Академический Документы

Профессиональный Документы

Культура Документы

A320 Dual Hydraulic Loss

Загружено:

Luca ZaffaroniОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A320 Dual Hydraulic Loss

Загружено:

Luca ZaffaroniАвторское право:

Доступные форматы

A320 - Dual

hydraulic loss

By: Michel PALOMEQUE

Flight Safety Advisor

A318/A319/A320/A321 program

1 Introduction Speed Motor/ Generator (CSM/G) is used to provide

aircraft electrical power in case of emergency.

The A320 may experience a series of dual hydraulic

loss when, at low altitude, a leak in the green On the green & yellow systems, the normal source

hydraulic system causes the loss of the yellow of pressure is the Engine Driven Pump (EDP) and

circuit. the auxiliary source is the Power Transfer Unit

To understand how this may happen, this article (PTU). The PTU is a hydraulic motor pump which

will first describe the aircraft’s hydraulic system transfers hydraulic power between the green and

and explain the respective roles of the Power yellow systems without transfer of fluid.

Transfer Unit (PTU) and ECAM caution in case of It operates automatically, whenever the pressure

pressure differential between the green and yellow differential between the two systems reaches

systems. 500 PSI.

The second part of the article will describe how

the combination of a major leak in the green circuit In case of low fluid level in either the green or yellow

and the ECAM inhibition below 1,500 feet may system, an amber caution is triggered on the ECAM,

lead to the dual hydraulic loss. which requests the pilot to switch off the PTU as

The third and last part will develop on the corrective well as the EDP. This to avoid having the PTU

actions proposed to avoid this type of occurrences. running at maximum speed and causing the

overheating and loss of the properly functioning

hydraulic system.

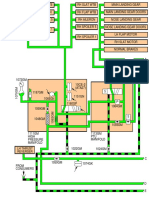

2 General overview According to the Airbus philosophy of not

overloading the flight crew during the critical phases

The A320 hydraulic system is composed of three of flight, the above amber caution is inhibited below

different and fully independent circuits: Green, 1,500 feet.

Yellow & Blue. The users are shared between the

systems in order to ensure the control of the aircraft, The figure below shows all the systems, which are

even when one system is inoperative. interconnected to the hydraulic systems:

On the blue hydraulic system, the normal source

of pressure is the electrical pump, and the auxiliary

source is the Ram Air Turbine (RAT). The Constant

Safety first #04 June 2017 - 1/5

FLIGHT CONTROLS

LANDING GEAR FLIGHT CONTROLS

BRAKES FLIGHT CONTROLS BRAKES

NOSE WHEEL STEER CONSTANT SPEED PARKING BRAKE

REVERSER ENG 1 MOTOR/GENERATOR REVERSER ENG 2

3000 PSI 3000 PSI POWER TRANSFER 3000 PSI

UNIT (PTU)

ACCUMULATOR ACCUMULATOR ACCUMULATOR

CARGO DOOR

ENGINE DRIVEN ENGINE DRIVEN

PUMP (EDP)1 PUMP (EDP) 2

S S

RAM AIR

TURBINE

M ELECTRIC M ELECTRIC

(RAT)

ENG 1 PUMP ENG 2 PUMP

FIRE FIRE

HAND

SHUT-OFF SHUT-OFF PUMP

VALVE VALVE

GREEN BLUE YELLOW

RESERVOIR RESERVOIR RESERVOIR

SYSTEM OVERVIEW / RAT

Example of architecture.

Aircraft pre modification 26925.

PTU is automatically

operated when a certain

ΔP (500PSI) appears

between Green

and Yellow circuits.

Safety first #04 June 2017 - 2/5

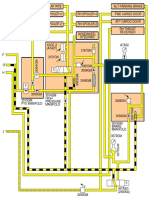

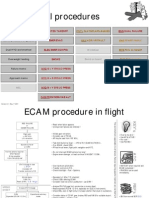

3 Dual hydraulic loss

scenario

The scenario of the dual hydraulic

loss is the following:

1) During takeoff, a leak in the

gear retraction circuit leads to

the loss of the green hydraulic

system. This loss stops the

retraction of the landing gear.

