Академический Документы

Профессиональный Документы

Культура Документы

Approval Document ASSET DOC LOC 299

Загружено:

Anonymous a3K3WgАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Approval Document ASSET DOC LOC 299

Загружено:

Anonymous a3K3WgАвторское право:

Доступные форматы

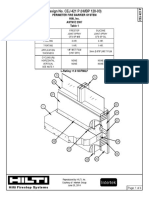

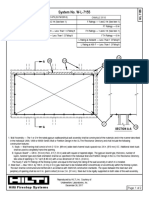

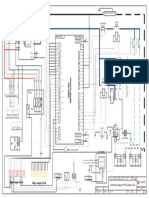

HI/BPF 120-06

Design No. HI/BPF 120-06

PERIMETER FIRE BARRIER SYSTEM

Hilti, Inc.

ASTM E 2307

Table 1

FIRESTOP SILICONE

JOINT SPRAY JOINT SPRAY

CFS-SP WB CFS-SP SIL

F-RATING 2-HR. 2-HR.

T-RATING 1-HR. 1-HR.

APPLICATION

1/8" WET FILM 2mm (0.079") WET FILM

THICKNESS

CYCLING (%)

HORIZONTAL ± 15 ± 7.5

VERTICAL ±5 ±5

SEE NOTE 1

L-Rating <1.0 SCFM/LF

2E

2G

3B

1

2B

2D

2F

3A

2C

Reproduced by HILTI, Inc.

Courtesy of Intertek Group

March 03, 2017

Hilti Firestop Systems Page: 1 of 3

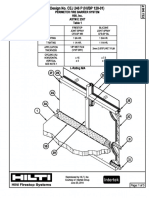

HI/BPF 120-06

Design No. HI/BPF 120-06

1. FLOOR ASSEMBLY: 2 hour rated concrete floor assembly made from either lightweight or normal weight concrete with a density of 100-150 pcf,

with a min. thickness of 4_1/2 in. at the joint face. Overall slab thickness may increase to accommodate various blockout depths (longitudinal

recesses) formed in the concrete, to house an architectural cover plate. The blockout width may also vary without restriction.

2. CURTAIN WALL ASSEMBLY: The curtain wall assembly shall incorporate the following construction features:

A. Mounting Attachment: (Not shown) Attachment of the curtain wall framing to the structural framing is required at each floor. The mounting

attachments to the floor slab shall be either to the top surface of the floor slab or the joint face of the floor slab, according to the curtain wall

manufacturer's instructions. The distance between mounting attachments shall be a min. 60 in. on center (oc). The mounting attachments

shall be steel.

B. Aluminum Framing: Rectangular aluminum tubing mullions and transoms, sized according to the curtain wall system manufacturer's

guidelines. Min. overall dimensions of framing required is 0.100 in. thick aluminum with a min. 5_1/4 in. height and a min. of 2-1/2 in. width of

the extrusion. Mullions are to be spaced a min. 60 in. oc and transoms are to be spaced a min. 72 in. oc. Transoms are to be located at a min.

height of 33 in. above the top surface of the concrete floor assembly (as measured from the bottom of the transom).

C. Glass Spandrel Panels: Glass spandrel panels shall be installed to curtain wall framing according to the curtain wall system manufacturer's

guidelines. Use a min. 1/4 in. thick, clear tempered glass with a max. width of 59 in. and height of 71 in. Panels are secured with a thermal

break (thermal-set rubber extrusion), pressure bar (aluminum extrusion), 1/4-20 × 5/8 in. long screws, and a snap face (aluminum extrusion).

The spandrel panels shall be insulated according to Item 2F.

D. Glass Vision Panels: Glass vision panels shall be at least 35-1/2 in. above the top surface of the floor assembly and installed to curtain wall

framing according to the curtain wall system manufacturer's guidelines. Same min. requirements as in Item 2C.

E. Impaling Pins: When pins are used instead of screws, they shall be located in the same manner as the screws in Item 2F, sized and installed

according to the curtain wall system manufacturer's guidelines, or be a min. 4-1/2 in. long, 12 GA steel pin attached to a nominal 2 in. × 2 in.

galvanized sheet steel plate, a nominal 2 × 2 × 2 in. long angle, or directly attached to the framing using a stud gun. Pins shall be spaced a

max. of 12 in. oc and installed around the periphery so that the interior face of the curtain wall insulation is flush with the interior face of the

framing.

