.076 8.151

26 607 1.517 948 1.896 2.844 3.792 2.276 4.551 2.654 5.308 3.033 6.067 3.413 6.826 3.792 7.585 4.172 8.344

28 653 1.633 1.021 2.042 3.063 4.084 2.451 4.901 2.858 5.716 3.267 6.533 3.675 7.351 4.084 8.168 4.493 8.985

30 700 1.750 1.094 2.188 3.282 4.376 2.626 4.251 3.062 6.124 3.500 7.000 3.938 7.876 4.376 8.751 4.814 9.627

32 747 1.867 1.167 2.334 3.501 4.667 2.801 5.602 3.266 6.533 3.733 7.467 4.200 8.401 4.667 9.335 5.134 10.269

36 840 2.100 1.313 2.625 3.938 5.251 3.151 6.302 3.675 7.349 4.200 8.400 4.725 9.451 5.251 10.502 5.776 11.553

38 887 2.217 1.386 2.771 4.157 5.543 3.326 6.652 3.879 7.757 4.433 8.867 4.988 4.976 5.543 11.085 6.097 12.194

40 933 2.333 1.459 2.917 4.376 5.834 3.501 7.002 4.083 8.166 4.667 9.333 5.250 10.501 5.834 11.669 6.418 12.836

45 1.050 2.625 1.641 3.282 4.923 6.564 3.939 7.877 4.593 9.186 5.250 10.500 5.907 11.814 6.564 13.127 7.220 14.441

50 1.166 2.917 1.823 3.646 5.470 7.293 4.376 8.752 5.104 10.207 5.833 11.667 6.563 13.126 7.293 14.586 8.023 16.045

55 1.283 3.208 2.006 4.011 6.017 8.022 4.814 9.628 5.614 11.228 6.417 12.833 7.219 14.439 8.022 16.044 8.825 17.650

60 1.400 3.500 2.188 4.376 6.564 8.751 5.251 10.503 6.124 12.249 7.000 14.000 7.876 15.751 8.751 17.503 9.627 19.254

65 1.516 3.792 2.370 4.740 7.111 9.481 5.689 11.378 6.635 13.269 7.583 15.167 8.532 17.064 9.481 18.962 10.429 20.859

70 1.633 4.083 2.553 5.105 7.658 10.210 6.127 12.253 7.145 14.290 8.167 16.333 9.188 18.377 10.210 20.420 11.232 22.463

75 1.750 4.375 2.735 5.470 8.204 10.939 6.564 13.129 7.655 15.311 8.750 17.500 9.845 19.689 10.939 21.879 12.034 24.068

80 1.866 4.667 2.917 5.834 8.751 11.669 7.002 14.004 8.166 16.331 9.333 18.667 10.501 21.002 11.669 23.337 12.836 25.672

85 1.983 4.958 3.099 6.199 9.298 12.398 7.440 14.879 8.676 17.352 9.917 19.833 11.157 22.315 12.398 24.796 13.639 27.277

90 2.100 5.250 3.282 6.564 9.845 13.127 7.877 15.754 9.186 18.373 10.500 21.500 11.814 23.627 13.127 26.254 14.441 28.882

95 2.216 5.542 3.464 6.928 10.392 13.856 8.315 16.630 9.697 19.394 11.083 22.167 12.470 24.940 13.856 27.713 15.243 30.486

100 2.333 5.833 3.646 7.293 10.939 14.586 8.752 17.505 10.207 20.414 11.667 23.333 13.126 26.252 14.586 29.172 16.045 32.091

Conculated considering specific gravity of steel as 7.85 Kg/mm2, and dimension in mm.

Not Available Sizes

Flat Products | Steel Plate 07

MILD STEEL PLATE

Mechanical Properties

Product Tensile Test Impact Test

Specification Grade Thickness Range Application Remarks

Thickness (mm) YS min. UTS E min. Bend Test Average Temp.

(mm)

(N/mm2) (N/mm2) (%) (Joule)

ASTM A-36 - 4 - 150 - 250 400 - 550 20 (200mm) - - For General Structure - For thickness below than

ASME SA-36 21 (50mm) Purpose 8mm, max width is 1,524mm

> 8 ≤ 12 260 410 min For General Structure (5’); above than 8mm, max

AS 3678 250 6 - 80 > 12 ≤ 50 250 20 (200mm) - - Purpose width is 3,048mm (10’).

> 50 240

≤ 16 235

40 A 6 - 80 > 16 ≤ 40 225 340 - 500 22 (200mm) - - - For thickness more than

> 40 ≤ 63 215 80mm can be supplied

> 63 ≤ 80 205 without mill certificate.

