Академический Документы

Профессиональный Документы

Культура Документы

ASME VIII Div 1 Clamp Connector Design Analysis

Загружено:

fahid masoodОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ASME VIII Div 1 Clamp Connector Design Analysis

Загружено:

fahid masoodАвторское право:

Доступные форматы

PIPEMILL - Piping Engineering, Design and Analysis

Version: 4.00 PIPEMILL VERSION 4

Clamp Connector Design and Analysis to ASME VIII Div. 1 (2013) Appendix 24

____________________________________________________________________________________________________________

Calculation by: ____________________ Checked by: ______________________ Saturday,Nov 24,2018

File Name: C:\Users\SEF\Desktop\IvySoft_Pipemill_4.0_Downloadly.ir\IvySoft Pipemill 4.0\run_original\Demo-examples\V-4 CLAMP-ASME-01.clm

Project / Description: h hn T

Calculation details:

Load case: Pressure only. g2

INPUT DATA:

g0 g1

HUB: CLAMP: BOLTS:

N B C A

D = 273.05 mm Bc = 215.9 mm Bolt Dia Bd = 25.4 mm

A = 317.5 mm Cw = 88.9 mm Bolt Area Ab = 354.838 mm2

B = 234.95 mm Ci = 298.45 mm Bolts per lug= 2

N = 284.48 mm La = 23.09 mm Bc

T = 25.4 mm Lh = 50.8 mm LOADS: A

h = 25.4 mm lc = 15.24 mm Pressure = 96.526 bar G La

g0 = 19.050 mm Ct = 34.925 mm Longit. Moment = 0 kN.m

g1 = 24.765 mm GASKET: Axial force = 0 kN A

g2 = 16.510 mm Gasket OD = 260.35 mm

Ci/2

ca = 0 mm (corr. allw.) Gasket ID = 234.95 mm

Lh

Angle mu = 5 deg. Gasket 'y' = 124.1055 MPa

Angle phi= 15 deg. Gasket 'm' = 5.5

hn = 19.05 mm Thk. tg = 5.08 mm eb Neutral axis

ALLOW. STRESS: COLD (MPa) HOT (MPa)

C X

HUB: SA(h)= 137.895 SO(h)= 124.105

CLAMP: SA(c)= 155.132 SO(c)= 133.069

BOLTS: SA(b)= 172.368 SO(b)= 124.105

Cg Cw

INTERMEDIATE DESIGN DATA:

Dimensions: Load data:

b = 6.350 mm P = 96.526 barG. H = 4.64933 e+5 N. Ci lc Ct

C = 307.975 mm Peq= .000 barG. Hp = 5.24539 e+5 N. Section A-A

G = 247.650 mm Pd = 96.526 barG. Hm = 6.13101 e+5 N.

Code Forces Bolt Requirements: Moment Loads: Shear Loads:

Wm1 = 1.11138 e+5 N. Am1 = 447.8 mm2. Masm = 1.54278 e+7 Nmm. Qasm = 3.84618 e+5 N.

Wm2 = 1.42147 e+5 N. Am2 = 412.4 mm2. Mop = - 9.61664 e+5 Nmm. Qop = - 2.39745 e+4 N.

Wm3 = 2.29408 e+5 N. Am3 = 665.5 mm2. MHasm = 1.61385 e+7 Nmm.

Wop = 1.11138 e+5 N. Am = 665.5 mm2. MHop = - 1.00597 e+6 Nmm.

Wasm = 1.18512 e+5 N. Ab = 709.7 mm2.

Internal Moments Bolt Requirements: Shape factors:

MD = 1.0098 e+7 Nmm. MF = 1.1958 e+6 Nmm. g1/g0 = 1.300 f(act) = .685 - actual value

MG = - 1.2139 e+7 Nmm. MP = 7.5724 e+4 Nmm. h/h0 = .380 alpha = 12.68 deg.

MT = 1.549 e+6 Nmm. MR = - 1.7409 e+6 Nmm. f = 1.000 - used in calc.