F. Curtain Wall Insulation: All spandrel panels shall be insulated with a min. 2 in. thick, 8 pcf, mineral wool batt insulation**, faced on one side

with aluminum foil scrim (vapor retarder) which is exposed to the room interior. (**Listed with Intertek) They are fitted tightly between vertical

framing members, secured with screws placed a max. 8 in. oc, attached to a min. 16 GA angle around the entire perimeter of each batt. The

vertical 16 GA angles are attached to the mullions with screws. At the horizontal butt joints of the insulation in the field of the glass spandrel

panels (Item 2C), the horizontal angles are placed back to back to form a "T", which is located at the horizontal centerline of the perimeter

joint protection. All other horizontal seams in the insulation are to be at least 6 in. from the top surface of the perimeter joint treatment. The

interior face of the batts is flush with the interior face of the curtain wall framing. A min. 2 in. air space is created between the glass and the

insulation. The 36 in. wide batts shall be installed without vertical seams, spanning the full length between the vertical and horizontal curtain

wall framing members, which create the spandrel panel area.

G. Framing Covers: Strips made of min. 1 in. thick × 4 in. wide, 8 pcf, mineral wool batt insulation**, faced on one side with aluminum foil scrim

(vapor retarder) which is exposed to the room interior. (**Listed with Intertek). Framing covers are centered over each vertical framing member

and secured to the member with impaling pins and clips spaced at least 12 in. oc. Framing covers do not pass through the perimeter joint

treatment. They are butted to the top and bottom surfaces of the perimeter joint treatment. The sides of the mullion covers are sealed with

aluminum foil tape.

Reproduced by HILTI, Inc.

Courtesy of Intertek Group

March 03, 2017

Hilti Firestop Systems Page: 2 of 3

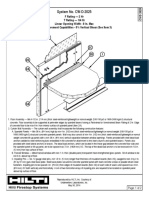

HI/BPF 120-06

Design No. HI/BPF 120-06

3. PERIMETER JOINT PROTECTION: The perimeter joint (linear opening) shall not exceed a 6 in. nominal joint width (joint width at installation) and

the perimeter joint treatment shall incorporate the following construction features:

A. Packing Material: Use a min. 4 in. thick, 4 pcf density, mineral wool batt insulation**, installed with the fibers running parallel to the slab edge

and curtain wall. (**Listed with Intertek). The packing material shall be compressed 50% in the nominal joint width. Compress the batt

insulation into the perimeter joint such that the top surface of the batt insulation is flush with the top surface of the concrete floor slab. Splices

(butt joints) in the lengths of mineral wool batt insulation are to be tightly compressed together. Reference the Introduction to Fire Resistive

Joint Systems Section of this Directory for more details on how to determine the cut width of the insulation to be installed in the nominal joint

width, and how to determine the compressed percentage of a known insulation width installed in a known nominal joint width.

B. CERTIFIED MANUFACTURER: Hilti Corporation

CERTIFIED PRODUCT: Joint Spray or Sealant

MODEL: Firestop Joint Spray CFS-SP WB or Silicone Joint Spray CFS-SP SIL

Fill, Void, or Cavity Material: To be spray applied to cover the exposed surface of the mineral wool installed in the perimeter joint. Apply at the

thickness specified in Table 1 and overlap the material a min. 1/2 in. onto the adjacent curtain wall assembly and concrete floor slab

assembly. If the spraying process is stopped and the applied liquid cures to an elastomeric film before process is restarted, then overlap the

edge of the cured material at least 1/8 in. with the spray. Reference Product Section of this Directory for more details about the Listed product.

C. Support Clips: (Not Shown) Support clips are optional but recommended for installations subject to vertical shear movement. Standard

Z-shaped clips are 20 GA galvanized steel with the following dimensions: 1 in. wide × 3 in. high with a 2 in. upper leg and 3 in. lower leg.

Reproduced by HILTI, Inc.

