Академический Документы

Профессиональный Документы

Культура Документы

Oil Water Separator

Загружено:

Panagiotis MouzenidisИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Oil Water Separator

Загружено:

Panagiotis MouzenidisАвторское право:

Доступные форматы

An oily water separator (OWS) (marine) is a piece of equipment specific to the shipping or marine industry.

It

is used to separate oil and water mixtures into their separate components. This page refers exclusively to oily

water separators aboard marine vessels. They are found on board ships where they are used to separate oil

from oily waste water such as bilge water before the waste water is discharged into the environment. These

discharges of waste water must comply with the requirements laid out in Marpol 73/78.[1] For information on

more general oil water separators Oily Water Separators (general).

Bilge water is a near-unavoidable product of shipboard operations. Oil leaks from running machinery such as

diesel generators, air compressors, and the main propulsion engine. Modern OWSs have alarms and

automatic closure devices which are activated when the oil storage content of the waste water exceeds a

certain limit.

Purpose[edit]

Oily water separator piping diagram

The primary purpose of a shipboard oily water separator (OWS) is to separate oil and other contaminants that

could be harmful for the oceans. The International Maritime Organization (IMO) publishes regulations through

the Marine Environment Protection Committee (MEPC). [2] On July 18, 2003, the MEPC issued new regulations

that each vessel built after this date had to follow. This document is known as MEPC 107(49) [3] and it details

revised guidelines and specifications for pollution prevention equipment for machinery space bilges of ships.

Each OWS must be able to achieve clean bilge water under 15 ppm of type C oil or heavily emulsified oil, and

any other contaminates that may be found. All oil content monitors (OCM) must be tamper-proof. Also

whenever the OWS is being cleaned out the OCM must be active. An OWS must be able to clear out

contaminants as well as oil. Some of these contaminating agents include lubricating oil, cleaning product, soot

from combustion, fuel oil, rust, sewage, and several other things that can be harmful to the ocean

environment.[4]

Bilge content[edit]

The bilge area is the lowest area on a ship. The bilge water that collects here include drain water or leftover

water from the boilers, water collecting tanks, drinking water and other places where water can not overflow.

However, bilge water doesn't just include water drainage. Another system that drains into the Bilge system

comes from the propulsion area of the ship. Here fuels, lubricants, hydraulic fluid, antifreeze, solvents, and

cleaning chemicals drain into the engine room bilges in small quantities. The OWS is intended to remove a

large proportion of these contaminants before discharge to the environment (overboard to the sea).

Design and operation[edit]

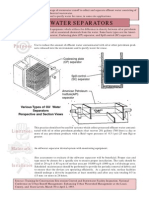

All OWS equipment, new or old, can, in a laboratory setting, separate oil and water, do so automatically, and

produce clean water for discharge overboard that contains no more than 15 parts per million oil. OWS

equipment is approved by testing it with specific cocktails of mixed oil and water. Initially these combinations

were very simple, basically no more than a mixture of clean water and diesel fuel, but they have become more

sophisticated under MARPOL MEPC 107(49).[3][4] The vast majority of these many equipment models,

manufacturers, and types start with some sort of gravity separation of bilge water. Simply letting oil and water

sit is called decanting, and this does not always meet the 15 ppm criterion, which is why each manufacturer

has added additional features to his equipment to ensure that this criterion can be met. The separation that

takes place inside the OWS allows oil that floats to the top to be automatically skimmed off to a sludge tank or

dirty oil holding tank.[4] There is no official standard for tank naming convention but there are some proposals

for that.[5]

An OWS needs to be fitted with an oil content meter (OCM) that samples the OWS overboard discharge water

for oil content. If the oil content is less than 15 ppm, the OCM allows the water to be discharged overboard. If

the oil content is higher than 15 ppm, the OCM will activate an alarm and move a three-way valve that, within

a short period of time, will recirculate the overboard discharge water to a tank on the OWS suction side. [4]