__________________________________________________________________________________________________

CALCULATED STRESS:

Assembly Allowable Operating Allowable

MPa MPa MPa MPa

S1: Hub Longitudinal 193.519 206.843 8.648 186.158

S2: Hub Hoop Stress 0. 137.895 51.074 124.105

S3: Hub Axial Shear 33.798 110.316 65.424 99.284

S4: Hub Radial Shear 28.526 110.316 -1.778 99.284

S5: Clamp Longitudinal 87.794 232.698 169.946 199.604

S6: Clamp Tangential 130.81 232.698 122.671 199.604

S7: Clamp Lip Shear 40.339 124.106 78.087 106.455

S8: Clamp Lug Bending 35.785 155.132 33.558 133.069

S9: Contact Bearing 55.502 220.632 107.437 198.568

__________________________________________________________________________________________________

SUMMARY: Stresses Acceptable

Вам также может понравиться

- LPT 1618 TC/52 Parts List (Engine, Gearbox & ChassisДокумент286 страницLPT 1618 TC/52 Parts List (Engine, Gearbox & Chassisharneak0% (1)

- GranTurismo enДокумент0 страницGranTurismo enaiigee100% (1)

- Technical specifications of private Citroen vehiclesДокумент133 страницыTechnical specifications of private Citroen vehiclesRicardo Santos100% (1)

- Design of large diameter slip on flangeДокумент6 страницDesign of large diameter slip on flangeAKSHAY BHATKARОценок пока нет

- Stresses in Intersecting Cylinders Under PressureДокумент33 страницыStresses in Intersecting Cylinders Under Pressurefahid masoodОценок пока нет

- Stresses in Intersecting Cylinders Under PressureДокумент33 страницыStresses in Intersecting Cylinders Under Pressurefahid masoodОценок пока нет

- Stresses in Intersecting Cylinders Under PressureДокумент33 страницыStresses in Intersecting Cylinders Under Pressurefahid masoodОценок пока нет

- Weld Neck Flange Design - As Per Denis MorisДокумент2 страницыWeld Neck Flange Design - As Per Denis Morissouren1975Оценок пока нет

- ASME B16.5 Flanges PDFДокумент50 страницASME B16.5 Flanges PDFPedro De Mesquita Soares CamposОценок пока нет

- ASME B16.5 Flanges PDFДокумент50 страницASME B16.5 Flanges PDFPedro De Mesquita Soares CamposОценок пока нет

- ASME B16.5 Flanges PDFДокумент50 страницASME B16.5 Flanges PDFPedro De Mesquita Soares CamposОценок пока нет

- Service TOTALДокумент160 страницService TOTALmilovacs6720Оценок пока нет

- CARTRIDGE FILTER TECHNICAL MANUALДокумент30 страницCARTRIDGE FILTER TECHNICAL MANUALabessiОценок пока нет

- Mitsubishi 4g69 Engine ManualДокумент66 страницMitsubishi 4g69 Engine ManualAlbert Briceño75% (8)

- Basics of Pipe Stress AnalysisДокумент79 страницBasics of Pipe Stress Analysisarjunprasannan7100% (1)

- Hot Tapping On Operating LinesДокумент20 страницHot Tapping On Operating LinesCelestine Ozokechi100% (1)

- RB 4700 BrochureДокумент6 страницRB 4700 Brochuretuan pham minhОценок пока нет

- TC 449 2011 IeДокумент414 страницTC 449 2011 IeVincent RoyОценок пока нет

- Standard Hook-Up Wires & Cables For ElectronicsДокумент124 страницыStandard Hook-Up Wires & Cables For ElectronicsdlstoneОценок пока нет

- Pipeline Pigging BrochureДокумент14 страницPipeline Pigging BrochureMiguel Gonzalez100% (1)

- 4d94e17 Be2 PDFДокумент160 страниц4d94e17 Be2 PDFdend juandiОценок пока нет

- Solis-75N-90N-Parts Catalogue PDFДокумент257 страницSolis-75N-90N-Parts Catalogue PDFkvsj2001Оценок пока нет

- Mitsubishi Purifier SJ10G Spare PartsДокумент16 страницMitsubishi Purifier SJ10G Spare PartsAtikah Azmi SiregarОценок пока нет

- Smart Trap PDFДокумент2 страницыSmart Trap PDFdmitos100% (1)

- 399AДокумент24 страницы399ADana Mera100% (2)