≤ 16 235

40 B 6 - 80 > 16 ≤ 40 340 - 500 22 (200mm) - 20 oC [27]

> 40 ≤ 63 215 (as per order) - Max. length is 15,000mm.

> 63 ≤ 80 205 However the final sizes are

≤ 16 235 subject to reconfirm by our

40 C 6 - 80 > 16 ≤ 40 225 340 - 500 22 (200mm) - 0 oC [27] mill.

> 40 ≤ 63 215

> 63 ≤ 80 210

≤ 16 235 - Shotblasting and primer

BS 4360 40 D 6 - 80 > 16 ≤ 40 225 340 - 500 22 (200mm) - -20 oC [27] For General Structure shop are available, with max.

> 40 ≤ 63 215 Purpose width 3,048mm (10’).

> 63 ≤ 80 215

≤ 16 275

43 A 6 - 80 > 16 ≤ 40 265 430 - 580 20 (200mm) - -

> 40 ≤ 63 255

> 63 ≤ 80 245

≤ 16 275

43 B 6 - 80 > 16 ≤ 40 265 430 - 580 20 (200mm) - 20 oC [27]

> 40 ≤ 63 255

> 63 ≤ 80 245

≤ 16 275

43 C 6 - 80 > 16 ≤ 40 265 430 - 580 20 (200mm) - 0 oC [27]

> 40 ≤ 63 255

> 63 ≤ 80 245

≤ 16 235 22 (200mm)

ST 37.2 6 - 80 > 16 ≤ 40 225 363 - 441 21 (200mm) 1XT/180o 20 oC [27]

DIN 17100 > 40 225 20 (200mm) For General Structure

≤ 16 275 22 (200mm) Purpose

ST 42.2 6 - 80 > 16 ≤ 40 265 412 - 490 21 (200mm) 2XT/180o 20 oC [27]

> 40 255 20 (200mm)

≤5 245 21 (50mm) Bending

JIS G 3101 SS 400 6 - 150 > 5 ≤ 16 245 400 - 510 17 (200mm) - Rolled Steel For

> 16 ≤ 40 235 21 (200mm) 180o General Structure

> 40 215 23 (RB-50mm) 1.5 x t

08 Flat Products | Steel Plate

MILD STEEL PLATE

Mechanical Properties

Product Tensile Test Impact Test

Specification Grade Thickness Range Application Remarks

Thickness (mm) YS min. UTS E min. Bend Test Average Temp.

(mm)

(N/mm2) (N/mm2) (%) (Joule)

≤ 16 245 18 (200mm) - For thickness below than

SM 400 A 6 - 80 > 16 ≤ 40 235 400 - 510 22 (200mm) - - 8mm, max width is 1,524mm

> 40 ≤ 75 215 24 (RB-50mm) (5’); above than 8mm, max

≤ 16 245 18 (200mm) 0oC [27] For General Structure width is 3,048mm (10’).

JIS G 3106 SM 400 B 6 - 80 > 16 ≤ 40 235 400 - 510 22 (200mm) - < 12mm no Purpose

> 40 ≤ 75 215 24 (RB-50mm) impact test

≤ 16 245 18 (200mm) 0oC [47] - For thickness more than

SM 400 C 6 - 80 > 16 ≤ 40 235 400 - 510 22 (200mm) - < 12mm no 80mm can be supplied

> 40 ≤ 75 215 24 (RB-50mm) impact test without mill certificate.

≤ 16 235 24 (5.65VSo)

> 16 ≤ 40 255 24 (5.65VSo) 20 oC [27]

S 235 JRG2 6 - 150 > 40 ≤ 63 215 340 - 470 23 (5.65VSo) - (as per order) - Max. length is 15,000mm.

> 63 ≤ 80 215 22 (5.65VSo) However the final sizes are

> 80 ≤ 100 215 22 (5.65VSo) subject to reconfirm by our

> 100 ≤ 150 195 22 (5.65VSo) mill.

≤ 16 235 24 (5.65VSo)

S 235 JR > 16 ≤ 40 225 24 (5.65VSo) 20 oC [27]

Only Available 6 - 150 > 40 ≤ 63 - 340 - 470 23 (5.65VSo) - (as per order) - Shotblasting and primer

for thickness > 63 ≤ 80 - 22 (5.65VSo) shop are available, with max.

< 25mm > 80 ≤ 100 - 22 (5.65VSo) For General Structure width 3,048mm (10’).

