Академический Документы

Профессиональный Документы

Культура Документы

Guidelines Regarding The Use of Alcohols in Acidic Stimulation Fluids

Загружено:

wasayrazaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Guidelines Regarding The Use of Alcohols in Acidic Stimulation Fluids

Загружено:

wasayrazaАвторское право:

Доступные форматы

Guidelines Regarding the Use of Alcohols in

Acidic Stimulation Fluids

B. R. Keeney, Halliburton Services

J. G. Frost, Halliburton Services

Introduction

One of the problems associated with treating gas wells in the organic acid for the desired stimulation reaction is

sandstone formations is the slow recovery of the spent possible.

acid solution. This problem often results from high water

saturation in the critical matrix surrounding the wellbore. CH3 COOH + CH3 0H ~~ CH3 COOCH3 + H2 0

Water blocks can be caused by the capillary forces present acetic acid methanol methyl acetate

in porous rock and by the high mobility ratio of gas and .....................( 1)

water. 1 When a well is put on production following a However, in an alcoholic solution of hydrochloric acid,

workover or a stimulation treatment, the gas forces some a reaction takes place, that results in the formation of

of the water out of the rock and then may break through, organic chlorides. The following are two examples.

leaving a high water saturation around the wellbore. This

residual high water saturation reduces the effective per- CH3 0H + HCl ~. CH3 Cl

meability of the formation to gas flow. methanol hycfrochloric acid methyl chloride

The lower alcohols have been used for a number of +H2 0 (2)

years in acidic stimulation fluids to aid in rapid recovery

of spent acid. The reasons for this use are well founded. CH3 CHOHCH3 + HCl ~

Alcohols aid ,in cleanup of spent acid by lowering the isopropanol hydrochloric acid

surface tension and increasing the vapor pressure of the CH3 CHClCH3 + H20 .... (3)

solution. 2 In recent years, this technique has gained popu- isopropyl chloride

larity to the extent that it is used routinely in gas- well

stimulation treatments and, to some degree, in oilwell This reaction poses a genuine' problem in acidic gas·-

acidizing. well stimulation. A reaction such as in Eq. 2 or Eq. 3 is

This paper deals with an undesirable side reaction at- irreversible, and any HCllost to this reaction can not be

tendant when alcohols are used in acid. Even under regenerated, as was possible with organic acids (Eq. 1).

moderate-temperature conditions, alcohols will react Thus, this reaction competes with the acidic-stimulation

readily with acid. 3 In the cases of organic acids (acetic or reaction for the HCI content. A second problem concerns

formic acid, for example), these reactions will result in the reaction products themselves. Although the presence

ester formation, with the only resulting problem being of organic chlorides in natural gas might not present any

possibly a loss of available acid for the stimulation reac- special problems, their presence in produced crudes or

tion. Even this may be of small consequence since the distillates is considered a serious contamination. For these

esterification reaction is reversible aq.d regeneration of reasons, this paper is limited to HCI-alcohol reactions.

Using alcohols in acidic stimulationfluids for fast cleanup ofspent acid can lead to the formation

ofhigh concentrations oforganic reaction products and an attendant loss ofavailable acid. The

problem can be minimized by limiting the alcohol concentration to a maximum of32 percent (by

volume) and by limiting treatment temperatures to 175°Ffor sandstone and 200°Ffor limestone

formations.

552 JOURNAL OF PETROLEUM TECHNOLOGY

Comparisons are presented of the amount o~ aGid con- t4rol1gh a discharge valve· while mairitaining a constant

sumed at various temperatures by t4e reaction ofHCI with pressure of 500 psi. The ,acid samples .were then retitrated

three different alcohols: methanol, iso.propanol, and to determine the remaining acid content.

ethanol. The effects of alcohol concentration, acid Determinations of the so~ub.ility of methyl chloride in

strength, time, and temperature on the rea<;tion of kerosene were conducted using a, Wickbold combustion

methanol with HCI are also studied. :Methanol was apparatus, an instru;ment. in which organIcally bound

selected because of its common use in field operations. chlorine is converted to titratable chloride ion. The tes~