- Pressure-Operated Valves Series 290-390-298-398Документ8 страницPressure-Operated Valves Series 290-390-298-398Nelson AlvarezОценок пока нет

- Type Ezr EstancoДокумент40 страницType Ezr EstancoJuan JuanОценок пока нет

- EZR Installation ManualДокумент40 страницEZR Installation ManualRoberto Aldayuz HerediaОценок пока нет

- GS02 directional proportional solenoid valve specifications and performance dataДокумент2 страницыGS02 directional proportional solenoid valve specifications and performance dataAdal VeraОценок пока нет

- Solenoid Operated Valves: Nuclear Power GenerationДокумент12 страницSolenoid Operated Valves: Nuclear Power GenerationVeerabhadra BujurkeОценок пока нет

- 67Документ10 страниц67johnnylim456Оценок пока нет

- HP Regulators v2Документ9 страницHP Regulators v2Danny SánchezОценок пока нет

- (Job Title #1) / (Job Title #2) : (NAME)Документ3 страницы(Job Title #1) / (Job Title #2) : (NAME)Rashid Mahmood JaatОценок пока нет

- Separator NadobyДокумент15 страницSeparator NadobyVidyasenОценок пока нет

- FloBoss™ S600+ Flow Computer Instruction Manual PDFДокумент152 страницыFloBoss™ S600+ Flow Computer Instruction Manual PDFSibabrata ChoudhuryОценок пока нет

- Rotork GP & GH RangeДокумент8 страницRotork GP & GH RangeJavier BarreraОценок пока нет

- FEPA Gas-over-oil ActuatorsДокумент4 страницыFEPA Gas-over-oil Actuatorstoader56Оценок пока нет

- Length Power Dynamic Viscosity Heat FluxДокумент5 страницLength Power Dynamic Viscosity Heat FluxAnanthan IndukaladharanОценок пока нет

- 650 01 GB 0111 01Документ12 страниц650 01 GB 0111 01Phan HaiОценок пока нет

- FCДокумент46 страницFCJcRodriguezОценок пока нет

- Slam Shut Off FlowgridДокумент16 страницSlam Shut Off FlowgridmateuОценок пока нет

- Intro Process Xmitters (Suresh)Документ33 страницыIntro Process Xmitters (Suresh)sreeyukthaОценок пока нет

- 28.GOMA Pump T-8000 CatalougeДокумент2 страницы28.GOMA Pump T-8000 Catalougeramesh babuОценок пока нет

- 21314Документ5 страниц21314HirkanipatilОценок пока нет

- Sample Exam2cДокумент10 страницSample Exam2cnaefmubarakОценок пока нет

- Natural Gas Chromatograph (NGC) 8206: Data Sheet 2101164-AGДокумент5 страницNatural Gas Chromatograph (NGC) 8206: Data Sheet 2101164-AGishibhoomiОценок пока нет

- Thermodynamics QuestionsДокумент4 страницыThermodynamics QuestionsPiyush BaidОценок пока нет

- 01 - Transfer Pumps & TexsteamДокумент26 страниц01 - Transfer Pumps & TexsteamMarsyaОценок пока нет

- INGAAДокумент108 страницINGAAEric NusinowОценок пока нет

- Pipeline Cleaning Case StudyДокумент5 страницPipeline Cleaning Case StudyJason MooreОценок пока нет

- Punch List Gas MeteringДокумент4 страницыPunch List Gas MeteringJamal BakhtОценок пока нет

- Pipeline AccessoriesДокумент8 страницPipeline Accessoriesdan2009Оценок пока нет

- IC 8155 InformationДокумент13 страницIC 8155 InformationKajol PhadtareОценок пока нет

- 8255 - SeminarДокумент28 страниц8255 - SeminarJKОценок пока нет

- Data Sheet S7 - 2020 - ENG - Light - CavagnaДокумент12 страницData Sheet S7 - 2020 - ENG - Light - CavagnaWND PRTMОценок пока нет

- 12186Документ2 страницы12186Harsh BhatiaОценок пока нет

- Compare ASTM A216 Grade WCB To ASTM A216 Grade WCCДокумент3 страницыCompare ASTM A216 Grade WCB To ASTM A216 Grade WCCRachel BaileyОценок пока нет