2) The 500 PSI pressure differen-

tial between the green and

yellow hydraulic pressure is

reached and the PTU auto-

matically switches ON.

3) The loss of the green system

normally triggers the corres-

ponding ECAM caution, which

requests the crew to switch off

the PTU.

4) However, below 1,500 feet, the

ECAM caution is inhibited.

5) The PTU therefore remains

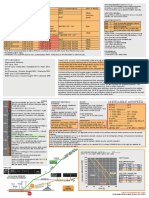

ON, and operates at its maxi- • In case of green low level, if PTU is not switched off this will lead to

mum speed. • A Yellow overheat (around 2 minutes later)

6) As a consequence of the non • Then to a double G+Y hydraulic failure

retraction of the landing gear,

the crew may be busy commu- G RSVR LO

nicating with ATC and mana- As a summary, LVL (inhibited G+Y SYS LO PR

the following figure below 1500ft) (displayed above 1500ft)

ging the situation, leaving the can be used to describe

aircraft flying below 1,500 feet shortly the scenario of

longer than usual, and thus Y RSVR

the dual hydraulic loss: OVHT

keeping the ECAM caution (inhibited below

1500ft)

inhibited.

1500ft

7) Within less than two minutes, Landing gear retraction

the PTU overheats the yellow tentative

hydraulic system and causes Green hydraulic

leakage

its loss. PTU &

pumps are

Lift off switched

PTU not OFF

switched

Automoatic OFF

stars

of the PTU

Sudden increase of PTU

duration

the hydraulic leak

Safety first #04 June 2017 - 3/5

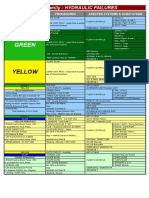

4 Corrective actions 5 Conclusion

This scenario already occurred in-service, leading The scenario of dual hydraulic loss occurred in-

to the following design change: service.

Below 1,500 feet the PTU is automatically switched l The green hydraulic system was lost during gear

to OFF. retraction.

l The PTU automatically switched ON.

This solution was preferred to the following l The ECAM warning requesting to switch OFF

alternatives: the PTU remained inhibited below 1,500 feet.

l Upgrading the ECAM caution to a red warning. l The aircraft remained below that altitude for more

l Cancelling the inhibition of the ECAM warning than two minutes after the start of the operation

below 1,500 feet. of the PTU, which led the yellow system to

overheat and caused its loss.

Indeed, red warnings require immediate action,

which is not justified in this case, and cancelling A design change has been developed, which

the inhibition would only overload the crew during consists in the automatic switching of the PTU to

a busy flight phase. OFF below 1,500 feet.

The operational consequences of such change

are described below: This change is covered

by the following modifications.

In case of hyd leak in flight:

• No longer risk of dual hydraulic loss if no rapid MOD 34236 + 35879 / SB 29-1115:

crew action. Install provisions for new PTU inhibition logic

• Follow “G(Y) SYS LO PR” ECAM caution when

MOD 35938 / SB 29-1126:

triggered.

Activate new PTU inhibition logic

Note: the ECAM procedure requests a manual

confirmation to switch off the PTU. Modifications 34236 & 35879

are now standard on production lines

In case of hyd leak on ground: from MSN2740.

• No PTU logic change: Modification 35938 is optional,

Follow “G(Y) SYS LO PR” ECAM caution and must be requested.

In case of single engine taxi, We therefore encourage airlines

or hydraulic pump failure to retrofit these modifications.

or engine failure…:

• No change : PTU runs to recover the normal

pressure in the affected system.

No ECAM change with new PTU

logic:

• ECAM still requests to switch OFF the PTU

– Only Pilot confirmation (in flight)

with new logic

– Common ECAM definition with old logic

Safety first #04 June 2017 - 4/5

Safety First

The Airbus Safety Magazine

For the enhancement of safe flight through

increased knowledge and communications.