EN 10025 TH > 100 ≤ 150 - 22 (5.65VSo) Purpose

1993 ≤ 16 235 24 (5.65VSo)

> 16 ≤ 40 225 24 (5.65VSo)

S 235 JO 6 - 150 > 40 ≤ 63 215 340 - 470 23 (5.65VSo) - 0 oC [27]

> 63 ≤ 80 215 22 (5.65VSo)

> 80 ≤ 100 215 22 (5.65VSo)

> 100 ≤ 150 195 22 (5.65VSo)

≤ 16 235 24 (5.65VSo)

> 16 ≤ 40 225 24 (5.65VSo)

S 235 J2G3 6 - 150 > 40 ≤ 63 215 340 - 470 23 (5.65VSo) - -20 oC [27]

> 63 ≤ 80 215 22 (5.65VSo)

> 80 ≤ 100 215 22 (5.65VSo)

> 100 ≤ 150 195 22 (5.65VSo)

≤ 16 275 20 (5.65VSo)

> 16 ≤ 40 265 20 (5.65VSo) 20 oC [27]

S 275 JR 6 - 120 > 40 ≤ 63 255 410 - 560 19 (5.65VSo) - (as per order)

> 63 ≤ 80 245 18 (5.65VSo)

> 80 ≤ 100 235 18 (5.65VSo)

> 100 ≤ 120 225 400 - 540 18 (5.65VSo)

≤ 16 275 20 (5.65VSo)

> 16 ≤ 40 265 20 (5.65VSo)

EN 10025 S 275 JO 6 - 120 > 40 ≤ 63 255 410 - 560 19 (5.65VSo) - 0 oC [27] For General Structure

> 63 ≤ 80 245 18 (5.65VSo) Purpose

> 80 ≤ 100 235 18 (5.65VSo)

> 100 ≤ 120 225 400 - 540 18 (5.65VSo)

≤ 16 275 20 (5.65VSo)

> 16 ≤ 40 265 20 (5.65VSo)

S 275 J2G3 6 - 120 > 40 ≤ 63 255 410 - 560 19 (5.65VSo) - -20 oC [27]

> 63 ≤ 80 245 18 (5.65VSo)

> 80 ≤ 100 235 18 (5.65VSo)

> 100 ≤ 120 225 400 - 540 18 (5.65VSo)

Flat Products | Steel Plate 09

PRESSURE VESSEL

Mechanical Properties

Product Tensile Test Impact Test

Application Remarks

Specification Grade Thickness (mm) Thickness Range YS min. UTS E min. Bend Test Average Temp.

(mm)

(N/mm2) (N/mm2) (%) (Joule)

B 6 - 80 - 185 345 - 450 25 (200mm) - - For Pressure Vessel - For thickness below than

28 (50mm) Plate Carbon Steel 8mm, max width is 1,524mm

ASTM A-283 C 6 - 40 - 205 380 - 515 22 (200mm) - - Low AQND (5’); above than 8mm, max

width is 3,048mm (10’).

ASTM SA-283 25 (50mm) Intermediate

D 6 - 15 - 230 415 - 550 20 (200mm) - - Tensile Strength

23 (50mm) - Max. length is 15,000mm.

A 6 - 50 - 165 310 - 450 27 (200mm) - - For Pressure Vessel However the final sizes are

30 (50mm) Plate Carbon Steel subject to reconfirm by our

ASTM A-285 B 6 - 50 - 185 345 - 485 25 (200mm) - - Low AQND mill.

ASTM SA-285 28 (50mm) Intermediate

C 6 - 50 - 205 380 - 515 23 (200mm) - - Tensile Strength

27 (50mm) - Shotblasting and primer

shop are available, with max.

60 12.5 - 220 415 - 550 21 (200mm) - - For Pressure Vessel

width 3,048mm (10’).

ASTM A-516 25 (50mm) Plate Carbon Steel

ASTM SA 516 65 up to 40 - 240 450 - 585 19 (200mm) - - Low AQND

23 (50mm) Intermediate

70 up to 40 - 260 485 - 620 17 (200mm) - - Tensile Strength

21 (50mm)

10 Flat Products | Steel Plate

SHIP BUILDING PLATE

Mechanical Properties

Product Tensile Test Impact Test

Specification Grade Thickness Range Application Remarks

Thickness (mm) YS min. UTS E min. Bend Test Average Temp.