- Therminol vp1Документ10 страницTherminol vp1karthik1amarОценок пока нет

- Da and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1Документ3 страницыDa and Dhda Datasheet Master - XLSM - Hpu-Dhda118-4.1 Rev1jujuroyaleОценок пока нет

- GgsДокумент21 страницаGgsKrishna KumarОценок пока нет

- Directional Valves WebinarДокумент18 страницDirectional Valves WebinarhaggОценок пока нет

- Manual Regulators Man Slamshut 2-4inchДокумент20 страницManual Regulators Man Slamshut 2-4inchDelfin Rosanieto TapiaОценок пока нет

- Iscan2 ScannerДокумент2 страницыIscan2 ScannerjqithriОценок пока нет

- FloBoss IO ModulesДокумент5 страницFloBoss IO ModulesAdeel HassanОценок пока нет

- 1290 RegulatorsДокумент3 страницы1290 RegulatorsPitichai PakornrersiriОценок пока нет

- Mdpe Tpi Questions AnswerДокумент29 страницMdpe Tpi Questions AnswerShashi ChouhanОценок пока нет

- Grove g4n Gate Valve BrochureДокумент24 страницыGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- Thermowell Calculation Guide V1.3Документ19 страницThermowell Calculation Guide V1.3AymanelorbanyОценок пока нет

- Domestic Gas MetersДокумент3 страницыDomestic Gas MetersSrinivas VenkatramanОценок пока нет

- Afv TDB 9610.6 Capacity TablesДокумент24 страницыAfv TDB 9610.6 Capacity TablesJorge BaronОценок пока нет

- 8155 PPI Chapter Explains Programmable Peripheral InterfaceДокумент12 страниц8155 PPI Chapter Explains Programmable Peripheral InterfacebelihuОценок пока нет

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОт EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОценок пока нет

- Minimum tensile strength materials chartДокумент8 страницMinimum tensile strength materials chartTrishul Nath PallayОценок пока нет

- GROUP6 - GC42 - Design of Column Beam and SlabДокумент8 страницGROUP6 - GC42 - Design of Column Beam and SlabAlexander P. BelkaОценок пока нет

- Column DesignДокумент1 страницаColumn DesignNick OperarioОценок пока нет

- Material Properties Reinforcement Details: Design of Concrete ColumnДокумент1 страницаMaterial Properties Reinforcement Details: Design of Concrete ColumnMark Christian EsguerraОценок пока нет

- Basic Vibration Analysis ?Документ20 страницBasic Vibration Analysis ?Avinash KamuniОценок пока нет

- SAES-L-105 (Piping Material Specification) SAES-L-120 (Piping Flexibility Analysis) SAES-L-310 (Design of Piping) SAES-B-055 (Plant Layout)Документ1 страницаSAES-L-105 (Piping Material Specification) SAES-L-120 (Piping Flexibility Analysis) SAES-L-310 (Design of Piping) SAES-B-055 (Plant Layout)fahid masoodОценок пока нет

- 83 Determination PDFДокумент7 страниц83 Determination PDFSrini VasanОценок пока нет

- Piping specifications, analysis, design and layout documentsДокумент1 страницаPiping specifications, analysis, design and layout documentsfahid masoodОценок пока нет

- SAESДокумент1 страницаSAESfahid masoodОценок пока нет

- What is Carbon Steel? Its Properties and UsesДокумент1 страницаWhat is Carbon Steel? Its Properties and Usesfahid masoodОценок пока нет

- MaterialДокумент1 страницаMaterialfahid masoodОценок пока нет

- Pipe SpanДокумент1 страницаPipe Spanfahid masoodОценок пока нет

- Other To Carry Loads and Provide Full RigidityДокумент1 страницаOther To Carry Loads and Provide Full Rigidityfahid masoodОценок пока нет

- Fesif: When You Need Accurate B31 Sifs and FlexibilitiesДокумент2 страницыFesif: When You Need Accurate B31 Sifs and Flexibilitiesfahid masoodОценок пока нет

- Poaceae (Grass. Poaceae Includes TheДокумент1 страницаPoaceae (Grass. Poaceae Includes Thefahid masoodОценок пока нет

