Академический Документы

Профессиональный Документы

Культура Документы

Floating Floc Issues in Raw Water Clarifier

Загружено:

ja23gonzОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Floating Floc Issues in Raw Water Clarifier

Загружено:

ja23gonzАвторское право:

Доступные форматы

7/5/2019 Poor Raw Water Clarifier Preformance - Floating Floc - Flat

Water DiscussionsPoor Raw Water Clarifier Preformance - Floating Floc Flat

Posted By Post

Started: 6/28/2019 9:00 AM View Properties Reply

Poor Raw Water Clarifier Preformance - Floating Floc

My customer is struggling to improve effluent quality in their lamella style raw water clarifier. The flowrate through the equipment is understood to be ~150gal/min too high

for the size of the unit to promote good settling and consistent effluent quality, but due to water demand of the plant the flow must be kept at this rate. Coagulant and

Pennell, Alicia flocculant dosages have been confirmed appropriate in many jar tests, however effluent quality is poor, with visible floc being carried out to the pressure filters and the

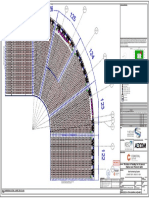

demin trains down stream. Floc seems to be floating in large amounts rather than settling, see picture attached. Due to the amount of floating sludge the customer

frequently needs to drain the clarifier and clean it. They drain water level to below their settlers and wash using a hose to force floating floc back down below

the sludge settling columns or honeycombs. This rarely helps for long if at all.

There is no sludge recirculation in this unit. The clarifier sludge valleys are blown down 2X/day. If initial blow down is clear the valleys are backwashed and blown down again

until the water runs clear.

Any similar experience or suggestions to improve floc settling and effluent quality would be appreciated.

Thanks

Posted: 6/28/2019 3:14 PM View Properties Reply

Hi Alicia,

What coagulant and flocculant is being used and at what dosages? Have they increased or decreased the water treatment chemistries to see how that changes the

system? How much of an increase is 150 gal/min over design What is the quality of the influent and what are the KPIs of the system? Does the influent water quality change

over time/does it change rapidly?

Duttlinger Jr, William Not sure if there is an ITC in your area. If there is, give them a shout and see if you can get a field visit. Otherwise, I'd be happy to try to help as best I can.

Regards,

Bill

Posted: 7/3/2019 10:12 AM View Properties Reply

One other question I had was regarding injection points: Where are they in relation to the clarifier?

Duttlinger Jr, William

Posted: 7/4/2019 7:23 PM View Properties Reply

Hello Alicia, I am an ITC with OFC Upstream Water Solutions. A Lamella clarifier desires to run at the unit's specific design. They are not as forgiving like a dissolved air

floatation unit (DAF) that includes energy. If the Lamella influent rate is higher than the design, the clarification will struggle with providing efficient settling and result

in carryover even if the jar test indicates the type chemistry and dose is right. Excessive flowrate will cause disruption of the settling in the plates and chronic carryover. If

the water quality (oil, TDS, TSS) is laden and you apply chemistry to enhance clarification to generate liquid / solids separation and the clarifier is at flow rate higher than the

clarifier can handle, you will see what you are seeing. The plates / packing can load too fast or not allow good solids settling and after that the solids have to go somewhere

Schellenberg, John which is carryover. Once the clarifier is at maximum loading, there is no where for the solids to go except as carryover. If at the cleaning cycle they are not getting clean

enough, when they put the unit back in service you will loose solids capture since solids are already in the packing and shortens run and then carryover. In addition, you

may find changing the chemistry may help if you can tighten up the solids to improve settling efficiency. This will take more bench testing. In your bench jar testing do you

see significant floating solids on top of the jar sample, center of the jar is clear and there are solids settled on the bottom? If there is an underfeed or over feed of chemistry

you can experience poor separation and carryover.