(mm)

(N/mm2) (N/mm2) (%) (Joule)

A -50 - 235 400 - 520 22 (5.65 VSo) - - - For thickness below than

B -30 - 235 400 - 520 22 (5.65 VSo) - 0o [27] 8mm, max width is 1,524mm

AH36 8 - 50 - 355 490 - 620 21 (5.65 VSo) - 0o [34] (5’); above than 8mm, max

DH36 8 - 50 - 355 490 - 620 21 (5.65 VSo) - -20o [34] Steel Plates For Use in width is 3,048mm (10’).

A.B.S. EH36 8 - 50 - 355 490 - 620 21 (5.65 VSo) - -40o [34] Ship Construction

AH40 8 - 30 - 390 510 - 650 20 (5.65 VSo) - 0o [39]

DH40 8 - 30 - 390 510 - 650 20 (5.65 VSo) - -20o [39] - Max. length is 15,000mm.

EH40 8 - 30 - 390 510 - 650 20 (5.65 VSo) - -40o [39] However the final sizes are

B.K.I. A -50 - 235 400 - 520 22 (5.65 VSo) - - Steel Plates For Use in Ship Construction subject to reconfirm by our

A -50 - 235 400 - 520 22 (5.65 VSo) - - mill.

B -50 - 235 400 - 520 22 (5.65 VSo) - 0o [27]

AH36 8 - 50 - 255 490 - 620 21 (5.65 VSo) - 0o [34]

DH36 8 - 50 - 355 490 - 620 21 (5.65 VSo) - -20o [34] - Shotblasting and primer

L.R. EH36 8 - 50 - 355 490 - 620 21 (5.65 VSo) - -40o [34] Steel Plates For Use in shop are available, with max.

AH40 8 - 50 - 390 510 - 650 20 (5.65 VSo) - 0o [39] Ship Construction width 3,048mm (10’).

DH40 8 - 50 - 390 510 - 650 20 (5.65 VSo) - -20o [39]

EH40 8 - 50 - 390 510 - 650 20 (5.65 VSo) - -40o [39]

360 AR 8 - 40 - 190 360 - 480 24 (5.65 VSo) - -

410 AR 8 - 40 - 215 410 - 530 21 (5.65 VSo) - -

A 8 - 50 - 235 400 - 520 22 (5.65 VSo) - -

B 8 - 50 - 235 400 - 520 22 (5.65 VSo) - 0o [27]

D 8 - 25 - 235 400 - 520 22 (5.65 VSo) - -20o [27]

AH32 8 - 50 - 315 440 - 570 22 (5.65 VSo) - 0o [31]

G.L. DH32 8 - 50 - 315 440 - 570 22 (5.65 VSo) - -20o [31] Steel Plates For Use in

AH36 8 - 50 - 355 490 - 630 21 (5.65 VSo) - 0o [34] Ship Construction

DH36 8 - 50 - 355 440 - 630 21 (5.65 VSo) - -20o [34]

AH40 8 - 12 - 390 510 - 660 20 (5.65 VSo) - 0o [41]

DH40 8 - 12 - 390 510 - 660 20 (5.65 VSo) - -20o [41]

A 8 - 50 - 235 400 - 520 22 (5.65 VSo) - -

B 8 - 50 - 235 400 - 520 22 (5.65 VSo) - -0o [27]

D 8 - 35 - 235 400 - 520 22 (5.65 VSo) - -20o [27]

AH36 8 - 50 - 355 490 - 620 21 (5.65 VSo) - 0o [34]

B.V. DH36 8 - 50 - 355 490 - 620 21 (5.65 VSo) - -20o [34] Steel Plates For Use in

EH36 8 - 30 - 355 490 - 620 21 (5.65 VSo) - -40o [34] Ship Construction

AH40 8 - 30 - 390 510 - 620 20 (5.65 VSo) - 0o [39]

DH40 8 - 30 - 390 510 - 620 20 (5.65 VSo) - -20o [39]

EH40 8 - 30 - 390 510 - 620 20 (5.65 VSo) - -40o [39]

A 8 - 50 - 235 400 - 520 22 (5.65 VSo) - -

B 8 - 50 - 235 400 - 520 22 (5.65 VSo) - -0o [27]

D 8 - 50 - 235 400 - 520 22 (5.65 VSo) - -20 [27]

o

AH36 8 - 50 - 355 490 - 620 21 (5.65 VSo) - 0o [34]

D.N.V. DH36 8 - 50 - 355 490 - 620 21 (5.65 VSo) - -20o [34] Steel Plates For Use in

EH36 8 - 50 - 355 490 - 620 21 (5.65 VSo) - -40o [34] Ship Construction

AH40 8 - 30 - 390 510 - 660 20 (5.65 VSo) - 0o [41]

DH40 8 - 30 - 390 510 - 660 20 (5.65 VSo) - -20o [41]

EH40 8 - 30 - 390 510 - 660 20 (5.65 VSo) - -40o [41]

Flat Products | Steel Plate 11

HIGH STRENGTH LOW ALLOY

Mechanical Properties

Product Tensile Test Impact Test

Application Remarks

Specification Grade Thickness (mm) Thickness Range YS min. UTS E min. Bend Test Average Temp.