- 1-Fee 2 - Interview/travel/skype 3 - Job Offer Bound To Take/can Reject 4 - Salary Equivalent or Less 5 - Which RotationДокумент1 страница1-Fee 2 - Interview/travel/skype 3 - Job Offer Bound To Take/can Reject 4 - Salary Equivalent or Less 5 - Which Rotationfahid masoodОценок пока нет

- c2UG 799 PDFДокумент1 страницаc2UG 799 PDFfahid masoodОценок пока нет

- T&P Skill Builder P1Документ14 страницT&P Skill Builder P1fahid masoodОценок пока нет

- Going With The Flow With Inventor® Tube & Pipe: Learning ObjectivesДокумент35 страницGoing With The Flow With Inventor® Tube & Pipe: Learning ObjectivesBemvilac BritoОценок пока нет

- A Harness Is A Looped Restraint or Support. Specifically, It May Refer To One of The Following Harness TypesДокумент1 страницаA Harness Is A Looped Restraint or Support. Specifically, It May Refer To One of The Following Harness Typesfahid masoodОценок пока нет

- WRC Bulletin 107 (537) : Environment (On Page 48)Документ1 страницаWRC Bulletin 107 (537) : Environment (On Page 48)fahid masoodОценок пока нет

- WRC368Документ1 страницаWRC368fahid masoodОценок пока нет

- Power TrainДокумент11 страницPower TrainKapil Dev SinghОценок пока нет

- Espace III Service Repair ManualДокумент1 452 страницыEspace III Service Repair ManualCorrado MeassoОценок пока нет

- Marine drive line components catalogДокумент3 страницыMarine drive line components catalogaiyubi2Оценок пока нет

- ZF 8 HP 45Документ4 страницыZF 8 HP 45victor arevaloОценок пока нет

- Supplied Parts PhotoДокумент5 страницSupplied Parts PhotoJuliyanto STОценок пока нет

- Manual de Transmisión de Daewoo NubiraДокумент90 страницManual de Transmisión de Daewoo NubiraFelipe ChimborazoОценок пока нет

- Fastener Manufacturers in IndiaДокумент8 страницFastener Manufacturers in IndiaKaloti IndiaОценок пока нет

- Electronically Controlled Transmission: 2004 COROLLA (EWD533U)Документ6 страницElectronically Controlled Transmission: 2004 COROLLA (EWD533U)Al-Ameen MohammedОценок пока нет

- Homework 2 (2023)Документ5 страницHomework 2 (2023)Aahjssb HznsmsbОценок пока нет

- History of GearsДокумент12 страницHistory of GearsmorolosusОценок пока нет

- Radiator - Coolant Recovery SystemДокумент2 страницыRadiator - Coolant Recovery SystemBillОценок пока нет

- OriginalДокумент28 страницOriginalPatrick JanssensОценок пока нет

- Helvig Lifeboat Engine ManualДокумент20 страницHelvig Lifeboat Engine ManualjeyanthОценок пока нет

- Perkins Boletin MotorДокумент7 страницPerkins Boletin MotorWilliams Araya100% (1)

- Threads and Thread CuttingДокумент21 страницаThreads and Thread CuttingravijecrcОценок пока нет

- Tutorial 1Документ4 страницыTutorial 1Ahmad AfnanОценок пока нет

- Engine Cooling SystemДокумент22 страницыEngine Cooling SystemDidier ÁlvarezОценок пока нет

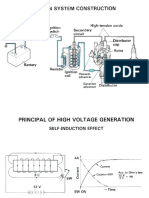

- IgnitionДокумент46 страницIgnitionAgung Febiyanto100% (1)

- 11.08 2S0321 ZZ9999 05701604 Cylinder HeadДокумент9 страниц11.08 2S0321 ZZ9999 05701604 Cylinder Headeshopmanual TigaОценок пока нет

- Single Core Cables - 600/1000 V: Dimensions & WeightsДокумент5 страницSingle Core Cables - 600/1000 V: Dimensions & WeightsMohan KОценок пока нет

- Eclate HZL f300Документ40 страницEclate HZL f300pointparpoint65Оценок пока нет