Courtesy of Intertek Group

March 03, 2017

Hilti Firestop Systems Page: 3 of 3

Вам также может понравиться

- How to Build a Global Model Earthship Operation II: Concrete WorkОт EverandHow to Build a Global Model Earthship Operation II: Concrete WorkОценок пока нет

- FS - Muro Cortina - ASSET-DOC-LOC-7765712Документ3 страницыFS - Muro Cortina - ASSET-DOC-LOC-7765712S. Priscila Castillo V.Оценок пока нет

- Flame StopДокумент31 страницаFlame StopaОценок пока нет

- Firestop CEJ 421 PДокумент4 страницыFirestop CEJ 421 PErlanggaRizkiFauziОценок пока нет

- Fire Stop InstallationДокумент3 страницыFire Stop InstallationAristo OnanОценок пока нет

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersДокумент2 страницыDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimОценок пока нет

- CEJ114PДокумент2 страницыCEJ114PGauri Calderon TrujilloОценок пока нет

- Approval Document ASSET DOC LOC 319Документ5 страницApproval Document ASSET DOC LOC 319aОценок пока нет

- Baumit Facade Insulating Board EPS-F: ProductДокумент6 страницBaumit Facade Insulating Board EPS-F: ProductIbrahim SahinОценок пока нет

- Approval Document ASSET DOC LOC 340Документ2 страницыApproval Document ASSET DOC LOC 340aОценок пока нет

- Ezt-Fc 60-06Документ3 страницыEzt-Fc 60-06ashenafiiОценок пока нет

- 18.10 Plywood Sheets Overview On The German MarketДокумент8 страниц18.10 Plywood Sheets Overview On The German MarketSameh AbboudОценок пока нет

- Firestop Application Handbook (Macau) - Part-9 PDFДокумент40 страницFirestop Application Handbook (Macau) - Part-9 PDFSharoon S raoОценок пока нет

- System PDF Files - 1. UL and cUL Systems - cwd1033Документ3 страницыSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlОценок пока нет

- Approval Document ASSET DOC LOC 145Документ2 страницыApproval Document ASSET DOC LOC 145Amir IqbalОценок пока нет

- BILL OF QUANTITIES - KIHONDA FINAL TANePSДокумент27 страницBILL OF QUANTITIES - KIHONDA FINAL TANePSD A R K S K YОценок пока нет

- Estimated Boq For Furniture Work PDFДокумент5 страницEstimated Boq For Furniture Work PDFMD ASIF100% (1)

- System No. HW-D-0403Документ1 страницаSystem No. HW-D-0403Daniel Soaloon SibaraniОценок пока нет

- Bostik Paneltack HM Dekton Tds en 2020Документ5 страницBostik Paneltack HM Dekton Tds en 2020Miguel ZuzaОценок пока нет

- Classification: Internal UseДокумент6 страницClassification: Internal UseSiva SankarОценок пока нет

- HWD 0930 Sello de Junta Muro - Techo Acceso 1 Solo Lado y Ambos LadosДокумент2 страницыHWD 0930 Sello de Junta Muro - Techo Acceso 1 Solo Lado y Ambos Ladoscesar walter salazar garciaОценок пока нет

- Construction of Paper BoxДокумент9 страницConstruction of Paper BoxJaokОценок пока нет

- System No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)Документ2 страницыSystem No. CW-D-2025: Linear Opening Width - 8 In. Max Class II Movement Capabilities - 5% Vertical Shear (See Item 3)aОценок пока нет

- AD Fire AD-IMF 120-01Документ2 страницыAD Fire AD-IMF 120-01Jorge perezОценок пока нет

- Ul Fs On Max Rectangular Duct Block WallДокумент2 страницыUl Fs On Max Rectangular Duct Block WallhossamОценок пока нет

- Finishes Schedule - Annexure 1: 43-4 External CirculationДокумент1 страницаFinishes Schedule - Annexure 1: 43-4 External CirculationsathiyaprasathОценок пока нет

- Lite-Deck Book WebДокумент23 страницыLite-Deck Book WebFlorencio SandovalОценок пока нет

- Ì86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103Документ2 страницыÌ86WWDÇ!#ÈANÇ 4/pî: System No. WW-D-0103AnaMorenoОценок пока нет

- BITUCELLДокумент2 страницыBITUCELLVag KatsikopoulosОценок пока нет

- Forticrete Gemini 2 Page Leaflet FINAL 31st May 2011Документ2 страницыForticrete Gemini 2 Page Leaflet FINAL 31st May 2011Steven_Frost_262Оценок пока нет

- ICC-ES Report Firestone TPO Roofing MaterialДокумент16 страницICC-ES Report Firestone TPO Roofing MaterialKoushik ThunuguntlaОценок пока нет