Need to review where the chemicals are being fed, feed method and if are subjected to enough energy for good mixing. Are you using a coagulant and flocculant

combination? IF using a flocculant are you using a make down unit or other? You maybe able to get some relief with addition of a coagulant aid (current coagulant plus the

aid) to optimize solids settling. What is the actual products you are using at this time? What is the pH of the water and do you have influent and effluent water quality test

data?

Maybe prudent to have their engineer or their clarifier provider to review the mass balance for the mechanics. Have not seen your process survey and if you are onshore or

offshore, but if they are open to redesign, upgrade or possibly adding another clarification stage, they maybe able to reduce the carryover to get some relief. For simple

example, if the water is very oily, you could remove more oil in a 1st stage clarifier (oil/water separator) to reduce load to the Lamella clarifier/2nd stage. This is not

uncommon configuration for oily produced water. Let me know if I can help.

https://core.champ-tech.com/Wat/Lists/Discussions/Flat.aspx?RootFolder=%2fWat%2fLists%2fDiscussions%2fPoor Raw Water Clarifier Preformance … 1/1

Вам также может понравиться

- Water StructuringДокумент22 страницыWater StructuringBlack Hat100% (11)

- Primary Mathematics Book 5Документ87 страницPrimary Mathematics Book 5joseph kunikina0% (1)

- Rotor Weighfeeder Pfister DRW: Highly Accurate and Reliable Gravimetric Feeding of Pulverised FuelДокумент24 страницыRotor Weighfeeder Pfister DRW: Highly Accurate and Reliable Gravimetric Feeding of Pulverised Fuelja23gonzОценок пока нет

- LTE Advanced - Leading in Chipsets and Evolution: August 2013Документ33 страницыLTE Advanced - Leading in Chipsets and Evolution: August 2013Muneeb JavedОценок пока нет

- KSB Megaflow V: Pumps For Sewage, Effuents and MisturesДокумент18 страницKSB Megaflow V: Pumps For Sewage, Effuents and MisturesKorneliusОценок пока нет

- Consumer's Manual: 12 Volt Electronics, Shown With Optional 18x33 Blue Brine TankДокумент16 страницConsumer's Manual: 12 Volt Electronics, Shown With Optional 18x33 Blue Brine TankGisell ZapataОценок пока нет

- Attachment-4 D Dolphin Ineffective Replaced With ChemicalsДокумент13 страницAttachment-4 D Dolphin Ineffective Replaced With Chemicalsapi-392139141Оценок пока нет

- Jar TestДокумент2 страницыJar TestKaith GallegoОценок пока нет

- ACTEGA Kelstar Fountain Solution Troubleshooting GuideДокумент11 страницACTEGA Kelstar Fountain Solution Troubleshooting GuideJavier Martinez CañalОценок пока нет

- Jar TestДокумент3 страницыJar Testkhairil akramОценок пока нет

- Jar Test ProcedureДокумент5 страницJar Test ProceduresaaroomaniОценок пока нет

- Jar Test ProcedureДокумент6 страницJar Test ProcedureleonardseniorОценок пока нет

- As Level Osmosis CourseworkДокумент8 страницAs Level Osmosis Courseworkraxdouvcf100% (2)

- Imploder ApplicationsДокумент3 страницыImploder ApplicationsElwa SzaboОценок пока нет

- Water Treatment Processes - Coagulation and Flocculation ExplainedДокумент7 страницWater Treatment Processes - Coagulation and Flocculation ExplainedDr-Manoj GargОценок пока нет

- End TermДокумент9 страницEnd TermEducation PecОценок пока нет

- Jar Test Optimal CoagulationДокумент6 страницJar Test Optimal CoagulationPortia ShilengeОценок пока нет

- D0D009BCd01-Saltmaster ManualДокумент4 страницыD0D009BCd01-Saltmaster ManualGeoff DavisОценок пока нет

- Glencoe 2008 Chemlab Hard WaterДокумент3 страницыGlencoe 2008 Chemlab Hard WaterNear ChemОценок пока нет