Safety First is published by the Flight Safety Department requirements or technical orders. The contents do not

of Airbus. It is a source of specialist safety information supersede any requirements mandated by the State of

for the restricted use of flight and ground crew members Registry of the Operator’s aircraft or supersede or amend

who fly and maintain Airbus aircraft. It is also distributed any Airbus type-specific AFM, AMM, FCOM, MEL

to other selected organisations. documentation or any other approved documentation.

Material for publication is obtained from multiple sources Articles may be reprinted without permission, except where

and includes selected information from the Airbus Flight copyright source is indicated, but with acknowledgement

Safety Confidential Reporting System, incident and to Airbus. Where Airbus is not the author, the contents of

accident investigation reports, system tests and flight the article do not necessarily reflect the views of Airbus,

tests. Material is also obtained from sources within the neither do they indicate Company policy.

airline industry, studies and reports from government

agencies and other aviation sources. Contributions, comment and feedback are welcome. For

technical reasons the editors may be required to make editorial

All articles in Safety First are presented for information changes to manuscripts, however every effort will be made

only and are not intended to replace ICAO guidelines, to preserve the intended meaning of the original. Enquiries

standards or recommended practices, operator-mandated related to this publication should be addressed to:

Airbus

Product Safety department (GS)

1, rond point Maurice Bellonte

31707 Blagnac Cedex - France

Fax: +33(0)5 61 93 44 29

safetycommunication@airbus.com

Safety First

# 04 June 2007

Safety First is published

by Airbus S.A.S

1, rond point Maurice Bellonte

31707 Blagnac Cedex / France

© Airbus S.A.S. 2007 – All rights reserved. Confidential and proprietary documents.

Editors:

Yannick Malinge, By taking delivery of this Brochure (hereafter “Brochure”), you accept on behalf of your

Vice President Flight Safety company to comply with the following guidelines:

Christopher Courtenay, Ð No other intellectual property rights are granted by the delivery of this Brochure than the

Director of Flight Safety right to read it, for the sole purpose of information.

Concept Design by Ð This Brochure and its content shall not be modified and its illustrations and photos shall

HCSGM 20070592 not be reproduced without prior written consent of Airbus.

Production by Quat’coul

Ð This Brochure and the materials it contains shall not, in whole or in part, be sold,

Copyright: GSE rented, or licensed to any third party subject to payment.

Photos copyright Airbus This Brochure contains sensitive information that is correct at the time of going to press.

Photos by ExM: This information involves a number of factors that could change over time, effecting the

Hervé Berenger true public representation. Airbus assumes no obligation to update any information contained

Philippe Masclet in this document or with respect to the information described herein.

Hervé Goussé

Airbus SAS shall assume no liability for any damage in connection with the use of this

Printed in France Brochure and of the materials it contains, even if Airbus SAS has been advised of the

likelihood of such damages.

Safety first #04 June 2017 - 5/5

Вам также может понравиться

- A320 Mech BackupДокумент7 страницA320 Mech BackupPaschalis Paschalides67% (3)

- Engine Failure Above THR RED Altitude PDFДокумент27 страницEngine Failure Above THR RED Altitude PDFRajendra Dagaonkar50% (2)

- A320-Unreliable Speed IndicationДокумент6 страницA320-Unreliable Speed IndicationDavid Xue50% (2)

- MB A32F Ground Speed Mini - BulletinДокумент7 страницMB A32F Ground Speed Mini - BulletinMarcos Braga100% (1)

- FMA Presentation A320Документ153 страницыFMA Presentation A320Libya FreeОценок пока нет

- MB Eng Failure ECAM - PpsДокумент42 страницыMB Eng Failure ECAM - PpsMarcos Braga100% (1)

- A320-Slats or Flaps JammedДокумент19 страницA320-Slats or Flaps Jammedswathikanagarajan75% (4)

- A320 EIS FailureДокумент7 страницA320 EIS FailureMadhu Chopra100% (4)

- Airbus Stall and RecoveryДокумент30 страницAirbus Stall and RecoveryPablo CamachoОценок пока нет

- m03 29 Hydraulic PowerДокумент58 страницm03 29 Hydraulic Powermarshall100% (1)