An OCM takes a trickle sample from the OWS overboard discharge line and shines a light through the sample

to an optical sensor. Since small oil droplets will diffract and diffuse light, a change in signal at the sensor will

indicate the presence of oil. At a certain signal setting that is roughly equivalent to 15 ppm, the sensor will

conclude that there is too much oil going through the discharge line. [4] This calibration generally takes place in

a lab, but can be tested by use of a three-sample liquid aboard the vessel. If the OCM ends up sampling a

certain amount of heavy oil, the OCM will be fouled and it will need to be flushed or cleaned. [4]

Shipboard engine room

The cleaning can be done by running fresh water through the OCM via a permanent connection or can be

performed by opening the OCM sample area and scrubbing the sample area with a bottle brush. [4]

The water removed by the OWS flows to oil collecting spaces. There can be two stages. The first-stage filter

removes physical impurities present and promotes some fine separation. The second-stage filter uses

coalescer inserts to achieve the final de-oiling. Coalescence is the breakdown of surface tension between oil

droplets in an oil/water mixture which causes them to join and increase in size. The oil from the collecting

spaces is drained away automatically or manually. In most modern ships, the oil from collecting spaces is

drained away automatically.[6]

Oil record book[edit]

All Cargo vessels where MARPOL Convention is applicable must have an oil record book where the chief

engineer will record all oil or sludge transfers and discharges within the vessel. This is necessary in order for

authorities to be able to monitor if a vessel's crew has performed any illegal oil discharges at sea.

When making entries in the oil record book Part I, the date, operational code, and item number are inserted in

the appropriate columns and the required particulars shall be recorded in chronological order as they have

been executed on board. Each operation is to be fully recorded without delay so that all the entries in the book

appropriate to that operation are completed. [7]

History of regulations for treated water

discharge[edit]

In 1948 in the USA, a Water Pollution Control Act (WPA) was passed by the federal government. [8] This act

gave rights to the surgeon general of the public health service to make programs to decrease the amount of

pollution in the world's waters. The main concern was to save water, protect fish, and have clean water for

agricultural usage. The WPA also helped to start the process of building water treatment plants. This is to

guard against sewage from polluting drinking water. In 1972 the WPA was amended to include more

requirements in order to insure that the water is chemically sound. This amendment also furthered regulations

to insure the quality of the water was up to par. [9] In 1987 the WPA was amended again to put an even more

strict control on water supply pollution. With this new amendment water sources had to fit a specific set of

criteria to fight against pollution.[10]

Вам также может понравиться

- Khaksar KhanДокумент36 страницKhaksar KhanAlsamad Borkar100% (1)

- An Oily Water SeparatorДокумент3 страницыAn Oily Water SeparatorMin SoeОценок пока нет

- Oily Water SeparatorДокумент7 страницOily Water SeparatorVishu Sharma100% (2)

- Oily Water SeparatorДокумент24 страницыOily Water Separatormodisunami100% (1)

- How To Operate An Oily Water SeparatorДокумент2 страницыHow To Operate An Oily Water SeparatorKHOI TIMОценок пока нет

- C.E On Preventing PollutionДокумент3 страницыC.E On Preventing Pollutionwinhlaingoo100% (1)

- Bilge Water Instructions & Requirements - ENДокумент5 страницBilge Water Instructions & Requirements - ENclaudioОценок пока нет

- Oily Water Separator Method of Operation PDFДокумент1 страницаOily Water Separator Method of Operation PDFUnokhogie EmmanuelОценок пока нет

- Oily Water SeperatorsДокумент2 страницыOily Water SeperatorsJitendra KumarОценок пока нет

- Oily Water SeparatorДокумент5 страницOily Water SeparatorFe Capricho100% (1)

- Gas CargoesДокумент56 страницGas CargoesTom AlexОценок пока нет

- Fixed Tank Cleaning Machine Pm-10Документ89 страницFixed Tank Cleaning Machine Pm-10Mustafa YıldırımОценок пока нет

- Oil Water SeparatorДокумент4 страницыOil Water SeparatorrizkiОценок пока нет

- Eductor SystemДокумент8 страницEductor Systemapi-219509070Оценок пока нет

- Tank Cleaning Guide BP 2004Документ1 страницаTank Cleaning Guide BP 2004mabrouk2013Оценок пока нет