- Biology Coursework Osmosis A LevelДокумент5 страницBiology Coursework Osmosis A Levelafiwjkfpc100% (2)

- Using Bleaching PowderДокумент11 страницUsing Bleaching PowderNishant PatelОценок пока нет

- 01-Chemistry Project G12Документ13 страниц01-Chemistry Project G12HS SHARATHОценок пока нет

- VishalДокумент12 страницVishalsoumya.sj09Оценок пока нет

- Ocr Biology Coursework OsmosisДокумент4 страницыOcr Biology Coursework Osmosisvup0nemyj1n3100% (2)

- Puresilk Salt ChlorinatorДокумент10 страницPuresilk Salt Chlorinatornike_y2kОценок пока нет

- Osmosis Coursework A LevelДокумент6 страницOsmosis Coursework A Levelf5dvx95v100% (2)

- Membrane Maintenance: Faqs: Reverse Osmosis WaterДокумент4 страницыMembrane Maintenance: Faqs: Reverse Osmosis WaterTINALEETNT723Оценок пока нет

- Unit 2 SummaryДокумент22 страницыUnit 2 SummaryPutu HermayaniОценок пока нет

- Qualitative AnalysisДокумент16 страницQualitative AnalysisSHAFIQ SUBAHIRОценок пока нет

- Operation Water Biology Lessons Cover Chlorination and Contaminant RemovalДокумент16 страницOperation Water Biology Lessons Cover Chlorination and Contaminant RemovalCollet NdlovuОценок пока нет

- Optimize Water Treatment with Jar TestingДокумент26 страницOptimize Water Treatment with Jar Testingsunil kumar ojhaОценок пока нет

- Osmosis Investigation Coursework PotatoДокумент5 страницOsmosis Investigation Coursework Potatoafjwdprlzaxewj100% (2)

- Sanitizing Stored Water Supplies: Guide W-101Документ2 страницыSanitizing Stored Water Supplies: Guide W-101kathlene keith navarroОценок пока нет

- Optimized Solids Suspension: Achieving Uniform Dispersion is Critical to Product QualityДокумент7 страницOptimized Solids Suspension: Achieving Uniform Dispersion is Critical to Product QualitymichsantosОценок пока нет

- Water Softener Terminology Explained: Getting To Know Hard Water TermsДокумент6 страницWater Softener Terminology Explained: Getting To Know Hard Water Termsnermeen ahmedОценок пока нет

- Literature Review OsmosisДокумент8 страницLiterature Review Osmosisafdtvovhb100% (1)

- Chemistry ProjectДокумент14 страницChemistry ProjectTarun GuptaОценок пока нет

- Operator Reference Sheet MathДокумент5 страницOperator Reference Sheet MathPrashant RukmangadОценок пока нет

- Biology Coursework OsmosisДокумент7 страницBiology Coursework Osmosiszgctgvvcf100% (2)

- Coagulant ChemicalsДокумент7 страницCoagulant ChemicalsmouselineОценок пока нет

- Foaming in The Cooling Tower - FlatДокумент1 страницаFoaming in The Cooling Tower - FlatJavier GonzalezОценок пока нет

- Experiment 12: Qualitative Analysis of Cations: Pre-Laboratory AssignmentДокумент16 страницExperiment 12: Qualitative Analysis of Cations: Pre-Laboratory AssignmentMuhaimin ApekОценок пока нет

- Biology As Level Coursework OsmosisДокумент4 страницыBiology As Level Coursework Osmosisafiwgjbkp100% (2)

- Jar Test Lab ReportДокумент7 страницJar Test Lab ReportTeCkMunОценок пока нет

- Aquaponics Filtration Systems Explained - How To AquaponicДокумент6 страницAquaponics Filtration Systems Explained - How To AquaponicDhanraj PatilОценок пока нет