(mm)

(N/mm2) (N/mm2) (%) (Joule)

42 6 - 80 - 290 415 min 20 (200mm) - - - For thickness below than

24 (50mm) For Welded 8mm, max width is 1,524mm

ASTM A 572 50 6 - 80 - 345 450 min 18 (200mm) - - Construction With (5’); above than 8mm, max

21 (50mm) Improved Notch width is 3,048mm (10’).

55 6 - 80 - 380 485 min 17 (200mm) - - Tughness

20 (50mm)

58 6 - 40 - 220 400 - 490 21 (200mm) - - This Specification Covers - Max. length is 15,000mm.

24 (50mm) Structural Quality Carbon- However the final sizes are

ASTM A 573 65 6 - 40 - 240 450 - 530 20 (200mm) - - Manganese-Silicone Steel subject to reconfirm by our

23 (50mm) Plate Where Improved mill.

70 6 - 40 - 290 485 - 620 18 (200mm) - - Notch Toughness is

21 (50mm) Important

≤ 16 275 - Shotblasting and primer

43 D 6 - 80 > 16 ≤ 40 265 430 - 580 20 (200mm) - -20 oC [27] shop are available, with max.

> 40 ≤ 63 255 width 3,048mm (10’).

> 63 ≤ 80 245

≤ 16 355

50 A 6 - 80 > 16 ≤ 40 345 490 - 640 18 (200mm) - -

> 40 ≤ 63 340

> 63 ≤ 80 325

≤ 16 355

BS 4360 50 B 6 - 80 > 16 ≤ 40 345 490 - 640 18 (200mm) - 20 oC [27] General Structure With

> 40 ≤ 63 340 (as per order) Superior Weldability

> 63 ≤ 80 325

≤ 16 355

50 C 6 - 80 > 16 ≤ 40 345 490 - 640 18 (200mm) - 0 oC [27]

> 40 ≤ 63 340

> 63 ≤ 80 325

≤ 16 355

50 D 6 - 80 > 16 ≤ 40 345 490 - 640 18 (200mm) - -20 oC [27]

> 40 ≤ 63 340

> 63 ≤ 80 325

> 8 ≤ 12 360 General Structure With

AS 3678 350 6 - 80 > 12 ≤ 20 350 450 min 18 (200mm) - - Superior Weldability

> 20 340

12 Flat Products | Steel Plate

HIGH TENSILE PLATE

Mechanical Properties

Product Tensile Test Impact Test

Application Remarks

Specification Grade Thickness (mm) Thickness Range YS min. UTS E min. Bend Test Average Temp.

(mm)

(N/mm2) (N/mm2) (%) (Joule)

42 6 - 80 - 290 415 min 20 (200mm) - - - For thickness below than

24 (50mm) For Welded 8mm, max width is 1,524mm

ASTM A 572 50 6 - 80 - 345 450 min 18 (200mm) - - Construction With (5’); above than 8mm, max

21 (50mm) Improved Notch width is 3,048mm (10’).

55 6 - 80 - 380 485 min 17 (200mm) - - Tughness

20 (50mm)

58 6 - 40 - 220 400 - 490 21 (200mm) - - This Specification Covers - Max. length is 15,000mm.

24 (50mm) Structural Quality Carbon- However the final sizes are

ASTM A 573 65 6 - 40 - 240 450 - 530 20 (200mm) - - Manganese-Silicone Steel subject to reconfirm by our

23 (50mm) Plate Where Improved mill.

70 6 - 40 - 290 485 - 620 18 (200mm) - - Notch Toughness is

21 (50mm) Important

≤ 16 275 - Shotblasting and primer

43 D 6 - 80 > 16 ≤ 40 265 430 - 580 20 (200mm) - -20 oC [27] shop are available, with max.

> 40 ≤ 63 255 width 3,048mm (10’).