- Oily Water SeperatorsДокумент38 страницOily Water Seperatorsakusuper67% (3)

- Fuel Oil SystemДокумент3 страницыFuel Oil Systemaika hartini0% (1)

- Oil-Water Separation TechnogiesДокумент4 страницыOil-Water Separation TechnogiesBrian FreireОценок пока нет

- Technical CircularsДокумент3 страницыTechnical CircularsAjay SinghОценок пока нет

- SewageДокумент31 страницаSewagemaneeshОценок пока нет

- Tank CleaningДокумент2 страницыTank CleaninghayatmdazharОценок пока нет

- Sewage Treatment Plant FinalДокумент83 страницыSewage Treatment Plant FinalRodolfo L Suarez100% (1)

- Pipeline Arrangement in Oil TankersДокумент11 страницPipeline Arrangement in Oil TankersManpreet SinghОценок пока нет

- MIB 303 Separation System, Module - Operating Instructions - 1997Документ16 страницMIB 303 Separation System, Module - Operating Instructions - 1997Centrifugal SeparatorОценок пока нет

- Boiler Maintenance Checklist: Inspection and Safety Checks To Marine Steam BoilerДокумент9 страницBoiler Maintenance Checklist: Inspection and Safety Checks To Marine Steam BoilerChriscarl De LimaОценок пока нет

- Guidelines For VOC Management Plan - Final - 2010Документ31 страницаGuidelines For VOC Management Plan - Final - 2010Cari RiveraОценок пока нет

- LR BWTSДокумент16 страницLR BWTSNikolas VaporisОценок пока нет

- LBFD Boat 20 (Bilge Pumping Systems)Документ33 страницыLBFD Boat 20 (Bilge Pumping Systems)Mayura RanatungaОценок пока нет

- Working Principle of Purifier and ClarifierДокумент17 страницWorking Principle of Purifier and Clarifiershin deiruОценок пока нет

- Steering Gear SolasДокумент2 страницыSteering Gear SolasJithin Vijayan100% (1)

- 12 Air Starting of Diesel EnginesДокумент26 страниц12 Air Starting of Diesel EnginesCurtler PaquibotОценок пока нет

- Alcaclean HD 1Документ2 страницыAlcaclean HD 1leventasarОценок пока нет

- A Step by Step Guide of How To Operate ODME and Principle of Its OperationДокумент21 страницаA Step by Step Guide of How To Operate ODME and Principle of Its OperationKunal Singh100% (2)

- Ship Departure Checklist For Engine Department: What To Do When A Ship Leaves A Port?Документ2 страницыShip Departure Checklist For Engine Department: What To Do When A Ship Leaves A Port?SurajitSarkarОценок пока нет

- Marine Auxiliary MachineryДокумент56 страницMarine Auxiliary MachineryKris100% (3)

- Oil Water Separator TheoryДокумент3 страницыOil Water Separator Theoryjlcheefei9258Оценок пока нет

- Final Seemp PresentationДокумент16 страницFinal Seemp PresentationLyubomir LazarovОценок пока нет

- Checklist - LDO-UnLoading PumpДокумент12 страницChecklist - LDO-UnLoading PumpBandi Suryakanthareddy V G0% (1)

- Principle of OperationДокумент5 страницPrinciple of OperationAnonymous b68EQRОценок пока нет

- Cma CGM Tanger: 4Th Engineer Hand Over ReportДокумент8 страницCma CGM Tanger: 4Th Engineer Hand Over ReportFaical EljarmouniОценок пока нет

- Water TreatmentДокумент34 страницыWater TreatmentGogu Fara Basca100% (2)

- Guide To Oil in Water Monitoring & DischargeДокумент43 страницыGuide To Oil in Water Monitoring & DischargeKiran Cbaby Ayur100% (2)

- Cargo Oil SystemДокумент8 страницCargo Oil SystemAayush Agrawal100% (3)

- Oil Water Separator (OWS)Документ11 страницOil Water Separator (OWS)api-3701567100% (1)