- Auditorium B.O.Q All Complete PDFДокумент51 страницаAuditorium B.O.Q All Complete PDFDeepak Chandola100% (4)

- ACP WorkДокумент2 страницыACP WorkSyed AbthahirОценок пока нет

- BitucellДокумент2 страницыBitucellzultrsb689Оценок пока нет

- Hull, Girder and Bulkhead FRP WeighingДокумент3 страницыHull, Girder and Bulkhead FRP Weighingdarren visitacionОценок пока нет

- SECTION 07 21 13 Thermal InsulationДокумент10 страницSECTION 07 21 13 Thermal Insulationtaghreed shabanОценок пока нет

- Fosroc BitucellДокумент2 страницыFosroc Bitucellahmed abdulОценок пока нет

- Tyco TY313+TY323 TFP172 - 09 - 2022Документ5 страницTyco TY313+TY323 TFP172 - 09 - 2022First LAstОценок пока нет

- Basic Info TK-U.B.I Sleeves3Документ17 страницBasic Info TK-U.B.I Sleeves3Saradhi MedapureddyОценок пока нет

- Series TY-FRB, 5.6 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard CoverageДокумент4 страницыSeries TY-FRB, 5.6 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Quick Response, Standard CoverageWidier Duarte SandovalОценок пока нет

- BQ - General NotesДокумент1 страницаBQ - General NotesWaihoe KwanОценок пока нет

- ED33Документ8 страницED33İhsan TazeОценок пока нет

- BS1186 2-1988Документ17 страницBS1186 2-1988Marcelo Rodriguez FujimotoОценок пока нет

- SECTION 06 16 63 Cementitious SheathingДокумент4 страницыSECTION 06 16 63 Cementitious SheathingJuanPaoloYbañezОценок пока нет

- Wall Panel DetailsДокумент20 страницWall Panel Detailsdebbie89_myloves100% (1)

- Ausschreibungstexte Engl ExtractДокумент12 страницAusschreibungstexte Engl Extractqsdpfyb2c5Оценок пока нет

- PA02 Spec MIT Spot & Soda Blasting (IFC)Документ7 страницPA02 Spec MIT Spot & Soda Blasting (IFC)Mohd YusriОценок пока нет

- Specification PDFДокумент54 страницыSpecification PDFsothilingamnОценок пока нет

- ICC-ES Evaluation Report ESR-2218Документ12 страницICC-ES Evaluation Report ESR-2218Mark J LeingangОценок пока нет

- Scope of Job:-: Attachment To PR 10-2275 Page 1 of 9 Hot Insulation Jobs in Fre Job Scope & Notes To VendorsДокумент9 страницScope of Job:-: Attachment To PR 10-2275 Page 1 of 9 Hot Insulation Jobs in Fre Job Scope & Notes To VendorsraghbirОценок пока нет

- Toll Plaza Structure - Technical SpecificationsДокумент3 страницыToll Plaza Structure - Technical SpecificationsNeeraj SinghОценок пока нет

- UntitledДокумент2 страницыUntitledandy_ramblaОценок пока нет

- SECTION 09 29 00 Gypsum BoardДокумент10 страницSECTION 09 29 00 Gypsum BoardRima Baz FadousОценок пока нет

- The Designers' Guide To The Use of Expamet Hy-RibДокумент34 страницыThe Designers' Guide To The Use of Expamet Hy-Ribprasad perkaОценок пока нет

- AluminiДокумент10 страницAluminiDeepan KumarОценок пока нет

- BitucellДокумент2 страницыBitucellDillesh ReddyОценок пока нет

- Bituthene 3000/3000 HC: Self-Adhesive Rubber/bitumen Polyethylene Waterproof Membrane For Basements and Sub-StructuresДокумент2 страницыBituthene 3000/3000 HC: Self-Adhesive Rubber/bitumen Polyethylene Waterproof Membrane For Basements and Sub-StructuresSankar CdmОценок пока нет

- General Authority of Civil Aviation Building Project: Procurement Long Lead Items Cut Off Date: 23 10 2021Документ1 страницаGeneral Authority of Civil Aviation Building Project: Procurement Long Lead Items Cut Off Date: 23 10 2021Anonymous a3K3WgОценок пока нет