- Hellenbrand Residential Water Softener Promate6 Consumers Manual PDFДокумент16 страницHellenbrand Residential Water Softener Promate6 Consumers Manual PDFsteve_vtОценок пока нет

- Water Filters Be Replacement FrequencyДокумент3 страницыWater Filters Be Replacement Frequencychootymalli9760Оценок пока нет

- 5-Waters in One MachineДокумент2 страницы5-Waters in One MachineTony GarciaОценок пока нет

- Guide For DLS Sample Preparation: Eric Farrell & Jean-Luc Brousseau PH.DДокумент3 страницыGuide For DLS Sample Preparation: Eric Farrell & Jean-Luc Brousseau PH.DDeidre CadeОценок пока нет

- Jar Test Lab ReportДокумент20 страницJar Test Lab Reportkhairulhakam33% (3)

- Assessment of Sterilization of WaterДокумент15 страницAssessment of Sterilization of WaterR.P.M VideosОценок пока нет

- Lab Report Waste Water 1Документ10 страницLab Report Waste Water 1eidalinОценок пока нет

- Research Paper On Osmosis in PotatoesДокумент7 страницResearch Paper On Osmosis in Potatoesafnhgssontbxkd100% (1)

- Water: The Foundation of Life: No Living Thing On Earth Can Survive in The Absolute Absence of Water. ItДокумент2 страницыWater: The Foundation of Life: No Living Thing On Earth Can Survive in The Absolute Absence of Water. ItStere StereОценок пока нет

- Pool Maintenance ProceduresДокумент4 страницыPool Maintenance ProceduresSean OsborneОценок пока нет

- The Guide For Water Softening (Impt)Документ10 страницThe Guide For Water Softening (Impt)ambuenaflorОценок пока нет

- Hard Water CourseworkДокумент6 страницHard Water Courseworkf5e28dkq100% (2)

- Assignment 7Документ7 страницAssignment 7JejeОценок пока нет

- Household Water Quality Water HardnessДокумент4 страницыHousehold Water Quality Water HardnessAquasafeSystemsОценок пока нет

- Osmosis in Potatoes CourseworkДокумент7 страницOsmosis in Potatoes Courseworkf675ztsf100% (2)

- FDA Disclaimer for Cosmic Energy Stones and WaterДокумент25 страницFDA Disclaimer for Cosmic Energy Stones and WaterOsamah Bakerman100% (1)

- WL1 and AF1 Virginia Form P-378 Product BulletinДокумент2 страницыWL1 and AF1 Virginia Form P-378 Product BulletinTwisty OliverОценок пока нет

- Neutralizing Amine Overdosing Risks - Vacuum Overhead - FlatДокумент1 страницаNeutralizing Amine Overdosing Risks - Vacuum Overhead - Flatja23gonzОценок пока нет

- Pitting Corrosion Rate - Flat PDFДокумент1 страницаPitting Corrosion Rate - Flat PDFja23gonzОценок пока нет

- How Come From Colloidal Silica For Raw Water - FlatДокумент1 страницаHow Come From Colloidal Silica For Raw Water - Flatja23gonzОценок пока нет

- High Potential Near MissДокумент12 страницHigh Potential Near Missja23gonzОценок пока нет

- Crude Unit Overhead Corrosion - Velocity of EC1010H - FlatДокумент3 страницыCrude Unit Overhead Corrosion - Velocity of EC1010H - Flatja23gonzОценок пока нет

- Entrenamiento COMPASSДокумент8 страницEntrenamiento COMPASSja23gonzОценок пока нет

- Delayed Coker SW Impacting SWS - FlatДокумент1 страницаDelayed Coker SW Impacting SWS - Flatja23gonzОценок пока нет

- Pitting Corrosion Rate - FlatДокумент1 страницаPitting Corrosion Rate - Flatja23gonzОценок пока нет

- CW Closed Loop System - Nitrite PH Control - FlatДокумент1 страницаCW Closed Loop System - Nitrite PH Control - Flatja23gonzОценок пока нет