> 63 ≤ 80 245

≤ 16 355

50 A 6 - 80 > 16 ≤ 40 345 490 - 640 18 (200mm) - -

> 40 ≤ 63 340

> 63 ≤ 80 325

≤ 16 355

BS 4360 50 B 6 - 80 > 16 ≤ 40 345 490 - 640 18 (200mm) - 20 oC [27] General Structure With

> 40 ≤ 63 340 (as per order) Superior Weldability

> 63 ≤ 80 325

≤ 16 355

50 C 6 - 80 > 16 ≤ 40 345 490 - 640 18 (200mm) - 0 oC [27]

> 40 ≤ 63 340

> 63 ≤ 80 325

≤ 16 355

50 D 6 - 80 > 16 ≤ 40 345 490 - 640 18 (200mm) - -20 oC [27]

> 40 ≤ 63 340

> 63 ≤ 80 325

> 8 ≤ 12 360 General Structure With

AS 3678 350 6 - 80 > 12 ≤ 20 350 450 min 18 (200mm) - - Superior Weldability

> 20 340

Flat Products | Steel Plate 13

Вам также может понравиться

- Instructions For Repairing AlternatorДокумент3 страницыInstructions For Repairing AlternatordamoccaОценок пока нет

- Crane Operator Rigger TrainingДокумент55 страницCrane Operator Rigger TrainingAli Jalil80% (5)

- Formula Notes For Cracking Fluid Mechanics For Gate by Jain SirДокумент27 страницFormula Notes For Cracking Fluid Mechanics For Gate by Jain SirSachin Saini93% (27)

- Motor TestingДокумент26 страницMotor TestingGas Gas DucatiОценок пока нет

- Unit 1 Vehicle Components - BackДокумент20 страницUnit 1 Vehicle Components - BackCarlos CabreraОценок пока нет

- Statistical Constants FileДокумент12 страницStatistical Constants FileAnandhi ChidambaramОценок пока нет

- 008 Cat-6060 Attachment Functions FSДокумент37 страниц008 Cat-6060 Attachment Functions FSenrico100% (3)

- 06-DC Compound MotorДокумент44 страницы06-DC Compound MotorN. iManОценок пока нет

- GI Sheet Kg-m2Документ1 страницаGI Sheet Kg-m2farshan296015Оценок пока нет

- IS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-100Документ1 страницаIS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-100Deputy Executive Engineeer RWS & S Nrpm100% (2)

- Table B - Distribution Critical ValuesДокумент1 страницаTable B - Distribution Critical ValuesSinisaОценок пока нет

- Probabilidades (O Áreas Bajo La Curva de La Distribución T) - Valores de TДокумент1 страницаProbabilidades (O Áreas Bajo La Curva de La Distribución T) - Valores de TLuzОценок пока нет

- (Lab Report Operation Unit) Experiment 3: Separation of An Ordinary Binary Mixture Consisting of Acetic Acid and Water by Using Simple Batch Distillation Technique.Документ8 страниц(Lab Report Operation Unit) Experiment 3: Separation of An Ordinary Binary Mixture Consisting of Acetic Acid and Water by Using Simple Batch Distillation Technique.Fazsroul100% (9)

- Obturation Techniques and DevicesДокумент29 страницObturation Techniques and DevicesArivinthaan Tanigajalam100% (1)

- Ba 88aДокумент77 страницBa 88aAnonymous GhWU5YK8Оценок пока нет

- Z and T Test Table PcofshtДокумент6 страницZ and T Test Table PcofshtAzariel MikuОценок пока нет

- ASA Pipe SchedulesДокумент1 страницаASA Pipe SchedulesPaul GuillaumeОценок пока нет

- Cross Section Modung BaruДокумент20 страницCross Section Modung Baruone driveОценок пока нет

- Anexa 2 Repartitia Student PDFДокумент1 страницаAnexa 2 Repartitia Student PDFEvelina AnileveОценок пока нет

- Data SheetДокумент2 страницыData SheetArielОценок пока нет

- Structure Profile PDFДокумент6 страницStructure Profile PDFBang OchimОценок пока нет

- T TableДокумент1 страницаT Tablejham jhamОценок пока нет

- Table V Percentage Points T: Appendix AДокумент1 страницаTable V Percentage Points T: Appendix AJuan DcruzОценок пока нет

- Table V Percentage Points T: Appendix AДокумент1 страницаTable V Percentage Points T: Appendix AAubrey LastimosaОценок пока нет

- TVM TablesДокумент13 страницTVM TablesSaurabh ShuklaОценок пока нет

- Statistial TablesДокумент8 страницStatistial TablesOshi Ahmed100% (1)

- QT Tables Rug-MergedДокумент14 страницQT Tables Rug-MergedNikhil GuptaОценок пока нет

