Академический Документы

Профессиональный Документы

Культура Документы

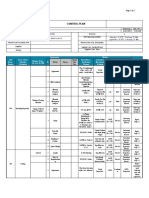

Part Number Part Name Customer Auditor Name: Audit Date

Загружено:

BARDLYОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Part Number Part Name Customer Auditor Name: Audit Date

Загружено:

BARDLYАвторское право:

Доступные форматы

Part Number Part Name Customer Auditor Name : Audit Date :

OK Complete Action

PROCESS CONTROL ITEM Std Spec. Finding/Actual Data Corrective Action

/NG Date Section/PIC

1. Material Material Name

Material Maker

Material Symbol

Dimensional Material Thickness

Standard Material Width

Stocking Qty /Time

Keeping Method

First-in , First-out , Control

2. Machine/ Press machine name / Tonnage

Process Revolution of Crank type

Condition Lubricant Oil Name & Type No.

Material feeding (Auto/Manual).

Parts Release method(Auto/Air/Manual)

Press

Number of Process stage

Machine

Main Air Pressure

Lubrication Oil Pressure

Die Height

Maximum stroke(spm)

Machine PM check

Maintenance Item

Check Record

Tooling

Cutting Blade Validity

Die structure change record

3. Washing Machine Name /Type

Rust Solution maker /name

Washing

No. of quantity /time

Work Guide check

5. Secondary

Process

4.Lot Lot Define

Identification Process Lot Mark Method

Process History

In Case of Trouble shoot Method

Trouble Trouble shoot History

5. IPQC / OQC No. of Item check

Control Sampling size

Check Interval

In-Process

Data Sheet

Control

Appearance Caution sheet

Appearance check Method

Action at Unusual(Machine stop)

No. of Item check

Sampling size

Out-going

Data Sheet

Control

Appearance Caution sheet

Appearance check Method

Std Spec

Measuring-1 Tool

Method

Std Spec

Measuring-2 Tool

Method

Std Spec

Measuring-3 Tool

Method

6. Final Product Work Instruction

Packaging

Arrangement Material & Quality

Periodacally Dust confirmation

Identification label /FIFO system

Warehouse Storage area/Location

Environment (Dust/humidity control)

Вам также может понравиться

- Control Plan-General SampleДокумент7 страницControl Plan-General SampleMartin PetricОценок пока нет

- Never Can Say Goodbye Katherine JacksonДокумент73 страницыNever Can Say Goodbye Katherine Jacksonalina28sept100% (5)

- COMPOSITION Analysis of A Jazz StandardДокумент9 страницCOMPOSITION Analysis of A Jazz StandardAndresОценок пока нет

- Control PlanДокумент9 страницControl Planjose antonioОценок пока нет

- Control Plan TrainingДокумент20 страницControl Plan TraininglittlekheongОценок пока нет

- Control Plan & FmeaДокумент9 страницControl Plan & FmeaManu SharmaОценок пока нет

- Method Validation ProtocolДокумент17 страницMethod Validation ProtocolDilawar Bakht100% (2)

- CR Injector Repair Kits 2016Документ32 страницыCR Injector Repair Kits 2016Euro Diesel100% (2)

- PPAP Workbook TemplateДокумент18 страницPPAP Workbook TemplateRaju.PalОценок пока нет

- 7 Strategies To Assess Learning NeedsДокумент11 страниц7 Strategies To Assess Learning Needshammouam100% (1)

- Incoming Inspection ReportДокумент19 страницIncoming Inspection ReportManikandanОценок пока нет

- Control PlanДокумент11 страницControl PlanRadhika GuptaОценок пока нет

- Control Plan Template 2011 PDFДокумент1 страницаControl Plan Template 2011 PDFSenthil_KОценок пока нет

- CP20200804-A Model Control Plan - FoundationsДокумент6 страницCP20200804-A Model Control Plan - Foundationsmanno200Оценок пока нет

- MRA Project Milestone 2Документ20 страницMRA Project Milestone 2Sandya Vb69% (16)

- Quality Control PlanДокумент1 страницаQuality Control PlanScha Affin100% (1)

- Quality Problem Corrective Action - QPCAДокумент3 страницыQuality Problem Corrective Action - QPCAsateeshkoriОценок пока нет

- FM - MKT - 02 Quality Control Process ChartДокумент4 страницыFM - MKT - 02 Quality Control Process Chartbarja subarjaОценок пока нет

- Control Plan For Zinc Flake CoatingДокумент3 страницыControl Plan For Zinc Flake Coatingx y100% (1)

- Control Plan ExampleДокумент1 страницаControl Plan Examplelingkungan.agathaОценок пока нет

- Control Plan TrainingДокумент20 страницControl Plan TrainingAbi Parilla100% (2)