- RДокумент1 страницаRAnonymous a3K3WgОценок пока нет

- GACA weekly progress As per Mashroat Mechanism - 31-8-2021 - خلاصة لمبنى الهيئةДокумент1 страницаGACA weekly progress As per Mashroat Mechanism - 31-8-2021 - خلاصة لمبنى الهيئةAnonymous a3K3WgОценок пока нет

- RBS 30-12-2021.XER-8-ActivitiesДокумент7 страницRBS 30-12-2021.XER-8-ActivitiesAnonymous a3K3WgОценок пока нет

- RBS 30-12-2021.XER-7-ActivitiesДокумент388 страницRBS 30-12-2021.XER-7-ActivitiesAnonymous a3K3WgОценок пока нет

- General Authority of Civil Aviation Building Project: Procurement Non Long Lead Items Cut Off Date: 23 10 2021Документ1 страницаGeneral Authority of Civil Aviation Building Project: Procurement Non Long Lead Items Cut Off Date: 23 10 2021Anonymous a3K3WgОценок пока нет

- General Authority of Civil Aviation Building Project: Construction Activities Cut Off Date: 23 10 2021Документ5 страницGeneral Authority of Civil Aviation Building Project: Construction Activities Cut Off Date: 23 10 2021Anonymous a3K3WgОценок пока нет

- P&C NEW Modified GACA BLD ProjectДокумент9 страницP&C NEW Modified GACA BLD ProjectAnonymous a3K3WgОценок пока нет

- General Authority of Civil Aviation Building: Construction ConstructionДокумент3 страницыGeneral Authority of Civil Aviation Building: Construction ConstructionAnonymous a3K3WgОценок пока нет

- Progress Report Cut-Off Date: 24-07-2021: Activity Name Performance % Complete Schedule % CompleteДокумент3 страницыProgress Report Cut-Off Date: 24-07-2021: Activity Name Performance % Complete Schedule % CompleteAnonymous a3K3WgОценок пока нет

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsДокумент3 страницыGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgОценок пока нет

- S-Curve 21-08-2021Документ1 страницаS-Curve 21-08-2021Anonymous a3K3WgОценок пока нет

- Progress by Division 15-05-2021Документ3 страницыProgress by Division 15-05-2021Anonymous a3K3WgОценок пока нет

- MEP Update 10-07-2021Документ90 страницMEP Update 10-07-2021Anonymous a3K3WgОценок пока нет

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsДокумент3 страницыGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgОценок пока нет

- MEP Update 10-07-2021Документ90 страницMEP Update 10-07-2021Anonymous a3K3WgОценок пока нет

- Marshall Mix Design ProcedureДокумент31 страницаMarshall Mix Design Procedurebraackw100% (2)

- Hot Ashalt Mix Desing System MOTДокумент48 страницHot Ashalt Mix Desing System MOTAnonymous a3K3WgОценок пока нет

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsДокумент3 страницыGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgОценок пока нет

- MEP Update 10-07-2021Документ90 страницMEP Update 10-07-2021Anonymous a3K3WgОценок пока нет

- S-Curve 24-07-2021Документ1 страницаS-Curve 24-07-2021Anonymous a3K3WgОценок пока нет

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsДокумент3 страницыGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgОценок пока нет

- Table 5.02 - Marshall Mix Design CriteriaДокумент1 страницаTable 5.02 - Marshall Mix Design CriteriaMahesh Kumar sukhadiyaОценок пока нет

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsДокумент3 страницыGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgОценок пока нет

- S-Curve 10-04-2021Документ1 страницаS-Curve 10-04-2021Anonymous a3K3WgОценок пока нет

- S-Curve 03-04-2021Документ1 страницаS-Curve 03-04-2021Anonymous a3K3WgОценок пока нет

- S-Curve 13-03-2021Документ1 страницаS-Curve 13-03-2021Anonymous a3K3WgОценок пока нет

- General Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsДокумент3 страницыGeneral Authority of Civil Aviation Building: Gaca Buildings Gaca BuildingsAnonymous a3K3WgОценок пока нет

- S-Curve 08-05-2021Документ1 страницаS-Curve 08-05-2021Anonymous a3K3WgОценок пока нет

- Progress by Division 15-05-2021Документ3 страницыProgress by Division 15-05-2021Anonymous a3K3WgОценок пока нет

- Gear Tooth Speed SensorsДокумент3 страницыGear Tooth Speed SensorsKartik GvrОценок пока нет