- T DistributionДокумент2 страницыT DistributionaltarescessОценок пока нет

- Table Sched 40 & 80Документ1 страницаTable Sched 40 & 80Clinton HarmanОценок пока нет

- Pipe Schedule PDFДокумент1 страницаPipe Schedule PDFbayu270589100% (1)

- 9 PDFДокумент3 страницы9 PDFsterlingОценок пока нет

- Test Student StatisticsДокумент6 страницTest Student StatisticskhadidjaОценок пока нет

- Valores de La T-Student A Niveles de Confianza (A Dos Colas)Документ1 страницаValores de La T-Student A Niveles de Confianza (A Dos Colas)Rolando Torres PachecoОценок пока нет

- Orifice Tables PDFДокумент35 страницOrifice Tables PDFAli RazzaqОценок пока нет

- Aga TableДокумент35 страницAga TableilublessingОценок пока нет

- Steel PIPE CHART PDFДокумент1 страницаSteel PIPE CHART PDFSatria 'igin' Girindra NugrahaОценок пока нет

- 2.1 Tabel Distribusi T - Edit For MhsДокумент2 страницы2.1 Tabel Distribusi T - Edit For MhsMarditya Amey SiahayaОценок пока нет

- IS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-63Документ1 страницаIS: 4984 Wall Thickness & Weight Chart of Pipes For Material Grade PE-63Deputy Executive Engineeer RWS & S Nrpm100% (2)

- Financial Tables - Present and Future Value TablesДокумент7 страницFinancial Tables - Present and Future Value TablesN Rakesh86% (7)

- Plate Spec 4Документ2 страницыPlate Spec 4Nabilla ZaheraОценок пока нет

- Tabla - Distribucion Normal (Z)Документ3 страницыTabla - Distribucion Normal (Z)mirandaОценок пока нет

- ASME B18.2.1 Heavy Hex Bolt DimensionДокумент1 страницаASME B18.2.1 Heavy Hex Bolt DimensionHienОценок пока нет

- Statistical Tables: AppendixДокумент6 страницStatistical Tables: AppendixMita YuliaОценок пока нет

- Guide To Types 'X' and 'R' Otis Landing NipplesДокумент1 страницаGuide To Types 'X' and 'R' Otis Landing NipplesAnthony LakpahОценок пока нет

- TVM TablesДокумент21 страницаTVM Tablesanamika prasadОценок пока нет

- Gauge Sizes ChartДокумент5 страницGauge Sizes ChartGonzalo MazaОценок пока нет

- Tabla de T StudentДокумент2 страницыTabla de T StudentVictor OlayaОценок пока нет

- T StudentДокумент2 страницыT StudentAlberto GiorgiОценок пока нет

- RFJ FjpoeДокумент27 страницRFJ FjpoeNate JamesОценок пока нет

- Financial Tables PDFДокумент10 страницFinancial Tables PDFKimmy2010Оценок пока нет

- Square & CubeДокумент1 страницаSquare & CubeEntertainment Buddy'sОценок пока нет

- Table T StudentДокумент1 страницаTable T Studentlosvak removakОценок пока нет

- Sheet Size ChartДокумент7 страницSheet Size ChartTusharОценок пока нет

- Polycab LT Cables Pricelist 2017Документ2 страницыPolycab LT Cables Pricelist 2017Rajaa The greatОценок пока нет

- Specialty PIPE SCHEDULES PDFДокумент1 страницаSpecialty PIPE SCHEDULES PDFAlfred LamОценок пока нет

- VAM ACE Rev (1) .3 - 07-2005Документ8 страницVAM ACE Rev (1) .3 - 07-2005frankslwslee59Оценок пока нет

- Tabel: Distribusi: Memberikan Harga P T T (KДокумент1 страницаTabel: Distribusi: Memberikan Harga P T T (Krizka Putri KurniaОценок пока нет

- Hidrostatic Bonjean - 0216030029 - Abdul Azis Rev2 - Area 20m2Документ43 страницыHidrostatic Bonjean - 0216030029 - Abdul Azis Rev2 - Area 20m2Abdul AzisОценок пока нет

- T Distribution: DF T-Score T-Score T-Score T-Score T-Score T-Score T-Score T-Score T-Score T-Score T-Score T-ScoreДокумент33 страницыT Distribution: DF T-Score T-Score T-Score T-Score T-Score T-Score T-Score T-Score T-Score T-Score T-Score T-ScoreMega AuliaОценок пока нет