- O-W Separator LiteratureДокумент8 страницO-W Separator Literatureernesto_sugiharto100% (1)

- A B&C A&b C&D B&CДокумент16 страницA B&C A&b C&D B&CJireh Regalado MandaweОценок пока нет

- Bunkering Code of Practice PDFДокумент62 страницыBunkering Code of Practice PDFsijuwolaoluranti100% (3)

- Main Engine Layout FamiliarizationДокумент4 страницыMain Engine Layout Familiarizationrajjsmit1989Оценок пока нет

- Live Graving Dry DockДокумент36 страницLive Graving Dry DockAshiq AbdullahОценок пока нет

- Gas Freein ProceduresДокумент3 страницыGas Freein ProceduresSamarinerSingh100% (1)

- 6.water Treatment and Make-Up Water SystemДокумент18 страниц6.water Treatment and Make-Up Water Systempepenapao1217100% (1)

- Engine Room DocumentsДокумент5 страницEngine Room DocumentsФурад ДжакумовОценок пока нет

- Are You Doing All These Checks On Your Davit Type LifeboatsДокумент15 страницAre You Doing All These Checks On Your Davit Type Lifeboatsbaaziz2015Оценок пока нет

- Fixed Co2 Fire Fighting SystemДокумент20 страницFixed Co2 Fire Fighting SystemMagesh ShanmughamОценок пока нет

- Oil Water Separator Installation Manual PDFДокумент13 страницOil Water Separator Installation Manual PDFCastoriadisОценок пока нет

- SIRE Observations For 2018, 02 Jan'19Документ14 страницSIRE Observations For 2018, 02 Jan'19Romāns BogdanovsОценок пока нет

- Oil Water SeparationДокумент3 страницыOil Water SeparationrohitkushОценок пока нет

- Auxiliary Machinery 1: Assignment Reseach inДокумент6 страницAuxiliary Machinery 1: Assignment Reseach inFernando CruzОценок пока нет

- Gas Safety WeldingДокумент8 страницGas Safety Weldingshin deiruОценок пока нет

- Bilge Oily Water SeparatorДокумент25 страницBilge Oily Water Separatornguyenvanhai19031981100% (2)

- 517 - FamiliarisationДокумент2 страницы517 - FamiliarisationPanagiotis MouzenidisОценок пока нет

- 517 - FamiliarisationДокумент2 страницы517 - FamiliarisationPanagiotis MouzenidisОценок пока нет

- 517 - FamiliarisationДокумент2 страницы517 - FamiliarisationPanagiotis MouzenidisОценок пока нет

- 517 - FamiliarisationДокумент2 страницы517 - FamiliarisationPanagiotis MouzenidisОценок пока нет

- 517 - FamiliarisationДокумент2 страницы517 - FamiliarisationPanagiotis MouzenidisОценок пока нет

- MI 295B Garbage Record BookДокумент7 страницMI 295B Garbage Record BookPanagiotis MouzenidisОценок пока нет

- 517 - Familiarisation RESTITUTOДокумент1 страница517 - Familiarisation RESTITUTOPanagiotis MouzenidisОценок пока нет

- Venting On TankersДокумент20 страницVenting On TankersPanagiotis MouzenidisОценок пока нет

- Risk AssesmentДокумент17 страницRisk AssesmentPanagiotis MouzenidisОценок пока нет

- Cargo Calculations Oil TankerДокумент17 страницCargo Calculations Oil TankerPanagiotis Mouzenidis100% (1)

- Air ComppressorДокумент2 страницыAir ComppressorPanagiotis MouzenidisОценок пока нет

- The Pump Room May Also Contain A Number of Potential Ignition Sources Unless FormalДокумент6 страницThe Pump Room May Also Contain A Number of Potential Ignition Sources Unless FormalPanagiotis MouzenidisОценок пока нет

- Loadline CalculationДокумент6 страницLoadline CalculationPanagiotis Mouzenidis100% (1)

- Voyage Instructions MasterДокумент23 страницыVoyage Instructions MasterPanagiotis Mouzenidis100% (2)