- Manual de PFD FMA Airbus A320httpsyoutu - beub36ffWAqgQ 2Документ51 страницаManual de PFD FMA Airbus A320httpsyoutu - beub36ffWAqgQ 2Leonardo SerranoОценок пока нет

- Flexible Takeoff vs Derated TakeoffДокумент73 страницыFlexible Takeoff vs Derated TakeoffKunal HindujaОценок пока нет

- June 1997 North American Native Orchid JournalДокумент117 страницJune 1997 North American Native Orchid JournalNorth American Native Orchid JournalОценок пока нет

- Sistemas A320Документ115 страницSistemas A320Juan Pablo Montoya MОценок пока нет

- 29 Hydraulic PowerДокумент234 страницы29 Hydraulic PowerUcok BabaОценок пока нет

- Airbus A320 Primary Flight Controls - DutchOps - Com PoweredДокумент3 страницыAirbus A320 Primary Flight Controls - DutchOps - Com PoweredLaugh Generator100% (1)

- Organizational Transformations: Population Ecology TheoryДокумент25 страницOrganizational Transformations: Population Ecology TheoryTurki Jarallah100% (2)

- A380-Level II&III - Ata 29 Hydraulic PowerДокумент56 страницA380-Level II&III - Ata 29 Hydraulic Powerfiretooth10Оценок пока нет

- A320 Dual Hyd Lo LVLДокумент28 страницA320 Dual Hyd Lo LVLali4957270Оценок пока нет

- A320 AutothrustДокумент14 страницA320 AutothrusthhgaffadfОценок пока нет

- 15 Hidraulico Inicial A320 Alfa Jun23Документ78 страниц15 Hidraulico Inicial A320 Alfa Jun23Piloto TrujillanoОценок пока нет

- Figure 29-00-00-13400-00-U / SHEET 1/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Документ1 страницаFigure 29-00-00-13400-00-U / SHEET 1/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Pankaj SrivastavaОценок пока нет

- Figure 29-00-00-13400-00-U / SHEET 4/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Документ1 страницаFigure 29-00-00-13400-00-U / SHEET 4/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Pankaj SrivastavaОценок пока нет

- Tech Question BankДокумент105 страницTech Question BankChetna PuriОценок пока нет

- CFM56 Hydraulic Training ManualДокумент72 страницыCFM56 Hydraulic Training ManualHeber CastroОценок пока нет

- A320 Family HYDRAULIC FAILURES PDFДокумент2 страницыA320 Family HYDRAULIC FAILURES PDFPyong YangerОценок пока нет

- Aviate Navigate ManageДокумент1 страницаAviate Navigate ManagerpommerОценок пока нет

- ECAM Philosophy GuideДокумент35 страницECAM Philosophy GuideBhaskar Lal100% (1)

- Atr 72-500 Pilot HandbookДокумент27 страницAtr 72-500 Pilot HandbookFredyRedDevilz88% (8)

- Failure ManagmentДокумент2 страницыFailure ManagmentVan Loock BartОценок пока нет

- A320 Abnormal ProceduresДокумент26 страницA320 Abnormal ProceduresCarlos RicoОценок пока нет

- Choice of Take Off Config.: Preparation For Vac Oral InterviewДокумент24 страницыChoice of Take Off Config.: Preparation For Vac Oral Interviewflybearvaleriy100% (1)

- A320 TakeOffДокумент1 страницаA320 TakeOffHazemОценок пока нет

- Low VisДокумент13 страницLow VisVan Loock BartОценок пока нет

- Single Aisle Technical Training Manual T1+T2 (IAE V2500) (LVL 2&3) Hydraulic PowerДокумент130 страницSingle Aisle Technical Training Manual T1+T2 (IAE V2500) (LVL 2&3) Hydraulic Power이용일Оценок пока нет

- CTE A-320 QuestionsДокумент144 страницыCTE A-320 QuestionsSam Kapoor.100% (1)

- A320 SysДокумент18 страницA320 SysLibya FreeОценок пока нет

- Groundwater Control For Cross PassagesДокумент6 страницGroundwater Control For Cross PassageskrainajackaОценок пока нет

- Schneider Electric Strategy PresentationДокумент10 страницSchneider Electric Strategy PresentationDeepie KaurОценок пока нет