The solubility of methyl chloride in kerosene is also solutions were prepared by .bubbling gaseous methyl

investigated. chloride through samples of kerosene for I-hour periods at

?2°P and atmospheri,c pressure. T~e chloride ion concen-

Test Procedure and Equipment trations of the samples were then measured with the

The HCI-alcohol, solutions were prepared using reagent- Wickbold apparatus at various time intervals. The

grade chemicals and deionized water. The st~ength.ofthe methyl chloride content was calculated from the chloride

reagent-grade HCI was- 37.8 percen.t (23.3°Be). All the ion determinations.

test solutions initially contained the amount of HCI that

would be normally present in a HCI-H2 0 solution of Discussion of Data

equival~nt strength. After mixing, the solutions were ti- The effects of various concentrations of methanol, iso-

trated to determine the exact acid content. propanol, and ethanol on acid-st~ength reduction 'Of HCI

The pressure or reaction vessel used for conducting the at temperatures of 200° and 300 P, for a period of 1

0

.1-hour tests was a test cell presently under consideration hour, are shown in Pigs. '1 and 2. In all the tests, the initial

by the joint NACE-API Standards Committee for Corro- acid content of the alcohol-a<;id mixtures wa~ equivalent

sion Inhibitor Evaluation. The test cell was modified to the amount of HCI present in a IS-percent HCI-H2 0

slightly for investigating the effects of time on. the acid- solution .

0

alcohol reactions. A second pressure vessel for holding . At a temperature of 200 P, the reactivity order of the

the test solution at rOOm temperature (72°P) was fitted to three alcohols with HCI was methanol > isopropanol

the reaction cell. The reaction cell ,was filled with > ethanol. It should be noted that these reactivities

kerosene apd was preheated to the desired rest tempera- are based on volume rather than on molar concen-

ture. The acid-alcohol solution was then displaced from tratio~s .of. the alcohols. At the higher temperature. of

the pressure vessel (at 72°P) into the heated cell under 600 30bop, t~e residual acid concentrations w:ith ethanol and

psi nitrogen pressure. ~ample injection was c6nsid~red isopropanol were almost identical, while significantly

complete when an equivalent amount of kerosene had lower acid conc;entrations were measured at this tempera-

been displaced through a backpressure regulator, set at ture with methanol.

500 psi, on the preheated cell. The nitrogen pressure was The amount of acid conversion as a function of time (0

then lowered to 500 psi and the line was reconnected to the to 60 minutes) was measured for four different concentra-

cell so that samples could be periodically withdrawn tions of methanol (16, 32, 48, and 64 volume percent) in

IN MINUTES

Fig. 3-Effect of various concentrations of methanol on acid

Fig. l-Effect of various alcohols on acid strength. strength as a function of time.

Fig. 4-Effect of various concentrations of methanol on acid

Fig. 2-Effect of various alcohols on acid strength. strength as a function of time.

MAY, 1975 553

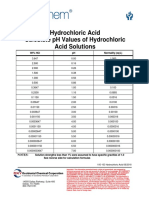

TABLE l~VOLATILITY OF METHYL CHLORIDE IN KEROSENE

Test Temperature: Room Te.mperature (72°F)

Pressure: Atmospheric

Time Methyl Chloride

(hours) (gm/liter)

Initial 30.1

1.0 26.3

3.0 24.8

6.0 23.7

48 22.7

72 21.2

Fig. 5,-Effect of various concentrations of methanol on acid

strength at increasing temperatures.

HCl at temperatures of 200 0 and 300oP. These data are

shown in Pigs. 3 and 4.,At a temperature of 200°f, no

measurable acid loss was recorded for concentrations .of

16 and 32 volume percent methandlduring a 45-minute

period. This is significant in that methanol, at concentra~

tions as high as.32 volume percent, possibly could be used

when treatip.g 3: limestone formation because of the rapid

spending action of the acid on the rock. At the higher

conc,entration of 48 volume perc~nt. methanol, a small

amount of acid loss (0.25 percent) was recorded after 45

minutes. Even though this amount of acid conversion Fig. 6-Reduction in acid strength with various concentrations of

HCI containing 64 percent (by volume) methanol.

appears to be small, it represents the formation of methyl

chloride in the acid solution at a concentration of 3 700

mg/liter. A significant amount of contamination of 'pro- valved when using alcoholic-HCl solutions for .stimula-

duced hydrocarbons could result from this ,concentration tion treatme~ts of .oil-bearing formations because of the

of methy~ chloride. Even higher acid· losses were recorded possibility of contaminating the hydrocarbon- production

with methanol at £1 concentration of 64 volume percent. fluids with organic chlorides.