- Process Flow Fmea Control PlanДокумент5 страницProcess Flow Fmea Control Plansudeep_singh1Оценок пока нет

- Total Quality Process Control for Injection MoldingОт EverandTotal Quality Process Control for Injection MoldingРейтинг: 5 из 5 звезд5/5 (1)

- Synthesis - Mind Rubrics: Moderator Dr.P.Satyaveni M.D.Homoeo Dept of RepertoryДокумент79 страницSynthesis - Mind Rubrics: Moderator Dr.P.Satyaveni M.D.Homoeo Dept of RepertorySharika BachuОценок пока нет

- Control Plan TrainingДокумент20 страницControl Plan TrainingGAURAV SHARMAОценок пока нет

- BuildingBotWithWatson PDFДокумент248 страницBuildingBotWithWatson PDFjavaarchОценок пока нет

- Laurel VS GarciaДокумент2 страницыLaurel VS GarciaRon AceОценок пока нет

- Foreign Policy During Mahathir EraДокумент7 страницForeign Policy During Mahathir EraMuhamad Efendy Jamhar0% (1)

- The Flowers of May by Francisco ArcellanaДокумент5 страницThe Flowers of May by Francisco ArcellanaMarkNicoleAnicas75% (4)

- BASICS of Process ControlДокумент31 страницаBASICS of Process ControlMallikarjun ManjunathОценок пока нет

- Control Plan TemplateДокумент1 страницаControl Plan TemplaterajarajanОценок пока нет

- Format 9 - Control PlanДокумент1 страницаFormat 9 - Control PlanvijayОценок пока нет

- Pro-Quality Associates Control PlanДокумент1 страницаPro-Quality Associates Control PlanDeepak kumarОценок пока нет

- Pro-Quality Associates Control PlanДокумент1 страницаPro-Quality Associates Control PlanDeepak kumarОценок пока нет

- Template Traceability Audit Checklist ExampleДокумент2 страницыTemplate Traceability Audit Checklist ExampleTrinh DuОценок пока нет

- 1 Process Control Plan FormatДокумент1 страница1 Process Control Plan FormatNirmal WiresОценок пока нет

- Control Plan: Cervantes Chavez, Sanchez Hernandez, Espinoza Rodriguez, Torres MuñizДокумент8 страницControl Plan: Cervantes Chavez, Sanchez Hernandez, Espinoza Rodriguez, Torres MuñizLuis Guillermo Cervantes ChávezОценок пока нет

- Control Plan H.TДокумент1 страницаControl Plan H.TABHISHEK PANDEYОценок пока нет

- Control PlanДокумент1 страницаControl Plansantosh kumarОценок пока нет

- Control Plan: Prototype Pre-Launch XДокумент1 страницаControl Plan: Prototype Pre-Launch XkishortilekarОценок пока нет

- Saudi Aramco Test ReportДокумент8 страницSaudi Aramco Test Reportnadeem shaikhОценок пока нет

- InspectionДокумент1 страницаInspectionvg_vvgОценок пока нет

- Control Plan TRANINGДокумент18 страницControl Plan TRANINGqualityОценок пока нет

- Basic Seven ToolsДокумент33 страницыBasic Seven ToolsSin TungОценок пока нет

- Control PlanДокумент6 страницControl PlanEshioОценок пока нет

- Control Plan: Process Characteristics Machines, Fixture, Tools, Manufacture Op Sequence NumberДокумент4 страницыControl Plan: Process Characteristics Machines, Fixture, Tools, Manufacture Op Sequence Numberske-schneider.plОценок пока нет

- Instructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224Документ7 страницInstructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224IrmaMedinaОценок пока нет

- Saudi Aramco Test ReportДокумент2 страницыSaudi Aramco Test Reportnadeem shaikhОценок пока нет

- Satr A 2010Документ2 страницыSatr A 2010nadeem shaikhОценок пока нет

- Saudi Aramco Test ReportДокумент2 страницыSaudi Aramco Test ReportEswari AnandОценок пока нет

- SAIC-A-1015 Rev 8 HDPE Liner Receic Ving and Storage Insp Final.Документ1 страницаSAIC-A-1015 Rev 8 HDPE Liner Receic Ving and Storage Insp Final.Tito GarciaОценок пока нет

- Saudi Aramco Test ReportДокумент2 страницыSaudi Aramco Test ReportPradeepОценок пока нет

- Layered Process Audit ChecklistДокумент1 страницаLayered Process Audit ChecklistMuniyappan TОценок пока нет

- Control Plan TemplateДокумент1 страницаControl Plan TemplateWelbert ChavesОценок пока нет

- Control Plan TemplateДокумент1 страницаControl Plan Templateharish puОценок пока нет

- Instructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224Документ13 страницInstructions © 2010 Knowware International Inc: Sheet 2253 S Oneida ST Ste 3D Denver, Co 80224Ruanda NelОценок пока нет

- Satr A 2001Документ8 страницSatr A 2001ansar aliОценок пока нет

- 8D For ID Over sizeTECUMSEHДокумент4 страницы8D For ID Over sizeTECUMSEHKuldeep SinghОценок пока нет

- Quality Control PlanДокумент1 страницаQuality Control PlanM. Pandu SetiawanОценок пока нет

- Page 1 of 1: Control PlanДокумент1 страницаPage 1 of 1: Control PlannormalОценок пока нет

- Advanced AuditДокумент3 страницыAdvanced AuditHoai thu NguyenОценок пока нет

- Control Plan Form VAДокумент33 страницыControl Plan Form VAsanjoyОценок пока нет

- Validating The Training ProcessДокумент46 страницValidating The Training ProcessLamiaa JadidОценок пока нет

- Prototype Control Plan Worksheet 1Документ1 страницаPrototype Control Plan Worksheet 1pankaj100% (1)

- QCTR-A-2013 Rev 0Документ2 страницыQCTR-A-2013 Rev 0Madhan KannanОценок пока нет

- Product Quality Plan (PQP)Документ2 страницыProduct Quality Plan (PQP)Jolene JourneОценок пока нет

- Test Plan Quality PlanДокумент6 страницTest Plan Quality PlanPhucОценок пока нет

- Saudi Aramco Test ReportДокумент6 страницSaudi Aramco Test ReportGOSP3 QC MechanicalОценок пока нет

- F-PD-02 Control PlanДокумент1 страницаF-PD-02 Control PlanTrivesh SharmaОценок пока нет

- Satr A 2001Документ8 страницSatr A 2001razzak.me.enggОценок пока нет

- Cambridge Latin Course Book I Vocabulary Stage 1 Stage 2Документ3 страницыCambridge Latin Course Book I Vocabulary Stage 1 Stage 2Aden BanksОценок пока нет

- Educational Psychology EDU-202 Spring - 2022 Dr. Fouad Yehya: Fyehya@aust - Edu.lbДокумент31 страницаEducational Psychology EDU-202 Spring - 2022 Dr. Fouad Yehya: Fyehya@aust - Edu.lbLayla Al KhatibОценок пока нет

- Organisational Behaviour - II India Yamaha Motors Interim PPT (Download To View Full Presentation)Документ28 страницOrganisational Behaviour - II India Yamaha Motors Interim PPT (Download To View Full Presentation)mahtaabkОценок пока нет

- Rulings On MarriageДокумент17 страницRulings On MarriageMOHAMED HAFIZ VYОценок пока нет

- Interpret Market Trends and Developments TASk 1Документ7 страницInterpret Market Trends and Developments TASk 1Raí SilveiraОценок пока нет

- Theater - The View ArticleДокумент2 страницыTheater - The View ArticleRishi BhagatОценок пока нет

- Gullivers TravelДокумент3 страницыGullivers TravelRanen Das MishukОценок пока нет

- Chapter 7: Identifying and Understanding ConsumersДокумент3 страницыChapter 7: Identifying and Understanding ConsumersDyla RafarОценок пока нет

- Rule Against Multiplicity and Child PornoДокумент3 страницыRule Against Multiplicity and Child PornoHouston Criminal Lawyer John T. FloydОценок пока нет

- KANDIDAT (Jurnal Mahasiswa Universitas Abulyatama)Документ8 страницKANDIDAT (Jurnal Mahasiswa Universitas Abulyatama)intan fazlianiОценок пока нет

- Mamaoui PassagesДокумент21 страницаMamaoui PassagesSennahОценок пока нет

- Chapter 6 - Scheduling AlgorithmДокумент42 страницыChapter 6 - Scheduling AlgorithmBinyam KebedeОценок пока нет

- Future Dusk Portfolio by SlidesgoДокумент40 страницFuture Dusk Portfolio by SlidesgoNATALIA ALSINA MARTINОценок пока нет

- History RizalДокумент6 страницHistory RizalIrvin LevieОценок пока нет

- Remarkings AirportsДокумент1 страницаRemarkings AirportsJuan Jose CaleroОценок пока нет

- Hapter 2: Theoretical FrameworkДокумент18 страницHapter 2: Theoretical FrameworkMohamed HamzaОценок пока нет

- Failure of Composite Materials PDFДокумент2 страницыFailure of Composite Materials PDFPatrickОценок пока нет

- Exercise Reported SpeechДокумент3 страницыExercise Reported Speechapi-241242931Оценок пока нет

- 5568 AssignmentДокумент12 страниц5568 AssignmentAtif AliОценок пока нет