- PurifierДокумент5 страницPurifierPanagiotis MouzenidisОценок пока нет

- Tanker FireДокумент18 страницTanker FirePanagiotis MouzenidisОценок пока нет

- 8 Simple Mistakes Navigators Make While Using Traffic Separation SchemeДокумент23 страницы8 Simple Mistakes Navigators Make While Using Traffic Separation SchemePanagiotis MouzenidisОценок пока нет

- Ship AlarmsДокумент6 страницShip AlarmsPanagiotis MouzenidisОценок пока нет

- Static ElectricityДокумент20 страницStatic ElectricityPanagiotis MouzenidisОценок пока нет

- Marine EngineДокумент12 страницMarine EnginePanagiotis MouzenidisОценок пока нет

- ScbaДокумент4 страницыScbaPanagiotis MouzenidisОценок пока нет

- Ship HandlingДокумент16 страницShip HandlingPanagiotis Mouzenidis100% (1)

- RadarДокумент16 страницRadarPanagiotis MouzenidisОценок пока нет

- Purifier RoomДокумент2 страницыPurifier RoomPanagiotis MouzenidisОценок пока нет

- Position FixДокумент29 страницPosition FixPanagiotis Mouzenidis100% (1)

- 5 Loadicator Tricks That Can Ease Your Life During Cargo OperationДокумент21 страница5 Loadicator Tricks That Can Ease Your Life During Cargo OperationCodruţ ErașcuОценок пока нет

- Loadicator TestsДокумент1 страницаLoadicator TestsPanagiotis MouzenidisОценок пока нет

- SludgesДокумент5 страницSludgesPanagiotis MouzenidisОценок пока нет

- Sox NoxДокумент16 страницSox NoxPanagiotis MouzenidisОценок пока нет

- Pilot LaddersДокумент7 страницPilot LaddersPanagiotis MouzenidisОценок пока нет

- Libel Arraignment Pre Trial TranscriptДокумент13 страницLibel Arraignment Pre Trial TranscriptAnne Laraga LuansingОценок пока нет

- Group 3 Presenta Tion: Prepared By: Queen Cayell Soyenn Gulo Roilan Jade RosasДокумент12 страницGroup 3 Presenta Tion: Prepared By: Queen Cayell Soyenn Gulo Roilan Jade RosasSeyell DumpОценок пока нет

- Gender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected PlaysДокумент6 страницGender and Patriarchy: Crisis, Negotiation and Development of Identity in Mahesh Dattani'S Selected Playsতন্ময়Оценок пока нет

- Duties and Responsibilities - Filipino DepartmentДокумент2 страницыDuties and Responsibilities - Filipino DepartmentEder Aguirre Capangpangan100% (2)

- Annotated Bibliography 2Документ3 страницыAnnotated Bibliography 2api-458997989Оценок пока нет

- GSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserДокумент13 страницGSM Based Prepaid Electricity System With Theft Detection Using Arduino For The Domestic UserSanatana RoutОценок пока нет

- New KitДокумент195 страницNew KitRamu BhandariОценок пока нет

- Zimbabwe - Youth and Tourism Enhancement Project - National Tourism Masterplan - EOIДокумент1 страницаZimbabwe - Youth and Tourism Enhancement Project - National Tourism Masterplan - EOIcarlton.mamire.gtОценок пока нет

- EQUIP9-Operations-Use Case ChallengeДокумент6 страницEQUIP9-Operations-Use Case ChallengeTushar ChaudhariОценок пока нет

- D&D 3.5 Edition - Fiendish Codex I - Hordes of The Abyss PDFДокумент191 страницаD&D 3.5 Edition - Fiendish Codex I - Hordes of The Abyss PDFIgnacio Peralta93% (15)

- Enzymes WorksheetДокумент5 страницEnzymes WorksheetgyunimОценок пока нет

- Self-Efficacy and Academic Stressors in University StudentsДокумент9 страницSelf-Efficacy and Academic Stressors in University StudentskskkakleirОценок пока нет