Prom 'the reduction in acid strength , the rate at which Conclusions

methyl.chloride was, produced at 300oP, at all four con-

centration~ of methanol, indicates th~ undesirability

1. Alcohols will readily react with 'acid solutions to

of using this alcohol at elevated temperatures. form organic reaction products, with an accompanying

, Pig. 5 sh0'Ys the effects of increasing temperature on loss.of acid strength.

the reduction of acid strength for the four concentrations 2. When alcohols are used in Hel stimulation treat-

of methanol ..The'se data sh~w that there was no significant ments, organic chlorides may, be formed as reaction

loss of acid strength with methanol concentrations up to products.

32 volume percept until the temperature exceeded 175°P. 3. One of these reaction products, methyl chloride, has

This is relevant when ~onsidering sandstone acidizing in been shown to have a high degree of solubility in a

which mixeq acid solutions of HP-Hel are used routinely. hydrocarbon fluid.

In. these treatments, a large portion of the Hel may not 4. The acid-alcohol reaction in acidic stimulation

rapidly spend on ,the formation. As a result, this acid fluids can be minimized by limiting the alcohol concentra-

would b~ available to react with methanol. Th~s, if these tion to a maximum of 32 volume percent, arid by limiting

~ea~ment temperatures to 17sop for sandstone and 200 P

0

acid mixtures with alcohol are considered for a sandstone

treatment, the ~imits of 175°P and/or 32 volume percent for limestone formations. The guidelines may require

m~thanol should ~e used as guidelines to help in prevent- modification as additional information becomes

ing this acid-alcohol reaction. , available.

Fig. 6 shows red.uction in acid strength as a function of Acknowledgment

time for three different concentrations (5, 10, and 15

percent) of~Cl cqniaining 64 volume percent methanol at We wish to express our appreciation to Halliburton Ser-

2500 P. A significant,reduction in acid strength was mea- vices for permission to prepare this paper, and to our

sured with all three concentrations of Hel in less than 30 co-workers fot their help in collecting the data.

minutes.. This indicates that lower-strength HCt·HP- References

alcoholic ·acid solutions still may not eliminate' organic

1. McLeod, H. 0., McGinty,.J. E., and Smith, C. F.: "Alcoholic Acid

ch1~ride formation 1?ecause of the significant amount Qf

Speeds Clean-Up in Sandstones," Pet. Eng. (Feb. 1966) 38, No.2,

organic chlorides formed even with acid strengths as low 66-70., .

as 5 percent. 2. McLeod, H. 0., McGinty, J. E., and Smith, C. F.: "Deep Well

To determine if methyl chloride has sufficient solubility Stimulation With Alcoholic Acid," paper S.PE 1558 presented at the

ip. oil to be consi~ered a significant contaminant, its vol- SPE-AIME 41st Annual Fall Meeting, Dallas, Oct. 2-5,1966.

3. Bordwell, Frederick G.: Organic Chemistry, The Macmillan Book

atility in kerosene was determined at 72°P and. atmo- Co., Inc., New York (1964) 59-60. JPT

spheric, pressure' (see Table 1). It was found that JPethyl

chloride has a very high degree of so~ubility in kerosene Original manuscript received in Society of Petroleum Engineers office July 30, -1974.

~ven when allowing the solu:tion to stand for a period of72 Rev.ised·manuscript received Feb: 10, 1975. Paper (SPE 5158) was first presented atthe

SPE-AIME 49th Annual Fall Meeting, held in Houston, Oct. 6-9,1974. @Copyright 1975

hours. This information further points out problems in- American Institute of Mining, Metallurgical, and Petroleum Engineers, Inc.