- A320 - A330 QRH Abnormal and Emergency Procedures SummaryДокумент8 страницA320 - A330 QRH Abnormal and Emergency Procedures SummaryAlexander Sturm50% (2)

- A330-Dual ADR FaultДокумент9 страницA330-Dual ADR Faultkelvinko0% (1)

- Engine Failure Above THR RED AltitudeДокумент27 страницEngine Failure Above THR RED AltitudeGopesh Obalappa100% (1)

- A320 Approach SpeedДокумент17 страницA320 Approach SpeedRodneyMashambaОценок пока нет

- Vragen VACBI A330-200 ATA 21Документ7 страницVragen VACBI A330-200 ATA 21Arkadiy Chernov100% (1)

- Abnormal NotesДокумент90 страницAbnormal NotesHaseeb Abu Alwan100% (2)

- A330 hydraulic training manual Trent 700Документ184 страницыA330 hydraulic training manual Trent 700Brayan Mejia VanegasОценок пока нет

- Single Aisle Technical Training Manual M35 LINE MECHANICS (IAE V2500) (LVL 2&3) Hydraulic PowerДокумент72 страницыSingle Aisle Technical Training Manual M35 LINE MECHANICS (IAE V2500) (LVL 2&3) Hydraulic Powermohan reddyОценок пока нет

- Takeoff RotationДокумент24 страницыTakeoff RotationJulioallendeОценок пока нет

- Abn Proc NotesДокумент21 страницаAbn Proc Notesdc932100% (1)

- RECURRENT A330 QUESTIONS C JANUARY To JUNE 2021 PILOTESДокумент7 страницRECURRENT A330 QUESTIONS C JANUARY To JUNE 2021 PILOTESHani Boudiaf100% (1)

- A320-Elec Emer ConfigДокумент15 страницA320-Elec Emer Configtugayyoung100% (4)

- A320 Memory Items PDFДокумент1 страницаA320 Memory Items PDFPai NangОценок пока нет

- Updated ADIRS and Inertial Reference System FunctionsДокумент51 страницаUpdated ADIRS and Inertial Reference System FunctionsJehad Badawi100% (2)

- Single Aisle Technical Training Manual T1 (CFM 56) (LVL 2&3) Hydraulic PowerДокумент120 страницSingle Aisle Technical Training Manual T1 (CFM 56) (LVL 2&3) Hydraulic Powersan2in100% (1)

- FCC TechДокумент13 страницFCC TechNguyen Thanh XuanОценок пока нет

- A320 CH 22 AutothrustДокумент34 страницыA320 CH 22 AutothrustVikramjit Banerjee100% (1)

- Wet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)Документ1 страницаWet With Sand or Dust: LPC Calculation Take-Off Is Not Authorised (Om A 8.3 8.3.3)patrouilledeafranceОценок пока нет

- Eazy Jet QuizДокумент13 страницEazy Jet Quizthe_gov100% (2)

- A320-Takeoff-Performance 2Документ6 страницA320-Takeoff-Performance 2HENIGUEDRIОценок пока нет

- A320 Abnormal Notes SummaryДокумент13 страницA320 Abnormal Notes SummaryDevdatt SondeОценок пока нет

- A320 PDP UpdateДокумент15 страницA320 PDP UpdateLohrasp Suraliwala100% (1)

- A.A AntagonismДокумент19 страницA.A Antagonismjraj030_2k6Оценок пока нет

- MTOW - Calc - Temp A320Документ51 страницаMTOW - Calc - Temp A320IlhamОценок пока нет

- A320-Dual HYD FaultДокумент12 страницA320-Dual HYD FaulttugayyoungОценок пока нет

- A320 - Hydraulic - Series 12 2023 MinДокумент6 страницA320 - Hydraulic - Series 12 2023 Minakshay.chauhan88Оценок пока нет

- NGV 2 Electdiag 1-10-02 14-09-03Документ58 страницNGV 2 Electdiag 1-10-02 14-09-03sanachОценок пока нет

- Potato Tuber CropsДокумент103 страницыPotato Tuber CropsNani NazirОценок пока нет