- T Dist TableДокумент33 страницыT Dist TableGlennОценок пока нет

- Critical Values of The Student T DistributionДокумент1 страницаCritical Values of The Student T DistributionSyifaОценок пока нет

- Dimensions of Chinese Standard Equal Leg AnglesДокумент3 страницыDimensions of Chinese Standard Equal Leg AnglesJJGM120Оценок пока нет

- Critical Value - ANOVAДокумент2 страницыCritical Value - ANOVAWei TingОценок пока нет

- Tablas de Constantes para Cartas de Control PDFДокумент1 страницаTablas de Constantes para Cartas de Control PDFDanna SánchezОценок пока нет

- Table of Critical Values For Student'S T DistributionsДокумент1 страницаTable of Critical Values For Student'S T Distributions.Оценок пока нет

- Tabla SmacnaДокумент2 страницыTabla SmacnaRodrigo caba venturaОценок пока нет

- Tahun Bulan 20.000.000 30.000.000 40.000.000 50.000.000 60.000.000 70.000.000 80.000.000 Jangka Waktu PlafondДокумент2 страницыTahun Bulan 20.000.000 30.000.000 40.000.000 50.000.000 60.000.000 70.000.000 80.000.000 Jangka Waktu PlafondYeri AkanfaniОценок пока нет

- Bang Phan PhoiДокумент16 страницBang Phan PhoiThư NguyễnОценок пока нет

- United States Census Figures Back to 1630От EverandUnited States Census Figures Back to 1630Оценок пока нет

- Power SteeringДокумент31 страницаPower SteeringpeskeirasОценок пока нет

- NAME Dendi Panji Nugraha: Career ExperiencesДокумент4 страницыNAME Dendi Panji Nugraha: Career ExperiencesAsep Ricky HerdiansyahОценок пока нет

- Design and Optimization of An XYZ Parallel Micromanipulator With Flexure HingesДокумент26 страницDesign and Optimization of An XYZ Parallel Micromanipulator With Flexure HingesVijay SakhareОценок пока нет

- M795 Spare PartsДокумент139 страницM795 Spare Partsวิรัตน์ อัครอภิโภคีОценок пока нет

- Lennox - G40UH - Service ManualДокумент46 страницLennox - G40UH - Service ManualKen Christoffersen0% (1)

- Boeing Fire AERO - 2011 - Q2 - Article3Документ10 страницBoeing Fire AERO - 2011 - Q2 - Article3Braulio GomesОценок пока нет

- 08aa301 Engineering Mathematics - IIIДокумент2 страницы08aa301 Engineering Mathematics - IIIVIGNESH L R60% (5)

- $MP 026 18Документ12 страниц$MP 026 18Safura BegumОценок пока нет

- ML10 OwnersManualДокумент16 страницML10 OwnersManualSalvador OlivasОценок пока нет

- AMZ PresenceДокумент6 страницAMZ Presencemarginwalker77Оценок пока нет

- 01-09-04MIL On, DTCs P1545, P0121, P0123, P0221 or P0222 Stored in ECM Fault MemoryДокумент7 страниц01-09-04MIL On, DTCs P1545, P0121, P0123, P0221 or P0222 Stored in ECM Fault MemoryKilobyte202005Оценок пока нет

- Camera Tubes NДокумент30 страницCamera Tubes NRamakrishna VadlamudiОценок пока нет

- Automatic Irrigation SystemДокумент3 страницыAutomatic Irrigation SystemVijay MОценок пока нет

- 2022 FuturaSun 150m 500W SILK Premium en UnlockedДокумент2 страницы2022 FuturaSun 150m 500W SILK Premium en UnlockedEVERY GHSОценок пока нет

- 022-000015B NvcaДокумент229 страниц022-000015B NvcaCarlos Terraza OyagaОценок пока нет

- Cks 180 Ton MIGAS BaruДокумент46 страницCks 180 Ton MIGAS BaruHario PramuditoОценок пока нет

- Cs Acrovyn CatalogueДокумент83 страницыCs Acrovyn CatalogueBoboc AndreiОценок пока нет

- Datasheet: G185XW01V2Документ33 страницыDatasheet: G185XW01V2فؤاد عشيشОценок пока нет

- Solartech Solar Pumping Inverter: Technical DataДокумент1 страницаSolartech Solar Pumping Inverter: Technical Dataadolfo escobarОценок пока нет

- Microgels As Model Colloids Adv. Colloid. Interface Sci. 1999 SaundersДокумент25 страницMicrogels As Model Colloids Adv. Colloid. Interface Sci. 1999 SaundersKevin PascualОценок пока нет