- Telemecanique LC1D09M7 DatasheetДокумент3 страницыTelemecanique LC1D09M7 DatasheetFelix Bocanegra RuizОценок пока нет

- Marechal Decontators V Plugs Decontactors DecontactorДокумент2 страницыMarechal Decontators V Plugs Decontactors DecontactorrocketvtОценок пока нет

- LED Floodlight BrochureДокумент8 страницLED Floodlight BrochuresatishmuggulaОценок пока нет

- Design of Steel Bridges: Components and ClassificationДокумент67 страницDesign of Steel Bridges: Components and ClassificationMohamed HalimОценок пока нет

- Utf-8' '2012041215332322Документ14 страницUtf-8' '2012041215332322Anonymous gH8rfDОценок пока нет

- Dieukhien Dong Co Ver 01Документ374 страницыDieukhien Dong Co Ver 01lamduxenhqnОценок пока нет

- Instruction - Current and Voltage Instrument Transformers - Instruction For Installation, Use andДокумент56 страницInstruction - Current and Voltage Instrument Transformers - Instruction For Installation, Use anddaveadeОценок пока нет

- Polydoros It / It-S Polydoros It / It-SДокумент10 страницPolydoros It / It-S Polydoros It / It-SMario Rodríguez100% (1)

- Operating Instructions: Modular Time SwitchДокумент1 страницаOperating Instructions: Modular Time SwitchwrpinacateОценок пока нет

- DN02 S09011 e XK 5501 01Документ44 страницыDN02 S09011 e XK 5501 01ayemyothantОценок пока нет

- Smart Lighting Product Catalogue 2020 Final SДокумент118 страницSmart Lighting Product Catalogue 2020 Final SarminsarajevoОценок пока нет

- Full Wave RectifireДокумент9 страницFull Wave Rectifireالزهور لخدمات الانترنيت100% (1)

- Tabelle Geometrie Ghost 2017Документ4 страницыTabelle Geometrie Ghost 2017Veronica MicozziОценок пока нет

- TransformadoresДокумент4 страницыTransformadoresTB11SDОценок пока нет

- CTs & VTsДокумент48 страницCTs & VTssulemankhalid100% (1)

- Schematic Drawing Egypt 12KW Rev02Документ1 страницаSchematic Drawing Egypt 12KW Rev02Saif Abdullah100% (1)

- Battery Disconnect 200amp "Big Boy": IntellitecДокумент4 страницыBattery Disconnect 200amp "Big Boy": IntellitecAbdyrahman HudaygulyyewОценок пока нет

- Motor Starting - Djordje SavinovicДокумент46 страницMotor Starting - Djordje SavinovicJulio RojasОценок пока нет

- Pin Assignment Pin Color Wire Size Option Function: Astra H - x48 - Under SeatДокумент12 страницPin Assignment Pin Color Wire Size Option Function: Astra H - x48 - Under SeatgerasimovruslanОценок пока нет

- 3Документ1 страница3Oluwadunmininu SoyinkaОценок пока нет

- BMW E70 X5 Ziza Interior LED LightsДокумент12 страницBMW E70 X5 Ziza Interior LED LightsAdi Pascale0% (1)

- Trip Relay ManualДокумент2 страницыTrip Relay Manualkkamal600Оценок пока нет

- Datasheet DINFIR3 Counter Lock For Fire and Panic Exit Doors 2022 - 05 (EN)Документ4 страницыDatasheet DINFIR3 Counter Lock For Fire and Panic Exit Doors 2022 - 05 (EN)Dragomir ArabadzhievОценок пока нет

- Comparison of Protection Relay TypesДокумент6 страницComparison of Protection Relay TypesVasudev AgrawalОценок пока нет

- Operating Instructions Finn-PowerДокумент32 страницыOperating Instructions Finn-PowerAugusto OliveiraОценок пока нет

- Lightning Link Printable Template V1.0Документ4 страницыLightning Link Printable Template V1.0Gilberto Hill83% (23)

- Termostato RTR-E 3000 SeriesДокумент2 страницыTermostato RTR-E 3000 Seriesajrojas1359Оценок пока нет

- (K-30) Datasheet - Stafford ValvesДокумент2 страницы(K-30) Datasheet - Stafford ValvesPRASANTH PRASANTHОценок пока нет