- Aits 2122 PT I Jeea 2022 TD Paper 2 SolДокумент14 страницAits 2122 PT I Jeea 2022 TD Paper 2 SolSoumodeep NayakОценок пока нет

- Jurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIДокумент9 страницJurnal KORELASI ANTARA STATUS GIZI IBU MENYUSUI DENGAN KECUKUPAN ASIMarsaidОценок пока нет

- Angeles City National Trade SchoolДокумент7 страницAngeles City National Trade Schooljoyceline sarmientoОценок пока нет

- Rules of Bursa Malaysia Securities Clearing 2019Документ11 страницRules of Bursa Malaysia Securities Clearing 2019Evelyn SeethaОценок пока нет

- Service Manual: NISSAN Automobile Genuine AM/FM Radio 6-Disc CD Changer/ Cassette DeckДокумент26 страницService Manual: NISSAN Automobile Genuine AM/FM Radio 6-Disc CD Changer/ Cassette DeckEduardo Reis100% (1)

- Idoc - Pub - Pokemon Liquid Crystal PokedexДокумент19 страницIdoc - Pub - Pokemon Liquid Crystal PokedexPerfect SlaNaaCОценок пока нет

- IRJ November 2021Документ44 страницыIRJ November 2021sigma gaya100% (1)

- Facts About The TudorsДокумент3 страницыFacts About The TudorsRaluca MuresanОценок пока нет

- A Wicked Game by Kate BatemanДокумент239 страницA Wicked Game by Kate BatemanNevena Nikolic100% (1)

- Jail Versus Substance Abuse TreatmentДокумент5 страницJail Versus Substance Abuse Treatmentapi-240257564Оценок пока нет

- Al-Farabi Fusul Al MadaniДокумент107 страницAl-Farabi Fusul Al MadaniDaniel G.G.100% (1)

- Pepsi Mix Max Mox ExperimentДокумент2 страницыPepsi Mix Max Mox Experimentanon_192325873Оценок пока нет

- Language EducationДокумент33 страницыLanguage EducationLaarni Airalyn CabreraОценок пока нет

- SOLVING THE STEADY STATE SOLVER AND UNSTEADY or TRANSIENT SOLVER 2D HEAT CONDUCTION PROBLEM BY USINGДокумент3 страницыSOLVING THE STEADY STATE SOLVER AND UNSTEADY or TRANSIENT SOLVER 2D HEAT CONDUCTION PROBLEM BY USINGGodwin LarryОценок пока нет

- Computer Science HandbookДокумент50 страницComputer Science HandbookdivineamunegaОценок пока нет

- 2015 Grade 4 English HL Test MemoДокумент5 страниц2015 Grade 4 English HL Test MemorosinaОценок пока нет

- Data Mining For Business Analyst AssignmentДокумент9 страницData Mining For Business Analyst AssignmentNageshwar SinghОценок пока нет

- Dehydration AssessmentДокумент2 страницыDehydration AssessmentzaheerbdsОценок пока нет

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseОт EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (51)

- The Laws of Thermodynamics: A Very Short IntroductionОт EverandThe Laws of Thermodynamics: A Very Short IntroductionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionОт EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedОт EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedРейтинг: 5 из 5 звезд5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОт EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AОценок пока нет

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideОт Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideРейтинг: 3.5 из 5 звезд3.5/5 (7)

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsОт EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsОценок пока нет

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisОт EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisРейтинг: 4 из 5 звезд4/5 (2)

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyОт EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyРейтинг: 5 из 5 звезд5/5 (1)

- Handbook of Mechanical and Materials EngineeringОт EverandHandbook of Mechanical and Materials EngineeringРейтинг: 5 из 5 звезд5/5 (4)

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersОт EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersРейтинг: 4 из 5 звезд4/5 (13)

- Mechanical Vibrations and Condition MonitoringОт EverandMechanical Vibrations and Condition MonitoringРейтинг: 5 из 5 звезд5/5 (1)

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchОт EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchРейтинг: 4 из 5 звезд4/5 (10)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsОт EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsОценок пока нет

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CОт EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CОценок пока нет