- Inmarsat M2M Terminal ComparisonДокумент2 страницыInmarsat M2M Terminal Comparisonmaruka33Оценок пока нет

- Pinto Pm2 Ch01Документ21 страницаPinto Pm2 Ch01Mia KulalОценок пока нет

- Kamencak D Dip LiteraturaДокумент2 страницыKamencak D Dip Literaturaprodaja47Оценок пока нет

- CARAGA REGIONAL SCIENCE HIGH SCHOOL ASSESSMENT #1Документ3 страницыCARAGA REGIONAL SCIENCE HIGH SCHOOL ASSESSMENT #1Joana Jean SuymanОценок пока нет

- Gautam KДокумент12 страницGautam Kgautam kayapakОценок пока нет

- Tribal Ethics of Mizo and Ao NagasДокумент8 страницTribal Ethics of Mizo and Ao NagasVincent TharteaОценок пока нет

- Classification of IndustriesДокумент17 страницClassification of IndustriesAdyasha MohapatraОценок пока нет

- Marketing Case Study - MM1 (EPGPX02, GROUP-06)Документ5 страницMarketing Case Study - MM1 (EPGPX02, GROUP-06)kaushal dhapareОценок пока нет

- Activity 1: 2. Does His Homework - He S 3 Late ForДокумент10 страницActivity 1: 2. Does His Homework - He S 3 Late ForINTELIGENCIA EDUCATIVAОценок пока нет

- NUC BIOS Update Readme PDFДокумент3 страницыNUC BIOS Update Readme PDFSuny Zany Anzha MayaОценок пока нет

- PB13MAT - 13 Project Stakeholder ManagementДокумент30 страницPB13MAT - 13 Project Stakeholder ManagementYudhi ChristianОценок пока нет

- Amgen Inc. v. F. Hoffmann-LaRoche LTD Et Al - Document No. 423Документ19 страницAmgen Inc. v. F. Hoffmann-LaRoche LTD Et Al - Document No. 423Justia.comОценок пока нет

- An Equivalent SDOF System Model For Estimating The Earthquake Response of R/C Buildings With Hysteretic DampersДокумент8 страницAn Equivalent SDOF System Model For Estimating The Earthquake Response of R/C Buildings With Hysteretic DampersAlex MolinaОценок пока нет

- ĐỀ MINH HỌA 15-19Документ25 страницĐỀ MINH HỌA 15-19Trung Vũ ThànhОценок пока нет

- Aerospace Propulsion Course Outcomes and Syllabus OverviewДокумент48 страницAerospace Propulsion Course Outcomes and Syllabus OverviewRukmani Devi100% (2)

- Connotative and Denotative, Lexical and StylisticДокумент3 страницыConnotative and Denotative, Lexical and StylisticEman Jay FesalbonОценок пока нет

- Christian Ministry Books: 00-OrientationGuideДокумент36 страницChristian Ministry Books: 00-OrientationGuideNessieОценок пока нет

- June 3rd 1947 Partition PlanДокумент2 страницыJune 3rd 1947 Partition PlanZ_Jahangeer88% (16)

- Shell Rimula R7 AD 5W-30: Performance, Features & Benefits Main ApplicationsДокумент2 страницыShell Rimula R7 AD 5W-30: Performance, Features & Benefits Main ApplicationsAji WibowoОценок пока нет

- Product Data: Real-Time Frequency Analyzer - Type 2143 Dual Channel Real-Time Frequency Analyzers - Types 2144, 2148/7667Документ12 страницProduct Data: Real-Time Frequency Analyzer - Type 2143 Dual Channel Real-Time Frequency Analyzers - Types 2144, 2148/7667jhon vargasОценок пока нет

- Samonte Vs CAДокумент7 страницSamonte Vs CAMaricel Caranto FriasОценок пока нет

- Ganuelas v. CawedДокумент4 страницыGanuelas v. CawedHanna AlfantaОценок пока нет

- Polyester Staple Fibre Product ListДокумент2 страницыPolyester Staple Fibre Product Listnunu7478Оценок пока нет