- Pregunta: Servicios IndustrialesДокумент2 страницыPregunta: Servicios Industrialesja23gonzОценок пока нет

- Fe Publica Merly Castro GomezДокумент4 страницыFe Publica Merly Castro Gomezja23gonzОценок пока нет

- Scilab Reference Manual Online DocumentationДокумент649 страницScilab Reference Manual Online DocumentationJeanMichelMОценок пока нет

- Ref Paper 2Документ4 страницыRef Paper 2Subhanjali MyneniОценок пока нет

- Friday Night FightsДокумент8 страницFriday Night Fightsapi-629904068Оценок пока нет

- Damage To Stern Tube Bearing and SealsДокумент4 страницыDamage To Stern Tube Bearing and SealsJoão Henrique Volpini MattosОценок пока нет

- ESG Service Information: BackgroundДокумент6 страницESG Service Information: BackgroundAbdulSattarОценок пока нет

- Siemens 1LE1 PDFДокумент308 страницSiemens 1LE1 PDFharold100% (1)

- Timeline of Programming Languages PDFДокумент11 страницTimeline of Programming Languages PDFMohd Khir ZainunОценок пока нет

- Aikah ProfileДокумент20 страницAikah ProfileMohammad ZeeshanОценок пока нет

- Environmentally-Friendly LPG Forklift Trucks with Superior Power & PerformanceДокумент5 страницEnvironmentally-Friendly LPG Forklift Trucks with Superior Power & PerformanceCarlos Miguel Apipilhuasco GonzálezОценок пока нет

- Gillette and The Men's Wet Shaving Market: Group 8 Section BДокумент12 страницGillette and The Men's Wet Shaving Market: Group 8 Section BAmit Hemant JainОценок пока нет

- OFFICE 365 PROXY GUIDEДокумент4 страницыOFFICE 365 PROXY GUIDErossloveladyОценок пока нет

- AMG ActuatorsДокумент12 страницAMG ActuatorsMohan ArumugavallalОценок пока нет

- Understand Centrifugal CompressorДокумент16 страницUnderstand Centrifugal Compressorramanathan72-1100% (2)

- Mechanical Engineer Resume - Digambar BhangeДокумент3 страницыMechanical Engineer Resume - Digambar BhangeTOP DHAMAKAОценок пока нет

- 3P61 Service Manual PDFДокумент17 страниц3P61 Service Manual PDFgulaab786Оценок пока нет

- Brigada Eskwela Activities With PicsДокумент6 страницBrigada Eskwela Activities With PicsCharisse TocmoОценок пока нет

- Milenium BypassДокумент1 страницаMilenium BypassdinotecОценок пока нет

- Smart Payment MeterДокумент2 страницыSmart Payment MeterJesus Castro OrozcoОценок пока нет

- Intermot Hydraulic Motors IAM+ Series Technical CatalogueДокумент81 страницаIntermot Hydraulic Motors IAM+ Series Technical CatalogueeduardoraulОценок пока нет

- 12 Fa02Документ4 страницы12 Fa02corsovaОценок пока нет

- Nec 2006Документ59 страницNec 2006loots69Оценок пока нет

- INFRARED BASED VISITOR COUNTER TECHNOLOGYДокумент21 страницаINFRARED BASED VISITOR COUNTER TECHNOLOGYRahul KumarОценок пока нет

- SE01 SE04 SE03 SE02 E14 E13: As BuiltДокумент1 страницаSE01 SE04 SE03 SE02 E14 E13: As BuiltgenricОценок пока нет

- 176Документ3 страницы176Karthik AmigoОценок пока нет

- August 2017Документ72 страницыAugust 2017Treatment Plant Operator MagazineОценок пока нет

- Julia Warner 2018Документ1 страницаJulia Warner 2018Julia WarnerОценок пока нет

- Panasonic WJ FS616Документ62 страницыPanasonic WJ FS616triliteОценок пока нет