554 JOURNAL OF PETROLEUM TECHNOLOGY

Вам также может понравиться

- Tough economic decisions finally being takenДокумент28 страницTough economic decisions finally being takenwasayrazaОценок пока нет

- Meezan Bank FMR April 2022Документ28 страницMeezan Bank FMR April 2022wasayrazaОценок пока нет

- Meezan Bank FMR July 2022Документ27 страницMeezan Bank FMR July 2022wasayrazaОценок пока нет

- Meezan Bank FMR June 2022Документ30 страницMeezan Bank FMR June 2022wasayrazaОценок пока нет

- PSX Quote 31-08-2022Документ42 страницыPSX Quote 31-08-2022wasayrazaОценок пока нет

- Quote 202002novДокумент27 страницQuote 202002novwasayrazaОценок пока нет

- Effect of Chelating Agent On Lithology of Porous MediaДокумент15 страницEffect of Chelating Agent On Lithology of Porous MediawasayrazaОценок пока нет

- Improved HSe Profile of Green StimulationДокумент6 страницImproved HSe Profile of Green StimulationwasayrazaОценок пока нет

- Annual Report)Документ149 страницAnnual Report)junaid ahmadОценок пока нет

- Franchi 2008Документ9 страницFranchi 2008wasayrazaОценок пока нет

- Chelating Agent in SandstoneДокумент16 страницChelating Agent in SandstonewasayrazaОценок пока нет

- Multichelate Acid With Low Damage and Weak DissolutionДокумент12 страницMultichelate Acid With Low Damage and Weak Dissolutionsuhaimi manОценок пока нет

- The Hub Power Company Limited - Material InformationДокумент1 страницаThe Hub Power Company Limited - Material InformationwasayrazaОценок пока нет

- Thomas 1981Документ10 страницThomas 1981wasayrazaОценок пока нет

- TAS Technical Reference ManualДокумент58 страницTAS Technical Reference ManualBrayan OОценок пока нет

- FACT ManualДокумент22 страницыFACT ManualOscar RamirezОценок пока нет

- Hydrochloric Acid Handbook: OxychemДокумент47 страницHydrochloric Acid Handbook: OxychemVikashОценок пока нет

- Baker D and DB Retainer Production Packers H43210 PDFДокумент7 страницBaker D and DB Retainer Production Packers H43210 PDFwasayrazaОценок пока нет

- A Report Says The End To The Kafala System Is Also Aimed at Promoting Economic Growth and Expanding Commercial ActivitiesДокумент2 страницыA Report Says The End To The Kafala System Is Also Aimed at Promoting Economic Growth and Expanding Commercial ActivitieswasayrazaОценок пока нет

- Saudi host tells firms to lay off foreigners over locals amid pandemicДокумент3 страницыSaudi host tells firms to lay off foreigners over locals amid pandemicwasayrazaОценок пока нет

- SPE-176195-MS Coiled Tubing Gas Lift Design and Troubleshooting - Case HistoryДокумент6 страницSPE-176195-MS Coiled Tubing Gas Lift Design and Troubleshooting - Case HistoryManuel ChОценок пока нет

- Tech-Calculated PH Values HCLДокумент3 страницыTech-Calculated PH Values HCLNurlaila Ela IlaОценок пока нет

- Oil & Gas Safety Regulation 1974Документ82 страницыOil & Gas Safety Regulation 1974Hamza Shehzad100% (3)

- Gullf NewsДокумент2 страницыGullf NewswasayrazaОценок пока нет

- Continuous Warnings: Second WaveДокумент3 страницыContinuous Warnings: Second WavewasayrazaОценок пока нет

- Prayer Log: Date Fajr Zuhur Asr Maghrib IshaДокумент1 страницаPrayer Log: Date Fajr Zuhur Asr Maghrib IshawasayrazaОценок пока нет

- 2017 Petrobowl Championship, Usa: Team DetailsДокумент1 страница2017 Petrobowl Championship, Usa: Team DetailswasayrazaОценок пока нет

- HSEQ PresentationДокумент9 страницHSEQ PresentationwasayrazaОценок пока нет

- Mcleod1966 PDFДокумент11 страницMcleod1966 PDFwasayrazaОценок пока нет

- Quote 201924mayДокумент32 страницыQuote 201924maywasayrazaОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Cement Energy GuideДокумент70 страницCement Energy GuideAmr A. NaderОценок пока нет

- Petroquiz 2018Документ18 страницPetroquiz 2018Fabian PazmiñoОценок пока нет

- PP Aaa PP1 122Документ19 страницPP Aaa PP1 122Rabah AmidiОценок пока нет

- Attachment 05 - BFD, ELD and P&I Diagrams-PearlДокумент77 страницAttachment 05 - BFD, ELD and P&I Diagrams-Pearlum er100% (1)

- Ansaldo Energia AE94 2 Upgrading Project PDFДокумент20 страницAnsaldo Energia AE94 2 Upgrading Project PDFRaden MasОценок пока нет

- Optimisation of Product Yield and Coke Formation in A RFCC UnitДокумент5 страницOptimisation of Product Yield and Coke Formation in A RFCC UnitCHE.ENG1734Оценок пока нет

- Top 10 Companies Green MarketingДокумент4 страницыTop 10 Companies Green MarketingMahalakshmi RavikumarОценок пока нет

- P&A Gudelines HandbookДокумент73 страницыP&A Gudelines HandbookRustam RusОценок пока нет

- List of Abbreviations in Oil and Gas Exploration and ProductionДокумент25 страницList of Abbreviations in Oil and Gas Exploration and ProductionSalam TekbaliОценок пока нет

- Discussion Text Nuclear EnergyДокумент2 страницыDiscussion Text Nuclear EnergySamuel Adi Santosa100% (1)

- A2 Amonia NH3 Poster Safety GuideДокумент1 страницаA2 Amonia NH3 Poster Safety GuideimtiyazОценок пока нет

- Synthetics Lubricant Basestock BrochureДокумент54 страницыSynthetics Lubricant Basestock BrochureJako MishyОценок пока нет

- Control Corrosion Offline Steam BoilersДокумент3 страницыControl Corrosion Offline Steam BoilersYousuf MemonОценок пока нет

- Growth Opportunities For HydrogenДокумент20 страницGrowth Opportunities For HydrogenPhani100% (2)

- Environmental Balance of Salt Production Speaks in Favour of Solar SaltworksДокумент8 страницEnvironmental Balance of Salt Production Speaks in Favour of Solar SaltworksminingnovaОценок пока нет

- Lost Circulation Materials SelectionДокумент22 страницыLost Circulation Materials SelectionFauzan Rahman HaqОценок пока нет

- CNG Solenoid Valves for High Pressure DispensingДокумент3 страницыCNG Solenoid Valves for High Pressure DispensingALEJANDROОценок пока нет

- Well Intervention and ControlДокумент10 страницWell Intervention and ControlAry RachmanОценок пока нет

- IGCSE Chem Ch1 QuestionsДокумент2 страницыIGCSE Chem Ch1 QuestionsPusat Tuisyen Bestari Ilmu100% (3)

- Chemical Flooding in EOR: A Case Study of Enhanced Oil Recovery Using Surfactant and Polymer InjectionДокумент18 страницChemical Flooding in EOR: A Case Study of Enhanced Oil Recovery Using Surfactant and Polymer InjectionAli AbukhzamОценок пока нет

- Increase in Global Electricity Generation by 2040: 770 Million PeopleДокумент21 страницаIncrease in Global Electricity Generation by 2040: 770 Million PeopleJonson CaoОценок пока нет

- GE Energy: Gas Turbine (50hz)Документ2 страницыGE Energy: Gas Turbine (50hz)Rolando Antonio Cuenca PironaОценок пока нет

- Envirocoal Coal Specs 2015 PDFДокумент2 страницыEnvirocoal Coal Specs 2015 PDFtoniОценок пока нет

- As 2337.3-2006 Gas Cylinder Test Stations Transportable Gas Cylinders - Periodic Inspection and Testing of CoДокумент8 страницAs 2337.3-2006 Gas Cylinder Test Stations Transportable Gas Cylinders - Periodic Inspection and Testing of CoSAI Global - APACОценок пока нет

- Elem Coal StudyguideДокумент9 страницElem Coal Studyguideapi-252162505Оценок пока нет

- Designing An Optimal Pipeline Network For Transporting Natural GasДокумент16 страницDesigning An Optimal Pipeline Network For Transporting Natural GasMarcelo Varejão CasarinОценок пока нет

- 444safety & Customer Service - CourseraДокумент3 страницы444safety & Customer Service - CourseraRajKumarОценок пока нет

- BP Greater Plutonio UpdateДокумент2 страницыBP Greater Plutonio UpdatenjennsОценок пока нет

- Practical GuideДокумент19 страницPractical GuideIshan RanganathОценок пока нет

- Top Select - Services & Products - Production Enhancement - Wellbore Clean OutДокумент4 страницыTop Select - Services & Products - Production Enhancement - Wellbore Clean OutTg TarroОценок пока нет